FZ32 - Portal Milling Machine - galika

FZ32 - Portal Milling Machine - galika

FZ32 - Portal Milling Machine - galika

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

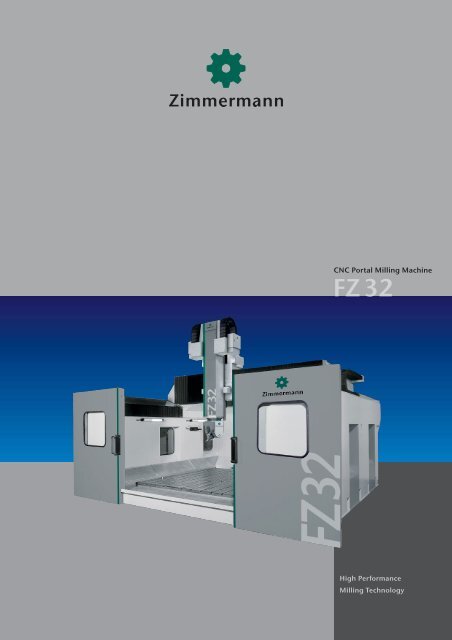

CNC <strong>Portal</strong> <strong>Milling</strong> <strong>Machine</strong><br />

FZ 32<br />

High Performance<br />

<strong>Milling</strong> Technology

FZ 32<br />

HSC <strong>Portal</strong> <strong>Milling</strong> <strong>Machine</strong><br />

