PHENYL MAKING INTRODUCTION: The unit propose to ... - smallB

PHENYL MAKING INTRODUCTION: The unit propose to ... - smallB

PHENYL MAKING INTRODUCTION: The unit propose to ... - smallB

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

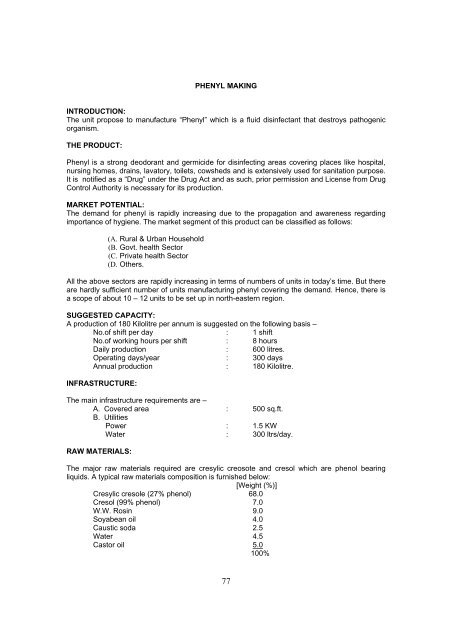

<strong>PHENYL</strong> <strong>MAKING</strong><br />

<strong>INTRODUCTION</strong>:<br />

<strong>The</strong> <strong>unit</strong> <strong>propose</strong> <strong>to</strong> manufacture “Phenyl” which is a fluid disinfectant that destroys pathogenic<br />

organism.<br />

THE PRODUCT:<br />

Phenyl is a strong deodorant and germicide for disinfecting areas covering places like hospital,<br />

nursing homes, drains, lava<strong>to</strong>ry, <strong>to</strong>ilets, cowsheds and is extensively used for sanitation purpose.<br />

It is notified as a “Drug” under the Drug Act and as such, prior permission and License from Drug<br />

Control Authority is necessary for its production.<br />

MARKET POTENTIAL:<br />

<strong>The</strong> demand for phenyl is rapidly increasing due <strong>to</strong> the propagation and awareness regarding<br />

importance of hygiene. <strong>The</strong> market segment of this product can be classified as follows:<br />

(A. Rural & Urban Household<br />

(B. Govt. health Sec<strong>to</strong>r<br />

(C. Private health Sec<strong>to</strong>r<br />

(D. Others.<br />

All the above sec<strong>to</strong>rs are rapidly increasing in terms of numbers of <strong>unit</strong>s in <strong>to</strong>day’s time. But there<br />

are hardly sufficient number of <strong>unit</strong>s manufacturing phenyl covering the demand. Hence, there is<br />

a scope of about 10 – 12 <strong>unit</strong>s <strong>to</strong> be set up in north-eastern region.<br />

SUGGESTED CAPACITY:<br />

A production of 180 Kilolitre per annum is suggested on the following basis –<br />

No.of shift per day : 1 shift<br />

No.of working hours per shift : 8 hours<br />

Daily production : 600 litres.<br />

Operating days/year : 300 days<br />

Annual production : 180 Kilolitre.<br />

INFRASTRUCTURE:<br />

<strong>The</strong> main infrastructure requirements are –<br />

A. Covered area : 500 sq.ft.<br />

B. Utilities<br />

Power : 1.5 KW<br />

Water : 300 ltrs/day.<br />

RAW MATERIALS:<br />

<strong>The</strong> major raw materials required are cresylic creosote and cresol which are phenol bearing<br />

liquids. A typical raw materials composition is furnished below:<br />

[Weight (%)]<br />

Cresylic cresole (27% phenol) 68.0<br />

Cresol (99% phenol) 7.0<br />

W.W. Rosin 9.0<br />

Soyabean oil 4.0<br />

Caustic soda 2.5<br />

Water 4.5<br />

Cas<strong>to</strong>r oil 5.0<br />

100%<br />

77

Since none of the raw materials are manufactured in the region, but most of them are available in<br />

the local market in Guwahati.<br />

SUGGESTED LOCATION:<br />

Suggested locations are –<br />

Assam : Guwahati, Nagaon, Jorhat, Tezpur, Dibrugarh<br />

Bongaigaon.<br />

Meghalaya : Shillong, Tura, Jowai.<br />

Manipur : Imphal<br />

Arunachal Pradesh : Itanagar, Naharlagun.<br />

Tripura : Agartala.<br />

Sikkim : Gang<strong>to</strong>k, Pakyong, Mangan, Penlang, Lachung<br />

PRODUCTION PROCESS:<br />

<strong>The</strong> process of manufacturing phenyl are as follows in step-wise –<br />

