Hot runner nozzle - Günther Heisskanaltechnik ...

Hot runner nozzle - Günther Heisskanaltechnik ...

Hot runner nozzle - Günther Heisskanaltechnik ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

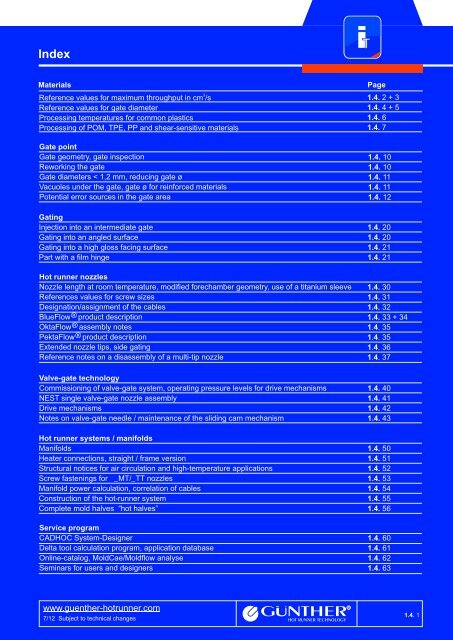

Index<br />

Materials<br />

3<br />

Reference values for maximum throughput in cm /s<br />

Reference values for gate diameter<br />

Processing temperatures for common plastics<br />

Processing of POM, TPE, PP and shear-sensitive materials<br />

Gate point<br />

Gate geometry, gate inspection<br />

Reworking the gate<br />

Gate diameters < 1,2 mm, reducing gate ø<br />

Vacuoles under the gate, gate ø for reinforced materials<br />

Potential error sources in the gate area<br />

Gating<br />

Injection into an intermediate gate<br />

Gating into an angled surface<br />

Gating into a high gloss facing surface<br />

Part with a film hinge<br />

<strong>Hot</strong> <strong>runner</strong> <strong>nozzle</strong>s<br />

Nozzle length at room temperature, modified forechamber geometry, use of a titanium sleeve<br />

References values for screw sizes<br />

Designation/assignment of the cables<br />

BlueFlow® product description<br />

OktaFlow® assembly notes<br />

PektaFlow® product description<br />

Extended <strong>nozzle</strong> tips, side gating<br />

Reference notes on a disassembly of a multi-tip <strong>nozzle</strong><br />

Valve-gate technology<br />

Commissioning of valve-gate system, operating pressure levels for drive mechanisms<br />

NEST single valve-gate <strong>nozzle</strong> assembly<br />

Drive mechanisms<br />

Notes on valve-gate needle / maintenance of the sliding cam mechanism<br />

<strong>Hot</strong> <strong>runner</strong> systems / manifolds<br />

Manifolds<br />

Heater connections, straight / frame version<br />

Structural notices for air circulation and high-temperature applications<br />

Screw fastenings for _MT/_TT <strong>nozzle</strong>s<br />

Manifold power calculation, correlation of cables<br />

Construction of the hot-<strong>runner</strong> system<br />

Complete mold halves “hot halves”<br />

Service program<br />

CADHOC System-Designer<br />

Delta tool calculation program, application database<br />

Online-catalog, MoldCae/Moldflow analyse<br />

Seminars for users and designers<br />

www.guenther-hot<strong>runner</strong>.com<br />

7/12 Subject to technical changes<br />

iT<br />

Page<br />

1.4. 2 + 3<br />

1.4. 4 + 5<br />

1.4. 6<br />

1.4. 7<br />

1.4. 10<br />

1.4. 10<br />

1.4. 11<br />

1.4. 11<br />

1.4. 12<br />

1.4. 20<br />

1.4. 20<br />

1.4. 21<br />

1.4. 21<br />

1.4. 30<br />

1.4. 31<br />

1.4. 32<br />

1.4. 33 + 34<br />

1.4. 35<br />

1.4. 35<br />

1.4. 36<br />

1.4. 37<br />

1.4. 40<br />

1.4. 41<br />

1.4. 42<br />

1.4. 43<br />

1.4. 50<br />

1.4. 51<br />

1.4. 52<br />

1.4. 53<br />

1.4. 54<br />

1.4. 55<br />

1.4. 56<br />

1.4. 60<br />

1.4. 61<br />

1.4. 62<br />

1.4. 63<br />

1.4. 1

Materials<br />

Reference values for maximum <strong>nozzle</strong> throughput per second<br />

Nozzle length: 50/ 100 mm<br />

120<br />

3<br />

Throughput in cm /s<br />

120<br />

3<br />

Throughput in cm /s<br />

3<br />

Throughput in cm /s<br />

Low viscosity material: e. g. PA, PS, PP<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

ø 4 mm<br />

Nozzle length 50 mm<br />

Nozzle length 100 mm<br />

www.guenther-hot<strong>runner</strong>.com<br />

7/12 Subject to technical changes<br />

ø 5 mm<br />

Medium viscosity material: e. g. ABS, PPO<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

ø 4 mm<br />

Nozzle length 50 mm<br />

Nozzle length 100 mm<br />

ø 5 mm<br />

ø 6 mm<br />

ø 6 mm<br />

High viscosity material: e. g. Polycarbonate, Bayblend, Polysulfon<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

