Influence of automotive industry developments on the future - Mol

Influence of automotive industry developments on the future - Mol

Influence of automotive industry developments on the future - Mol

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2010/1<br />

Challenges<br />

MOL Scientific Magazine<br />

2010 / 1<br />

<str<strong>on</strong>g>Influence</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>automotive</str<strong>on</strong>g> <str<strong>on</strong>g>industry</str<strong>on</strong>g> <str<strong>on</strong>g>developments</str<strong>on</strong>g><br />

<strong>on</strong> <strong>the</strong> <strong>future</strong> fuel demand structures<br />

Impacts <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> current ec<strong>on</strong>omic crisis <strong>on</strong><br />

downstream investments in oil&gas <str<strong>on</strong>g>industry</str<strong>on</strong>g><br />

Alternative methods for evaluating explorati<strong>on</strong> projects<br />

The effects <str<strong>on</strong>g>of</str<strong>on</strong>g> nucleating/clarifying agents in polypropylene<br />

1<br />

1MOL GROUP

MOL Scientific Magazine<br />

2010/1<br />

Editorial Board:<br />

Béla Csorba; István Godó; Jenô Hancsók, Dr.; Horváth Péter; László Isaák; Pál Kapusy; Zoltán Kocsis; Márta<br />

Krámer, Dr.; László Lázár; Zoltán Mart<strong>on</strong>; Zsolt <strong>Mol</strong>nár; Attila Plecskó; László Rácz, Dr.; László Rácz, Jr.; Nóra<br />

Saláta; Dóra Somlyai; Gabriella Szalmás, Dr.; Artur Thernesz<br />

Managing editor: Virág Sim<strong>on</strong><br />

Chairman <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> Editorial Board: György Mos<strong>on</strong>yi<br />

ISSN 2060-338X<br />

2<br />

1MOL GROUP

2010/1<br />

MOL Scientific Magazine<br />

C<strong>on</strong>tents<br />

2010/1<br />

Challenges<br />

Máté Zöldy, Dr. – Róbert Auer, Dr. – János Hidi – Ádám Horváth:<br />

<str<strong>on</strong>g>Influence</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>automotive</str<strong>on</strong>g> <str<strong>on</strong>g>industry</str<strong>on</strong>g> <str<strong>on</strong>g>developments</str<strong>on</strong>g> <strong>on</strong> <strong>the</strong> <strong>future</strong> fuel demand structures 4<br />

György Wilde, Dr.:<br />

The European Petroleum Industry in 2008 15<br />

István Maráczi: Petrochemicals in <strong>the</strong> oil <str<strong>on</strong>g>industry</str<strong>on</strong>g> value chain 22<br />

János Schr<strong>on</strong>k:<br />

Impacts <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> current ec<strong>on</strong>omic crisis <strong>on</strong> downstream investments in oil & gas <str<strong>on</strong>g>industry</str<strong>on</strong>g> 28<br />

Focus<br />

Csaba Hollósi – Ferenc Nagy Szakál:<br />

Energy saving opportunities in petrol stati<strong>on</strong> operati<strong>on</strong><br />

(use <str<strong>on</strong>g>of</str<strong>on</strong>g> renewable energy sources) 39<br />

László Kovács:<br />

The applicati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Live Loading technology at Duna Refinery,<br />

and its impact <strong>on</strong> VOC-emissi<strong>on</strong>s 49<br />

Development<br />

Ágnes Jancsicsné Kun – László Nagy:<br />

Experiences from <strong>the</strong> SIL project 59<br />

Workshop<br />

Péter Suba:<br />

The effects <str<strong>on</strong>g>of</str<strong>on</strong>g> nucleating/clarifying agents in polypropylene 66<br />

Pavol Valent – Tibor Margetiny, Ing.:<br />

Slovnaft Refinery operati<strong>on</strong> during <strong>the</strong> “gas crisis” 74<br />

Judit Fekete – Zoltán Dániel:<br />

C<strong>on</strong>versi<strong>on</strong> increasing at MOL vacuum gasoil hydro treater unit 78<br />

Imre Drávucz:<br />

Problem solving using FTIR spectroscopy in hydrocarb<strong>on</strong> explorati<strong>on</strong> and producti<strong>on</strong> 84<br />

Balázs Szinger – Adrienn Szekszárdi:<br />

Functi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> geological study in Pakistan hydrocarb<strong>on</strong> research 92<br />

Lajos Erdôs – Gyula Németh:<br />

Analysis <str<strong>on</strong>g>of</str<strong>on</strong>g> simple and complex technology systems with automated process-simulati<strong>on</strong><br />

technology 102<br />

Tamás Vincze, Dr.:<br />

Alternative methods for evaluating explorati<strong>on</strong> projects 114<br />

Publicati<strong>on</strong>s have been received from authors until Q3 <str<strong>on</strong>g>of</str<strong>on</strong>g> 2009<br />

3<br />

1MOL GROUP

Challenges<br />

2010/1<br />

<str<strong>on</strong>g>Influence</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>automotive</str<strong>on</strong>g><br />

<str<strong>on</strong>g>industry</str<strong>on</strong>g> <str<strong>on</strong>g>developments</str<strong>on</strong>g><br />

<strong>on</strong> <strong>the</strong> <strong>future</strong><br />

fuel demand structures<br />

Máté Zöldy, Dr.<br />

Vehicle and ebgine technology specialist<br />

MOL Group – MOL DSD Product Development<br />

E-mail: mzoldy@mol.hu<br />

Róbert Auer, Dr.<br />

Head <str<strong>on</strong>g>of</str<strong>on</strong>g> Analitics<br />

MOL Group − MOL DSD Product Development<br />

E-mail: rauer@mol.hu<br />

János Hidi<br />

Ec<strong>on</strong>omist<br />

Ádám Horváth<br />

Ec<strong>on</strong>omist Executive Assistant<br />

MOL Refining<br />

Email: adhorvath@mol.hu<br />

Abstract<br />

Based <strong>on</strong> <strong>the</strong> MOL’s Free University<br />

Presentati<strong>on</strong> that was held under <strong>the</strong> title<br />

Improvements in <strong>the</strong> <str<strong>on</strong>g>automotive</str<strong>on</strong>g> <str<strong>on</strong>g>industry</str<strong>on</strong>g><br />

– effects <strong>on</strong> <strong>the</strong> petroleum market at<br />

24 th <str<strong>on</strong>g>of</str<strong>on</strong>g> August 2008 by Máté Zöldy dr.<br />

an interdepartmental workgroup have<br />

been established to map <strong>the</strong> effect <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

main <str<strong>on</strong>g>automotive</str<strong>on</strong>g> <str<strong>on</strong>g>developments</str<strong>on</strong>g> and tendencies<br />

<strong>on</strong> fuel demand structures.<br />

Am<strong>on</strong>g o<strong>the</strong>rs <strong>the</strong> workgroup focused<br />

<strong>on</strong> downsizing, dieselizati<strong>on</strong>, alternative<br />

combusti<strong>on</strong> processes, electric vehicles,<br />

hybridizati<strong>on</strong>, car park grow/change<br />

trends and ec<strong>on</strong>omical envir<strong>on</strong>ment.<br />

Bey<strong>on</strong>d <strong>the</strong> ec<strong>on</strong>omic downturn, European<br />

gasoline-diesel demand imbalance<br />

will worsen due to <strong>the</strong> foreseeable<br />

<str<strong>on</strong>g>automotive</str<strong>on</strong>g> <str<strong>on</strong>g>developments</str<strong>on</strong>g>: <str<strong>on</strong>g>automotive</str<strong>on</strong>g><br />

diesel demand will c<strong>on</strong>tinue to rise,<br />

wher eas gasoline keeps <strong>on</strong> declining.<br />

Summarized our c<strong>on</strong>sequences diesel<br />

will play more and more important role in<br />

<strong>the</strong> near <strong>future</strong> extended with alternative<br />

combusti<strong>on</strong> systems and alternative fuel<br />

resources. The petroleum <str<strong>on</strong>g>industry</str<strong>on</strong>g> and<br />

