Survival and Growth of Bacterial Pathogens on Raw Meat During ...

Survival and Growth of Bacterial Pathogens on Raw Meat During ...

Survival and Growth of Bacterial Pathogens on Raw Meat During ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<str<strong>on</strong>g>Survival</str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g> <str<strong>on</strong>g>Growth</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>Bacterial</str<strong>on</strong>g> <str<strong>on</strong>g>Pathogens</str<strong>on</strong>g> <strong>on</strong> <strong>Raw</strong> <strong>Meat</strong> <strong>During</strong> Chilling 1<br />

<str<strong>on</strong>g>Survival</str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g> <str<strong>on</strong>g>Growth</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>Bacterial</str<strong>on</strong>g> <str<strong>on</strong>g>Pathogens</str<strong>on</strong>g><br />

<strong>on</strong> <strong>Raw</strong> <strong>Meat</strong> <strong>During</strong> Chilling<br />

compiled by M. Ellin Doyle, Ph.D.<br />

Food Research Institute, February 2002<br />

Introducti<strong>on</strong><br />

Intact tissues from healthy animals are sterile. However, when these animals are slaughtered,<br />

bacteria from the hide, the gut, or the processing envir<strong>on</strong>ment may c<strong>on</strong>taminate the surfaces <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

meat. This occurs despite <str<strong>on</strong>g>of</str<strong>on</strong>g> washing animals before slaughter, various treatments to clean<br />

carcasses during processing, <str<strong>on</strong>g>and</str<strong>on</strong>g> programs to keep the envir<strong>on</strong>ment clean. Some <str<strong>on</strong>g>of</str<strong>on</strong>g> these<br />

organisms are spoilage bacteria while others are pathogenic to humans.<br />

Many bacteria are unable to grow at low temperatures but can survive storage in the cold.<br />

Generally, numbers <str<strong>on</strong>g>of</str<strong>on</strong>g> viable bacterial cells decrease with time during refrigerated storage (1, 3,<br />

4, 21). Other bacteria, including Listeria, Yersinia, some strains <str<strong>on</strong>g>of</str<strong>on</strong>g> Clostridium botulinum <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

Bacillus cereus, <str<strong>on</strong>g>and</str<strong>on</strong>g> some spoilage organisms, are psychrotrophic <str<strong>on</strong>g>and</str<strong>on</strong>g> can grow at refrigerati<strong>on</strong><br />

temperatures (Table 1). However, growth during chilled storage is usually slow (18).<br />

Several research papers have described protocols <str<strong>on</strong>g>and</str<strong>on</strong>g> experimental results for determining<br />

the hygienic adequacy <str<strong>on</strong>g>of</str<strong>on</strong>g> cooling processes by c<strong>on</strong>sidering published data <strong>on</strong> growth rates<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> pathogens <str<strong>on</strong>g>and</str<strong>on</strong>g> the temperature history <str<strong>on</strong>g>of</str<strong>on</strong>g> the meat (2, 9–16).<br />

Temperature is not the <strong>on</strong>ly factor limiting growth <str<strong>on</strong>g>of</str<strong>on</strong>g> bacteria. Experiments have shown<br />

that bacteria grow more slowly <strong>on</strong> meat at a more acidic (lower) pH (25). Washing carcasses<br />

with organic acids, trisodium phosphate, or alkaline soluti<strong>on</strong>s significantly decreases pathogen<br />

levels (5, 6). Some pathogenic bacteria are not very good competitors <str<strong>on</strong>g>and</str<strong>on</strong>g> grow much more<br />

slowly in the presence <str<strong>on</strong>g>of</str<strong>on</strong>g> other bacteria that may be present <strong>on</strong> meat. Air cooling process may<br />

cause drying at the surface <str<strong>on</strong>g>of</str<strong>on</strong>g> the meat <str<strong>on</strong>g>and</str<strong>on</strong>g> this inhibits bacterial growth. For these reas<strong>on</strong>s, <strong>on</strong>e<br />

cannot simply extrapolate growth data from bacteria grown in the lab to commercial cooling<br />