ø 4 mm<br />

Nozzle length 50 mm<br />

Nozzle length 100 mm<br />

ø 5 mm<br />

ø 6 mm<br />

iT<br />

The specified throughputs are reference<br />

values. Considerable deviations<br />

for specific materials cannot<br />

be excluded. We will be glad to<br />

assist you with the selection of<br />

channel Ø.<br />

Additional applications which have<br />

already been implemented can be<br />

found in the application database on<br />

our website<br />

www.guenther-hot<strong>runner</strong>.com<br />

menu item: “Application Database”.<br />

1.4. 2

The specified throughputs are<br />

reference values. Considerable<br />

deviations for specific materials<br />

cannot be excluded. We will be glad<br />

to assist you with the selection of<br />

channel Ø.<br />

Additional applications which have<br />

already been implemented can be<br />

found in the application database on<br />

our website<br />

www.guenther-hot<strong>runner</strong>.com<br />

menu item: “Application Database”.<br />

1.4. 3<br />

iT<br />

3<br />

Throughput in cm /s<br />

Low viscosity material: e. g. PA, PS, PP<br />

2500<br />

2250<br />

2000<br />

1750<br />

1500<br />

1250<br />

1000<br />

750<br />

500<br />

250<br />

0<br />

Materials<br />

Reference values for maximum <strong>nozzle</strong> throughput per second<br />

Nozzle lengths: 60/ 100 mm<br />

3<br />

Throughput in cm /s<br />

3<br />

Throughput in cm /s<br />

ø 8 mm ø 10 mm ø 12 mm<br />

Nozzle length 60 mm<br />

Nozzle length 100 mm<br />

Medium viscosity: e. g. ABS, PPO<br />

2500<br />

2000<br />

1500<br />

1000<br />

500<br />

0<br />

ø 8 mm ø 10 mm ø 12 mm<br />

Nozzle length 60 mm<br />

Nozzle length 100 mm<br />

High viscosity material: e. g. Polycarbonate, Bayblend,<br />

Polysulphone<br />

500<br />

450<br />

400<br />

350<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

0<br />

ø 8 mm ø 10 mm ø 12 mm<br />

Nozzle length 60 mm<br />

Nozzle length 100 mm<br />

www.guenther-hot<strong>runner</strong>.com<br />

Subject to technical changes 7/12

Materials<br />

Determining the gate diameter for standard materials depending on<br />

the part weight<br />

Gate diameter<br />

Ø D mm<br />

Ø D mm<br />

Material: PC + ABS<br />

www.guenther-hot<strong>runner</strong>.com<br />

7/12 Subject to technical changes<br />

Article weight<br />

2.8<br />

2.4<br />

2.0<br />

1.6<br />

1.2<br />

0.8<br />

0.4<br />

0.1 1 3 5 8 10 100 1000<br />

Article weight g<br />

Material: PMMA<br />

2.8<br />

2.4<br />

2.0<br />

1.6<br />

1.2<br />

0.8<br />

0.4 0.1 1 3 5 8 10 100 1000<br />

Article weight g<br />

Ø D mm<br />

Ø D mm<br />

Material: PE<br />

Please note:<br />

All specified reference values for the<br />

gate diameter apply only to hot<br />

<strong>runner</strong> <strong>nozzle</strong>s with vertical gating.<br />

Gate diameter for fibre reinfor-ced<br />

materials<br />

The gate diameters for glass fibre<br />

reinforced materials or materials<br />

containing additives (flame retar-<br />

dants, heat stabilisers) 0.2 to 0.3 mm<br />

larger.<br />

The same applies to multi-tip <strong>nozzle</strong>s.<br />

Please contact us for all other types<br />

of gating.<br />

2.8<br />

2.4<br />

2.0<br />

1.6<br />

1.2<br />

0.8<br />

0.4<br />

0.1 1 3 5 8 10 100 1000<br />

Article weight g<br />

Material: POM, PA 6, ABS<br />

iT<br />

2.8<br />

2.4<br />

2.0<br />

1.6<br />

1.2<br />

0.8<br />

0.4<br />

0.1 1 3 5 8 10 100 1000<br />

Article weight g<br />

1.4. 4

Ø D mm<br />

Ø D mm<br />

Ø D mm<br />

Ø D mm<br />

Ø D mm<br />

2.8<br />

2.4<br />

2.0<br />

1.6<br />

1.2<br />

0.8<br />

0.4<br />

2.8<br />

2.4<br />

2.0<br />

1.6<br />

1.2<br />

0.8<br />

0.4<br />

2.8<br />

2.4<br />

2.0<br />

1.6<br />

1.2<br />

0.8<br />

0.4<br />

2.8<br />

2.4<br />

2.0<br />

1.6<br />

1.2<br />

0.8<br />

0.4<br />

2.8<br />

2.4<br />

2.0<br />

1.6<br />

1.2<br />

0.8<br />

0.4<br />

1.4. 5<br />

iT<br />

Material: PBT<br />

0.1 1 3 5 8 10 100 1000<br />

Article weight g<br />

Material: PS<br />

0.1 1 3 5 8 10 100 1000<br />

Article weight g<br />

Material: PPO<br />

0.1 1 3 5 8 10 100 1000<br />

Article weight g<br />

Material: PSU, PC<br />

0.1 1 3 5 8 10 100 1000<br />

Article weight g<br />

Material: LCP<br />

0.1 0,5 1 3 5 8 10 100 1000<br />

Article weight g<br />

Ø D mm<br />

Ø D mm<br />

Ø D mm<br />

Ø D mm<br />

2.8<br />

2.4<br />

2.0<br />

1.6<br />

1.2<br />

0.8<br />

0.4<br />

2.8<br />

2.4<br />

2.0<br />

1.6<br />

1.2<br />

0.8<br />

0.4<br />

2.8<br />

2.4<br />

2.0<br />

1.6<br />

1.2<br />

0.8<br />

0.4<br />

2.8<br />

2.4<br />

2.0<br />

1.6<br />

1.2<br />

0.8<br />

0.4<br />

Material: PA 6.6 (glas filled + 0.3 mm)<br />

Materials<br />

0.1 1 3 5 8 10 100 1000<br />

Article weight g<br />

Material: TPU, TPE<br />

0.1 1 3 5 8 10 100 1000<br />

Article weight g<br />

Material: SB, SAN<br />

0.1 1 3 5 8 10 100 1000<br />

Article weight g<br />

Material: PP<br />

0.1 1 3 5 8 10 100 1000<br />

Article weight g<br />

www.guenther-hot<strong>runner</strong>.com<br />

Subject to technical changes 7/12

Materials<br />

Material<br />

PP<br />

PE<br />

PS<br />

ABS<br />

SAN<br />

PA 6<br />

PA 6.6<br />

POM<br />

PC<br />

PMMA<br />

PBT<br />

ABS / PC<br />

LCP*<br />

PPS<br />

PEEK<br />

* depending on polymer-type<br />

Price / performance<br />

The performance pyramid<br />

High temperature resistant<br />

plastics<br />

(HDT > 150°C)<br />

Technical plastics<br />

(HDT = 100 - 150°C)<br />

Standardplastics<br />

www.guenther-hot<strong>runner</strong>.com<br />

7/12 Subject to technical changes<br />

Recommended<br />

processing temperature (°C)<br />

220 - 280<br />

220 - 280<br />

220 - 280<br />

220 - 250<br />

220 - 250<br />

240 - 250<br />

270 - 290<br />

205 - 215<br />

280 - 310<br />

220 - 250<br />

245 - 270<br />

260 - 270<br />

300 - 345<br />

310 - 340<br />

360 - 400<br />

COC<br />

PAR<br />

PI<br />

PES PEI<br />

PC<br />

PPO<br />

PSU<br />

PEK<br />

FP<br />

LCP PAI<br />

PPS<br />

PA 46 PPA<br />

PET<br />

PBT<br />

POM<br />

LFT<br />

SAN ABS PMMA PP<br />

PS<br />

PVC<br />

SAN<br />

PE-LD<br />

Recommended<br />

WZ-temperatur (°C)<br />

PA6.6<br />

20 - 60<br />

20 - 60<br />

20 - 70<br />

40 - 80<br />

40 - 80<br />

40 - 60<br />

40 - 80<br />

60 - 120<br />

80 - 120<br />

40 - 90<br />

60 - 80<br />

70 - 100<br />

80 - 120<br />

140 - 145<br />

140 - 180<br />

PE-HD<br />

amorphous semy-crystalline<br />

iT<br />

Processing window for common<br />

plastics<br />

Further information on selecting<br />

<strong>nozzle</strong>s depending on the material<br />

can be found in <strong>nozzle</strong> chapter 2.<br />

High temperature resistant<br />

plastics<br />

High temperature resistant plastics<br />

with processing temperatures<br />

>300°C:<br />

• Liquid Crystal Polymer (LCP)<br />

• Polyphenylene sulphide (PPS)<br />

• Polyetherketone /<br />

Polyetheretherketone<br />

(PEK/ PEEK)<br />

• Polysulphone (PSU)<br />

• Polyether-Imide (PEI) etc.<br />

1.4. 6

1.4. 7<br />

iT<br />

40°<br />

55°<br />

Fig.Tip geometry for polypropylene<br />

2,5...3,5<br />

ØD1<br />

ØD2<br />

Fig. Gate design A and hot-<strong>runner</strong> <strong>nozzle</strong> with<br />

