Case study Alfred Ritter GmbH & Co. KG - Fastec GmbH

Case study Alfred Ritter GmbH & Co. KG - Fastec GmbH

Case study Alfred Ritter GmbH & Co. KG - Fastec GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Case</strong> <strong>study</strong><br />

<strong>Alfred</strong> <strong>Ritter</strong> <strong>GmbH</strong> & <strong>Co</strong>. <strong>KG</strong><br />

The family-owned company <strong>Alfred</strong> <strong>Ritter</strong> <strong>GmbH</strong> & <strong>Co</strong>. <strong>KG</strong>, founded in 1912, employs around 800 people, who<br />

are involved in the production of around 250 tonnes of the square-shaped chocolate in the widest variety of<br />

types at the company‘s factory in Waldenbuch. The RITTER SPORT label is available in almost all German grocery<br />

stores as well as in 90 other countries around the world. Quality is a top priority throughout the entire company<br />

and particularly in the production area, which is attested to by the IFS (International Food Standard) and<br />

BRC (British Retail <strong>Co</strong>nsortium) certifications awarded.<br />

Even though an<br />

MDE / BDE solution<br />

was already in<br />

place at <strong>Alfred</strong> <strong>Ritter</strong><br />

<strong>GmbH</strong>‘s production<br />

facilities, the need to record and<br />

assess in great detail the reasons behind<br />

downtimes at certain machines<br />

became apparent. For this reason, a<br />

system was sought that could be employed<br />

alternately. It would therefore<br />

have to be flexible and easy to<br />

install and configure as well as being<br />

uncomplicated to operate.<br />

The productivity measuring device<br />

easyOEE from FASTEC <strong>GmbH</strong>, who<br />

have been successfully developing IT<br />

solutions since 1995, was selected.<br />

Impressive start<br />

‟FASTEC was able to meet all our<br />

requirements“, says Torsten Schlegel,<br />

CIP <strong>Co</strong>ordinator (CIP = continuous<br />

improvement process) at <strong>Alfred</strong><br />

<strong>Ritter</strong> <strong>GmbH</strong> & <strong>Co</strong>. <strong>KG</strong>, adding: ‟In<br />

our case for instance, the flexibility<br />

of the solution and its independence<br />

from the existing infrastructure were<br />

important preconditions.<br />

*OEE = Overall Equipment Effectiveness<br />

With easyOEE Portable GSM*,<br />

found exactly the right system to<br />

allow us to evaluate and optimise<br />

different machines.“<br />

easyOEE Portable with GSM as an<br />

extra function offer the advantage<br />

that its doesn‘t require any network<br />

connections where the machines<br />

and plants are located. Instead, the<br />

information captured is sent to a<br />

web server via mobile communications<br />

technology and can then be retrieved<br />

from the workstation PC over<br />

the internet (provided the user has<br />

the right password). Alternatively,<br />

the data can be accessed (again,<br />

using a password) through the network<br />

or offline using a USB interface.<br />

Since easyOEE portable GSM was<br />

supplied preconfigured to <strong>Ritter</strong><br />

Sport, a smooth, prompt start-up<br />

was guaranteed. The necessary<br />

digital signals of the machines to<br />

be monitored were captured within<br />

minutes via the light barrier (which<br />

is included in the scope of delivery).<br />

*GSM = Global System for Mobile <strong>Co</strong>mmunications (a standard for mobile communications networks)<br />

