Lamination of Volvo Penta IPS hull mold plugs - Haisma Scheeps

Lamination of Volvo Penta IPS hull mold plugs - Haisma Scheeps

Lamination of Volvo Penta IPS hull mold plugs - Haisma Scheeps

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Lamination</strong> instructions<br />

<strong>Volvo</strong> <strong>Penta</strong> <strong>IPS</strong> * Twin, Triple & Quadruple installation,<br />

using <strong>Volvo</strong> <strong>Penta</strong> <strong>IPS</strong> <strong>hull</strong> <strong>mold</strong> plug<br />

General information<br />

* <strong>IPS</strong>350/400/450/500/550G/600<br />

1<br />

<strong>Lamination</strong> policy<br />

Why use <strong>Volvo</strong> <strong>Penta</strong> <strong>hull</strong> requirements<br />

The purpose <strong>of</strong> this lamination poster is to guide the design and integration <strong>of</strong> the <strong>Volvo</strong> <strong>Penta</strong> <strong>IPS</strong> system into the <strong>hull</strong> structure. These requirements emphasize the stringer design and<br />

<strong>hull</strong> construction requirements established by <strong>Volvo</strong> <strong>Penta</strong> to minimize the risk <strong>of</strong> water intrusion in the event <strong>of</strong> groundings.<br />

Normal scantling rules (e.g., ISO 12215) focus on variables such as propeller thrust, steering forces, mass <strong>of</strong> machinery, etc. The <strong>Volvo</strong> <strong>Penta</strong> <strong>IPS</strong> <strong>hull</strong> requirements focus on ensuring an<br />

adequate structure to keep the <strong>hull</strong> intact in a hard grounding where the drives are designed to shear <strong>of</strong>f under certain conditions. Extensive full scale testing and calculations conducted<br />

by <strong>Volvo</strong> <strong>Penta</strong> show that forces generated in an underwater collision or grounding are more than 10 times higher than protection afforded by following traditional scantling rules.<br />

IMPORTANT!<br />

The <strong>Volvo</strong> <strong>Penta</strong> <strong>IPS</strong> is designed to function as an integrated part <strong>of</strong> the <strong>hull</strong> and laminate structure. The strength <strong>of</strong> the entire system is dependant on the integrated strength <strong>of</strong> the <strong>IPS</strong><br />

and the <strong>hull</strong> and laminate structure. The strength <strong>of</strong> the <strong>hull</strong> structure is dependant upon a number <strong>of</strong> factors including shape, fiberglass quality and strength, type and quality <strong>of</strong> resin,<br />

lamination conditions, laminator skill, etc. The ultimate responsibility to ensure that all <strong>Volvo</strong> <strong>Penta</strong> <strong>IPS</strong> <strong>hull</strong> are produced consistently with these requirements rests exclusively with the<br />

boat builder.<br />

IMPORTANT! This instruction replace prevoius lamination instructions found in drawing no. 3591073<br />

2<br />

E-LTM<br />

Glass information<br />

E-BXM<br />

E = E-Glass<br />

L = Longitudinal direction (0°)<br />

T = Transverse direction (90°)<br />

LT = 0°/90° Biaxial<br />

BX = +45°/-45° Biaxial or Double Bias<br />

M = Chopped strand mat (CSM)<br />

Placement <strong>of</strong> <strong>Volvo</strong> <strong>Penta</strong> <strong>IPS</strong> <strong>hull</strong> <strong>mold</strong> <strong>plugs</strong><br />

Core information<br />

IMPORTANT! Core material must be <strong>of</strong>f balsa, plywood or plastic foam material<br />

with hardness ≥ 60 kg/m 3 (3.8 lb/ft 3 ) (also known as 60H) or similar<br />

IMPORTANT! The use <strong>of</strong> general <strong>hull</strong> core material does not yield any deviations<br />

from the instructions regarding <strong>Volvo</strong> <strong>Penta</strong> <strong>IPS</strong> reinforcements<br />

3<br />

See separate poster; Installation Reference, <strong>Volvo</strong> <strong>Penta</strong> <strong>IPS</strong> Hull Plug and<br />

Engine Foundation or Installation Manual for placing <strong>of</strong> <strong>Volvo</strong> <strong>Penta</strong> <strong>IPS</strong><br />