<strong>nozzle</strong> piece version C<br />

ØD2<br />

ØD1<br />

Fig. Gate design version C and hot-<strong>runner</strong> <strong>nozzle</strong> with<br />

<strong>nozzle</strong> piece version A<br />

Materials<br />

Polyacetal (POM) and Thermo Plastic Elastomers (TPE)<br />

Gate design A<br />

When processing polyacetal (POM) and thermoplastic<br />

elastomers (TPE) with a hot <strong>runner</strong> <strong>nozzle</strong> with <strong>nozzle</strong><br />

piece, version C and the gate design A, a good injection<br />

gate quality should be attained. <strong>Hot</strong> <strong>runner</strong> <strong>nozzle</strong>s with<br />

<strong>nozzle</strong> piece, version C can be used for injection onto an<br />

intermediate gate and also for direct gating. In direct<br />

gating a higher residual sprue must be expected than<br />

when a <strong>nozzle</strong> with tip is used. The gate design A must<br />

be used for <strong>nozzle</strong>s with tip and for open <strong>nozzle</strong>s. It must<br />

be taken into account here that the injection gate<br />

diameter in gate bushing "D1" must be smaller than the<br />

diameter in the <strong>nozzle</strong> piece "D2”<br />

(D1 < D2). When a <strong>nozzle</strong> piece, version C is used, the<br />

shear in the melt in the area of the injection gate is lower<br />

than when a <strong>nozzle</strong> with tip is used.<br />

Shear-sensitive materials<br />

Gate design C<br />

Single <strong>nozzle</strong>s are mostly used when processing shearsensitive<br />

materials through an intermediate gate. The<br />

gate design C is exclusively used for open <strong>nozzle</strong>s with a<br />

<strong>nozzle</strong> piece, version A.<br />

It must be taken into account here that the injection gate<br />

diameter in the "D1" gate bushing must be larger than the<br />

diameter of the <strong>nozzle</strong> piece "D2" (D1 > D2).<br />

Parts made of Polypropylene (PP)<br />

<strong>Hot</strong> <strong>runner</strong> <strong>nozzle</strong>s with modified tip geometry should be<br />

used to process polypropylene. At a height of 2.5 to 3.5<br />

mm (depending on the <strong>nozzle</strong> type) the tip angle is<br />

reduced from 55° to 40°.<br />

This modified geometry must be ordered separately.<br />

www.guenther-hot<strong>runner</strong>.com<br />

Subject to technical changes 7/12

Gating<br />

Fig. Gate geometry<br />

H [mm]<br />

4,0<br />

3,5<br />

3,0<br />

2,5<br />

2,0<br />

d = 3 mm<br />

d<br />

80°<br />

ØD<br />

www.guenther-hot<strong>runner</strong>.com<br />

7/12 Subject to technical changes<br />

6,3<br />

H<br />

sharp-edged<br />

d = 4 mm<br />

1,0 1,5 2,0 2,5 3,0<br />

Fig. Inspecting the gate<br />

Fig. Reworking the gate<br />

Wrong<br />

Ø D [mm]<br />

iT<br />

Gating<br />

The hot <strong>runner</strong> <strong>nozzle</strong>’s function is<br />

essentially influenced by gate size<br />

diameter “D”.<br />

An enlargement of gate size must<br />

be done at an 80° angle. The edge<br />

must be sharp to achieve clean<br />

separation.<br />

Note:<br />

The most frequented faults on<br />

commissioning a mould are due to<br />

the incorrect design of the gate<br />

geometry.<br />

Inspecting the gate<br />

The correct position of the 80° angle<br />

is inspected with a measuring ball.<br />

Reworking the gate<br />

It is wrong to rework the gate by<br />

boring it out. The flow gap will not be<br />

substatially enlarged but the tear-off<br />

height on the part will become larger.<br />

1.4. 10

Fig. Nozzle installed in a retracted position<br />

Within the framework of permissible processing<br />

parameters, the smallest possible gate diameter means:<br />

small gate diameter<br />

Fig. Reducing the gate diameter<br />

Fig. Vacuoles under the gate<br />

1.4. 11<br />

iT<br />

ØD<br />

L + L + 0.02<br />

tool temperature<br />

processing temperature<br />

This is the point at<br />

which the material<br />

solidifies at last.<br />

Gating<br />

Reworking the gate<br />

With gate diameters smaller than<br />

ØD = 1.2 mm, the <strong>nozzle</strong> must<br />

beinstalled further back.<br />

You will find a Delta Tool calculation<br />

program on our homepage at<br />

www.guenther-hot<strong>runner</strong>.com<br />

available for download free of charge.<br />

Reducing the gate diameter<br />

The gate diameter cannot be<br />

arbitrarily reduced. The smallest<br />

permissible diameter is dependent<br />

on the material used.<br />

Furthermore, the gate size is also influenced<br />

by the mold temperature<br />

and processing temperature.<br />

Vacuoles under the gate<br />

Direct gating with a hot <strong>runner</strong> system<br />

can produce vacuoles under the<br />

gate.<br />

Remedy:<br />

Longer holding pressure time to<br />

compensate for shrinkage.<br />

Gate diameter for fibre reinforced<br />

materials<br />

The gate diameters for glass fibre<br />

reinforced materials or materials<br />

containing additives (flame retardants,<br />

heat stabilisers) 0.2 to 0.3 mm<br />

larger. The same applies to multi-tip<br />

<strong>nozzle</strong>s.<br />

www.guenther-hot<strong>runner</strong>.com<br />

Subject to technical changes 7/12

Gating<br />

0.5<br />

At 250°C the hot <strong>runner</strong> <strong>nozzle</strong> extends 0.5 mm into<br />

the part if the <strong>nozzle</strong> is installed to the nominal<br />

length.<br />

Fig. <strong>Hot</strong> <strong>runner</strong> <strong>nozzle</strong> installed correctly<br />