MOL Group have to pay lot <str<strong>on</strong>g>of</str<strong>on</strong>g> attenti<strong>on</strong><br />

to <strong>the</strong>se to streng<strong>the</strong>n it positi<strong>on</strong>s <strong>on</strong> <strong>the</strong><br />

market.<br />

Összefoglalás<br />

A MOL Szabadegyetemen 2008 ôszén<br />

Zöldy Máté dr. által “Improvements in<br />

<strong>the</strong> <str<strong>on</strong>g>automotive</str<strong>on</strong>g> <str<strong>on</strong>g>industry</str<strong>on</strong>g> – effects <strong>on</strong> <strong>the</strong><br />

petroleum market” címmel tartott elôadás<br />

nyomán egy munkacsoport jött létre<br />

azért, hogy a jármûipari fej lesztések és<br />

trendek hatását vizs gál ja az üzemanyag<br />

keresletre. A mun kacsoport többek<br />

között vizs gálta a dízelizációt, alternatív<br />

égés rendszereket, downsizingot, elektro<br />

mos jármûveket, hibridizációt, jármûpark<br />

mennyiségi növekedését és<br />

össze tételének változását és a gazdasági<br />

kör nyezetet.<br />

A gazdasági krízis korrekciós ha tá sa<br />

mellett az európai gázolaj-ben zin egyensúly<br />

változásának ten den ciái megmaradnak<br />

a vizsgált té nyezôk alapján, azaz a dízel<br />

iránti i gény várhatóan növekedni fog és<br />

a benzin iránti kereslet csökken. Összesítve<br />

a megállapításainkat, a gáz olaj<br />

egyre növekvô szerepet fog ját szani a<br />

közeli jövôben, kiegészítve az alter natív<br />

égési rendszerekkel illetve alternatív<br />

alapanyagokból készülô üzemanyagokkal.<br />

Az olajipar és a MOL csoport számára<br />

ezek figyelemmel kö vetése, illetve a<br />

felké szülés az elter je désükre elôsegíti a<br />

piaci pozíciók erô sítését.<br />

4<br />

1MOL GROUP

2010/1<br />

Challanges<br />

Introducti<strong>on</strong><br />

Ec<strong>on</strong>omic output <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> world and its fuel<br />

c<strong>on</strong>sumpti<strong>on</strong> has always been closely linked.<br />

Majority <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> oil <str<strong>on</strong>g>industry</str<strong>on</strong>g> products is utilised by<br />

<strong>the</strong> <str<strong>on</strong>g>automotive</str<strong>on</strong>g> <str<strong>on</strong>g>industry</str<strong>on</strong>g>. The <str<strong>on</strong>g>automotive</str<strong>on</strong>g> <str<strong>on</strong>g>industry</str<strong>on</strong>g><br />

technological and financial changes effecting <strong>the</strong><br />

petroleum <str<strong>on</strong>g>industry</str<strong>on</strong>g> due vehicles are <strong>the</strong> main<br />

customers <str<strong>on</strong>g>of</str<strong>on</strong>g> oil products. Transportati<strong>on</strong> fuels<br />

c<strong>on</strong>sumpti<strong>on</strong> is especially sensitive to ec<strong>on</strong>omic<br />

cycles. The ec<strong>on</strong>omic slowdown which started in<br />

2007 broke <strong>the</strong> previous trend <str<strong>on</strong>g>of</str<strong>on</strong>g> ever rising fuel<br />

c<strong>on</strong>sumpti<strong>on</strong>. Recent experience points toward<br />

a prol<strong>on</strong>ged time period <str<strong>on</strong>g>of</str<strong>on</strong>g> ec<strong>on</strong>omic weakness.<br />

From which a recovery is <strong>on</strong>ly expected from 2012<br />

and it is subject to <strong>the</strong> success <str<strong>on</strong>g>of</str<strong>on</strong>g> government<br />

and central bank interventi<strong>on</strong>s, as well as to <strong>the</strong><br />

development <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> financial system.<br />

The magnitude <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> ec<strong>on</strong>omic turmoil is<br />

reflected by several indicators. While <strong>the</strong> global<br />

ec<strong>on</strong>omic growth was relatively high in <strong>the</strong> last<br />

couple years, with a growth rate <str<strong>on</strong>g>of</str<strong>on</strong>g> as high as<br />

5.2% in 2007, this indicator dropped to around<br />

3% or lower in 2008, and based <strong>on</strong> data <strong>on</strong><br />

industrial activity, financial performance, as well<br />

as c<strong>on</strong>sumer and business c<strong>on</strong>fidence indices,<br />

2009 is expected to bring a negative growth<br />

rate globally. Although 2010 can be a somewhat<br />

better year with positive growth, it is subject to<br />

major uncertainties. Given that <strong>the</strong> fiscal stimulus<br />

and m<strong>on</strong>etary easing will be effective, <strong>the</strong> growth<br />

rate <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> global ec<strong>on</strong>omy is expected to recover<br />

to pre-crisis levels <strong>on</strong>ly from 2012.<br />

Given this prospect, forecasts <str<strong>on</strong>g>of</str<strong>on</strong>g> technological<br />

advancements and c<strong>on</strong>sumpti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> transportati<strong>on</strong><br />

fuels that were prepared before <strong>the</strong><br />

crisis should be shifted fur<strong>the</strong>r by about four<br />

years. Moreover, <strong>the</strong> ec<strong>on</strong>omic turmoil may<br />

bring such changes into <strong>the</strong> behaviour <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

governments, regulators, developers, producers<br />

and c<strong>on</strong>sumers which could cause structural<br />

changes in <strong>the</strong> development <str<strong>on</strong>g>of</str<strong>on</strong>g> technologies and<br />

transportati<strong>on</strong> fuel mix. The relative price <str<strong>on</strong>g>of</str<strong>on</strong>g> fossil<br />

fuels is expected to increase again <strong>on</strong>ce global<br />

ec<strong>on</strong>omic output recovers, while investments<br />

into alternative energy sources move into <strong>the</strong><br />

focus <str<strong>on</strong>g>of</str<strong>on</strong>g> fiscal spending during <strong>the</strong> crisis. These<br />

in turn will have a significant impact <strong>on</strong> <strong>the</strong> choice<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> technology and fuel in <strong>the</strong> <strong>future</strong>.<br />

However, supply and demand side adjustments<br />

have <strong>the</strong>ir technological limits. These issues are<br />

explored in <strong>the</strong> following analysis.<br />

Gasoline – diesel<br />

balance: traditi<strong>on</strong><br />

versus new trend<br />

The two sides <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> Atlantic basin which covers<br />

app. 70% <str<strong>on</strong>g>of</str<strong>on</strong>g> world’s gasoline c<strong>on</strong> sumpti<strong>on</strong><br />

are characterized by very different motor fuel<br />

c<strong>on</strong>sumpti<strong>on</strong> structure. Europe is historically<br />

short <strong>on</strong> diesel and l<strong>on</strong>g <strong>on</strong> gas oline and <strong>on</strong> <strong>the</strong><br />

o<strong>the</strong>r hand North America is extremely short<br />

<strong>on</strong> gasoline, thus according to <strong>the</strong> traditi<strong>on</strong>al<br />

product flow gasoline is transferred to <strong>the</strong> United<br />

States from Europe. Moreover, from 2008 a<br />

new tendency has been born: diesel flow has<br />

stabilized from US to Europe.<br />

This present imbalanced situati<strong>on</strong> in <strong>the</strong> US-<br />

European oil product supply-demand balances<br />

are <strong>the</strong> result <str<strong>on</strong>g>of</str<strong>on</strong>g> a different customers behaviour,<br />

tax regimes, envir<strong>on</strong>mental regulati<strong>on</strong>s and<br />

c<strong>on</strong>sequently <strong>the</strong> different development path <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

car manufacturing <str<strong>on</strong>g>industry</str<strong>on</strong>g> and reacti<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> oil<br />

refiners in <strong>the</strong> last decades.<br />

With <strong>the</strong> recovery <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> global ec<strong>on</strong>omy <strong>the</strong><br />

existing imbalanced situati<strong>on</strong> could tighten fur<strong>the</strong>r.<br />

The <strong>future</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> this imbalanced situati<strong>on</strong> will<br />

have great impact both <strong>on</strong> refining and <strong>on</strong> l<strong>on</strong>ger<br />

term <strong>on</strong> car manufacturing <str<strong>on</strong>g>industry</str<strong>on</strong>g>.<br />

This <strong>future</strong> depends <strong>on</strong> <strong>on</strong>e hand from <strong>the</strong><br />

additi<strong>on</strong>al c<strong>on</strong>sumpti<strong>on</strong> and from <strong>the</strong> structural<br />

change <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> existing <strong>on</strong>es.<br />

The biggest part <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> additi<strong>on</strong>al motor fuel<br />

c<strong>on</strong>sumpti<strong>on</strong> will come from <strong>the</strong> emerging countries,<br />

especially from <strong>the</strong> Asian Pacific and <strong>the</strong><br />

Middle East regi<strong>on</strong>s. The evoluti<strong>on</strong>ary way which<br />

is chosen by this regi<strong>on</strong> and <strong>the</strong> structure <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

<strong>the</strong> oil product c<strong>on</strong>sumpti<strong>on</strong> will have a huge<br />

impact not <strong>on</strong>ly <strong>on</strong> <strong>the</strong> regi<strong>on</strong>al, but <strong>the</strong> global<br />

oil <str<strong>on</strong>g>industry</str<strong>on</strong>g>.<br />

China outnumbered <strong>the</strong> US as <strong>the</strong> biggest new<br />

passenger car market in <strong>the</strong> first four m<strong>on</strong>ths <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

2009 and expected to double its passenger car<br />

park, less than 5 years. This enormous new fleet<br />

will almost entirely dedicated to gasoline engine<br />

in China and most <str<strong>on</strong>g>of</str<strong>on</strong>g> o<strong>the</strong>r emerging countries,<br />

as it fits better to <strong>the</strong> main c<strong>on</strong>sumer needs:<br />

cheap (simpler technology) first family car with<br />

relative low c<strong>on</strong>sumpti<strong>on</strong> (small vehicles).<br />