with Overhead Gantry<br />

with upper moving portal – high<br />

axial accelerations and perfect<br />

surface finishes can be achieved,<br />

resulting in an overall economic<br />

solution.<br />

Low<br />

moving masses<br />

High<br />

structural stiffness<br />

High dynamic and<br />

surface quality<br />

The highly dynamic portal milling<br />

machine of the second generation,<br />

for sophisticated applications<br />

in the aircraft industry and in<br />

automotive development. Well<br />

balanced technology tailored<br />

specifically to accuracy, thermal<br />

stability and rigidity requirements<br />

for composite and aluminium<br />

machining.<br />

acceleration values. It has been<br />

designed to meet customer needs<br />

for the highest cost effectiveness,<br />

dependable accuracy and high<br />

dynamics.<br />

Using the latest FEM simulation<br />

techniques it has been possible<br />

to create a machine with the<br />

greatest possible stiffness which<br />

at the same time has low<br />

moving masses. With this advanced<br />

machining concept –<br />

based on the Zimmermann<br />

overhead gantry technology<br />

The side walls form an integral<br />

part of the machine housing.<br />

Windows on the left or right<br />

side – whichever the customer<br />

prefers – offer a good view of the<br />

working area. Loading and unloading<br />

is carried out through<br />

a sliding door at the face side.<br />

The FZ 32 is designed for<br />

dynamic speed 5-sided<br />

machining of aluminium<br />

and composite materials as<br />

well as for simultaneous<br />

finishing of steel with high<br />

Dust-proof bellows.<br />

Vertical slide / Z-RAM<br />

2-axis milling head VH 2.<br />

Heavy duty machine table with<br />

sheet covers on all sides.<br />

Lamella bellows<br />

for the drive systems.<br />

Overhead gantry moving in X-direction.<br />

Fixed side wall, filled with<br />

special concrete.<br />

Integrated safety guarding.<br />

Encapsulated tool changer<br />

outside the machining area,<br />

pickup or chain design magazine.<br />

2 CNC <strong>Portal</strong> <strong>Milling</strong> <strong>Machine</strong> FZ 32

VH 2 –<br />

The Compact<br />

Wherever low interference contours<br />

and reduced moving masses<br />

are required, the extremely<br />

powerful VH 2 comes into its own.<br />

Maximum working areas<br />

A particular specialty of the<br />

Zimmermann portal milling machine<br />

is the mastery of very large<br />

working areas due to its optimal<br />

structural rigidity.<br />

Particularly with very long Z- and /<br />

or Y-axes, the mass of the milling<br />

head plays an important role<br />

in milling accuracy. Above all,<br />

deflection and torsion must be<br />

kept to a minimum in order to<br />

achieve the best possible surface<br />

finish and contour<br />

accuracy.<br />

Where large working areas are<br />

required but hardly any heavy<br />

materials are to be machined or<br />

high machining speeds are<br />

needed, the weight optimized<br />

VH 2 milling head is an ideal<br />

solution.<br />

Complicated contours<br />

<strong>Portal</strong> milling machines are<br />

being used to machine increasingly<br />

complex workpieces with<br />

tight contours. Often intricate<br />

clamping fixtures are needed<br />

which restrict access during the<br />

milling process. With its compact<br />

design the VH 2 is often ideal for<br />

working efficiently in this limited<br />

space.<br />

Lightweight machines<br />

The VH 2 is particularly suitable<br />

for medium-volume machining of<br />

lightweight materials up to aluminium<br />

and for finish machining<br />

of steel and cast iron.<br />

A new design<br />

■ Low interference<br />

contour for better access.<br />

■ Water-cooled worm drive<br />

and spindle flange for higher<br />

accuracy and to eliminate<br />

thermal influences.<br />

■ Higher swivel speeds<br />

to reduce overall machining<br />

times.<br />

■ Clamping of rotary axes<br />

for greater stiffness during roughing.<br />

■ Robust, reliable grease<br />

replenishment system to ensure<br />

long life and profitability.<br />

Applications<br />

The VH 2 is basically an allrounder<br />

and thus offers great<br />

advantages as to order flexibility.<br />

However, it really comes into<br />

its own where high power combined<br />

with low weight and / or<br />

compact size is required.<br />

Very large working areas and<br />

complicated workpieces –<br />

such as in the design field and<br />

in aircraft manufacture – are the<br />

applications the VH 2 is often at<br />

its best.<br />

3

FZ 32<br />

Technical Specification<br />

Design<br />

The portal design with fixed<br />

