5/2 Directional Control Valves Actuation: Electromagnetic ... - Auser

5/2 Directional Control Valves Actuation: Electromagnetic ... - Auser

5/2 Directional Control Valves Actuation: Electromagnetic ... - Auser

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

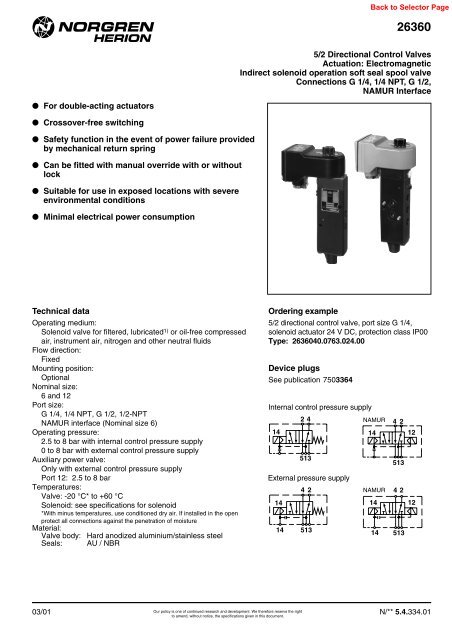

26360<br />

● For double-acting actuators<br />

5/2 <strong>Directional</strong> <strong>Control</strong> <strong>Valves</strong><br />

<strong>Actuation</strong>: <strong>Electromagnetic</strong><br />

Indirect solenoid operation soft seal spool valve<br />

Connections G 1/4, 1/4 NPT, G 1/2,<br />

NAMUR Interface<br />

● Crossover-free switching<br />

● Safety function in the event of power failure provided<br />

by mechanical return spring<br />

● Can be fitted with manual override with or without<br />

lock<br />

● Suitable for use in exposed locations with severe<br />

environmental conditions<br />

● Minimal electrical power consumption<br />

Technical data<br />

Operating medium:<br />

Solenoid valve for filtered, lubricated 1) or oil-free compressed<br />

air, instrument air, nitrogen and other neutral fluids<br />

Flow direction:<br />

Fixed<br />

Mounting position:<br />

Optional<br />

Nominal size:<br />

6 and 12<br />

Port size:<br />

G 1/4, 1/4 NPT, G 1/2, 1/2-NPT<br />

NAMUR interface (Nominal size 6)<br />

Operating pressure:<br />

2.5 to 8 bar with internal control pressure supply<br />

0 to 8 bar with external control pressure supply<br />

Auxiliary power valve:<br />

Only with external control pressure supply<br />

Port 12: 2.5 to 8 bar<br />

Temperatures:<br />

Valve: -20 °C* to +60 °C<br />

Solenoid: see specifications for solenoid<br />

*With minus temperatures, use conditioned dry air. If installed in the open<br />

protect all connections against the penetration of moisture<br />

Material:<br />

Valve body: Hard anodized aluminium/stainless steel<br />

Seals: AU / NBR<br />

Ordering example<br />

5/2 directional control valve, port size G 1/4,<br />

solenoid actuator 24 V DC, protection class IP00<br />

Type: 2636040.0763.024.00<br />

Device plugs<br />

See publication 7503364<br />

Internal control pressure supply<br />

14<br />

24<br />

513<br />

External pressure supply<br />

14<br />

42<br />

14 513<br />

NAMUR<br />

42<br />

14 12<br />

NAMUR<br />

513<br />

4 2<br />

14 12<br />

14 513<br />

03/01<br />

Our policy is one of continued research and development. We therefore reserve the right<br />

N/** 5.4.334.01<br />

to amend, without notice, the specifications given in this document.

26360<br />

General information<br />

Symbol Type Pipe connections Nominal Operating pressure (bar) <strong>Control</strong> pressure supply (bar) Flow rate Weight Dimensional Special features<br />