processes.<br />

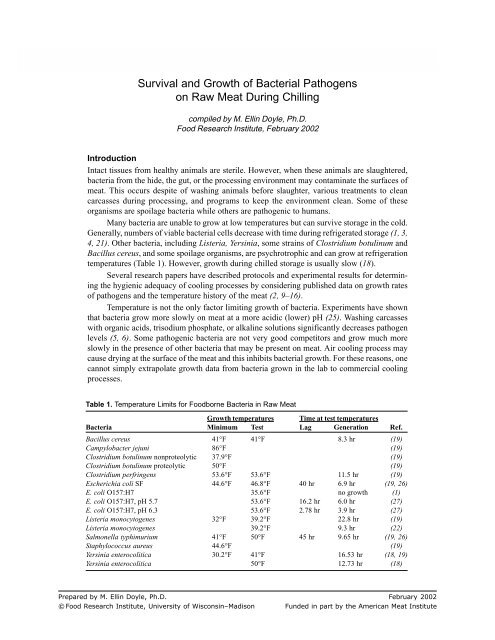

Table 1. Temperature Limits for Foodborne Bacteria in <strong>Raw</strong> <strong>Meat</strong><br />

<str<strong>on</strong>g>Growth</str<strong>on</strong>g> temperatures Time at test temperatures<br />

Bacteria Minimum Test Lag Generati<strong>on</strong> Ref.<br />

Bacillus cereus 41°F 41°F 8.3 hr (19)<br />

Campylobacter jejuni 86°F (19)<br />

Clostridium botulinum n<strong>on</strong>proteolytic 37.9°F (19)<br />

Clostridium botulinum proteolytic 50°F (19)<br />

Clostridium perfringens 53.6°F 53.6°F 11.5 hr (19)<br />

Escherichia coli SF 44.6°F 46.8°F 40 hr 6.9 hr (19, 26)<br />

E. coli O157:H7 35.6°F no growth (1)<br />

E. coli O157:H7, pH 5.7 53.6°F 16.2 hr 6.0 hr (27)<br />

E. coli O157:H7, pH 6.3 53.6°F 2.78 hr 3.9 hr (27)<br />

Listeria m<strong>on</strong>ocytogenes 32°F 39.2°F 22.8 hr (19)<br />

Listeria m<strong>on</strong>ocytogenes 39.2°F 9.3 hr (22)<br />

Salm<strong>on</strong>ella typhimurium 41°F 50°F 45 hr 9.65 hr (19, 26)<br />

Staphylococcus aureus 44.6°F (19)<br />

Yersinia enterocolitica 30.2°F 41°F 16.53 hr (18, 19)<br />

Yersinia enterocolitica 50°F 12.73 hr (18)<br />

Prepared by M. Ellin Doyle, Ph.D. February 2002<br />

© Food Research Institute, University <str<strong>on</strong>g>of</str<strong>on</strong>g> Wisc<strong>on</strong>sin–Madis<strong>on</strong> Funded in part by the American <strong>Meat</strong> Institute

2 <str<strong>on</strong>g>Survival</str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g> <str<strong>on</strong>g>Growth</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>Bacterial</str<strong>on</strong>g> <str<strong>on</strong>g>Pathogens</str<strong>on</strong>g> <strong>on</strong> <strong>Raw</strong> <strong>Meat</strong> <strong>During</strong> Chilling<br />

BEEF<br />

Potential pathogens (Staphylococcus aureus, Clostridium perfringens, <str<strong>on</strong>g>and</str<strong>on</strong>g> fecal coliforms) were<br />

more numerous <strong>on</strong> hot-b<strong>on</strong>ed beef cooled at slower chilling rates (9 <str<strong>on</strong>g>and</str<strong>on</strong>g> 12 hours to 69.8°F)<br />

than <strong>on</strong> beef chilled more rapidly (3 <str<strong>on</strong>g>and</str<strong>on</strong>g> 5 hours to 69.8°F). The authors recommend chilling<br />

hot b<strong>on</strong>ed meat to 69.8°F within 3–9 hours after fabricati<strong>on</strong> with c<strong>on</strong>tinuous chilling to

<str<strong>on</strong>g>Survival</str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g> <str<strong>on</strong>g>Growth</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>Bacterial</str<strong>on</strong>g> <str<strong>on</strong>g>Pathogens</str<strong>on</strong>g> <strong>on</strong> <strong>Raw</strong> <strong>Meat</strong> <strong>During</strong> Chilling 3<br />

