PANDROL PANGUARD™ - Pandrol USA

PANDROL PANGUARD™ - Pandrol USA

PANDROL PANGUARD™ - Pandrol USA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>PANDROL</strong> PANGUARD

PANGUARD <br />

In vibration and noise sensitive areas, most track designs in use around the world work on one of two principles<br />

to reduce groundborne vibration – either by increasing the mass of the resiliently supported track structure or<br />

by reducing the stiffness of the support. The lower the track stiffness which can be achieved, the lower the<br />

resonant frequency becomes, and the better the vibration attenuation which results. But before the<br />

<strong>Pandrol</strong> PANGUARD system, large vertical deflections also resulted in unacceptable lateral movement of<br />

the rail head.<br />

The <strong>Pandrol</strong> PANGUARD system delivers an assembly with both very low vertical stiffness and minimal rail roll<br />

and delivers exceptional vibration reduction performance at a much lower cost than floating slab.<br />

In the <strong>Pandrol</strong> PANGUARD assembly, the rail is supported under the head and in the web with large rubber wedges, leaving the<br />

foot of the rail suspended. The rubber wedges are held in place by cast-iron side brackets which are in turn fastened either to a<br />

shoulder cast into a concrete tie or block, or to a baseplate fixed to the track base using either bolts or screwspikes. The<br />

baseplate system can be used on slab track, wood ties or on steel or concrete bridges.<br />

The assembly allows large vertical deflections, and although it is resilient in a lateral direction, rail roll is minimised because the<br />

forces applied to the rail head are reacted much closer to their line of application than in a conventional fastening.<br />

Key components<br />

Cast in Shoulder Assembly<br />

Side support bracket<br />

Rubber wedge<br />

Cast iron<br />

locking<br />

wedge<br />

Typical key dimensions<br />

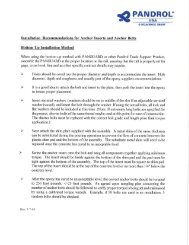

Inclination of the rail is provided in the concrete tie or<br />

slab into which the assembly is set.<br />

Height of rail base above concrete level: 5/8" (17mm)<br />

Length of rubber rail supports: 9 7/8" (250mm)<br />

Width of assembly along rail axis: 5 7/8" (150mm)<br />

Width of assembly perpendicular to rail axis: 13"<br />

(330mm)<br />

Shoulder

Key components<br />

Baseplate Assembly<br />

Rubber wedge<br />

Side support bracket<br />

Serrated Adjustment<br />

Washer<br />

Cast iron<br />

locking<br />

wedge<br />

Typical key dimensions<br />

Inclination of the rail is provided in the baseplate.<br />

Height of rail base above tie: 1 3/16" (30mm)<br />

Length of rubber rail supports: 9 7/8" (250mm)<br />

Width of assembly along rail axis: 7 7/8" (200mm)<br />

Width of assembly perpendicular to rail axis: 19 1/4"<br />

(490mm)<br />

Baseplate<br />

Hook In<br />

Shoulder<br />

Advantages<br />

•Very low dynamic stiffness – 4.28 X104 lb/in (7.5kN/mm) or less leads to:<br />

✓ minimal rail roll<br />

✓ a low vibration performance similar to floating slab track but<br />

- at a much lower cost and<br />

- with much better access for maintenance or adjustment<br />

•Reduces vibration and secondary noise significantly<br />

•Very low profile:<br />

✓ can fit within existing restricted rail heights to:<br />

- provide a retrofit solution in areas where space or cost prohibits the use of floating slab track<br />

- reduce tunnel diameters and costs for new track construction, giving very large savings in project costs.<br />

•All components are easily replaced for ease of maintenance<br />

•Low longitudinal stiffness avoids load transfer between rail and bridge on thermal expansion<br />

•Longitudinal creep resistance can be adjusted in situ to suit requirement<br />

•Uses proven materials technology

PANGUARD <br />

Application and Installation<br />

The <strong>Pandrol</strong> PANGUARD system is available in two different versions – as a baseplate assembly, or as a<br />

cast-in assembly. Both offer the same low stiffness and consequent high vibration attenuation capability.<br />

The choice as to which to use depends mainly on the preferred method of installation. The cast-in version<br />

on ties or individual rail seat blocks is particularly suitable for top down construction and for retrofit in<br />

place of existing ties or blocks. The baseplate assembly has been designed in order that it can be easily<br />

slid into place under the rail as a retrofit in place of existing less resilient rail fasteners. As with other<br />

baseplates, it can also be used for new construction with either the top down or bottom up method.<br />

Cast-in Assembly<br />

Baseplate Assembly<br />

Installation Tools<br />

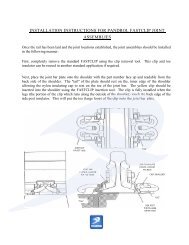

The <strong>Pandrol</strong> PANGUARD system fastens the rail at the web unlike<br />

conventional fasteners that clamp the rail base. Therefore slightly<br />

different techniques are used to install this assembly. However, all<br />

conventional forms of track construction can be applied when<br />

fitting PANGUARD and there is no need for expensive or<br />

complicated equipment. The principle of installation is to apply a<br />

lateral precompression to the rubber supporting blocks. This force<br />

maintains the rail position laterally while allowing it to deflect in the<br />

vertical plane. Installation is a one man operation using a simple<br />

hand tool to apply the clamping force.