<strong>hull</strong> <strong>mold</strong> <strong>plugs</strong><br />

47700596 - 1(6) 09-2009

<strong>Lamination</strong> <strong>of</strong> <strong>Volvo</strong> <strong>Penta</strong> <strong>IPS</strong> <strong>hull</strong> <strong>mold</strong> <strong>plugs</strong><br />

<strong>Lamination</strong> layers<br />

4 5<br />

NOTE! All pictures in this poster show a standard 2 degree toe-in installation<br />

NOTE! Pictures do not<br />

show correct scale<br />

IMPORTANT! If narrower mats are used a mat overlap <strong>of</strong> minimum 50 mm (2”) on the <strong>hull</strong> <strong>mold</strong> plug must be<br />

applied<br />

Cross sections<br />

Mat contour fit<br />

IMPORTANT! Alternative directed fiber mats<br />

(not CSM) <strong>of</strong> density less than 1500 g/m 2<br />

(44.3 oz/yd 2 ) may be used from layer # 4 as<br />

long as minimum requirements for number <strong>of</strong><br />

layers, total density and total mat thickness<br />

are met. All mats must be <strong>of</strong> both type +45°/-<br />

45° and 0°/90°. These mats should be altered<br />

in similar way as in recommended layup (see<br />

table above).<br />

IMPORTANT! If vacuum infusion is used a<br />

total thickness <strong>of</strong> minimum 21 mm (0.8”) must<br />

still be met<br />

IMPORTANT! Secondary bondings must be<br />

avoided for the lamination<br />

NOTE! Ensure good mat contour fit. Extend mats up<br />

to at least 35 mm (1.4”) from top <strong>of</strong>f <strong>hull</strong> <strong>mold</strong> plug<br />

6<br />

Result in <strong>hull</strong> <strong>mold</strong><br />

NOTE! Mats should be extended at least 150<br />

mm (6”) up on the aft bulkhead (transom)<br />

IMPORTANT! The mat lengths must be<br />

extended for every layer to ensure proper<br />

slope, see cross section figures. First layer<br />

must extend minimum 100 mm (4”) from the<br />

<strong>hull</strong> <strong>mold</strong> plug.<br />

Placement <strong>of</strong> reinforcement rings<br />

Sectional view<br />

7 8<br />

IMPORTANT! Putty must be high glass fiber<br />

content mix<br />

IMPORTANT! Putty must not be used in the v-<br />

groove before glass fiber layout is completed<br />

Top view<br />

NOTE! The reinforcement ring core<br />

can be made <strong>of</strong> several segments<br />

Sectional view<br />

IMPORTANT! Core material<br />

must be <strong>of</strong>f balsa, plywood<br />

or plastic foam material with<br />

density ≥60 kg/m 3 (3.8 lb/ft 3 )<br />

or similar<br />

Final measurement requirements<br />

IMPORTANT!<br />

Adjust core dimensions to<br />

meet final ring measurement<br />

requirements (see figure)<br />

9<br />

Result in <strong>hull</strong> <strong>mold</strong><br />

47700596 - 2(6) 09-2009

<strong>Lamination</strong> <strong>of</strong> reinforcement rings<br />

10<br />

<strong>Lamination</strong> layers<br />

IMPORTANT! Alternative directed fiber mats (not CSM)<br />

<strong>of</strong> density less than 1500 g/m2 (44.3 oz/yd2) may be<br />

used as long as minimum requirements for number <strong>of</strong><br />

layers, mat density and total mat thickness are met<br />

11 Sectional view<br />

IMPORTANT! Secondary bondings must be avoided<br />

for the lamination<br />

IMPORTANT! Putty must be high<br />

glass fiber content mix<br />

12<br />

Cross section<br />

13<br />

Result in <strong>hull</strong> <strong>mold</strong><br />

IMPORTANT! Minimum 50 mm (2”)<br />

overlap must be applied between the<br />

mats. This yields even if narrower<br />

mats are used<br />

NOTE! In order to avoid thicker areas<br />

each layer should be rotated<br />

Mat contour fit<br />

NOTE! Mats should be extended up on the<br />

aft bulkhead (transom) when applicable<br />

NOTE! Ensure good mat contour fit. Extend<br />

mats up to at least 35 mm (1.4”) from top <strong>of</strong>f<br />

<strong>Volvo</strong> <strong>Penta</strong> <strong>IPS</strong> <strong>hull</strong> <strong>mold</strong> plug<br />