This will generate a massive increase in gasoline<br />

demand in <strong>the</strong> regi<strong>on</strong>. On <strong>the</strong> o<strong>the</strong>r hand <strong>the</strong><br />

impressive ec<strong>on</strong>omy growth in <strong>the</strong> recent years<br />

5<br />

1MOL GROUP

Challanges<br />

2010/1<br />

generated an accelerating regi<strong>on</strong>al diesel demand<br />

which was even bigger than <strong>the</strong> gasoline<br />

growth. This demand growth expected to re-gain<br />

after ec<strong>on</strong>omic downturn.<br />

China, India and o<strong>the</strong>r Asian emerging markets<br />

answer for this growing oil product demand with<br />

impressive refinery building programs. One <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

<strong>the</strong> key questi<strong>on</strong>s from oil <str<strong>on</strong>g>industry</str<strong>on</strong>g> point <str<strong>on</strong>g>of</str<strong>on</strong>g> view<br />

is that how big porti<strong>on</strong> could Asia cover from its<br />

emerging demand, or what is more threatening<br />

for Western refineries, how much oil product will<br />

be exported to <strong>the</strong> Atlantic basin.<br />

Thus as <strong>on</strong> <strong>on</strong>e hand <strong>the</strong> impact <str<strong>on</strong>g>of</str<strong>on</strong>g> Asian oil<br />

markets <strong>on</strong> Atlantic basin expected to increase<br />

<strong>on</strong> <strong>the</strong> o<strong>the</strong>r hand <strong>the</strong> <strong>future</strong> development <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

existing motor fuel demand and its structure in<br />

Europe and US is also a crucial questi<strong>on</strong> for <strong>the</strong><br />

<str<strong>on</strong>g>industry</str<strong>on</strong>g>. This <strong>future</strong> structure will mostly depend<br />

<strong>on</strong> <strong>the</strong> technological <str<strong>on</strong>g>developments</str<strong>on</strong>g>, which are<br />

discussed in more details in this analysis.<br />

Car park – growth<br />

& compositi<strong>on</strong><br />

trends<br />

G l o b a l p a s s e n g e r c a r<br />

p r o d u c t i o n t i l l 2 0 1 5<br />

Trend analyses show that car producti<strong>on</strong> in EU,<br />

US and Japan will go down c<strong>on</strong>tinuously even<br />

after having recaptured <strong>the</strong> 2008 path. The o<strong>the</strong>r<br />

part <str<strong>on</strong>g>of</str<strong>on</strong>g> Asia is foreseen to grow by 10% from <strong>the</strong><br />

end <str<strong>on</strong>g>of</str<strong>on</strong>g> crisis to 2015-2020, reaching <strong>the</strong> same<br />

producti<strong>on</strong> mass as EU and US toge<strong>the</strong>r. China<br />

is expected to see 30% increase compared to<br />

2008 level. (Figure 1.)<br />

G l o b a l P a s s e n g e r c a r<br />

& L i g h t D u t y E n g i n e<br />

p r o d u c t i o n<br />

Gasoline engine will keep <strong>on</strong> dominating over<br />

diesel (68 › 75%), in which <strong>the</strong> following trends<br />

are forecasted:<br />

• increasing share <str<strong>on</strong>g>of</str<strong>on</strong>g> advanced gasoline<br />

engines with improved fuel ec<strong>on</strong>omy<br />

• flex fuel c<strong>on</strong>tinuously represents approx 3%<br />

• hybrid to grow from 1,7% to 3.0%<br />

(Figure 2.)<br />

Figure 1. Vehicle producti<strong>on</strong> by manufacturers 1965-2015<br />

6<br />

1MOL GROUP

2010/1<br />

Challanges<br />

In <strong>the</strong> world’s pers<strong>on</strong>al vehicle market, diesel<br />

share is expected to decline from 30% to 23%<br />

by 2020, whereas CNG, LPG and alternative<br />

fuel propulsi<strong>on</strong> will see a marginal share <str<strong>on</strong>g>of</str<strong>on</strong>g> 2.2%.<br />

The average power <str<strong>on</strong>g>of</str<strong>on</strong>g> both diesel and gasolinepowered<br />

vehicles seem to flatten, stop-ping<br />

<strong>the</strong> decades-l<strong>on</strong>g mainstream development<br />

tendencies. All power classes will grow with <strong>the</strong><br />

same intensity. (Figure 3, 5)<br />

E u r o p e a n P a s s e n g e r c a r<br />

p r o d u c t i o n<br />

In Europe, basically, diesel and gasoline will<br />

dominate even by 2020. Projected share <str<strong>on</strong>g>of</str<strong>on</strong>g> full<br />

hybrid and flex-fuel toge<strong>the</strong>r is less than 3%,<br />

whereas CNG, LPG and hydrogen are even<br />

more negligible. Dieselizati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> EU passenger<br />

car fleet is expected to c<strong>on</strong>tinue bey<strong>on</strong>d <strong>the</strong><br />

crisis: diesel engine producti<strong>on</strong> will be <strong>on</strong> rise,<br />

while gasoline engine producti<strong>on</strong> decreases<br />

with, and <strong>the</strong>n <strong>the</strong> ratio will be stabilized at 1/3<br />

gasoline, 2/3 diesel vehicles within 5-6 years.<br />

The average power <str<strong>on</strong>g>of</str<strong>on</strong>g> both diesel and gasoline is<br />

expected to flatten. (Figure 4.)<br />

European road<br />

transportati<strong>on</strong><br />

statistics<br />

Based <strong>on</strong> recent Eurostat data <strong>on</strong> freight<br />

transport, analyzing <strong>the</strong> 1999-2005 period an<br />

average increase <str<strong>on</strong>g>of</str<strong>on</strong>g> 4.2 % in freight transport,<br />

expressed in milli<strong>on</strong> t<strong>on</strong>-km, took place in EU15,<br />

Figure 2. Global vehicle producti<strong>on</strong> by propulsi<strong>on</strong> technology<br />

[AVLGlobal Insight, AVL]<br />

Figure 3. Power distributi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> PC engines worldwide [Global Insight, AVL]<br />

7<br />

1MOL GROUP

Challanges<br />

2009/2 2010/1<br />

Figure 4. Power distributi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> PC engines Western Europe [AVL, Global Insight]<br />

Figure 5. Trends in <strong>the</strong> <str<strong>on</strong>g>automotive</str<strong>on</strong>g> <str<strong>on</strong>g>industry</str<strong>on</strong>g> [AVL, Global Insight]<br />

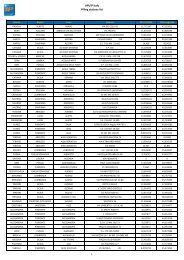

whereas in <strong>the</strong> period 2005/06 a 5% annual<br />

increase was observed in EU27. In <strong>the</strong> Central-<br />

European regi<strong>on</strong> road transport increased much<br />

faster than that <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> rail. (Table 1.)<br />

In Europe 2004, passenger cars accounted for<br />

87% <str<strong>on</strong>g>of</str<strong>on</strong>g> passenger road transport, while coach,<br />

trolley and city buses represented approximately<br />

10% share in passenger km. Between 2002 and<br />

2004 <strong>the</strong> rate <str<strong>on</strong>g>of</str<strong>on</strong>g> road passenger transport in <strong>the</strong><br />

EU-27 increased with moderate rate 0.5% p.a., in<br />

Hungary and Slovakia no increase and moderate<br />

decline could be observed. When projecting <strong>the</strong><br />

past tendencies to <strong>the</strong> post-crisis period, <strong>on</strong>e<br />

might foresee that passenger car transport will<br />

c<strong>on</strong>tinuously increase in <strong>the</strong> EU with moderate<br />

rate and steeper worldwide.<br />

8<br />

1MOL GROUP

2009/2 2010/1<br />

Challanges<br />

Table 1. [Eurostat: Modal split in <strong>the</strong> inland transport <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> EU - Freight and passenger transport up to 2006, 35/2008]<br />

Vehicle technology<br />

<str<strong>on</strong>g>developments</str<strong>on</strong>g> and<br />

<strong>the</strong>ir effects <strong>on</strong><br />

<strong>future</strong> fuel demand<br />

structure<br />

T r e n d – S h i f t i n<br />

c o n s u m e r t r e n d c h o i c e<br />

t o w a r d s l o w e r f u e l<br />

c o n s u m p t i o n<br />

In Europe, next to <strong>the</strong> c<strong>on</strong>venti<strong>on</strong>al customer<br />

expectati<strong>on</strong>s, like drivability, power and speed,<br />

a clear trend towards more fuel efficient cars<br />

can be observed. It is important to know,<br />

that carb<strong>on</strong>-dioxide emissi<strong>on</strong> and vehicle fuel<br />

c<strong>on</strong>sumpti<strong>on</strong> goes <strong>on</strong> hand to hand and <strong>on</strong>e to<br />