Potential error sources<br />

Problem:<br />

- Higher vestige<br />

- No flow gap despite a larger gate<br />

Fig. Cylindrical part at the gate<br />

Problem: - No sufficient insulation gap<br />

- Higher temperature needed<br />

- Great temperature fluctuations<br />

- Stringing<br />

Fig. The forechamber contour not produced correctly<br />

www.guenther-hot<strong>runner</strong>.com<br />

7/12 Subject to technical changes<br />

iT<br />

Problem:<br />

- The expanded <strong>nozzle</strong> closes the gate.<br />

Fig. Gate

Injection<br />

Fig. Injection into an intermediate gate<br />

www.guenther-hot<strong>runner</strong>.com<br />

7/12 Subject to technical changes<br />

ØD L<br />

Ød 1 mm > ØD<br />

˜<br />

Fig. Gating into an angled surface<br />

catch pits<br />

advantageous<br />

advantageous<br />

disadvantageous<br />

iT<br />

Correct injection into an intermediate<br />

gate<br />

In order to obtain defined separation,<br />

the aperture in the face surface of the<br />

intermediate gate Ød should be<br />

larger than ØD. This is particularly<br />

true for reinforced thermoplastics<br />

(engineering plastics).<br />

If possible, employ a catch pit in the<br />

intermediate gate.<br />

Gating into an angled surface<br />

Direct gating into an angled surface<br />

never results in an optimal gate point<br />

with a small vestige. We therefore<br />

recommend gating into a surface at<br />

right angle to the <strong>nozzle</strong> axis.<br />

1.4. 20

Tempering<br />

1.4. 21<br />

iT<br />

Fig. Reserve gating into a high gloss facing surface<br />

Fig. Parts with a film hinge<br />

Insert<br />

Film hinge<br />

Tempering<br />

Gating<br />

Reserve gating into a high gloss<br />

facing surface<br />

Sufficient cooling is recommended<br />

for the gate area, next to the <strong>nozzle</strong><br />

and on the ejector side to dissipate<br />

the heat additionally induced by<br />

shear.<br />

The cooling circuit control must be<br />

separated from the other tempering<br />

circuits.<br />

Articles with a film hinge<br />

When gating a part with a film hinge,<br />

the gating point must be located<br />

away from the surface center<br />

opposite to the film hinge. The flow<br />

front may not come to a standstill<br />

during the filling process.<br />

www.guenther-hot<strong>runner</strong>.com<br />

Subject to technical changes 7/12

<strong>Hot</strong> <strong>runner</strong> <strong>nozzle</strong><br />

±0.02<br />

Z<br />

Fig. Nozzle length at room temperature<br />

Standard<br />

90°<br />

Increased angle<br />

120°<br />

Attention!<br />

Provide for adequate<br />

wall thickness.<br />

Fig. Modification of forechamber geometry<br />

120°<br />

Fig. Employment from a titanium sleeve<br />

www.guenther-hot<strong>runner</strong>.com<br />

7/12 Subject to technical changes<br />

Insulation gap<br />

Insulation gap<br />

Titanium sleeve<br />

Insulation gap<br />

iT<br />

Nozzle length at room temperature<br />

Our <strong>nozzle</strong> length is made to the size<br />

that already provides for ist length<br />

change when heated to 250° C. The<br />

<strong>nozzle</strong> tip will then extend by 0.5 mm<br />

into the cavity contour. Dimension Z<br />

(as measured at room temperature)<br />

is equal to:<br />

Z = L + 0.5 - l (250°)<br />

l consequently depending on L<br />

itself.<br />

l is the temperature dependent<br />

longitudinal expansion of the<br />

hot <strong>runner</strong> <strong>nozzle</strong>.<br />

Modification of fore chamber<br />

geometry<br />

Fore chamber geometry can be<br />

modified for special applications or<br />

difficult-to-process materials (e. g.<br />

V0-adjusted materials).<br />

To avoid mistakes, we recommend<br />

that you consult with our<br />

application engineers.<br />

Enlarging the angle to 120°<br />

The standard angle of 90° in the forechamber<br />

can be widened to 120°.<br />

This will enlarge the insulation gap<br />

between the hot <strong>runner</strong> <strong>nozzle</strong> and<br />

the mold. The <strong>nozzle</strong> can be operated<br />

at a lower temperature so that<br />

thermally sensitive material will not<br />

be damaged.<br />

Using a titanium sleeve over the<br />

<strong>nozzle</strong> shaft in combination with<br />

an angle of 120 °.<br />

The insulation gap between the hot<br />

<strong>runner</strong> <strong>nozzle</strong> and the mold also<br />

becomes larger and the heat transfer<br />

to the cavity plate is reduced.<br />

1.4. 30

Thread<br />

designation<br />

Regular type<br />

screw threads<br />

M8<br />

M10<br />

1.4. 31<br />

iT<br />

Reference values for screw sizes<br />

The centering flange and screws of<br />

single <strong>nozzle</strong>s must absorb the<br />

emerging lift forces.<br />

Screws and centering flange are to<br />

be appropriately dimensioned and<br />

the pitch circle of the screws is to be<br />

kept as small as possible.<br />

Guide values for screw selection can<br />

taken from the table below. Tightening<br />

torque M A for producing the screw<br />

connection must afford sufficient<br />

pretensioning force F v so that the<br />

required initial tension is still present<br />

when under the influence of operating<br />

force (i. e. operating force of the hot<br />

<strong>runner</strong> <strong>nozzle</strong>).<br />

F should be a<br />

Pretensioning force v<br />

factor 2 to 4 greater than the anticipated<br />

operating force. Screws<br />

should be selected which are as<br />

long as possible.<br />

Tightening torque for hot <strong>runner</strong> <strong>nozzle</strong>s<br />

Pretension F v and tightening tor-que M A,<br />

for screws with head beaning surfaces per<br />

DIN EN ISO 4762 and 4014.<br />

Shaft screws ( µ ges. = 0.125)<br />

M12<br />

M16<br />

M20<br />

M24<br />

Maximum pretension F V in kN<br />

Property class<br />

F = force<br />

p = injection<br />

pressure<br />

A = area of the<br />

<strong>nozzle</strong>s shaft Ø<br />

Fine pitch<br />

thread<br />

M8x 1 26 31<br />

40<br />

M10x1,25 41 43<br />

77<br />

M12x1,5<br />

M16x1,5<br />

M20x1,5<br />

M24x2<br />

10.9 12.9<br />

24<br />

38<br />

56<br />

105<br />

165<br />

235<br />

59<br />

114<br />

188<br />

265<br />

28<br />

45<br />

65<br />

122<br />

190<br />

275<br />

69<br />

134<br />

220<br />

310<br />

Maximum tightening torque M in Nm<br />

A<br />

Property class<br />

37<br />

73<br />

125<br />

315<br />

615<br />

1050<br />

<strong>Hot</strong> <strong>runner</strong> <strong>nozzle</strong><br />

Example:<br />

<strong>Hot</strong> <strong>runner</strong> <strong>nozzle</strong>: 5SET50 ( ØS = 22 mm)<br />