IMPORTANT! The mat lengths must be<br />

extended for every layer to ensure proper<br />

slope, see cross section figure. First layer<br />

must extend minimum 100 mm (4”) from the<br />

ring core<br />

Placement <strong>of</strong> reinforcement beams<br />

Sectional view<br />

14 15<br />

Result in <strong>hull</strong> <strong>mold</strong><br />

IMPORTANT! The aft beam must be<br />

placed aft <strong>of</strong> the reinforcement ring and in<br />

line with the centerline <strong>of</strong> the <strong>hull</strong> plug<br />

IMPORTANT! Beams must be long enough<br />

to meet both reinforcement ring and inner<br />

transom bulkhead or compartment sides<br />

IMPORTANT! Core material must be <strong>of</strong>f balsa,<br />

plywood or plastic foam material with density<br />

≥60 kg/m3 (3.8 lb/ft3) or similar<br />

IMPORTANT!<br />

Drainage holes in any reinforcement beam must not have a<br />

diameter larger than 25 mm (1”). For the aft reinforcement<br />

beam the hole should be placed in the center <strong>of</strong> the beam<br />

IMPORTANT! Dimension the core<br />

so that final ring measurement<br />

requirements are met, see<br />

8<br />

47700596 - 3(6) 09-2009

<strong>Lamination</strong> <strong>of</strong> reinforcement beams<br />

16<br />

<strong>Lamination</strong> layers<br />

17<br />

IMPORTANT! Fill transition first with putty <strong>of</strong> high fiber<br />

content mix to ease the mat layup<br />

IMPORTANT! If lamination mats are divided into several<br />

segments a minimum overlap <strong>of</strong> 50 mm (2”) must be applied<br />

IMPORTANT! Alternative directed fiber mats (not CSM)<br />

<strong>of</strong> density less than 1500 g/m2 (44.3 oz/yd2) may be<br />

used as long as minimum requirements for number <strong>of</strong><br />

layers, mat density and total mat thickness are met<br />

Attachment <strong>of</strong> engine bed<br />

IMPORTANT! Secondary bondings must be avoided for the lamination<br />

IMPORTANT! Mat length must be extended for each layer. There must be is a minimum<br />

extension <strong>of</strong> 50 mm (2”) for every layer to ensure a proper slope. First layer must extend<br />

minimum 100 mm (4”) from the beam core (see figure to the right)<br />

Construction <strong>of</strong> engine bed<br />

18<br />

W2 ≈ W1<br />

IMPORTANT! Attachment <strong>of</strong> the engine bed<br />

stringers must be made to the forward part <strong>of</strong><br />

the reinforcement ring and approximately at a<br />

90 degree angle from the ring<br />

IMPORTANT! Maintain the width <strong>of</strong> the<br />

engine bed stringers all the way up to the<br />

reinforcement ring<br />

19<br />

See Installation Manual and drawings for engine bed construction<br />

and dimensions<br />

Final result after lamination<br />

Final geometry<br />

20 21<br />

Zones <strong>of</strong> requirements<br />

IMPORTANT! Within zone A, both <strong>Volvo</strong> <strong>Penta</strong> requirements found in<br />

"<strong>Lamination</strong> <strong>of</strong> <strong>Volvo</strong> <strong>Penta</strong> <strong>IPS</strong> <strong>hull</strong> mould <strong>plugs</strong>" ( 4 - 6 ) and<br />

general scantling rules applies. Minimum required <strong>hull</strong> bottom thickness<br />

within this zone is given by the thickest requirement <strong>of</strong> these.<br />

IMPORTANT! Zone B refers to the lamination <strong>of</strong> the<br />

reinforcement rings and the reinforcement beams.<br />

See requirements in 10 - 13 and 18 - 19<br />

47700596 - 4(6) 09-2009

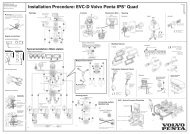

Triple and Quadruple installations<br />

NOTE! The lamination geometry may vary in a Triple <strong>Volvo</strong> <strong>Penta</strong> <strong>IPS</strong><br />

installation depending on the tunnel design<br />

Placement <strong>of</strong> <strong>Volvo</strong> <strong>Penta</strong> <strong>IPS</strong> <strong>hull</strong> <strong>mold</strong> <strong>plugs</strong><br />