<strong>on</strong>e. Decreasing fuel c<strong>on</strong>sumpti<strong>on</strong> causes lower<br />

CO 2<br />

emissi<strong>on</strong>.<br />

A shift was shown (see Figure 6.) in Germany<br />

already in 2006/07 when <strong>the</strong> sales <str<strong>on</strong>g>of</str<strong>on</strong>g> cars with<br />

low fuel c<strong>on</strong>sumpti<strong>on</strong>, less than 140 g/km CO 2<br />

emissi<strong>on</strong>, increased while those <str<strong>on</strong>g>of</str<strong>on</strong>g> above 140g/<br />

km decreased str<strong>on</strong>gly.<br />

Figure 6. C<strong>on</strong>sumers moving into <strong>the</strong> lower CO 2<br />

emissi<strong>on</strong> vehicles<br />

[AVL 2008]<br />

9<br />

1MOL GROUP

Challanges<br />

2009/2 2010/1<br />

On <strong>the</strong> following picture ano<strong>the</strong>r aspect <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong><br />

decreasing CO 2<br />

emissi<strong>on</strong> is shown: in <strong>the</strong> UK<br />

<strong>the</strong> average new car carb<strong>on</strong>-dioxide emissi<strong>on</strong> is<br />

decreased yearly. It underprops <strong>the</strong> tendency<br />

shown in Germany that a shift could be recognised<br />

to <strong>the</strong> lower CO 2<br />

-emitting thus lower fuel<br />

c<strong>on</strong>suming passenger vehicles. Fuel ec<strong>on</strong>omy<br />

/CO 2<br />

emissi<strong>on</strong> is <strong>on</strong>e <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> development key<br />

factor. (Figure 7.)<br />

• Manufacturers in Europe will need to cut<br />

<strong>the</strong>ir average CO 2<br />

emissi<strong>on</strong>s between<br />

10% to 25% to hit <strong>the</strong>ir targets by 2012,<br />

o<strong>the</strong>rwise <strong>the</strong>y will have to pay penalty<br />

increasing <strong>on</strong> a year-to-year basis.<br />

• In case <str<strong>on</strong>g>of</str<strong>on</strong>g> n<strong>on</strong>-compliance, if <strong>the</strong>y do<br />

not improve at all, <strong>the</strong>y have to charge<br />

c<strong>on</strong>sumers with an average extra-fee <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

2500 €/vehicle by 2015.<br />

• The likely scenario is that such a huge fuel<br />

ec<strong>on</strong>omy improvement can be <strong>on</strong>ly partly<br />

achieved by 2012, this is especially difficult<br />

for manufacturers c<strong>on</strong>structing heavier, more<br />

powerful vehicles, thus <strong>the</strong> c<strong>on</strong>secutive<br />

penalty will be charged to <strong>the</strong> c<strong>on</strong>sumer [3].<br />

A u t o m o t i v e i n d u s t r y<br />

r e s p o n s e s – D o w n s i z i n g<br />

a n d h y b r i d i z a t i o n o f<br />

g a s o l i n e e n g i n e s<br />

Figure 7. The average new car CO 2<br />

emissi<strong>on</strong>s since 1997 in <strong>the</strong> UK<br />

[Society <str<strong>on</strong>g>of</str<strong>on</strong>g> Motor Manufacturers and Traders]<br />

The EU increases <strong>the</strong> role <str<strong>on</strong>g>of</str<strong>on</strong>g> CO 2<br />

emissi<strong>on</strong> for<br />

<str<strong>on</strong>g>automotive</str<strong>on</strong>g> manufacturers with penalty system<br />

<strong>on</strong> CO 2<br />

emissi<strong>on</strong>. Mandatory EU vehicle CO 2<br />

target 130 g/km by 2012 with penalties for n<strong>on</strong>compliance<br />

could affect <strong>the</strong> end selling prices <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

<strong>the</strong> new vehicles in <strong>the</strong> EU.<br />

The mainstream development directi<strong>on</strong>s as<br />

downsizing (Turbocharged Homogeneous GDI)<br />

will expectedly bring about 10% decrease in<br />

fuel c<strong>on</strong>sumpti<strong>on</strong>. This, coupled with mild hybridizati<strong>on</strong><br />

has a potential to bring about 15%<br />

reducti<strong>on</strong> by 2015.<br />

The figures <strong>on</strong> <strong>the</strong> Figure 8. are potential numbers,<br />

indicating that this could be achieved.<br />

The main trend shows that some technologies<br />

are used not for fuel saving but for increasing<br />

<strong>the</strong> vehicle power and driveability. Obviously it<br />

is not <strong>on</strong>ly for <strong>the</strong> fun, <strong>the</strong> stricter safety rules<br />

and increasing level <str<strong>on</strong>g>of</str<strong>on</strong>g> electricity require extra<br />

power.<br />

Figure 8. The average new car CO 2<br />

emissi<strong>on</strong>s since 1997 in <strong>the</strong> UK [Society <str<strong>on</strong>g>of</str<strong>on</strong>g> Motor Manufacturers and Traders ]<br />

10<br />

1MOL GROUP

2009/2 2010/1<br />

Challanges<br />

The price difference between diesel and gasoline<br />

technologies will not increase. Hybrids<br />

will be less expensive; <strong>the</strong>ir extra cost could be<br />

halved according to <strong>the</strong> calculati<strong>on</strong>s. It means<br />

that <strong>the</strong> pricing differentiati<strong>on</strong>s will not result<br />

great changes <strong>on</strong> <strong>the</strong> vehicle pool [1].<br />

distance and metropolitan utilisati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> vehicles<br />

but it has great hindrances, mostly based <strong>on</strong> <strong>the</strong><br />

extra weight added <strong>on</strong> l<strong>on</strong>g distance motorway<br />

runs (Figure 10).<br />

Figure 9. C<strong>on</strong>sumers moving into <strong>the</strong> lower CO 2<br />

emissi<strong>on</strong> vehicles [AVL 2008]<br />

Downsizing technology is under market introducti<strong>on</strong><br />

by most <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> car manufacturers. Volkswagen<br />

has introduced it first in its cars. The main<br />

characteristics and benefits are clearly show <strong>on</strong><br />

Figure. 9.: increased fuel pressure for improved<br />

combusti<strong>on</strong> efficiency and higher octane number<br />

request for better combusti<strong>on</strong> c<strong>on</strong>trol. The<br />

decrease <str<strong>on</strong>g>of</str<strong>on</strong>g> combusti<strong>on</strong> chamber volume from<br />

1984 cm 3 to 1390 cm 3 has been accompanied<br />

by <strong>the</strong> implementati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> a turbocharger and a<br />

compressor with a charge pressure <str<strong>on</strong>g>of</str<strong>on</strong>g> 2,5 bar.<br />

This technology with <strong>the</strong> direct injecti<strong>on</strong> gives a<br />

13% higher power output and app. 5% lower fuel<br />

c<strong>on</strong>sumpti<strong>on</strong>.<br />

A u t o m o t i v e i n d u s t r y<br />

r e s p o n s e s – d i e s e l<br />

v e h i c l e f u e l e c o n o m y<br />

p o t e n t i a l<br />

Diesel passenger cars have a potential <str<strong>on</strong>g>of</str<strong>on</strong>g> 6%<br />

fuel ec<strong>on</strong>omy improvement via downsizing,<br />

stop-start and mild hybridizati<strong>on</strong> to be attained<br />

by 2015. Hybridizati<strong>on</strong> is <strong>the</strong> most expensive<br />

soluti<strong>on</strong> to decease fuel c<strong>on</strong>sumpti<strong>on</strong> at both<br />

gasoline and diesel side. It has benefits in short<br />

Diesel engines fuel efficiency improvement<br />

potential could be improved up to 2015 in<br />

<strong>the</strong> heavy duty vehicle category up to 6% via<br />

reducti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> losses, improved EGR (Exhaust Gas<br />

Recycling) & EAS (Electr<strong>on</strong>ic Air Suspensi<strong>on</strong>) and<br />

use <str<strong>on</strong>g>of</str<strong>on</strong>g> kinetic energy <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> exhaust gases. The<br />

main drivers <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> engine development in this<br />

timescale are <strong>the</strong> Euro-6 emissi<strong>on</strong> limit values.<br />

The expected fur<strong>the</strong>r increase <str<strong>on</strong>g>of</str<strong>on</strong>g> fuel prices and<br />