Fast, measurable benefit<br />

Immediately after connection to the<br />

first machine, the system delivered<br />

the desired OEE*-relevant indicators<br />

on a continuous basis, including<br />

availability, performance, quality,<br />

downtimes / cycle times, quantities,<br />

which can be retrieved from any PC<br />

connected to the internet.<br />

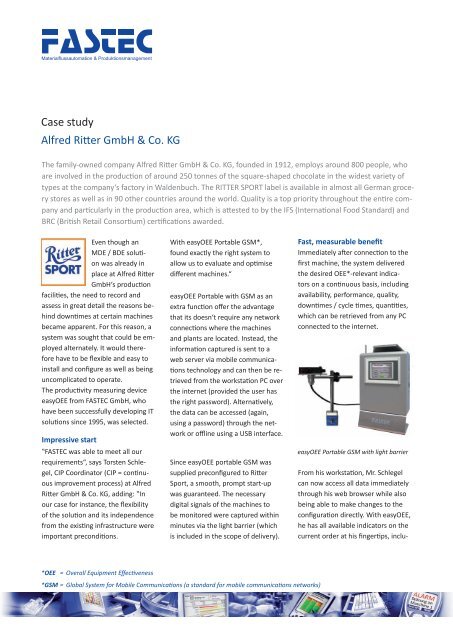

easyOEE Portable GSM with light barrier<br />

From his workstation, Mr. Schlegel<br />

can now access all data immediately<br />

through his web browser while also<br />

being able to make changes to the<br />

configuration directly. With easyOEE,<br />

he has all available indicators on the<br />

current order at his fingertips, inclu-

A measuring device for all machines in any location<br />

Mobile data transfer to a web server<br />

ding quantity produced and rejects<br />

as well as a detailed statement of all<br />

downtimes. All OEE-relevant indicators<br />

can be displayed immediately in<br />

easy-to-read diagram format.<br />

Using these evaluations, the reasons<br />

behind downtimes for example can<br />

be examined according to the frequency<br />

of their occurrence over a<br />

defined period of time. This allowed<br />

CIP measures to be developed in<br />

order to increase the productivity of<br />

the machine in a sustainable manner.<br />

The success of these optimisation<br />

measures was then made quantifiable<br />

by way of results controls and<br />

can now be monitored regularly.<br />

Simple handling during<br />

operations<br />

Because easyOEE is designed to be<br />

ergonomical and easy to use, it was<br />

accepted very quickly by the staff at<br />

<strong>Ritter</strong> Sport.<br />

For instance, a detailed breakdown<br />

of the reasons behind downtimes<br />

can be easily and intuitively captured<br />

within four or five seconds<br />

by the machine operator using a<br />

touchscreen facility, either by way of<br />

predefined reasons or by free text<br />

entry.<br />

For defined machine problems, an<br />

alarm is sent immediately by e-mail<br />

or SMS to the CIP <strong>Co</strong>ordinator<br />

Torsten Schlegel so that machine<br />

downtimes can be rectified quickly<br />

and, above all, for the long term.<br />

Once a machine has been optimised,<br />

easyOEE can be connected within<br />

minutes to the next machine. At<br />

the same time, the configuration<br />

information and database for each<br />

machine can be saved locally, which<br />

means it can be retrieved at any<br />

time when needed.<br />

Overview:<br />

z Sector: Food<br />

z Productivity measuring device<br />

easyOEE Portable with<br />

optional GSM<br />

z 5.7“ touch panel PC<br />

z Data can be accessed wirelessly,<br />

via USB interface or through the<br />

network<br />

z Downtimes are recorded to the<br />

nearest second<br />

„Although<br />

FASTEC offers<br />

its customers<br />

the<br />

option of onsite<br />

start-up,<br />

we decided<br />

to do this<br />

ourselves. Even at the test phase, we<br />

were impressed by the concept. The<br />

operating instructions supplied with<br />

the product as well as the manual<br />

on technical start-up are very well<br />

structured and leave no questions<br />

unanswered. Within a short period<br />

of time, we had easyOEE up and running<br />

and were able to use the system<br />

effectively.<br />

Torsten Schlegel, CIP <strong>Co</strong>ordinator at<br />

<strong>Alfred</strong> <strong>Ritter</strong> <strong>GmbH</strong> & <strong>Co</strong>. <strong>KG</strong><br />

FASTEC <strong>GmbH</strong> � Technologiepark 19 � D-33100 Paderborn � Tel.: +49 5251 1647-0 � Fax: +49 5251 1647-99 � E-Mail: info@fastec.de<br />

www.fastec.de � www.easyOEE.de � Subject to changes � Picture copyrights: FASTEC, photocase.com � © FASTEC <strong>GmbH</strong> 06.2011