Injection pressure: 2000 bar (200 N/ mm 2)<br />

Number of screws: 4<br />

Factor 2<br />

Lift force on the hot <strong>runner</strong> <strong>nozzle</strong>:<br />

p = F A<br />

A =<br />

F = p (N/ mm 2) • A ( mm 2)<br />

F = 200 N/ mm 2 • 380 mm2<br />

F = 76000 N<br />

F = 76000<br />

ges<br />

Pretension F v per screw:<br />

Fv =<br />

Fv =<br />

D 2 ( mm) • π<br />

4<br />

22 mm 2 • π<br />

A =<br />

4<br />

A = 380 mm 2<br />

N<br />

F ges ( N)<br />

Number of screws<br />

76000 N<br />

4<br />

F v = 38000 N per screw<br />

• factor<br />

• 2<br />

Chosen screws in consideration of factor 2.<br />

4 x M10 - 12.9 je 45 kN per scres<br />

10.9 12.9<br />

132<br />

340<br />

680<br />

1150<br />

43<br />

84<br />

148<br />

370<br />

700<br />

1250<br />

46<br />

90<br />

155<br />

390<br />

800<br />

1350<br />

www.guenther-hot<strong>runner</strong>.com<br />

Subject to technical changes 7/12

<strong>Hot</strong> <strong>runner</strong> <strong>nozzle</strong><br />

Standard<br />

Fixed connections<br />

Thermocouple ype L (FeCuNi)<br />

Standard<br />

Pluggable connections<br />

Thermocouple Type L (FeCuNi)<br />

* Volt Alternating Current<br />

Fig. Designation / correlation of cables<br />

www.guenther-hot<strong>runner</strong>.com<br />

7/12 Subject to technical changes<br />

CMLK<br />

Thermoplug<br />

CMT, 230 VAC*<br />

Power receptacle<br />

PE = earthed lead yellow-green<br />

N = neutral lead orange<br />

L = line lead black<br />

Blue = Minus<br />

PE = earthed lead bare wire<br />

Red = Plus<br />

iT<br />

PE = earthed lead yellow-green<br />

N = neutral lead blue<br />

L = ine lead brown<br />

Red = Plus<br />

PE = earthed lead bare wire<br />

Blue = Minus<br />

1.4. 32

BlueFlow® Fixed<br />

connections<br />

BlueFlow®<br />

min. 10 mm<br />

Power and thermo<br />

connection up to 10 mm<br />

bent only once in this area.<br />

Minimum bending radius R8.<br />

® P<br />

BlueFlow luggable connections<br />

Fig. Designation / correlation of cables<br />

1.4. 33<br />

iT<br />

Thickfilm heaters for hot-<strong>runner</strong><br />

<strong>nozzle</strong>s<br />

BlueFlow<strong>Günther</strong>'s new BlueFlow ®<br />

technology incorporates several<br />

advantages as compared to<br />

conventional heating methods: the<br />

heating elements are not only<br />

considerably smaller in diameter,<br />

they also allow a substantially better<br />

temperature distribution and<br />

accordingly, a quicker thermal<br />

response.<br />

CMT 230 VAC*<br />

Power receptacle<br />

Fig. <strong>Hot</strong> <strong>runner</strong> <strong>nozzle</strong> heater<br />

CMLK Thermocouple<br />

22 mm<br />

Further outstanding features are<br />

their high electric strength and<br />

resistance to moisture. All in all,<br />

these four features are important<br />

steps taken towards a more spacesaving,<br />

precise and energy-efficient<br />

hot <strong>runner</strong> design and, therefore, a<br />

more effective injection molding<br />

process.<br />

PE=earthed lead yellow-green<br />

N = neutral lead blue<br />

L = line lead brown<br />

Blue = Minus<br />

PE = earthed lead yellow-green<br />

Red = Plus<br />

L=line lead brown<br />

N=neutral lead blue<br />

Blue = Minus<br />

PE=arthed lead yellow-green<br />

PE=earthed lead bare wire<br />

Red = Plus<br />

Brass body with pressed-in heater BlueFlow® <strong>Hot</strong> <strong>runner</strong> <strong>nozzle</strong><br />

<strong>Hot</strong> <strong>runner</strong> <strong>nozzle</strong><br />

<strong>Hot</strong> <strong>runner</strong> <strong>nozzle</strong> heater<br />

Heater are pressed into a brass<br />

body. The heater is fixed in place by<br />

the mechanical structure of the<br />

carrier body. The homogeneous<br />

brass body ensures optimal heat<br />

transfer from the heater to the<br />

material tube, showing a highly<br />

reproducible temperature pattern.<br />

Thermocouple Type L (FeCuNi)<br />

* Volt Alternating Current<br />

18 mm<br />

www.guenther-hot<strong>runner</strong>.com<br />

Subject to technical changes 7/12

<strong>Hot</strong> <strong>runner</strong> <strong>nozzle</strong><br />

High Quality. Blue. BlueFlow®<br />

The BlueFlow® hot <strong>runner</strong> <strong>nozzle</strong><br />

sets new standards for quality and<br />

design of parts made of thermally<br />

sensitive plastics. This re-sults in<br />

better or even completely new<br />

application possibilities, depending<br />

on the application area in different<br />

sectors of industry.<br />

The thick film heater makes it<br />

possible to adjust the heating capacity<br />

to the exact power requirement<br />

in each single section over the<br />

entire <strong>nozzle</strong> length in order to reach<br />

a homogenous temperature.<br />

The plastic material in the material<br />

tube is hardly exposed to thermal<br />

stress, which means that the<br />

physical properties of the end<br />

product are obtainable even with<br />

thermally sensitive plastics and very<br />

small parts.<br />

www.guenther-hot<strong>runner</strong>.com<br />

7/12 Subject to technical changes<br />

FIg. Microfilter<br />

iT<br />

Example: Microfilter (automotive<br />

sector)<br />

Microfilter (outlet valve for an<br />

automotive application), injectionmolded<br />

in one process step from<br />

unreinforced PA66. This method has<br />

replaced the earlier procedure of<br />

insert-molding of an available metal<br />

or plastic mesh to obtain a ready-toinstall<br />

component. The resulting<br />

savings are dramatic: costs have<br />

decreased by 60-80%, depending<br />

on the product.<br />

Details: thread size 0.13;<br />

1848 gaps with 0.07 x 0.07 mm. 2<br />

Passage surface approx. 9 mm .<br />

Max. allowed flash is 4.5 µm.<br />

1.4. 34

1.4. 35<br />

iT<br />

Assembly of the star manifold<br />

Insert the star manifold and use 4<br />

hexagon socket head cap screws<br />

M3x12 to fasten it to the sleeve-type<br />

heating.<br />

®<br />

<strong>Hot</strong>-<strong>runner</strong> <strong>nozzle</strong> OktaFlow<br />

for side multi-tip gatin under 90°<br />

without cold slug, in connection with a<br />

manifold or can be used as a single<br />

<strong>nozzle</strong> with heated adaptor.)<br />

Assembly of support<br />

Insert the support and mount the lid<br />

from the parting line. Note: the lid<br />

must be solidly bonded to the insert.<br />

<strong>Hot</strong>-<strong>runner</strong> <strong>nozzle</strong> PektaFlow®<br />

Number of tips: up to 24 tips, for side<br />

multi-tip gating under 90° without cold<br />

slug.<br />

Be used as a single <strong>nozzle</strong> with<br />

heated adaptor.<br />

<strong>Hot</strong>-<strong>runner</strong> <strong>nozzle</strong> PektaFlow® type<br />