<strong>the</strong> CO 2<br />

challenge have opened a new dimensi<strong>on</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> system cost versus efficiency. On <strong>the</strong> basis<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> diesel price scenarios (c<strong>on</strong>servative) seeing<br />

a price increase from 1.2€/ltr in 2008 to 2.6€/<br />

ltr by 2020, <strong>the</strong>re is a huge room for attractive<br />

technical soluti<strong>on</strong>s.<br />

In mid term, 2015-2020 hybridizati<strong>on</strong> and<br />

downsizing might bring a fur<strong>the</strong>r 4%. For <strong>the</strong><br />

total mid period saving potential (10%) <strong>the</strong>re is<br />

an estimated 10.000 € additi<strong>on</strong>al cost, which<br />

has a pay-back time for a l<strong>on</strong>g-haul truck <str<strong>on</strong>g>of</str<strong>on</strong>g> 1<br />

year (at diesel price assumed increase 3.5-times<br />

compared to-date).<br />

11<br />

1MOL GROUP

Challanges<br />

2009/2 2010/1<br />

Figure 10. Utilisati<strong>on</strong> benefits <str<strong>on</strong>g>of</str<strong>on</strong>g> hybrid vehicle versus c<strong>on</strong>venti<strong>on</strong>al diesel<br />

C<strong>on</strong>tinuing improvement <str<strong>on</strong>g>of</str<strong>on</strong>g> injectors and increasing<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> injecti<strong>on</strong> pressure will be <strong>the</strong> main<br />

technologies to reach <strong>the</strong>se both goals. The main<br />

objective <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> injecti<strong>on</strong> system development is<br />

to improve spray atomizati<strong>on</strong> and increase spray<br />

momentum to improve air/fuel mixing for more<br />

complete and c<strong>on</strong>trolled combusti<strong>on</strong>. Table 2.<br />

shows <strong>the</strong> changes <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> main parameters <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

diesel injectors.<br />

have to aband<strong>on</strong> c<strong>on</strong>venti<strong>on</strong>al petrol and diesel<br />

engine in favour <str<strong>on</strong>g>of</str<strong>on</strong>g> a new type <str<strong>on</strong>g>of</str<strong>on</strong>g> energie. HCCI<br />

(Homogenous Charged Compressi<strong>on</strong> Igniti<strong>on</strong>) and<br />

CCS (Combined Com busti<strong>on</strong> System) are different<br />

attempts to reach this goal. The main goal <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong><br />

researches is to combine <strong>the</strong> low fuel c<strong>on</strong>sumpti<strong>on</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> compressi<strong>on</strong> igniti<strong>on</strong> (diesel) and good emissi<strong>on</strong><br />

characteristics <str<strong>on</strong>g>of</str<strong>on</strong>g> spark igniti<strong>on</strong> (gasoline) engines<br />

(Figure 11.).<br />

1gen.<br />

IDI CR 2.gen CR<br />

-1995 2000- 2005-<br />

Maximal injecti<strong>on</strong> pressure [bar] 350 1000 2000+<br />

Injecti<strong>on</strong>s/min @ 3000 rpm 1500 1500 7500+<br />

fuel temperature [°C]

2009/2 2010/1<br />

Challanges<br />

Partial HCCI engines are expected to enter <strong>the</strong><br />

market in <strong>the</strong> next few years. Daimler introduces<br />

its HCCI under <strong>the</strong> name <str<strong>on</strong>g>of</str<strong>on</strong>g> DiesOtto. These<br />

engines will run in HCCI mode in low loads, but<br />

revert to traditi<strong>on</strong>al operati<strong>on</strong> mode at higher<br />

loads. It means that <strong>the</strong>y will need similar fuels<br />

as <strong>the</strong> today’s engines.<br />

Figure 11. Combusti<strong>on</strong> start in <strong>the</strong> three combusti<strong>on</strong> types [C<strong>on</strong>cawe]<br />

I s e l e c t r i c v e h i c l e a<br />

r e a l a l t e r n a t i v e <br />

The utilizati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> electricity <str<strong>on</strong>g>of</str<strong>on</strong>g>ten comes forward<br />

to replace fossil fuels and internal combusti<strong>on</strong><br />

engines. The major driving force is <strong>the</strong> 3,5-<br />

times lower fuelling price: EU gas/diesel 0.42<br />

$/kWh (highly taxed) versus <str<strong>on</strong>g>of</str<strong>on</strong>g>f-peak electricity<br />

price: 0.12 $/kWh. It can be predicted that<br />

increasing transportati<strong>on</strong> use <str<strong>on</strong>g>of</str<strong>on</strong>g> electricity<br />

will be followed by a tax improvement to compensate<br />

<strong>the</strong> governmental state losses. The<br />

major technological drawbacks include: l<strong>on</strong>g<br />

re-charging period, distance between two refuelling<br />

is still short approx 200 km state-<str<strong>on</strong>g>of</str<strong>on</strong>g>-<strong>the</strong><br />

art. Advanced battery technologies are available<br />

but at extreme high cost and durability max 5 yrs<br />

is still a str<strong>on</strong>g issue. Global metal availability for<br />

advanced batteries is doubtful (see Figure 12.).<br />

C<strong>on</strong>clusi<strong>on</strong>s<br />

At global scale gasoline fuelled vehicles will<br />

dominate <strong>the</strong> <str<strong>on</strong>g>automotive</str<strong>on</strong>g> market driven by North<br />

America. Sub-stantial fuel ec<strong>on</strong>omy improvement<br />

is forecasted in Japan and <strong>the</strong> United State at<br />

a stable producti<strong>on</strong> quantity. In Asia growing<br />

vehicle use is expected but <strong>the</strong> fuel ec<strong>on</strong>omy<br />

improvement will be sloxer than in Japan or <strong>the</strong><br />

US since <strong>the</strong>ir people will buy <strong>the</strong>ir first low cost<br />

car.<br />

In Europe <strong>the</strong> total <str<strong>on</strong>g>automotive</str<strong>on</strong>g> diesel demand will<br />

be <strong>on</strong> rise, fuelled by freight transport. A slightly<br />

declining share <str<strong>on</strong>g>of</str<strong>on</strong>g> gasoline in vehicle fleet, with<br />

improved fuel ec<strong>on</strong>omy vehicles phased in<br />

gradually is expected. The str<strong>on</strong>gly increasing<br />

freight transport will <strong>on</strong>ly partly compensated by<br />

fuel ec<strong>on</strong>omy development at heavy duty side<br />

with slower phase-in rate. High bio-blends expectedly<br />

play minor roles.<br />

MOL Group´s diesel producti<strong>on</strong> should be<br />

intensified to streng<strong>the</strong>n <strong>the</strong> good posi-ti<strong>on</strong>s<br />

<strong>on</strong> <strong>the</strong> fuel market. Alternative fuels blending<br />

should be focussed <strong>on</strong> diesel comp<strong>on</strong>ents over<br />

gasoline <strong>on</strong>es. Main focus could be first <str<strong>on</strong>g>of</str<strong>on</strong>g> all <strong>on</strong><br />

syntetic fuel technologies and renewables o<strong>the</strong>r<br />

than biodiesel and 1 st generati<strong>on</strong> bioethanol.<br />

Advanced combusti<strong>on</strong> engines would require<br />

wide range <str<strong>on</strong>g>of</str<strong>on</strong>g> gasoline-diesel blend, MOL has to<br />

be ready to <str<strong>on</strong>g>of</str<strong>on</strong>g>fer HCCI compatible fuels at right<br />

time.<br />

Figure 12. Comparis<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> electic vehicle (EV) and internal combusti<strong>on</strong> engine (ICE)<br />

13<br />

1MOL GROUP

Challanges<br />

2009/2 2010/1<br />

References<br />

[1] On <strong>the</strong> Road in 2035, Laboratory for Energy<br />

and <strong>the</strong> Envir<strong>on</strong>ment Massachusetts<br />

Institute <str<strong>on</strong>g>of</str<strong>on</strong>g> Technology July 2008<br />

[2] Society <str<strong>on</strong>g>of</str<strong>on</strong>g> Motor Manufacturers and<br />

Traders<br />

[3] Ricardo: C<strong>on</strong>cawe Automotive C<strong>on</strong>sultancy<br />

Nov. 2008<br />

[4] AVL: C<strong>on</strong>cawe Automotive C<strong>on</strong>sultancy<br />

Pers<strong>on</strong>al Cars and Heavy Duty Diesel;<br />

2008 Nov.<br />

[5] AVL: C<strong>on</strong>cawe Automotive C<strong>on</strong>sultancy<br />

Gasoline Trends; 2008 Nov.<br />

[6] Á. Horváth – I. Vári – J. Zatykó – M. Zöldy:<br />

Car <str<strong>on</strong>g>industry</str<strong>on</strong>g> <str<strong>on</strong>g>developments</str<strong>on</strong>g> – oil <str<strong>on</strong>g>industry</str<strong>on</strong>g><br />

challenges, MOL Scientific Magazine<br />

2007/2 pp.122-137 ISSN 1217-2820<br />

[7] AutomotiveWorld.com: Electric, plug-in<br />

hybrids and fuel cell vehicles: technologies<br />

and trends, 2008 Oct.<br />

[8] C<strong>on</strong>cawe: Advanced combusti<strong>on</strong> for low<br />

emissi<strong>on</strong> and high efficiency: a literature<br />

review <str<strong>on</strong>g>of</str<strong>on</strong>g> HCCI combusti<strong>on</strong> c<strong>on</strong>cepts,<br />