22<br />

See separate poster; Installation Reference, <strong>Volvo</strong> <strong>Penta</strong> <strong>IPS</strong> Hull Plug and Engine<br />

Foundation or Installation Manual for placing <strong>of</strong> <strong>Volvo</strong> <strong>Penta</strong> <strong>IPS</strong> <strong>hull</strong> <strong>mold</strong> <strong>plugs</strong><br />

<strong>Lamination</strong> <strong>of</strong> <strong>Volvo</strong> <strong>Penta</strong> <strong>IPS</strong> <strong>hull</strong> <strong>mold</strong> <strong>plugs</strong><br />

23<br />

See procedure as for Twin <strong>Volvo</strong> <strong>Penta</strong> <strong>IPS</strong> installation; ⇒ 4 - 6<br />

24<br />

Result in <strong>hull</strong> <strong>mold</strong> - Triple<br />

Result in <strong>hull</strong> <strong>mold</strong> - Quadruple<br />

Placement <strong>of</strong> reinforcement rings<br />

25<br />

See procedure as for Twin <strong>Volvo</strong> <strong>Penta</strong> <strong>IPS</strong> installation; ⇒ 7 - 9<br />

<strong>Lamination</strong> <strong>of</strong> reinforcement rings<br />

26<br />

See procedure as for Twin <strong>Volvo</strong> <strong>Penta</strong> <strong>IPS</strong> installation; ⇒ 10 - 13<br />

27<br />

Result in <strong>hull</strong> <strong>mold</strong> - Triple<br />

Result in <strong>hull</strong> <strong>mold</strong> - Quadruple<br />

Placement <strong>of</strong> reinforcement beams<br />

28<br />

See procedure as for Twin <strong>Volvo</strong> <strong>Penta</strong> <strong>IPS</strong> installation; ⇒ 14 - 15<br />

29<br />

Result in <strong>hull</strong> <strong>mold</strong> - Triple<br />

Result in <strong>hull</strong> <strong>mold</strong> - Quadruple<br />

Triple<br />

Quadruple<br />

47700596 - 5(6) 09-2009

NOTE! The lamination geometry may vary in a Triple <strong>Volvo</strong> <strong>Penta</strong> <strong>IPS</strong><br />

installation depending on the tunnel design<br />

<strong>Lamination</strong> <strong>of</strong> reinforcement beams<br />

Triple and Quadruple installations<br />

30<br />

See procedure as for Twin <strong>Volvo</strong> <strong>Penta</strong> <strong>IPS</strong> installation; ⇒ 16 17 31<br />

-<br />

Result in <strong>hull</strong> <strong>mold</strong> - Triple<br />

Result in <strong>hull</strong> <strong>mold</strong> - Quadruple<br />

Attachment <strong>of</strong> engine bed<br />

Construction <strong>of</strong> engine bed<br />

See procedure as for Twin <strong>Volvo</strong> <strong>Penta</strong> <strong>IPS</strong> installation; ⇒ 18<br />

32 33 See Installation Manual for engine bed construction and dimensions<br />

Final result<br />

34<br />

Final geometry<br />

35<br />

Zones <strong>of</strong> requirements<br />

Triple<br />

IMPORTANT! Within zone A, both <strong>Volvo</strong> <strong>Penta</strong> requirements found in<br />

"<strong>Lamination</strong> <strong>of</strong> <strong>Volvo</strong> <strong>Penta</strong> <strong>IPS</strong> <strong>hull</strong> mould <strong>plugs</strong>" ( 4 - 6 ) and<br />

general scantling rules applies. Minimum required <strong>hull</strong> bottom thickness<br />

within this zone is given by the thickest requirement <strong>of</strong> these.<br />

Triple<br />

IMPORTANT! Zone B refers to the lamination <strong>of</strong> the<br />

reinforcement rings and the reinforcement beams.<br />

See requirements in 10 - 13 and 18 - 19<br />

Quadruple<br />

Quadruple<br />

47700596 - 6(6) 09-2009