1 + 3 2 + 3 size Min. Max. Internal External (l/min) (kg) drawing No.<br />

42 2636040.* G 1/4 G 1/4 6 2.5 8 ● – 900 0.7 M02<br />

2636042.* 1/4 NPT 1/4 NPT 6 2.5 8 ● – 900 0.7 M02<br />

14<br />

2636095.* 1/4 NPT 1/4 NPT 6 2.5 8 ● – 900 0.7 M02 Semi-automatic E 1.10<br />

2637040.* G 1/2 G 1/2 12 2.5 8 ● – 2200 1.3 M02<br />

513 2637049.* 1/2 NPT 1/2 NPT 12 2.5 8 ● – 2200 1.3 M02<br />

42 2636097.* G 1/4 G 1/4 6 0 8 – 2.5 bis 8 900 0.7 M02<br />

14<br />

2637097.* G 1/2 G 1/2 12 0 8 – 2.5 bis 8 2200 1.3 M02<br />

14 513<br />

42<br />

14 12<br />

2636240.* G 1/4 G 1/4 6 2.5 8 ● – 900 0.85 M04<br />

513<br />

4 2<br />

14 12<br />

2636297.* G 1/4 G 1/4 6 0 8 – 2.5 bis 8 900 0.85 M04<br />

14 513<br />

NAMUR flange<br />

Symbol Type Pipe connections Nominal Operating pressure (bar) <strong>Control</strong> pressure supply (bar) Flow rate Weight Dimensional Special features<br />

1 + 3 2 + 3 size Min. Max. Internal External (l/min) (kg) drawing No.<br />

24 2636044.* G 1/4 Flange 6 2.5 8 ● – 900 0.7 M01<br />

14<br />

2636094.* 1/4 NPT Flange 6 2.5 8 ● – 900 0.7 M01<br />

14<br />

513<br />

42<br />

2636099.* G 1/4 Flange 6 0 8 – 2.5 to 8 900 0.7 M01<br />

14 513<br />

42<br />

14 12<br />

2636244.* G 1/4 Flange 6 2.5 8 ● – 900 0.85 M03<br />

2636294.* 1/4 NPT Flange 6 2.5 8 ● – 900 0.85 M03<br />

513<br />

4 2<br />

14 12<br />

2636299.* G 1/4 Flange 6 0 8 – 2.5 to 8 900 0.85 M03<br />

14 513<br />

* When ordering please indicate solenoid, voltage and current type (frequency)..<br />

** 2 mounting screws M5 x 45 DIN 912 A2/A4 are included in the scope of delivery.<br />

Our policy is one of continued research and development. We therefore reserve the right<br />

N/** 5.4.334.02 to amend, without notice, the specifications given in this document.<br />

03/01

26360<br />

Solenoid parameters<br />

Type Power. consumption Rated current Rated voltage Protection class Temperature Weight Dimensional Circuit<br />

24 V DC 230 V AC 24 V DC 230 V AC tolerance Fluid max. Ambient drawing No. diagram<br />

(W) (VA) (mA) (mA) +(%) –(%) (°C) (°C) (kg) No.<br />

0763 1) 1.9 – 78 – 10 15 IP00 without connector +80 -25 to +60 0.3 M10 SB01<br />

IP65 with connector<br />

DIN 43650 form A<br />

0278 2) 3.2 – 135 – 10 15 SB04<br />

EEx m II T4 +70 -25 to +70 0.4 M09<br />

0279 2) – 3.5 – 15 10 15 SB07<br />

3900 3) 0.7 – 29 – 10 15 EEx me II T5/T6<br />

3910 3) 3.9 – 161 21 10 15 EEx me II T5/T6<br />

3911 3) – 4.9 – – 10 15 EEx me II T5/T6<br />

-20 to +80 (T5)<br />

-40 to +70 (T6)<br />

-20 to +80 (T5)<br />

-40 to +60 (T6)<br />

-20 to +80 (T5)<br />

-40 to +60 (T6)<br />

SB04<br />

0.85 M07 SB04<br />

SB07<br />

3720 4) 1.4 – 59 – 10 15 NEMA 4, 4X, 6, 6P, 7, 9 -20 to +60 0.4 M11 SB01<br />

stranded wire<br />

460 mm long<br />

Standard voltages 24 V DC, 230 V AC. Other voltages on request.<br />

1) Required device socket Type: 0570275 for DC, device socket with rectifier Type: 0663303 for AC or AC/DC<br />

2) Certificate of conformity KEMA No. Ex-93.C.8283 C<br />

3) Certificate of conformity PTB No. Ex-92.C.2175 C<br />

4) CSA-LR 57643-6, FM approved, for hazardous locations: Div. 1 and 2, Classes I, II and III<br />

Solenoid actuators for intrinsically-safe circuits, protection class EEx ia IIC T6** zone 1 and 2<br />

Type Nominal resist. Min. required Resistance Required voltage Ambient Max. Fluid- Weight Dimensional Circuit<br />

RV Coil switching current Rw 65 Coil* at terminal temperature temperature drawing No. diagram<br />