C<strong>on</strong>cawe 2008<br />

Reviewed by Márta Kámer dr.<br />

14<br />

1MOL GROUP

2010/1<br />

Challenges<br />

Challanges<br />

The European<br />

Industry<br />

Petroleum<br />

in 2008<br />

György Wilde, Dr.<br />

Secretary-General<br />

Hungarian Petroleum Associati<strong>on</strong><br />

E-mail: hpa@t-<strong>on</strong>line.hu<br />

Abstract<br />

On <strong>the</strong> General Informati<strong>on</strong> Meeting<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> EUROPIA, <strong>the</strong> representati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong><br />

European petroleum <str<strong>on</strong>g>industry</str<strong>on</strong>g> were<br />

discussed <strong>the</strong> events <str<strong>on</strong>g>of</str<strong>on</strong>g> 2008 most<br />

important from <strong>the</strong> point <str<strong>on</strong>g>of</str<strong>on</strong>g> view <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong><br />

oil <str<strong>on</strong>g>industry</str<strong>on</strong>g>. The present article, based<br />

<strong>on</strong> <strong>the</strong> lectures held here, informs <strong>on</strong><br />

<strong>the</strong> following topics in details:<br />

• energy efficiency<br />

• climate change<br />

• security <str<strong>on</strong>g>of</str<strong>on</strong>g> energy supply<br />

• air quality and envir<strong>on</strong>ment<br />

• fuel products.<br />

Összefoglalás<br />

A Z E U R Ó P A I K ô O L A J I P A R<br />

2 0 0 8 - B A N<br />

Az európai olajipar érdekképviselete,<br />

az EUROPIA éves közgyûlésén áttekin<br />

tették 2008. olajipar szemp<strong>on</strong>tjából<br />

legf<strong>on</strong>tosabb eseményeit. Ez alapján<br />

a jelen összefoglalásban a kö vetkezô<br />

témákat nézzük részletesen:<br />

• energiahaték<strong>on</strong>yság<br />

• éghajlatváltozás<br />

• energiabizt<strong>on</strong>ság<br />

• levegôminôség és környezet<br />

• üzemanyagok.<br />

The European Petroleum Industry Associati<strong>on</strong><br />

(EUROPIA) covering about 80% <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> European<br />

oil refining <str<strong>on</strong>g>industry</str<strong>on</strong>g> held <strong>the</strong> so-called “General<br />

Informati<strong>on</strong> Meeting” <strong>on</strong> May 27 th , 2009. The<br />

informati<strong>on</strong> written bellow is based <strong>on</strong> <strong>the</strong><br />

materials presented <strong>the</strong>re.<br />

Introducti<strong>on</strong><br />

2008 c<strong>on</strong>tinued to see c<strong>on</strong>cerns regarding<br />

energy prices, security <str<strong>on</strong>g>of</str<strong>on</strong>g> energy supply and<br />

climate change <strong>on</strong> top <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> political agenda at<br />

European and internati<strong>on</strong>al level. It was certainly<br />

<strong>on</strong>e <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> busiest but also most rewarding<br />

times for European Instituti<strong>on</strong>s. In particular, <strong>the</strong><br />

adopti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> EU Climate Change and Energy<br />

Package in December laid <strong>the</strong> foundati<strong>on</strong>s<br />

for a balanced approach to addressing <strong>the</strong>se<br />

challenges and gave a str<strong>on</strong>g signal <str<strong>on</strong>g>of</str<strong>on</strong>g> European<br />

leadership in this area. Aiming to provide a<br />

follow-up to <strong>the</strong> Kyoto Protocol, <strong>the</strong> Copenhagen<br />

C<strong>on</strong>ference <strong>on</strong> Climate Change in December<br />

2009 will lead to fur<strong>the</strong>r reflecti<strong>on</strong> <strong>on</strong> <strong>the</strong> role<br />

and choice <str<strong>on</strong>g>of</str<strong>on</strong>g> energy sources for <strong>the</strong> 21 st century<br />

at a global level. In this light, working with <strong>the</strong><br />

European Instituti<strong>on</strong>s to ensure that oil refining<br />

remains part <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> European soluti<strong>on</strong> to <strong>the</strong><br />

world energy challenge will be at <strong>the</strong> forefr<strong>on</strong>t <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

priorities <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> European petroleum <str<strong>on</strong>g>industry</str<strong>on</strong>g>.<br />

Energy Efficiency<br />

(The “Save more than fuel” campaign)<br />

Energy efficiency remains <strong>on</strong>e <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> EU’s<br />

top priorities as it is c<strong>on</strong>sidered <strong>the</strong> most<br />

cost effective way to c<strong>on</strong>tribute to achieving<br />

climate change objectives, enhancing EU<br />

competitiveness, and reducing EU energy supply<br />

dependency. In 2008 EUROPIA, in partnership<br />

with <strong>the</strong> European Commissi<strong>on</strong>, launched a<br />

cross-<str<strong>on</strong>g>industry</str<strong>on</strong>g> campaign <strong>on</strong> efficient use or road<br />

15<br />

1MOL GROUP

Challanges<br />

2009/2 2010/1<br />

transport fuels, aimed at educating c<strong>on</strong>sumers<br />

<strong>on</strong> how to drive more efficiently and ‘save more<br />

than fuel’.<br />

More than 40 <str<strong>on</strong>g>of</str<strong>on</strong>g> Europe’s leading oil companies<br />

joined forces with support from <strong>the</strong> Nati<strong>on</strong>al Oil<br />

Industry Associati<strong>on</strong>s, to run a pan-European<br />

c<strong>on</strong>sumer awareness campaign <strong>on</strong> <strong>the</strong> efficient<br />

use <str<strong>on</strong>g>of</str<strong>on</strong>g> transport fuels. It was for <strong>the</strong> first time that<br />

<strong>the</strong> European oil <str<strong>on</strong>g>industry</str<strong>on</strong>g> united and engaged with<br />

c<strong>on</strong>sumers in such a public initiative. The “Save<br />

more than fuel” campaign, champi<strong>on</strong>ed by <strong>the</strong><br />

European Energy Commissi<strong>on</strong>er, was launched<br />

simultaneously in 29 European countries <strong>on</strong><br />

<strong>the</strong> 27th May 2008. The campaign involved<br />

over 45,000 petrol stati<strong>on</strong>s across participating<br />

countries. Around 30 milli<strong>on</strong> leaflets in 24<br />

languages, <str<strong>on</strong>g>of</str<strong>on</strong>g>fering 10 simple tips, for driving<br />

more efficiently, were distributed to road users<br />

at participating petrol stati<strong>on</strong>s.<br />

In additi<strong>on</strong>, a website www.savemorethanfuel.<br />

eu, brought <strong>the</strong> 10 tips to life with animated<br />

carto<strong>on</strong>s and explanati<strong>on</strong>s, also in 24 languages,<br />

about <strong>the</strong> benefits <str<strong>on</strong>g>of</str<strong>on</strong>g> efficient driving behaviour.<br />

Behavioral change cannot be achieved in <strong>on</strong>e<br />

day. Repeating <strong>the</strong> message <str<strong>on</strong>g>of</str<strong>on</strong>g> efficient driving<br />

and its purpose is <strong>the</strong>refore fundamental to<br />

bringing about change.<br />

EUROPIA c<strong>on</strong>tinued to promote <strong>the</strong> campaign<br />

and its messages via advertising in selected<br />

publicati<strong>on</strong>s and via dedicated exhibiti<strong>on</strong>s at <strong>the</strong><br />

European Commissi<strong>on</strong>’s Green Week in June in<br />

Brussels, at <strong>the</strong> World Petroleum C<strong>on</strong>gress in<br />

July in Madrid, and at <strong>the</strong> UN Climate Change<br />

C<strong>on</strong>ference in December in Poznan.<br />

Climate change<br />

and energy policy<br />

C l i m a t e C h a n g e a n d<br />

E n e r g y P a c k a g e<br />

The European Commissi<strong>on</strong> started 2008 by<br />

issuing a set <str<strong>on</strong>g>of</str<strong>on</strong>g> legislative proposals to follow-up<br />

<strong>on</strong> <strong>the</strong> Climate Change and Energy policy adopted<br />

by <strong>the</strong> Council in 2007. This package c<strong>on</strong>firmed<br />

<strong>the</strong> European Uni<strong>on</strong>’s ambiti<strong>on</strong> to deliver its 20-<br />

20-20 targets: 20 % reducti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> greenhouse<br />

gases (GHG) emissi<strong>on</strong>s, 20 % share <str<strong>on</strong>g>of</str<strong>on</strong>g> renewable<br />

energy and 20 % energy efficiency improvement<br />

by 2020. In <strong>the</strong> unprecedented effort, <strong>the</strong> EU<br />