(A. Specification of fatty oils & rosin<br />

(B. Preparation of soft soap by adding boiling solution of caustic soda <strong>to</strong> the mixture<br />

of fatty oils & rosin.<br />

(C. Dissolving soft soap in hot water and adding cresol & cresol.<br />

(D. Filling in bottles.<br />

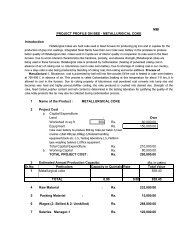

FIXED CAPITAL<br />

(Rs lakh)<br />

Land and Building<br />

On rent<br />

Plant & Machinery 0.90<br />

Misc. Fixed Assets 0.30<br />

Preliminary & Pre-operative expenses 0.25<br />

Total 1.75<br />

CAPITAL COST OF PROJECT:<br />

A. Fixed capital 1.75<br />

B. Working Capital 5.57<br />

Total 7.32<br />

WORKING CAPITAL REQUIREMENT:<br />

(Rs. Lakh)<br />

1. Raw materials & consumables ½ month 1.50<br />

2. Finished goods ½ month 1.60<br />

3. Receivable ½ month 2.47<br />

Total 5.57<br />

COST OF PRODUCTION & PROFITABILITY:<br />

(Rs Lakh)<br />

1. Raw materials & consumables 35.91<br />

2. Utilities & overheads 0.46<br />

3. Wages bill 1.89<br />

4. Other overheads 0.60<br />

5. Depreciation 0.12<br />

6. Selling expenses (@ 15% of annual sales) 7.56<br />

7. Interest on Term Loan 0.16<br />

8. Interest on Working Capital Loan 0.63<br />

Total 47.33<br />

PROFITABILITY:<br />

Based on the sales realization and the cost of production, the profit at target production would be<br />

Rs 3.07 lakh per year. This works out <strong>to</strong> be a return on sales at 6.09% and the return on<br />

investment at 41.93%.<br />

78

SALES REALIZATION (Turnover):<br />

Item Qty./Annum Price/Litre (Rs) Total Realization (Rs Lakh)<br />

Phenyl 1,80,000ltrs/ 28/- Rs 50.40<br />

180 Kilolitre<br />

NOTE: <strong>The</strong> north east market for phenyl is shared by a few local products and producers located<br />

at Kolkata like Kolkata Chemical & others. <strong>The</strong> detail price per litre ranges from Rs 35/- <strong>to</strong> Rs<br />

40/- . At ex-fac<strong>to</strong>ry price of Rs 28/- per litre, the annual sales turn over 180 Kilolitres of Phenyl is<br />

estimated at Rs 50.40 Lakh.<br />

SOURCE OF FINANCE:<br />

A. On Fixed Capital:<br />

Term Loan : Rs 0.44 lakh<br />

Promoter’s contribution : Rs 1.31 lakh<br />

Total Rs 1.75 lakh<br />

B. On Working Capital<br />

Bank Finance : Rs 4.17 lakh<br />

Promoter’s Contribution : Rs 1.70 lakh<br />

Total : Rs 5.57 lakh<br />

C. Total (Term Loan + Working Capital Loan)<br />

i) Loan amount(75%) Rs 5.48 lakh<br />

ii) Promoter’s contribution(25%) Rs 1.84 lakh<br />

Total Rs 7.32 lakh<br />

Note: <strong>The</strong> source of finance has been calculated at 75% as Bank Finance and<br />

25% as promoter’s equity.<br />

MACHINERY:<br />

<strong>The</strong> equipment required are –<br />

(A. Karahi – 500 Litre capacity.<br />

(B. Bottle washing machine 0.5 HP fitted on M.S. tank.<br />

(C. Pilfer proof cap. Sealing machine.<br />

(D. Weighing scale platform type of 300 Kg. capacity.<br />

COST OF RAW MATERIALS & CONSUMABLES:<br />

Sl.No. Materials Qty. <strong>to</strong>nne/KL Price<br />

Tonne/KL<br />

Amount<br />

(Rs Lakh)<br />

1. Cresylic cresole 100.80 18,000 18.14<br />

2. Cresol<br />

12.20 44,000 5.37<br />

(99% Phenol)<br />

3. W.W. Rosin 15.40 29,000 4.47<br />

4. Cas<strong>to</strong>r Oil<br />

9.00 15,500 1.39<br />

(Second presence)<br />

5. Soyabean Oil 6.40 36,000 2.30<br />

6. Caustic soda 4.5 16,500 0.74<br />

7. Packing Materials<br />

(Bottles, labels etc.)<br />

L.S 3.50<br />

79

COST OF UTILITIES & OVERHEADS:<br />

1. Power - 1.5 KW : Rs. 0.16 Lakh<br />

2. Other overheads : Rs 0.30 Lakh<br />

(Water – 300 ltrs./day<br />

@ Rs 100/day<br />

MANPOWER REQUIREMENT & WAGES BILL:<br />

Sl.No. Category No. Salary<br />

per person<br />

Amount<br />

(Rs Lakh)<br />

per month (Rs)<br />

1. Manager 1 4,000/- 0.48<br />

2. Salesman 1 3,000/- 0.36<br />

3. Skilled labour 2 2,500/- 0.60<br />

4. Semi-skilled labour 2 1,500/- 0.36<br />

5. Helper 1 700/- 0.09<br />

TOTAL 1.89<br />

FINANCIAL RATIOS:<br />

1. Profit + sales ratio : 6.09%<br />

2. Profit + investment ratio : 41.93%<br />

3. Break-Even Point<br />

a) at 100% utilization : 52.55%<br />

b) at 70% utilization : 36.76%<br />

MACHINERY SUPPLIERS:<br />

1. M/s Oriental Machinery (1919) Pvt. Ltd.<br />

25, R.N. Mukherjee Road,<br />

Kolkata – 700 001.<br />

2. M/s Gee Gee Co (P) Ltd.,<br />

B – 188/2, Savitri Nagar (Malaviya Nagar),<br />

New Delhi – 17<br />

3. M/s Archana Machinery<br />

A.T. Road,<br />

Guwahati (Assam)<br />

4. M/s Kamrup Machinery,<br />

A.T. Road,<br />

Guwahai (Assam).<br />

80