(Ω) (mA) (Ω) Rw 65 (°C) (°C) (kg) No.<br />

2030 124 43 150 6.4<br />

2031 159 38 193 7.3<br />

2032 198 34 240 8.2<br />

2033 248 30 3019.0<br />

2034 306 27 37110.0 -40 to +65 +65 0.83 M07 SB10<br />

2035 378 25 458 11.5<br />

2036 467 23 566 13.0<br />

2037 566 21686 14.4<br />

2038 692 19 839 15.9<br />

When selecting an intrinsically safe power supply, the permissible maximum values according to the Certificate of Conformity PTB No. Ex-<br />

95.D.2178 should be taken into account. On the other hand, the low effective inductivity and capacity can be ignored.<br />

Solenoid actuators with FM-approval<br />

Intrinsically safe: IS/I, II, III/1/ABCDEFG/ T6 Ta = 65 °C; I/0 AEx ia IIC/ T6 Ta = 65 °C - 0588672/B; Entity<br />

Nonincendive: NI/I/2/ABCD/ T6 Ta = 65 °C; S/II,III/2/FG/T6 Ta = 65 °C; NEMA Type 4<br />

Type Nominal resist. Min. required Resistance Required voltage Ambient Max. Fluid- Weight Dimensional Circuit<br />

RV Coil switching current Rw 65 Coil* at terminal temperature temperature drawing No. diagram<br />

(Ω) (mA) (Ω) Rw 65 (°C) (°C) (kg) No.<br />

2040 124 43 150 6.4<br />

2041 159 38 193 7.3<br />

2042 198 34 240 8.2<br />

2043 248 30 3019.0<br />

2044 306 27 37110.0 -40 to +65 +65 0.83 M08 SB10<br />

2045 378 25 458 11.5<br />

2046 467 23 566 13.0<br />

2047 566 21686 14.4<br />

2048 692 19 839 15.9<br />

When selecting an intrinsically safe power supply, the permissible maximum values according to the FM-approval should be taken into account. On<br />

the other hand, the low effective inductivity and capacity can be ignored.<br />

* RW 65 is the solenoid coil resistance at an ambient temperature of +65°C, including internal heat generation, with max. permissible power.<br />

** Certificate of Conformity PTB No. Ex-95.D.2178<br />

Our policy is one of continued research and development. We therefore reserve the right<br />

03/01 to amend, without notice, the specifications given in this document.<br />

N/** 5.4.334.03

26360<br />

General Information<br />

Symbol Type * Port size Nom. Operat. pressur (bar) Pilot pressure (bar) Flow Weight Dimensional Special features<br />

1 + 3 2 + 3 diameter Min. Max. Intern Extern (l/min) (kg) drawing No.<br />

2 1028110.208X G 1/4 G 1/4 6 2.5 8 ● – 900 0.7 M05<br />

12<br />

1028111.208X 1/4 NPT 1/4 NPT 6 2.5 8 ● – 900 0.7 M05<br />

1028120.208X G 1/2 G 1/2 12 2.5 8 ● – 2200 1.3 M05<br />

1028121.208X 1/2 NPT 1/2 NPT 12 2,.5 8 ● – 2200 1.3 M05<br />

3 1<br />

1028112.208X G 1/4 Flansch 6 2.5 8 ● – 900 1.5 M06 NAMUR interface<br />

Ordering example<br />

1028110. 2080. 001. 00<br />

Valve Pilot 5 mW Electr. connection –<br />

Pilot system<br />

* Please insert code for electrical connection:<br />

001 Pg 9<br />

002 Pg 11<br />

003 M 12 x 1,5<br />

004 Round connector<br />

Type Rated power Voltage at Rated current Rated current Resistance Max. values EEx i Type of Ambient Circuit<br />

terminal coil Ui Ii Pi protection # temperature diagram<br />

PN UN Ian Iab RN No.<br />

2080 5 mW ≥ 5 V ≥ 1 mA ≤ 0.1 mA 5100 Ω 28 V 120 mA 0.75 W EEx ia IIC T4 -40 to +65 °C<br />

25.2 155 mA 0.75 W EEx ia IIC T6 -40 to +45 °C<br />

SB10<br />

22 224 mA 0.75 W<br />

2081 50 mW ≥ 10 V ≥ 2.7 mA ≤ 1.3 mA 3700 Ω 28 V 120 mA 0.75 W EEx ia IIC T4 -40 to +65 °C<br />