PLT are designed for challenging<br />

applications e.g. in medical technology<br />

and packaging.<br />

• Direct injection onto the product<br />

• Divided inserts<br />

• Tips individually replaceable<br />

• Leading-edge area heated for optimum<br />

temperature development<br />

• Supported on floating bearings and<br />

therefore independent of the ther<br />

mal expansions<br />

<strong>Hot</strong> <strong>runner</strong> <strong>nozzle</strong><br />

Assembly of the hot-<strong>runner</strong> <strong>nozzle</strong><br />

Push the hot-<strong>runner</strong> <strong>nozzle</strong> (MT) in<br />

from the <strong>nozzle</strong> side!<br />

www.guenther-hot<strong>runner</strong>.com<br />

Subject to technical changes 7/12

<strong>Hot</strong> <strong>runner</strong> <strong>nozzle</strong><br />

Without extended <strong>nozzle</strong> tip With extended <strong>nozzle</strong> tip<br />

L +0.02<br />

L1 +0.02<br />

L1 +0.02<br />

Shimmed Inserted<br />

Shim<br />

7/12 Subject to technical changes<br />

+0.02<br />

L1<br />

Fig. Use of <strong>nozzle</strong> with extended tip<br />

Fig. Side gating under 90° without a “cold slug”<br />

www.guenther-hot<strong>runner</strong>.com<br />

+0.02<br />

L1<br />

Nozzle holding plate<br />

Cavity plate<br />

Nozzle<br />

holding plate<br />

Cavity plate<br />

iT<br />

Extended <strong>nozzle</strong> tips in<br />

connection with the material<br />

It is often necessary to use several<br />

different <strong>nozzle</strong> lengths when gating<br />

a part. Extended <strong>nozzle</strong> tips allow<br />

sprueless molding of parts even in<br />

space constrained environments.<br />

Side gating<br />

Under 90° without a ”cold slug” in<br />

combination with a manifold. Gating<br />

should always be against the core.<br />

Always specify the material to be<br />

processed and the part weight when<br />

making inqiries. Also specify whether<br />

a part is to be gated with several tips,<br />

or if several parts are to be molded.<br />

Note:<br />

Slide out the inserts only horizontally!<br />

1.4. 36

1.4. 37<br />

iT<br />

Fig. Disassembly of a multi-tip <strong>nozzle</strong><br />

<strong>Hot</strong> <strong>runner</strong> <strong>nozzle</strong><br />

Reference notes on disassembly of a multi-tip<br />

<strong>nozzle</strong><br />

To avoid damaging <strong>nozzle</strong> tips, we suggest a mechanical<br />

construction which imposes a change in the way the<br />

<strong>nozzle</strong> is disassembled :<br />

1. Loosen the wedge and the counter-pressure insert.<br />

2. Push out the divided form inserts to the right and left<br />

over the <strong>nozzle</strong> tips to their limits.<br />

3. Now pull out the form inserts downwards in the direction<br />

of the cavity.<br />

4. Loosen the screw fastening for the suppressor and<br />

remove it<br />

5. Now the <strong>nozzle</strong> can be taken up-wards.<br />

What should be observed in the construction phase:<br />

1 To prevent jetting, inject against a core, for example.<br />

2. The shear edge must amount to at least the injection<br />

gate diameter + 0.2 mm (see drawing).<br />

3. There should not be any draft angle in the injection<br />

gate area (see drawing).<br />

www.guenther-hot<strong>runner</strong>.com<br />

Subject to technical changes 7/12

Valve gate technology<br />

Fig. Valve gate system<br />

Commissioning<br />

• Before heating the <strong>nozzle</strong>s and the manifold, switch on<br />

the mould temperature control.<br />

Heating the hot <strong>runner</strong> system:<br />

• With the soft-start function the manifold is heated to about<br />

100°C and held at this temperature for approximately 10<br />

minutes.<br />

• The <strong>nozzle</strong>s and manifold must be heated evenly (ramp<br />

function). In any case, it is essential to prevent the <strong>nozzle</strong>s<br />

reaching the processing temperature before the manifold<br />

does. Heating the manifold to the required temperature<br />

can take up to 20 minutes depending on the size and<br />

circumstances.<br />

• Only when the hot <strong>runner</strong> system has reached<br />

production temperature, may the needle mechanism<br />

be put into operation, whereby it must be ensured too<br />

that the plastic is in molten form in the needle guide area. It<br />

might be necessary to extend the heating time for the <strong>nozzle</strong><br />

by 5… 10 minutes.<br />

• With putting into operation for the first time, several injections<br />

may be necessary to fill the hot <strong>runner</strong> completely with<br />

plastic.<br />

Until all parts are filled completely, the cavities must be<br />

checked after every cycle for parts that have not been<br />

filled completely.<br />

Dwell time:<br />

To keep the thermal damage to the melt as low as possible,<br />

the idle time at production temperature should be adapted to<br />

the sensitivity of the material. As a rule, the dwell time can be<br />

up to 10 minutes depending on the type of plastic.<br />

Interruption in production<br />

When a process is interrupted, the hot <strong>runner</strong> temperature<br />

must be lowered (depending on the material and down-time<br />

by 100… 150K). The needles must be in the “closed” position.<br />

Make sure the process temperature is reached again before<br />

activating the needles again.<br />

www.guenther-hot<strong>runner</strong>.com<br />

7/12 Subject to technical changes<br />

Connection values<br />

Electric<br />

Voltage 230 V~<br />

* If special <strong>nozzle</strong>s or other components with a pressure limit (less<br />

than 2000 bar) are fitted to systems or individual tools, this situation<br />

is documented in the height adjustment and on the type plate.<br />

Hydraulic<br />

Single valve- gate <strong>nozzle</strong><br />

Lifting plate mechanism<br />

Sliding cam mechanism<br />

Pneumatic<br />

max. permissible operating<br />

pressure in the hot-<strong>runner</strong> system<br />

Single valve gate <strong>nozzle</strong><br />

Single needle valve<br />

Lifting plate mechanism<br />

Sliding cam mechanism<br />

iT<br />

Set-up operation<br />

To prevent damage to the gate bores/valve needles from cold<br />

material in the needle guide, the valve needles may not be<br />

activated while the injection moulding machine is being set up<br />

or during the flushing-out process. If the melt is to be ejected<br />

through the open mould / hot <strong>runner</strong>, the needles must be<br />

opened during the injecting-through process and closed<br />

during the dosing phase.<br />

Switching off the hot <strong>runner</strong><br />

When the hot <strong>runner</strong> system is being turned off, all control<br />

circuits can be turned off at the same time. To prevent the hot<br />

<strong>runner</strong> system being damaged by the build-up of heat, let the<br />