machine bed and a gantry that<br />

travels in the X direction offers<br />

significant advantages for tool,<br />

mould and pattern making as<br />

well as for the aircraft industry.<br />

The cast-iron machine bed is<br />

permanently anchored to the<br />

foundation, so that the workpiece<br />

does not have to be moved.<br />

In this way, machining operations<br />

are independant of the weight of<br />

the workpiece. The moving mass<br />

is made up of the structurally<br />

stiff gantry, the transverse and<br />

Z-slides, and the milling head.<br />

The constant moving masses<br />

ensure highly consistent dynamic<br />

behaviour – a prerequisite for<br />

optimum surface finish and workpiece<br />

accuracy. This combination<br />

of high stability and stiffness,<br />

constant moving masses, and a<br />

highly dynamic drive make the<br />

machine suitable for machining<br />

of several types of materials,<br />

for example plastics, aluminium,<br />

kirksite and fibre-reinforced<br />

composite materials. When machining<br />

composites, the drives<br />

are characterised by very smooth<br />

running.<br />

The 2-axis milling head VH 2.<br />

<strong>Machine</strong> Frame and Slides<br />

The machine bed is made of cast<br />

iron; the side walls, gantry and<br />

Z-slide are of welded steel construction.<br />

The side walls are filled<br />

with a special, fibre-reinforced<br />

DemTec ® concrete. The guide,<br />

drive and measuring systems for<br />

the Y- and Z-axes are protected<br />

against contamination by dustproof<br />

bellows. The X-axis is fitted<br />

as standard with aluminium lamella<br />

bellows.<br />

4 CNC <strong>Portal</strong> <strong>Milling</strong> <strong>Machine</strong> FZ 32

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

Z<br />

X<br />

Y<br />

The FZ 32 always<br />

has as standard<br />

three driven linear<br />

axes (X, Y, Z).<br />

▼ Tool changer with chain.<br />

▼▼ Rack and pinion drive.<br />

C<br />

A<br />

On the 5-axis<br />

machine, the<br />

milling head can<br />

also be swivelled<br />

two axes (A, C),<br />

both driven.<br />

Drive System<br />

Independent of the supplier of<br />

the control system, all axes are<br />

equipped with Siemens “Simodrive”<br />

digital drives. The power<br />

transmission is carried out by means<br />

of a rack and pinion drive<br />

with electronically preloaded<br />

motors in all three linear axes X, Y<br />

and Z.<br />

The control-system gantry function<br />

ensures that the two X-axis drives<br />

are synchronised.<br />

■ Linear guides:<br />

Pre-loaded circulating-roller<br />

linear bearings, size 55 on the<br />

X-axis, and size 45 on the Y- and<br />

Z-axis. Up to 8 bearing carriages<br />

per axis.<br />

■ Rack and pinion:<br />

Rack and pinion, quality level 5<br />

with two electronically preloaded<br />

motors per drive unit in the<br />

X- and Y-axis one unit for backlash-free<br />

motion and drive in the<br />

Z-axis.<br />

Measuring systems<br />

The three linear axes, X, Y and<br />

Z, are equipped with direct<br />

length measuring systems with<br />

▼ Comparison of different structural<br />

materials for the side walls based on the<br />

most important functional criteria.<br />

DemTec ® Castings Steel<br />

Heidenhain glass-scales (steel<br />

meters / for axes with over 3 m<br />

travel).<br />

The measuring systems are protected<br />

against dirt and dust by a<br />

compressed air barrier.<br />

<strong>Milling</strong> spindle<br />

The milling spindle can be<br />

supplied with a power of 45 kW<br />

whereas the speed of rotation is<br />

25 000 min -1 (optional 30 000 min -1<br />

with oil-air-lubrication). In both<br />

cases, the spindle is supported in<br />

preloaded, ceramic, hybrid<br />

spindle bearings. The bearings<br />

have labyrinth seals with a<br />

compressed air protection. To<br />

minimise downtime in the event<br />

of damage, the spindle cartridge<br />

can be changed very quickly<br />

and easily. As an innovation the<br />

spindle is equipped with a<br />

permanent lubrication with<br />

automated grease replenishment<br />

system.<br />

This enables higher speeds and<br />

above all a longer life.<br />

Controls<br />

The FZ 32 has been designed<br />

so that it can be combined with<br />

various makes and types of<br />

control. Modern control systems<br />

provide functions such as<br />

“Look ahead”, jerk limitation,<br />

spline interpolation, and 5-axis<br />

machining. Equipment and<br />

software solutions for many additional<br />

tasks are available as an<br />

option.<br />

0<br />

Damping Rigidity Thermal<br />

conductivity<br />

Thermal accumulation<br />