<strong>Pandrol</strong> PANGUARD is suitable for application on concrete ties, wood ties, slab track and bridges. The assembly features height<br />

adjustment within the assembly itself, or by shimming under a baseplate. Lateral adjustment is also available, either within the<br />

assembly or via the baseplate.<br />

Bridge Application on Concrete Ties in Ballast<br />

Tunnel Application on Concrete Slab<br />

Baseplate Application on Concrete Slab<br />

Laboratory Testing<br />

Before its first installation in track, the <strong>Pandrol</strong> PANGUARD<br />

system was tested extensively in the laboratory. A range<br />

of tests and measurements were made, as follows:<br />

• Repeated inclined dynamic load test, run for more<br />

than 4.5 million cycles<br />

• Dynamic stiffness of the assembly<br />

• Longitudinal stiffness and creep properties<br />

• Electrical resistance<br />

• Accelerated ageing (corrosion)<br />

• Resistance to chemicals used on the track<br />

• Fire resistance<br />

Laboratory Test Reports are available on request.<br />

Inclined Dynamic Stiffness Test Arrangement

PANGUARD <br />

Suitable Applications<br />

Applications of <strong>Pandrol</strong> PANGUARD make use of the product’s unique characteristics. Its low overall<br />

height makes it very suitable where lower stiffness is required in existing track, but the rail head level<br />

cannot be raised. The very high level of vibration attenuation achieved with the system can be used to<br />

control ground vibration – for instance from trains running in tunnels, or to reduce the noise emitted from<br />

vibration of structures such as bridges or viaducts. Examples of two applications are given below – one<br />

in which a primary objective was control of ground vibration and the other in which it was used to<br />

investigate the system’s capacity to reduce noise from a bridge.<br />

Case Study 1<br />

London Underground, UK<br />

Installation of <strong>Pandrol</strong> PANGUARD on concrete ties in place of wooden ties with baseplates.<br />

The installation was intended to reduce groundborne vibration from tunnels.<br />

Rail Spacing Axle Load<br />

BS113A 0,9m 11 tons<br />

Invert Vertical Vibration<br />

90<br />

87.3<br />

Vibration velocity dB (ref. 5E-8m/s)<br />

80<br />

70<br />

60<br />

50<br />

40<br />

Before<br />

After<br />

69.7<br />

Insertion Loss – 17.6 dB<br />

Note - Bars show total<br />

vibration levels<br />

30<br />

50 100 200 500 1000 2000<br />

Frequency (Hz)

Case Study 2<br />

Railtrack, UK<br />

Installation of <strong>Pandrol</strong> PANGUARD on concrete ties on a ballasted steel bridge structure.<br />

The installation was aimed at the reduction of secondary noise resulting from vibration of a steel bridge under rail traffic.<br />

Rail Spacing Axle Load<br />

BS113A 0,65m 28 tons<br />

90<br />

Noise under bridge (4m below bridge)<br />

Sound Pressure Lmax dB(A) (ref 20E-6Pa)<br />

80<br />

70<br />

60<br />

Insertion Loss – 6.7 dB(A) 50<br />

Note – Bars show total<br />

sound pressure levels<br />

50<br />

63<br />

80<br />

Before<br />

After<br />

100<br />

125<br />

160<br />

200<br />

250<br />

315<br />

400<br />

Frequency (Hz)<br />

500<br />

630<br />

800<br />

1000<br />

1250<br />

1600<br />

2000<br />

2500<br />

3150<br />

4000<br />

5000<br />

83.4<br />

76.7<br />

Total<br />

dB(A)

<strong>Pandrol</strong> <strong>USA</strong>, LP<br />

501 Sharptown Road, P.O. Box 367<br />

Bridgeport, NJ 08014<br />

Phone (856) 467-3227 or (800) 221-CLIP<br />

Fax (856) 467-2994<br />

Website www.pandrolusa.com<br />

<strong>Pandrol</strong> Canada Limited<br />

6910 34th Street<br />

Edmonton, Alberta T6B 2X2, Canada<br />

Phone 780-413-4281<br />

Fax 780-413-4283<br />

‘PANGUARD’ is a registered trademark of <strong>Pandrol</strong> <strong>USA</strong>, LP<br />

The technical information given in this brochure was correct at the time of printing, but the company undertakes a continuing program of<br />

research and development and improvements may have since been introduced.<br />

2005