mould cooling run on at about 30°C for another 30 min.<br />

approximately.<br />

The valve gates should be in the “closed” position for this.<br />

Before starting disassembly, make sure the hot <strong>runner</strong> is<br />

switched off. To prevent damage to the needle guide/needle,<br />

the needles must be in the “open” position. Before putting the<br />

system into operation again, make sure the needles are in the<br />

“closed” position again.<br />

Needle actuation<br />

• To reach a high needle speed, the valve for actuation<br />

(hydraulics pneumatics) must be designed to be as lare<br />

as possible.<br />

• The connection tube dimensioning must be designed to<br />

suit the flow rate.<br />

• The distance between the pressure generation and<br />

pressureconsumption (mould) should be as little as<br />

possible. (Needle closing time 20-40 ms/7-10 mm travel)<br />

Note!<br />

The first filling of the hydraulic cylinders should be done at a<br />

low speed or the cylinders should be vented.<br />

System *<br />

max. permissible operating<br />

pressure in the hot-<strong>runner</strong> system 2000 bar<br />

40<br />

40-60<br />

40-60<br />

8-10<br />

8-10<br />

8-10<br />

8-10<br />

8-10<br />

bar<br />

bar<br />

bar<br />

bar<br />

bar<br />

bar<br />

bar<br />

bar<br />

1.4. 40

1.4. 41<br />

iT<br />

Insulation ring<br />

Fixed<br />

power connection<br />

Fixed<br />

thermo connection<br />

* Power receptacle CMT<br />

* Thermoplug CMLK<br />

* 5-6NEST = pluggable connection<br />

* 8-12NEST1 = fixed connection<br />

Fig. Single valve-gate <strong>nozzle</strong> 12NEST1<br />

Needle closing<br />

Needle opening<br />

There are three 0.1-mm shims over / under the needle<br />

head.<br />

Caution! When assembling / dismantling the needle<br />

holder (A/F 10), care must be taken not to deform the<br />

steel piston rings. Use the flat of the piston! It is essential<br />

to put the metal O ring back in after replacing the disk<br />

package. The piston and/or the steel piston rings must be<br />

greased again before assembly (GÜNTHER recommends<br />

Klüber paste UH 196-402 [NSF registered]).<br />

Furthermore, it is essential to ensure that the steel piston<br />

rings have been inserted correctly. The rings have a<br />

marking (XXX) on the face surface, indicating the side<br />

that must point towards the pressurised side.<br />

Installation of the complete <strong>nozzle</strong><br />

The cables for activating the needles are located at the<br />

bottom of the <strong>nozzle</strong>. Accordingly the centring ring can be<br />

produced as a “bell”. This measure makes it possible to<br />

reduce the height of the mould.<br />

Screw centring with at least 6x M10 (12.9) screws, with<br />

due consideration to lift forces. For an optimum thermal<br />

separation between the <strong>nozzle</strong> and the mould, use the<br />

(blue) insulation ring.<br />

Caution: Grind in the K dimension in compliance with the<br />

data in the chapter. 2.3 yellow page.<br />

Valve gate technology<br />

Steel piston ring, large<br />

Marking XXX<br />

Steel piston ring, small<br />

Marking XXX<br />

Inlet/ outlet pipes for activating the needle<br />

It is preferable to use channels with diameters of 6 mm<br />

and a minimum length of 200 mm. The inlet and outlet<br />

lines must be placed in the cooled mould plate in order to<br />

prevent the medium overheating. If the mould<br />

temperatures exceed the thermal stress capability of the<br />

pneumatic valves, a separately cooled manifold must be<br />

installed. The mechanics of the needle drive and the<br />

valve gate <strong>nozzle</strong> are absolutely capable of withstanding<br />

high temperatures.<br />

Note on guarantee<br />

GÜNTHER guarantees <strong>nozzle</strong> type NEST1 only if they<br />

have been fitted or serviced on GÜNTHER premises or<br />

by a GÜNTHER specialist. GÜNTHER will not provide<br />

any guarantee for damage caused by the incorrect fitting<br />

of the steel piston ring operated <strong>nozzle</strong> type NEST by<br />

the pur-chaser, its representatives or contractors.<br />

The same applies to inappropriate or neglected maintenance.<br />

www.guenther-hot<strong>runner</strong>.com<br />

Subject to technical changes 7/12

Valve gate technology<br />

Lifting plate mechanism ANEH<br />

The lifting mechanism is recommendable for a precisely<br />

simultaneous opening and closing of all needles.<br />

Special holes in the mould clamping plate allow the<br />

down-stroke depth of the valve needles to be adjusted<br />

individually from the outside.<br />

The maximum working temperature is 100° C.<br />

www.guenther-hot<strong>runner</strong>.com<br />

7/12 Subject to technical changes<br />

Electromagnet ME 10/UV75<br />

The ME 10 bistable heavy-duty lifting magnet serves<br />

to actuate the valve gate needles in valve gate<br />

systems.<br />

Excellent for fully electric injection moulding machines<br />

and for clean room use.<br />

Single needle valve ENV<br />

Needle actuation in single and multiple systems.<br />

Sequential opening and closing of the needles.<br />

Special holes in the mould clamping plate allow the<br />

down-stroke depth of the valve gate to be adjusted<br />

individually from the outside.<br />

Maximum working temperature is 100° C.<br />

Pay attention to the balancing of the oil feed and oil<br />

outlet ducts as well as of the air feed and air outlet ducts.<br />

Note on guarantee<br />

GÜNTHER guarantees single needle valves only if they have been fitted or serviced on GÜNTHER premises or by a<br />

GÜNTHER specialist. GÜNTHER will not provide any guarantee for damage caused by the incorrect fitting of the O-rings<br />

in hydraulically/pneumatically operated single needle valves by the purchaser, its representatives or contractors.<br />