Instituti<strong>on</strong>s c<strong>on</strong>cluded First Reading Agreement<br />

for all legislative proposals in December 2008.<br />

The oil <str<strong>on</strong>g>industry</str<strong>on</strong>g> actively engaged with <strong>the</strong> key<br />

instituti<strong>on</strong>al stakeholders throughout <strong>the</strong> codecisi<strong>on</strong><br />

process and stressed <strong>the</strong> importance <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

a balanced approach that takes into account <strong>the</strong><br />

three pillars <str<strong>on</strong>g>of</str<strong>on</strong>g> energy policy – competitiveness,<br />

sustainability and security <str<strong>on</strong>g>of</str<strong>on</strong>g> supply.<br />

In resp<strong>on</strong>se to <strong>the</strong> package, it was stressed that<br />

<strong>the</strong> Refining Industry shares <strong>the</strong> EU’s c<strong>on</strong>cerns<br />

around GHG emissi<strong>on</strong>s, and acknowledges <strong>the</strong><br />

need to take effective acti<strong>on</strong> to reduce <strong>the</strong>m. The<br />

clear recogniti<strong>on</strong> in <strong>the</strong> Commissi<strong>on</strong>’s proposals<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> need for a balanced approach – taking<br />

into account: competitiveness, sustainability and<br />

security <str<strong>on</strong>g>of</str<strong>on</strong>g> supply – was particularly welcomed.<br />

However, <strong>the</strong>re was also highlighted a number <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

c<strong>on</strong>cerns with <strong>the</strong> Commissi<strong>on</strong>’s proposals.<br />

After <strong>the</strong> Council had reached agreement, <strong>the</strong><br />

European Parliament adopted by large majorities<br />

all six Directives <strong>on</strong> 17 December 2008. This<br />

First Reading in just under a year was a very<br />

str<strong>on</strong>g signal <str<strong>on</strong>g>of</str<strong>on</strong>g> Europe’s commitment to its<br />

20:20:20 by 2020 climate goals. Achieving this<br />

agreement in 2008 was important in view <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong><br />

timing <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> United Nati<strong>on</strong> Climate C<strong>on</strong>ference<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> Parties: COP14 and 15 talks in Poznan<br />

(December 2008) and Copenhagen (December<br />

2009) respectively, and <strong>the</strong> electi<strong>on</strong>s in <strong>the</strong><br />

European Parliament in mid 2009.<br />

The oil <str<strong>on</strong>g>industry</str<strong>on</strong>g> focussed in particular <strong>on</strong> three<br />

dossiers: EU ETS (emissi<strong>on</strong>s trading scheme),<br />

Renewables and Fuel Quality Directives. In fact,<br />

Refining was unique as a sector in being str<strong>on</strong>gly<br />

impacted by all three proposals. A number <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

significant changes in <strong>the</strong> original proposals<br />

were agreed in <strong>the</strong> adopted Directives. These<br />

include:<br />

• EU ETS: Recogniti<strong>on</strong> that Refining is<br />

an Energy Intensive Industry and not<br />

an “energy” sector such as <strong>the</strong> Power<br />

Industry, which faces full aucti<strong>on</strong>ing from<br />

2013. Therefore, Refining should be<br />

assessed for its exposure to <strong>the</strong> risks <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

carb<strong>on</strong> leakage against quantitative criteria,<br />

with realistic thresholds.<br />

• Renewable Energy Directive: A bi<str<strong>on</strong>g>of</str<strong>on</strong>g>uels<br />

target <str<strong>on</strong>g>of</str<strong>on</strong>g> 10 % associated with a review<br />

clause in 2014. The legal basis for bi<str<strong>on</strong>g>of</str<strong>on</strong>g>uels<br />

sustainability criteria c<strong>on</strong>firmed as Article 95<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> Treaty, which allows a pan-European<br />

sustainability certificati<strong>on</strong> system and avoids<br />

proliferati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> nati<strong>on</strong>al systems.<br />

• Fuel Quality Directive: Reducti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong><br />

binding target for GHG emissi<strong>on</strong> reducti<strong>on</strong><br />

from road fuels from 10 % to 6 % and <strong>the</strong><br />

establishment <str<strong>on</strong>g>of</str<strong>on</strong>g> a review clause.<br />

16<br />

1MOL GROUP

2009/2 2010/1<br />

Challanges<br />

E U E m i s s i o n T r a d i n g<br />

S c h e m e<br />

The European Commissi<strong>on</strong> recognized <strong>the</strong> EU<br />

Emissi<strong>on</strong>s Trading Scheme (ETS) as <strong>on</strong>e <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong><br />

key tools in achieving Kyoto targets and reaching<br />

at least 20% reducti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> GHG emissi<strong>on</strong>s by<br />

2020 compared to 1990. Initiated in 2007, <strong>the</strong><br />

c<strong>on</strong>sultati<strong>on</strong> process resulted in <strong>the</strong> Revisi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

<strong>the</strong> Directive proposed by <strong>the</strong> Commissi<strong>on</strong> in<br />

January 2008 as part <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> CARE package. As<br />

a significant shift compared to initial proposals<br />

and as a result <str<strong>on</strong>g>of</str<strong>on</strong>g> extensive c<strong>on</strong>sultati<strong>on</strong>, <strong>the</strong><br />

Refining Industry is no l<strong>on</strong>ger subject to 100%<br />

aucti<strong>on</strong>ing with <strong>the</strong> power sector in 2013, but<br />

is now c<strong>on</strong>sidered an Energy Intensive Industry<br />

exposed to internati<strong>on</strong>al competiti<strong>on</strong>. Quantitative<br />

criteria and thresholds for assessing <strong>the</strong> risk <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

carb<strong>on</strong> leakage were included in <strong>the</strong> adopted<br />

Directive. Sectors that pass <strong>the</strong>se thresholds<br />

will qualify for 100% free allowances, within a<br />

sector benchmark.<br />

Coordinated c<strong>on</strong>tributi<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> EUROPIA, member<br />

companies and <strong>the</strong> Nati<strong>on</strong>al Oil Industry<br />

Associati<strong>on</strong>s, to <strong>the</strong> co-decisi<strong>on</strong> process<br />

focussed <strong>on</strong> clear and c<strong>on</strong>sistent messages,<br />

seeking fairness – not special treatment. The<br />

main thrust <str<strong>on</strong>g>of</str<strong>on</strong>g> this advocacy was to dem<strong>on</strong>strate<br />

that Refining is energy intensive and exposed<br />

to internati<strong>on</strong>al competiti<strong>on</strong>, and that EU<strong>on</strong>ly<br />

aucti<strong>on</strong>ing c<strong>on</strong>stitutes a risk to European<br />

competitiveness and security <str<strong>on</strong>g>of</str<strong>on</strong>g> energy supply.<br />

Through EUROPIA’s engagement with<br />

o<strong>the</strong>r Energy Intensive Industries (Ells) and<br />

BusinessEurope it became clear that EUROPIA’s<br />

key c<strong>on</strong>cerns were shared by o<strong>the</strong>r Ells.<br />

EUROPIA played a leading role in agreeing a<br />

joint letter, co-signed by sector-members <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong><br />

Alliance for a Competitive European Industry and<br />

<strong>the</strong> Alliance <str<strong>on</strong>g>of</str<strong>on</strong>g> Energy Intensive Industries. This<br />

letter stressed <strong>the</strong> need for fair and transparent<br />

assessment <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong>se two quantitative criteria<br />

and was sent as <strong>the</strong> final trialogue negotiati<strong>on</strong>s<br />

reached <strong>the</strong>ir c<strong>on</strong>clusi<strong>on</strong>s between <strong>the</strong> Council,<br />

<strong>the</strong> European Parliament and <strong>the</strong> Commissi<strong>on</strong>.<br />

These efforts were c<strong>on</strong>cluded in <strong>the</strong> final versi<strong>on</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> Directive adopted at First Reading in<br />

December. Specifically, <strong>the</strong> Refining Industry<br />

was recognized as “energy intensive” and not<br />

“energy”, separated from <strong>the</strong> power sector and<br />

<strong>the</strong>refore eligible for free allowances. The criteria<br />

promoted by EUROPIA were included and will be<br />

used to evaluate competitive risk to <strong>the</strong> sector<br />

ra<strong>the</strong>r than looking, as in <strong>the</strong> original proposals,<br />

at carb<strong>on</strong> costs from a c<strong>on</strong>sumer view point. The<br />

New Entrants definiti<strong>on</strong> was modified and should<br />

include major investments <strong>on</strong> existing refineries.<br />

This is <str<strong>on</strong>g>of</str<strong>on</strong>g> particular importance for <strong>the</strong> upgrading<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> refineries to meet new specificati<strong>on</strong>s and<br />

demands. Finally, despite <strong>the</strong> initial desire to wait<br />

until Copenhagen internati<strong>on</strong>al negotiati<strong>on</strong>s, <strong>the</strong><br />

dates for identifying exposed sectors and <strong>the</strong><br />

appropriate measures have been advanced.<br />

Security <str<strong>on</strong>g>of</str<strong>on</strong>g> energy<br />

supply<br />

S e c o n d S t r a t e g i c<br />

E n e r g y R e v i e w ( S E R I I )<br />

The European Commissi<strong>on</strong> c<strong>on</strong>tinued to place<br />

high priority <strong>on</strong> security <str<strong>on</strong>g>of</str<strong>on</strong>g> energy supply in 2008<br />

and in November published <strong>the</strong> accompanying<br />

legislative proposal for a Revised Directive <strong>on</strong><br />

Strategic Stocks. It also announced its plan to<br />

issue a “Communicati<strong>on</strong> <strong>on</strong> <strong>the</strong> c<strong>on</strong>tributi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