capacity<br />

5

FZ 32<br />

Technical Data<br />

<strong>Machine</strong> FZ 32<br />

Working ranges<br />

X-axis 2 000 – 40 000 mm 1<br />

Y-axis 3 000 – 4 000 mm 1<br />

Z-axis 1 250 – 1 500 mm 1<br />

Worktable size<br />

Length<br />

2 000 – 40 000 mm<br />

Width<br />

3 000 mm<br />

Height<br />

350 mm<br />

Max. worktable load 20 000 kg/m 2<br />

T-slots (longitudinal)<br />

18 H12<br />

Distance T-slots<br />

250 mm<br />

Feed drives<br />

Feed drive X, Y and Z-axes up to 50 000 mm/min.<br />

Acceleration of linear axes 2,5 – 3,5 m/s 2<br />

Accuracy 2<br />

Positioning accuracy X-axis<br />

Positioning accuracy Y-, Z-axis<br />

Repeatability X-axis<br />

Repeatability Y-, Z-axis<br />

0,030 mm<br />

0,020 mm<br />

0,015 mm<br />

0,010 mm<br />

<strong>Milling</strong> head VH 2<br />

Swivel ranges<br />

A-axis + 95°/ - 125° or ± 110°<br />

C-axis (Z = 1250 mm/Z=1500mm) ± 300° / ± 360°<br />

Performance<br />

Torque A-, C-axis<br />

800 Nm<br />

Acceleration A-, C-axis 300°/s 2<br />

Feed rates A-, C-axis<br />

60°/s perm., 90°/s max.<br />

Accuracy 2<br />

Positioning accuracy A, C-axis 15“=0,0041°<br />

Repeatability A, C-axis 10“=0,0027°<br />

Axes clamping<br />

Clamping A-axis<br />

Clamping C-axis<br />

Torque A-, C-axis<br />

hydraulic<br />

spring clamp<br />

1 600 Nm<br />

<strong>Milling</strong> spindle<br />

Universal<br />

Power S1 max. (100 % ED) 45 kW<br />

Max. torque S1 (100 % ED) 67 Nm<br />

Max. speed<br />

Permanent greasing 25 000 min -1<br />

Oil-air lubrication 30 000 min -1<br />

Constant power range from 6 400 min -1<br />

Tool holder<br />

Distance swivel axis – spindle nose<br />

Tool clamping<br />

Tool unclamping<br />

Lubrication<br />

HSK 63 A<br />

320 mm<br />

Spring clamp<br />

hydraulic<br />

Perm. grease lubrication + automatic<br />

grease replenishment<br />

system (opt. oil-air lubrication)<br />

1 Other dimension on request<br />

2 According to VDI / DGQ 3441<br />

Subject to technical changes<br />

6 CNC <strong>Portal</strong> <strong>Milling</strong> <strong>Machine</strong> FZ 32

VH 2 <strong>Milling</strong> spindle performance diagrams<br />

Permanent greasing<br />

Md [Nm]<br />

200<br />

150<br />

100<br />

67<br />

50<br />

0<br />

0<br />

Oil-air lubrication<br />

Md [Nm]<br />

200<br />

150<br />

100<br />

67<br />

50<br />

0<br />

0<br />

45 kW<br />

Torque Md Power P<br />

P [kW]<br />

70<br />

60<br />

67 Nm<br />

30<br />

20<br />

10<br />

0<br />

6400 15000 20000 25000 30000 35000<br />

n [min -1 ]<br />

45 kW<br />

67 Nm<br />

30<br />

20<br />

10<br />

0<br />

6400 15000 20000 25000 30000 35000<br />

n [min -1 ]<br />

45<br />

Torque Md Power P<br />

P [kW]<br />

70<br />

60<br />

45<br />

Dimensions<br />

X-axis approx. 2 000 – 40 000 mm<br />

Y-axis approx. 3 000 mm<br />

Height approx. 4 550 – 5 050 mm<br />

Z-axis 1 250 – 1 500 mm<br />

Worktable length 2 000 – 40 000 mm<br />

Width 5 500<br />

Worktable width<br />

3 000 mm<br />

Length approx. 4 500 – 42 500 mm<br />

All dimensions shown are examples of the FZ 32 in the minimum<br />

and maximum configurations. Special variations within this<br />

range are also possible.<br />

Options FZ 32<br />

Air-conditioned control cabinet ■<br />

Safety guarding<br />

■<br />

Simultaneous A-axis<br />

■<br />

Simultaneous C-axis<br />

■<br />

Coolant system<br />

■<br />

Minimal quantity lubrication<br />

■<br />

Measuring touch probe<br />

■<br />

(wireless, cable)<br />

Options FZ 32<br />

Tool changer 15, 30, 50, 80 positions ■<br />

Tool measuring (laser, tactile)<br />

■<br />

Special painting<br />

■<br />

Chip conveyer<br />

■<br />

Extraction system<br />

■<br />

Partitioned working area<br />

■<br />

Clamping A- / C-Achse<br />

■<br />

■ Standard ■ Option<br />

7

High Performance<br />

<strong>Milling</strong> Technology<br />

FZ 50<br />

FZ 42<br />

FZ 38<br />

FZ 37<br />

Zimmermann is synonymous<br />

with CNC portal milling machines<br />

on a big scale. Specialisation and<br />

our high rate of innovation has<br />

put our technology out in front<br />

worldwide.<br />

A uniquely wide and finely tuned<br />

programme, including a large<br />

number of different machines<br />

and milling heads, enables you to<br />

choose the perfect machine for<br />

every application, thus offering<br />

you the ideal solution with regard<br />

to quality and cost-effectiveness.<br />

FZ 35<br />

FZ 32<br />

FZ 30<br />

FZ 25<br />

FZ 15<br />

F. Zimmermann GmbH<br />

Goethestraße 23 – 27<br />

D-73770 Denkendorf, Germany<br />

Phone +49 (7 11) 93 49 35 - 0<br />

Fax +49 (7 11) 934935-300<br />

info@f-zimmermann.com<br />

www.f-zimmermann.com<br />

Apollo 11 08.07