Sonix Auto-Wafer

Sonix Auto-Wafer

Sonix Auto-Wafer

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

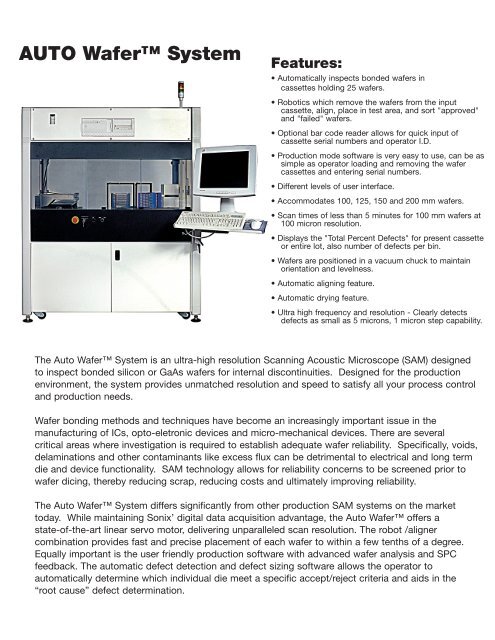

AUTO <strong>Wafer</strong> System<br />

Features:<br />

• <strong>Auto</strong>matically inspects bonded wafers in<br />

cassettes holding 25 wafers.<br />

• Robotics which remove the wafers from the input<br />

cassette, align, place in test area, and sort "approved"<br />

and "failed" wafers.<br />

• Optional bar code reader allows for quick input of<br />

cassette serial numbers and operator I.D.<br />

• Production mode software is very easy to use, can be as<br />

simple as operator loading and removing the wafer<br />

cassettes and entering serial numbers.<br />

• Different levels of user interface.<br />

• Accommodates 100, 125, 150 and 200 mm wafers.<br />

• Scan times of less than 5 minutes for 100 mm wafers at<br />

100 micron resolution.<br />

• Displays the "Total Percent Defects" for present cassette<br />

or entire lot, also number of defects per bin.<br />

• <strong>Wafer</strong>s are positioned in a vacuum chuck to maintain<br />

orientation and levelness.<br />

• <strong>Auto</strong>matic aligning feature.<br />

• <strong>Auto</strong>matic drying feature.<br />

• Ultra high frequency and resolution - Clearly detects<br />

defects as small as 5 microns, 1 micron step capability.<br />

The <strong>Auto</strong> <strong>Wafer</strong> System is an ultra-high resolution Scanning Acoustic Microscope (SAM) designed<br />

to inspect bonded silicon or GaAs wafers for internal discontinuities. Designed for the production<br />

environment, the system provides unmatched resolution and speed to satisfy all your process control<br />

and production needs.<br />

<strong>Wafer</strong> bonding methods and techniques have become an increasingly important issue in the<br />

manufacturing of ICs, opto-eletronic devices and micro-mechanical devices. There are several<br />

critical areas where investigation is required to establish adequate wafer reliability. Specifically, voids,<br />

delaminations and other contaminants like excess flux can be detrimental to electrical and long term<br />

die and device functionality. SAM technology allows for reliability concerns to be screened prior to<br />

wafer dicing, thereby reducing scrap, reducing costs and ultimately improving reliability.<br />

The <strong>Auto</strong> <strong>Wafer</strong> System differs significantly from other production SAM systems on the market<br />

today. While maintaining <strong>Sonix</strong>’ digital data acquisition advantage, the <strong>Auto</strong> <strong>Wafer</strong> offers a<br />

state-of-the-art linear servo motor, delivering unparalleled scan resolution. The robot /aligner<br />

combination provides fast and precise placement of each wafer to within a few tenths of a degree.<br />

Equally important is the user friendly production software with advanced wafer analysis and SPC<br />

feedback. The automatic defect detection and defect sizing software allows the operator to<br />

automatically determine which individual die meet a specific accept/reject criteria and aids in the<br />

“root cause” defect determination.

<strong>Auto</strong> <strong>Wafer</strong> Specs<br />

Scan Axis<br />

• Positioning Device:<br />

• Servo Max Velocity:<br />

• Servo Repeatability:<br />

• Linear Encoder Resolution:<br />

• Max Travel:<br />

Linear servo motor<br />

1000 mm/sec<br />

+/- 0.5 micron<br />

0.5 micron<br />

315 mm<br />

Step Axis<br />

• Positioning Device:<br />

• Step Axis Resolution:<br />

• Max Travel:<br />

Low-EMI<br />

microstep motor<br />

with zero-backlash<br />

lead screw<br />

0.25 micron<br />

327 mm<br />

Close-up of handling and inspection area<br />

showing robot, input/output cassettes,<br />

aligner and inspection area<br />

Focus Axis<br />

• Positioning Device:<br />

• Focus Axis Resolution:<br />

• Max Travel:<br />

Low-EMI<br />

microstep motor<br />

with zero-backlash<br />

lead screw<br />

0.5 micron<br />

7 mm<br />

Ultrasonic Instruments<br />

• DPR-500S Receiver with H1 remote<br />

pulser pre-amp (RPPA)<br />

• UHF kit including U1 RPPA with expanded<br />

bandwidth receiver and UHF transducer<br />

Enclosure<br />

• Footprint:<br />

1525 mm x 915 mm<br />

• Includes base cabinet for computer and<br />

instrumentation, with casters and leveling feet<br />

• Approved emergency off and safety interlock<br />

• Recommended floor space: 1600 mm x 990 mm<br />

Easy to use production software, showing<br />

accepted/rejected wafers and percent<br />

defects for each wafer in the cassette.<br />

8700 Morrissette Drive • Springfield, VA 22152<br />

tel: 703-440-0222 • fax: 703-440-512<br />

e-mail: info@sonix.com • www.sonix.com