Comparis<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> c<strong>on</strong>venti<strong>on</strong>al spray-chilling with spray-chilling preceded by a freezing<br />

tunnel indicted that temperatures were lower <str<strong>on</strong>g>and</str<strong>on</strong>g> potential proliferati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> E. coli <strong>on</strong> carcasses<br />

was less when carcasses were first cooled by the freezing air. Coolers usually have warmer <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

cooler areas depending <strong>on</strong> air flow <str<strong>on</strong>g>and</str<strong>on</strong>g> this freezing blast apparently keeps temperatures c<strong>on</strong>sistently<br />

low (11).<br />

LAMB<br />

An air cooling process for lamb carcasses, using air blown from refrigerati<strong>on</strong> coils at a temperature<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> about 32°F, has been evaluated for its hygienic performance (12). Temperatures measured<br />

at various sites <strong>on</strong> the surface, including the aitch-b<strong>on</strong>e pocket (which has been determined<br />

to be the slowest cooling area) reached

4 <str<strong>on</strong>g>Survival</str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g> <str<strong>on</strong>g>Growth</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>Bacterial</str<strong>on</strong>g> <str<strong>on</strong>g>Pathogens</str<strong>on</strong>g> <strong>on</strong> <strong>Raw</strong> <strong>Meat</strong> <strong>During</strong> Chilling<br />

References<br />

1. Ansay SE, Darling KA, <str<strong>on</strong>g>and</str<strong>on</strong>g> Kaspar CW. 1999. <str<strong>on</strong>g>Survival</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

Escherichia coli O157: H7 in ground-beef patties during<br />

storage at 2, –2, 15 <str<strong>on</strong>g>and</str<strong>on</strong>g> then –2°C, <str<strong>on</strong>g>and</str<strong>on</strong>g> –20°C. J Food Prot<br />

62:1243–1247.<br />

2. Avery SM, Huds<strong>on</strong> JA, Phillips DM. 1996. Use <str<strong>on</strong>g>of</str<strong>on</strong>g> resp<strong>on</strong>se<br />

surface models to predict bacterial growth from time/temperature<br />

histories. Food C<strong>on</strong>trol 7:121–128.<br />

3. Bostan K. 2001. Effects <str<strong>on</strong>g>of</str<strong>on</strong>g> cooking <str<strong>on</strong>g>and</str<strong>on</strong>g> cold storage <strong>on</strong> the<br />

survival <str<strong>on</strong>g>of</str<strong>on</strong>g> Campylobacter jejuni in meatballs. Arch<br />

Lebensmittelhyg 52:28–30.<br />

4. Chynoweth RW, Huds<strong>on</strong> JA, <str<strong>on</strong>g>and</str<strong>on</strong>g> Thom K. 1998. Aerobic<br />

growth <str<strong>on</strong>g>and</str<strong>on</strong>g> survival <str<strong>on</strong>g>of</str<strong>on</strong>g> Campylobacter jejuni in food <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

stream water. Lett Appl Microbiol 27:341–344.<br />

5. Cutter CN <str<strong>on</strong>g>and</str<strong>on</strong>g> Rivera-Betancourt M. 2000. Interventi<strong>on</strong>s<br />

for the reducti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Salm<strong>on</strong>ella typhimurium DT 104 <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

n<strong>on</strong>-O157:H7 enterohemorrhagic Escherichia coli <strong>on</strong> beef<br />

surfaces. J Food Prot 63:1326–1332.<br />

6. Dorsa WJ, Cutter CN, <str<strong>on</strong>g>and</str<strong>on</strong>g> Siragusa GR. 1998. L<strong>on</strong>g-term<br />

bacterial pr<str<strong>on</strong>g>of</str<strong>on</strong>g>ile <str<strong>on</strong>g>of</str<strong>on</strong>g> refrigerated ground beef made from carcass<br />

tissue, experimentally c<strong>on</strong>taminated with pathogens <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

spoilage bacteria after hot water, alkaline, or organic acid<br />

washes. J Food Prot 61:1615–1622.<br />

7. Epling LK, Carpenter JA, <str<strong>on</strong>g>and</str<strong>on</strong>g> Blankenship LC. 1993. Prevalence<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> Campylobacter spp. <str<strong>on</strong>g>and</str<strong>on</strong>g> Salm<strong>on</strong>ella spp. <strong>on</strong> pork<br />

carcasses <str<strong>on</strong>g>and</str<strong>on</strong>g> the reducti<strong>on</strong> effected by spraying with lactic<br />

acid. J Food Prot 56:536,540.<br />

8. Fung DYC, Kastner CL, Lee CY, Hunt MC, Dikeman ME,<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> Kropf DH. 1981. Initial chilling rate effects <strong>on</strong> bacterial<br />

growth <strong>on</strong> hot-b<strong>on</strong>ed beef. J Food Prot 44:539–544.<br />