25.2 155 mA 0.75 W EEx ia IIC T6 -40 to +45 °C<br />

SB10<br />

22 224 mA 0.75 W<br />

# Category II2G, EG Type Examination Certificate No. PTB 00 ATEX 2050<br />

NAMUR hole pattern<br />

32<br />

M5 thread 8 mm deep<br />

12<br />

8<br />

24<br />

Coding stud threaded<br />

M5x10 DIN 913-45 H<br />

M5<br />

2<br />

G 1 /4<br />

DIN/ISO 228/1<br />

Fitting accessories<br />

Description Type Use Weight See<br />

(kg) publication<br />

Flange plate 0559857 Direct attachment to pneumatic lifting drives with NAMUR ridge; in the case of wall mounting, 0.50<br />

dependent on position of piping 7502242<br />

Clamp 0540593 Used in conjunction with flange plate for attachment to pneumatic lifting drives with NAMUR post 0.10<br />

Spacer plate 0540109 Direct attachment to pneumatic swivel drives, e.g. when using solenoid with terminal box: 0.25<br />

Type: 39XX and 2030 to 2038 ; dependent on mounting position<br />

Adaptor plate 0603216 Direct attachment to pneumatic swivel drives with hole pattern corresponding to older type valves: 8020781 0.18<br />

Silencer 0014600 Pressure connection G 1/4. Max. back pressure 6 bar 0.01 7501080<br />

Exhaust throttle Port size G 1/4 4048104 Without silencer. Operating pressure 0 to 10 bar 0.06 7501069<br />

Port size G 1/2 4048204 0.20<br />

Our policy is one of continued research and development. We therefore reserve the right<br />

N/** 5.4.334.04 to amend, without notice, the specifications given in this document.<br />

03/01

26360<br />

Dimensional drawings valves<br />

M01<br />

119<br />

33<br />

66<br />

14<br />

9<br />

80<br />

148<br />

4<br />

2<br />

ø15,5<br />

ø19,5<br />

*<br />

223<br />

130<br />

A2<br />

14<br />

5<br />

1<br />

3<br />

12<br />

87 12<br />

Pg 13,5<br />

24 24<br />

ø5,5 x 3 deep<br />

M5<br />

A1<br />

7,5<br />

30<br />

Type A1 A2<br />

2636044 G 1/4 G 1/8<br />

2636094 1/4 NPT 1/8 NPT<br />

2636099 G 1/4 G 1/8<br />

32<br />

55<br />

* Manual override optionally available with/without detent<br />

3,6<br />

1 2,5<br />

M02<br />

33<br />

119<br />

66<br />

T 1<br />

9<br />

14<br />

80<br />

14<br />

B4<br />

Pg 13,5<br />

A2<br />

5<br />

1<br />

3<br />

4<br />

2<br />

B5<br />

B3<br />

B2<br />

C2<br />

C2<br />

A1<br />

C1<br />

*<br />

H<br />

B 1<br />

L<br />

* Manual override optionally available with/without detent<br />

Type A1 A2 B1 B2 B3 B4 C1 C2 C3 C4 H L T1<br />

2636040, 2636097 G 1/4 G 1/8 40 75 40 6.6 24 87 24 132.5 224 55 30<br />

2636042, 2636095 1/4 NPT 1/8 NPT 40 75 40 6.6 24 87 24 132.5 224 55 30<br />

2637040, 2637097 G 1/2 G 1/8 50 70.5 50 7 33 87 33 150 251 70 40<br />

03/01 N/** 5.4.334.05<br />

Our policy is one of continued research and development. We therefore reserve the right<br />

to amend, without notice, the specifications given in this document.

26360<br />

M03<br />

119<br />

33<br />

66<br />

14<br />

9<br />

80<br />

272<br />

123<br />

30<br />

4<br />

2<br />

ø15,5<br />

ø19,5<br />

45<br />

G1/8<br />

61<br />

14<br />

5<br />

1<br />

3<br />

32<br />

55<br />

12<br />

12<br />

136<br />

*<br />

Pg 13,5<br />

50<br />

24 24<br />

ø5,5 x 3 deep<br />

M5<br />

G1/4<br />

7,5<br />

4 1,9<br />

12<br />

* Manual override optionally available with/without detent<br />

M04<br />

119<br />

66<br />

33<br />

30<br />

14<br />

9<br />

*<br />

80<br />

14<br />

6,6<br />

Pg 13,5<br />

G1/4<br />

G1/8<br />

5<br />

272<br />

1<br />

3<br />

4<br />

2<br />

24<br />

40<br />

24<br />

24<br />

61<br />

40<br />

49<br />

4<br />

2,7<br />

55<br />

136<br />

*<br />

Manual override<br />

optionally available<br />

12<br />

Type <strong>Actuation</strong><br />

0553886 without detent<br />

0553887 with detent<br />

* Manual override optionally available with/without detent<br />

Our policy is one of continued research and development. We therefore reserve the right<br />