EU Refining to EU security <str<strong>on</strong>g>of</str<strong>on</strong>g> supply” in 2009 –<br />

a clear indicati<strong>on</strong> that <strong>the</strong> EU Refining Industry is<br />

now recognized as integral to such security.<br />

Although SER II (Sec<strong>on</strong>d Strategic Energy<br />

Review) – entitled “EU Energy Security and<br />

Solidarity Acti<strong>on</strong> Plan” – focussed mainly<br />

<strong>on</strong> upstream (crude oil explorati<strong>on</strong> and<br />

producti<strong>on</strong>) and electricity toge<strong>the</strong>r with <strong>the</strong>ir<br />

infrastructure, in timely engagement with <strong>the</strong><br />

Commissi<strong>on</strong> EUROPIA identified <strong>the</strong> omissi<strong>on</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> any reference to EU Refining. In support <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

<strong>the</strong> Refining Industry’s view <strong>the</strong> oil <str<strong>on</strong>g>industry</str<strong>on</strong>g><br />

organized a series <str<strong>on</strong>g>of</str<strong>on</strong>g> specialist workshops with<br />

<strong>the</strong> Commissi<strong>on</strong> to emphasiz e that energy<br />

supply encompasses not <strong>on</strong>ly crude oil supply<br />

but also infrastructure to refine it, and that EU<br />

Refining is an integral and key part <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> supply<br />

chain to deliver products to <strong>the</strong> c<strong>on</strong>sumer. The<br />

Commissi<strong>on</strong>’s final communicati<strong>on</strong> explicitly<br />

referred to EU Refining. The Commissi<strong>on</strong> also<br />

announced plans to issue a communicati<strong>on</strong> in<br />

2010 <strong>on</strong> Refining Capacity and EU Oil Demand<br />

in order to improve <strong>the</strong> level <str<strong>on</strong>g>of</str<strong>on</strong>g> transparency<br />

around refining capacity necessary to serve <strong>the</strong><br />

EU’s needs, and taking account <str<strong>on</strong>g>of</str<strong>on</strong>g> c<strong>on</strong>cerns<br />

regarding <strong>the</strong> potential availability <str<strong>on</strong>g>of</str<strong>on</strong>g> diesel fuel<br />

in <strong>the</strong> <strong>future</strong>.<br />

The 2008 rise in oil prices generated a number <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

communicati<strong>on</strong>s from <strong>the</strong> European Instituti<strong>on</strong>s<br />

aimed at addressing <strong>the</strong> challenge <str<strong>on</strong>g>of</str<strong>on</strong>g> secure<br />

energy supply: <strong>the</strong> Commissi<strong>on</strong> Communicati<strong>on</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> “Facing <strong>the</strong> challenge <str<strong>on</strong>g>of</str<strong>on</strong>g> higher oil prices”;<br />

17<br />

1MOL GROUP

Challanges<br />

2009/2 2010/1<br />

<strong>the</strong> French Presidency Report <strong>on</strong> <strong>the</strong> “Situati<strong>on</strong><br />

<strong>on</strong> oil markets, and short- to medium-term<br />

measures in resp<strong>on</strong>se to <strong>the</strong> surge in oil prices”<br />

submitted to <strong>the</strong> European Council; and <strong>the</strong><br />

European Parliament’s own report <strong>on</strong> “Facing<br />

Oil Challenges”.<br />

The SER II and o<strong>the</strong>r related communicati<strong>on</strong>s set<br />

out clear areas where more acti<strong>on</strong> is needed to<br />

secure sustainable energy supplies in Europe:<br />

• Make better use <str<strong>on</strong>g>of</str<strong>on</strong>g> Europe’s indigenous<br />

energy resources, both renewable and<br />

fossil.<br />

• More effective support for projects to build<br />

<strong>the</strong> required infrastructure.<br />

• Focus <strong>on</strong> solidarity, including EU crisis<br />

mechanisms, oil stocks and a variety <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

mechanisms to resp<strong>on</strong>d to possible gas<br />

disrupti<strong>on</strong>.<br />

• Additi<strong>on</strong>al and more urgent efforts to<br />

improve energy efficiency.<br />

• Greater focus <strong>on</strong> energy in <strong>the</strong> EU’s<br />

internati<strong>on</strong>al relati<strong>on</strong>s, including through<br />

establishment <str<strong>on</strong>g>of</str<strong>on</strong>g> relati<strong>on</strong>ships with supplier,<br />

transit and c<strong>on</strong>sumer countries based <strong>on</strong><br />

interdependence.<br />

The SER II will ultimately lead to <strong>the</strong> adopti<strong>on</strong> in<br />

March 2010 <str<strong>on</strong>g>of</str<strong>on</strong>g> a renewed Acti<strong>on</strong> Plan <strong>on</strong> Energy<br />

Policy for Europe, integrating 2050 in <strong>the</strong> picture.<br />

The Review <strong>the</strong>refore aimed to capture <strong>the</strong> first<br />

steps towards <strong>the</strong> definiti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> an EU resp<strong>on</strong>se<br />

to <strong>the</strong> l<strong>on</strong>ger term challenges.<br />

R e v i s e d D i r e c t i v e o n<br />

S t r a t e g i c S t o c k s<br />

The Sec<strong>on</strong>d Strategic Energy Review was<br />

accompanied by a number <str<strong>on</strong>g>of</str<strong>on</strong>g> proposals, including<br />

revisi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> Strategic Stocks Directive. Some<br />

provisi<strong>on</strong>s in this proposal are ambiguous and –<br />

depending <strong>on</strong> <strong>the</strong> interpretati<strong>on</strong> – could be ei<strong>the</strong>r<br />

detrimental to <strong>the</strong> Refining Industry or neutral. The<br />

oil <str<strong>on</strong>g>industry</str<strong>on</strong>g> supports <strong>the</strong> Commissi<strong>on</strong>’s efforts<br />

to maintain an effective system <str<strong>on</strong>g>of</str<strong>on</strong>g> emergency<br />

oil stocks but believes that this system should<br />

be fit-for-purpose and not lead to significant and<br />

unjustified costs.<br />

Specifically, <strong>the</strong> Directive should allow <strong>the</strong> use<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> existing facilities, logistics networks and<br />

operati<strong>on</strong>al procedures <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> ec<strong>on</strong>omic operators.<br />

In particular, <strong>the</strong> following points in <strong>the</strong><br />

Commissi<strong>on</strong>’s proposal have been identified as<br />

requiring fur<strong>the</strong>r discussi<strong>on</strong>.<br />

In our view <strong>the</strong>re is no evidence that weekly<br />

reporting <str<strong>on</strong>g>of</str<strong>on</strong>g> commercial stocks by Member States<br />

would c<strong>on</strong>tribute to better security <str<strong>on</strong>g>of</str<strong>on</strong>g> supply or<br />

improve market transparency. On <strong>the</strong> c<strong>on</strong>trary<br />

– it might have adverse effects, as experience<br />

has shown that weekly data are less accurate<br />

than <strong>the</strong> m<strong>on</strong>thly data and this inaccuracy could<br />

in practice lead to increased volatility.<br />

Air quality end<br />

envir<strong>on</strong>ment<br />

I n t e g r a t e d P o l l u t i o n<br />

P r e v e n t i o n a n d C o n t r o l<br />

D i r e c t i v e<br />

The Commissi<strong>on</strong> published its proposal for a<br />

revised Integrated Polluti<strong>on</strong> Preventi<strong>on</strong> and<br />

C<strong>on</strong>trol Directive (IPPC-D) in December 2007.<br />

Subsequently, in 2008 <strong>the</strong> proposal entered a<br />

rigorous co-decisi<strong>on</strong> process and it is unlikely<br />

that First Reading Agreement will be achieved.<br />

Like most industrial sectors, <strong>the</strong> Refining Industry<br />

is very c<strong>on</strong>cerned by <strong>the</strong> Commissi<strong>on</strong>’s proposal<br />

by <strong>the</strong> binding limits for large combusti<strong>on</strong> plants<br />

and inclusi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> refineries in this category.<br />

The EU has a set <str<strong>on</strong>g>of</str<strong>on</strong>g> comm<strong>on</strong> rules for permitting<br />

and c<strong>on</strong>trolling industrial installati<strong>on</strong>s in <strong>the</strong><br />

IPPC-D. Operators <str<strong>on</strong>g>of</str<strong>on</strong>g> industrial installati<strong>on</strong>s<br />

covered by <strong>the</strong> Directive are required to obtain<br />

an authorizati<strong>on</strong> (envir<strong>on</strong>mental permit) from <strong>the</strong><br />