9. Gill CO. 1996. Cold storage temperature fluctuati<strong>on</strong>s <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

predicting microbial growth. J Food Prot Suppl:43–47.<br />

10. Gill CO, J<strong>on</strong>es SDM, <str<strong>on</strong>g>and</str<strong>on</strong>g> T<strong>on</strong>g AKW. 1991. Applicati<strong>on</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> a temperature functi<strong>on</strong> integrati<strong>on</strong> technique to assess<br />

the hygienic adequacy <str<strong>on</strong>g>of</str<strong>on</strong>g> a process for spray chilling beef<br />

carcasses. J. Food Prot 54:731–736.<br />

11. Gill CO <str<strong>on</strong>g>and</str<strong>on</strong>g> J<strong>on</strong>es T. 1992. Assessment <str<strong>on</strong>g>of</str<strong>on</strong>g> the hygienic efficiencies<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> two commercial processes for cooling pig carcass.<br />

Food Microbiol 9:335–343.<br />

12. Gill CO <str<strong>on</strong>g>and</str<strong>on</strong>g> J<strong>on</strong>es T. 1997. Assessment <str<strong>on</strong>g>of</str<strong>on</strong>g> the hygienic performances<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> an air-cooling process for lamb carcasses <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

a spray-cooling process for pig carcasses. Int J Food<br />

Microbiol 38:85–93.<br />

13. Jericho KWF, Kozub GC, Bradley JA, Gann<strong>on</strong> VPJ,<br />

Golsteyn-Thomas EJ, Gierus M, Nishiyama BJ, King RK,<br />

Tanaka EE, D’Souza S, <str<strong>on</strong>g>and</str<strong>on</strong>g> Dix<strong>on</strong>-MacDougall JM. 1996.<br />

Microbiological verificati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the c<strong>on</strong>trol <str<strong>on</strong>g>of</str<strong>on</strong>g> the processes<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> dressing, cooling, <str<strong>on</strong>g>and</str<strong>on</strong>g> processing <str<strong>on</strong>g>of</str<strong>on</strong>g> beef carcasses at a<br />

high line-speed abattoir. Food Microbiol 13:291–301.<br />

14. Jericho KWF, Kozub GC, Gann<strong>on</strong> VPJ, <str<strong>on</strong>g>and</str<strong>on</strong>g> Taylor CM.<br />

2000. Microbiological testing <str<strong>on</strong>g>of</str<strong>on</strong>g> raw, boxed beef in the c<strong>on</strong>text<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> hazard analysis critical c<strong>on</strong>trol point at a high-linespeed<br />

abattoir. J Food Prot 63:1681–1686.<br />

15. Jericho KWF, Kozub GC, Gann<strong>on</strong> VPJ, Thomas EJG, King<br />

RK, Bigham RL, Tanaka EE, Dix<strong>on</strong>-MacDougall JM,<br />

Nishiyama BJ, Kirbys<strong>on</strong> H, <str<strong>on</strong>g>and</str<strong>on</strong>g> Bradley JA. 1997. Verificati<strong>on</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> the level <str<strong>on</strong>g>of</str<strong>on</strong>g> microbiological c<strong>on</strong>trol for the slaughter<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> cooling processes <str<strong>on</strong>g>of</str<strong>on</strong>g> beef carcass producti<strong>on</strong> at a highline-speed<br />

abattoir. J Food Prot 60:1509–1514.<br />

16. Jericho KWF, O’Laney G, <str<strong>on</strong>g>and</str<strong>on</strong>g> Kozub GC. 1998. Verificati<strong>on</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> the hygienic adequacy <str<strong>on</strong>g>of</str<strong>on</strong>g> beef carcass cooling processes<br />

by microbiological culture <str<strong>on</strong>g>and</str<strong>on</strong>g> the temperaturefuncti<strong>on</strong><br />

integrati<strong>on</strong> technique. J Food Prot 61:1347–1351.<br />

17. J<strong>on</strong>es RJ. 1993. The establishment <str<strong>on</strong>g>of</str<strong>on</strong>g> provisi<strong>on</strong>al quality<br />

assurance guidelines for assessing the hygienic adequacy<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> the lamb carcass cooling process. N Z Vet J 41:105–110.<br />