N/** 5.4.334.06 to amend, without notice, the specifications given in this document.<br />

03/01

26360<br />

M05<br />

102<br />

97<br />

Pg 9<br />

102<br />

14<br />

B4<br />

Pg 11<br />

H<br />

A2<br />

5<br />

1<br />

3<br />

4<br />

2<br />

B5<br />

B3<br />

C2<br />

C2<br />

A1<br />

88<br />

M 12 x 1,5<br />

C1<br />

B2<br />

92<br />

Round<br />

connector<br />

B 1<br />

L<br />

* Manual override with/without detent<br />

Type A1 A2 B1 B2 B3 B4 B5 C1 C2 C3 H L T1<br />

1028110 G 1/4 G 1/8 40 75 40 6.6 24 87 24 132.5 203 55 30<br />

1028111 1/4 NPT 1/8 NPT 40 75 40 6.6 24 87 24 132.5 203 55 30<br />

1028120 G 1/2 G 1/8 50 70.5 50 7 33 87 33 150 230 70 40<br />

1028121 1/2 NPT 1/8 NPT 50 70.5 50 7 33 87 33 150 230 70 40<br />

M06<br />

102<br />

97<br />

Pg 9<br />

102<br />

203<br />

148<br />

4<br />

2<br />

ø 15,5<br />

ø 19,5<br />

130<br />

G 1/8<br />

14<br />

5<br />

1<br />

3<br />

12<br />

87 12<br />

24 24<br />

ø 5,5 x 3 tief<br />

M5<br />

G 1/4<br />

88<br />

92<br />

Pg 11<br />

M 12 x 1,5<br />

Round<br />

connector<br />

30<br />

32<br />

55<br />

* Manual override with/without detent<br />

7,5<br />

3,6<br />

1 2,5<br />

Our policy is one of continued research and development. We therefore reserve the right<br />

03/01 to amend, without notice, the specifications given in this document.<br />

N/** 5.4.334.07

26360<br />

Dimensional drawings solenoids<br />

M07<br />

M08<br />

80<br />

66<br />

60<br />

41 6<br />

Ø16*<br />

97,5<br />

* Ø13 (with spacer tube)<br />

Pg 13,5<br />

63<br />

119<br />

33<br />

40,5<br />

62<br />

1/2 - 14 NPT<br />

Ø16*<br />

* Ø13 (with spacer tube)<br />

63<br />

84<br />

2<br />

43<br />

33,5<br />

60<br />

Ø16*<br />

* Ø13 (with spacer tube)<br />

1/2-14 NPT<br />

63<br />

33<br />

119<br />

66<br />

62<br />

41 6<br />

M09<br />

M10<br />

M11<br />

53,5<br />

49<br />

41<br />

17<br />

40,5<br />

56<br />

82,5<br />

89<br />

Connector can be<br />

indexed by4 x 90°<br />

Pg 11 12<br />

33<br />

43<br />

34<br />

27,5<br />

19,5<br />

63,5<br />

73<br />

27<br />

89<br />

26<br />

Stranded wire AWG 18<br />

(approx. 460 mm long)<br />

Electrical circuit diagrams<br />

SB01 SB04 SB07<br />

SB10<br />

Warning<br />

These products are intended for use in industrial compressed air systems only. Do not<br />

use these products where pressures and temperatures can exceed those listed under<br />

‘Technical Data’.<br />

Before using these products with fluids other than those specified, for non-industrial<br />

applications, life-support systems, or other applications not within published<br />

specifications, consult NORGREN.<br />

Through misuse, age, or malfunction, components used in fluid power systems can<br />

fail in various modes. The system designer is warned to consider the failure modes of<br />

all component parts used in fluid power systems and to provide adequate safeguards<br />

to prevent personal injury or damage to equipment in the event of such failure.<br />

System designers must provide a warning to end users in the system<br />

instructional manual if protection against a failure mode cannot be adequately<br />

provided.<br />

System designers and end users are cautioned to review specific warnings found in<br />

instruction sheets packed and shipped with these products where applicable.<br />

Our policy is one of continued research and development. We therefore reserve the right<br />

N/** 5.4.334.08 to amend, without notice, the specifications given in this document.<br />

03/01