18. Logue CM, Sheridan JJ, McDowell DA, Blair IS, <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

Harringt<strong>on</strong> D. 1998. A study <str<strong>on</strong>g>of</str<strong>on</strong>g> the growth <str<strong>on</strong>g>of</str<strong>on</strong>g> plasmid bearing<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> plasmid cured strains <str<strong>on</strong>g>of</str<strong>on</strong>g> antibiotic resistant Yersinia<br />

enterocolitica serotype O:3 <strong>on</strong> refrigerated beef, pork <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

lamb. Food Microbiol 15:603–615.<br />

19. Lund BM, Baird-Parker TC, <str<strong>on</strong>g>and</str<strong>on</strong>g> Gould GW. 2000. The<br />

Microbiological Safety <str<strong>on</strong>g>and</str<strong>on</strong>g> Quality <str<strong>on</strong>g>of</str<strong>on</strong>g> Food. Aspen Publishers<br />

Inc., Gaithersburg, MD.<br />

20. McDowell DA, Hobs<strong>on</strong> I, Strain JJ, <str<strong>on</strong>g>and</str<strong>on</strong>g> Owens JJ. 1986.<br />

<str<strong>on</strong>g>Bacterial</str<strong>on</strong>g> micr<str<strong>on</strong>g>of</str<strong>on</strong>g>lora <str<strong>on</strong>g>of</str<strong>on</strong>g> chill-stored beef carcasses. J Envir<strong>on</strong><br />

Health 94:65–68.<br />

21. Moore JE <str<strong>on</strong>g>and</str<strong>on</strong>g> Madden RH. 2001. <str<strong>on</strong>g>Survival</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> Campylobacter<br />

coli in porcine liver. Food Microbiol 18:1–10.<br />

22. Pawar DD, Malik SVS, Bhilega<strong>on</strong>kar KN, <str<strong>on</strong>g>and</str<strong>on</strong>g> Barbuddhe<br />

SB. 2000. Effect <str<strong>on</strong>g>of</str<strong>on</strong>g> nisin <str<strong>on</strong>g>and</str<strong>on</strong>g> its combinati<strong>on</strong> with sodium<br />

chloride <strong>on</strong> the survival <str<strong>on</strong>g>of</str<strong>on</strong>g> Listeria m<strong>on</strong>ocytogenes added<br />

to raw buffalo meat mince. <strong>Meat</strong> Sci 56:215–219.<br />

23. Reichel MP, Phillips DM, J<strong>on</strong>es R, <str<strong>on</strong>g>and</str<strong>on</strong>g> Gill CO. 1991.<br />

Assessment <str<strong>on</strong>g>of</str<strong>on</strong>g> the hygienic adequacy <str<strong>on</strong>g>of</str<strong>on</strong>g> a commercial<br />

hot b<strong>on</strong>ing process for beef by a temperature functi<strong>on</strong> integrati<strong>on</strong><br />

technique. Int J Food Microbiol 14:27–41.<br />

24. Saide-Albornoz JJ, Knipe CL, Murano EA, <str<strong>on</strong>g>and</str<strong>on</strong>g> Beran GW.<br />

1995. C<strong>on</strong>taminati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> pork carcasses during slaughter,<br />

fabricati<strong>on</strong>, <str<strong>on</strong>g>and</str<strong>on</strong>g> chilled storage. J Food Prot 59:993–997.<br />

25. Shineman TL <str<strong>on</strong>g>and</str<strong>on</strong>g> Harris<strong>on</strong> MA. 1994. <str<strong>on</strong>g>Growth</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> Listeria<br />

m<strong>on</strong>ocytogenes <strong>on</strong> different muscle tissues. J Food Prot<br />

57:1057–1062.<br />

26. Smith MG. 1985. The generati<strong>on</strong> time, lag time, <str<strong>on</strong>g>and</str<strong>on</strong>g> minimum<br />

temperature <str<strong>on</strong>g>of</str<strong>on</strong>g> growth <str<strong>on</strong>g>of</str<strong>on</strong>g> coliform organisms <strong>on</strong> meat,<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> the implicati<strong>on</strong>s for codes <str<strong>on</strong>g>of</str<strong>on</strong>g> practice in abattoirs.<br />

J Hygiene 94:289–300.<br />

27. Walls I <str<strong>on</strong>g>and</str<strong>on</strong>g> Scott VN. 1996. Validati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> predictive<br />

mathematical models describing the growth <str<strong>on</strong>g>of</str<strong>on</strong>g> Escherichia<br />

coli O157:H7 in raw ground beef. J Food Prot 59:1331–<br />

1335.<br />

Prepared by M. Ellin Doyle, Ph.D. February 2002<br />

© Food Research Institute, University <str<strong>on</strong>g>of</str<strong>on</strong>g> Wisc<strong>on</strong>sin–Madis<strong>on</strong> Funded in part by the American <strong>Meat</strong> Institute