The same applies to inappropriate or neglected maintenance.<br />

Note: See operating instructions for details.<br />

Sliding cam mechanism ANES<br />

iT<br />

For narrow cavity spacing a sliding cam mechanism is the<br />

preferred drive.<br />

Exact opening and closing of all needles.<br />

Special holes in the mould clamping plate allow the<br />

down-stroke depth of the valve gate to be adjusted<br />

individually from the outside.<br />

Maximum working temperature is 100° C.<br />

1.4. 42

1.4. 43<br />

iT<br />

Notes on valve needles<br />

The needle length is dependent on the <strong>nozzle</strong> length,<br />

type of actuation and manifold structure. The needles<br />

have a basic hardness of 64 HRC (HSS steel) and are<br />

coated. The needles are fitted with a cylindrical seal<br />

towards the cavity and are adjustable.<br />

The 2 mm Ø needle design for <strong>nozzle</strong>s with material<br />

tube-Ø 4 mm, threads M6x 0,5<br />

gate-Ø: 0,8 mm, 1,0 m, 1,2 mm, 1,4 mm, (1,6 mm).<br />

The 3 mm Ø needle design for <strong>nozzle</strong>s with material<br />

tube- Ø 5, 6 mm, threads M8 x 0,5<br />

gate Ø: 0,8mm, 1,0 mm, 1,2 mm, 1,4 mm.<br />

The 3 mm Ø needle design for <strong>nozzle</strong>s with material<br />

tube- Ø 8 mm, threads M8 x 0,5<br />

gate Ø: 2,0 mm, 2,5 mm.<br />

The 5 mm Ø needle design for <strong>nozzle</strong>s with material<br />

tube- Ø 10-12 mm, threads M10 x 0,75<br />

gate- Ø: 3,0 mm, 4,0 mm.<br />

Tools to disassembling the needle guide (piece of PM),<br />

see chapter 7.<br />

Thread tightening torque for needle adjustment<br />

Needle Ø Thread Tightening torque<br />

M A [Nm]<br />

Ø 2 mm M6 x 0,50 15<br />

Ø 3 mm M8 x 0,50 30<br />

Ø 5 mm M10 x 0,75 45<br />

Typ NEP<br />

Typ NHP<br />

Maintenance<br />

Fig.<br />

Sliding cam mechanism<br />

with externally accessible<br />

grease fittings<br />

Valve gate technology<br />

Sliding cam mechanismus -ANES-<br />

When fitting the sliding cam mechanism, use a hightemperature<br />

long-life grease to lubricate the movable<br />

parts. This allows the sliding cam mechanism to work<br />

without any problems even at higher temperatures over a<br />

long period of time. Make sure the mould temperature<br />

does not exceed 100° C in the area of the frame plate/<br />

clamping plate.<br />

During maintenance the sliding cam mechanism must be<br />

checked for dirt and wear. Melts that have exuded from<br />

the manifold sealing because of the stroke movement of<br />

the needles must be removed. In older hot-<strong>runner</strong><br />

systems the sliding cam mechanism can be relubricated<br />

through the ball impact holes (DIN 3410 Form F); in new<br />

systems the sliding cam mechanism can be relubricated<br />

without disassembly.<br />

Fig.<br />

Ball impact holes<br />

To ensure optimal greasing performance also at higher<br />

temperatures, avoid using different greases. We<br />

recommend the lubricating grease from Klueber<br />

Barrierta L55/2 high temperature long-life grease. The<br />

lubricating grease can be purchased either directly from<br />

the manufacturer or from us. Safety data sheets can be<br />

called up at www.klueber.com.<br />

Introduction: Lubrication after 150.000 shots or<br />

1x weekly.<br />

Maintainance work (cleaning) must be done on the<br />

needle-driving mechanisms every 400.000 shots!<br />

This frequency depends greatly on the material to be<br />

processed or the application. If a thermoplastic<br />

elastomer (TPE) is being processed, it may be necessary<br />

to do maintenance work on the sliding cam after just<br />

approximately 200.000 shots. This also concerns<br />

polymers, in which the viscosity is greatly reduced by the<br />

shearing.<br />

www.guenther-hot<strong>runner</strong>.com<br />

Subject to technical changes 7/12

<strong>Hot</strong> <strong>runner</strong> systems / manifolds<br />

www.guenther-hot<strong>runner</strong>.com<br />

7/12 Subject to technical changes<br />

V2<br />

iT<br />

Sign up at<br />

www.guenther-hot<strong>runner</strong>.com to start configuring your<br />

individual hot <strong>runner</strong> system with CADHOC V2 System<br />

Designer.<br />

You will save time and cut costs by having detailed<br />

information at an early phase of your project.<br />

<strong>Hot</strong> half on the basis of the<br />

•<br />

•<br />

•<br />

8-cavity H manifold“<br />

2-cavity straight manifold" and<br />

4-cavity cross manifold"<br />

For mould size up 196x296 mm to 796x996 mm<br />

(depending on the manifold size and manifold design).<br />

<strong>Hot</strong> half as 2-plate system, incl. guide elements, cable<br />

duct, cooling etc.<br />

All system <strong>nozzle</strong>s with a tip and an open <strong>nozzle</strong> piece<br />

can be used (Catalogue Chapter 2.1).<br />

Valve-gate systems with<br />

single needle valves for “individual” types of manifold.<br />

• Straight manifold 1-cavity, 2-cavity und 4-cavity<br />

• H manifold 4-cavity and 8-cavity,<br />

• T manifold 2-cavity and<br />

• Cross manifold 4-cavity<br />

with <strong>nozzle</strong>s from our valve gate portfolio.<br />

Catalogue Chapter 2.3).<br />

1.4. 50

1.4. 51<br />

iT<br />

View straight/frame version<br />

Fig. View: straight version<br />

Fig. View: f rame version<br />

<strong>Hot</strong> <strong>runner</strong> systems / manifolds<br />

Position of power connections<br />

Note:<br />

• Nozzles should always be surrounded by heater loops.<br />

• Heater lines should be routed mirror-inverted (cold<br />

ends of the tube heaters compensate for one another).<br />

• When possible, reserve an area for connectors where<br />

no material-carrying bore holes are located.<br />

• For high temperature applications > 320°C external<br />

connectors are appropriate.<br />

Fig. Internal heater<br />

connections<br />

Fig. Cable channel<br />

Not recommended<br />

Fig. External heater<br />

connections<br />

Frame plate / rail<br />

Edges absolutely burr-free<br />

Supporting plate /<br />

cavity plate<br />

Recommended<br />

Fig. Cable channel Fig. Cable channel<br />

www.guenther-hot<strong>runner</strong>.com<br />

Subject to technical changes 7/12

<strong>Hot</strong> <strong>runner</strong> systems / manifolds<br />

Air circulation<br />

Fig. Optimal air circulation<br />

Connector housing<br />

On account of heat convection, do<br />

not mount the connector housing<br />

onto the mould directly.<br />

We recommend the use of sufficiently<br />

long spacer bolts.<br />

High temperature application<br />

Special hot <strong>runner</strong> design is necessary<br />

for plastics with processing<br />

temperatures over 320°C. This includes<br />

full insulation, external heater<br />

connectors and high tempe-rature<br />

resistant thermo-couples.<br />

In the <strong>nozzle</strong> area it requires a fixed,<br />

high temperature resistant thermocouple<br />

connection, a hard metal tip<br />

(for reinforced polymers) as well as a<br />

high temperature pro-tective sleeve<br />

for cables.<br />

www.guenther-hot<strong>runner</strong>.com<br />

7/12 Subject to technical changes<br />

Clamping plate<br />

Insulating plate<br />

Frame structure<br />

Fig. Manifold for high temperature application<br />

Attachment<br />

:<br />

housing<br />

Manifold<br />

Fig. Cross section of a mold - optimal air circulation<br />

iT<br />

Distance bolts<br />

1.4. 52

Note:<br />

1.4. 53<br />

iT<br />

Fig. Screw fastenings for _MT/_TT <strong>nozzle</strong>s<br />

Titanium washer<br />

Screw M6,<br />

M8, M10, (12.9)<br />

depending on<br />

manifold design<br />

Nozzle type<br />

_MT, _TT<br />

<strong>Hot</strong> <strong>runner</strong> <strong>nozzle</strong>s of the _MT/_TT type are not screwfastened<br />

to the manifold. The system is started with coldstate<br />

play. Please refer to the respective heat expansion<br />

table. In its cold state, the hot <strong>runner</strong> system has no<br />

positive seal between <strong>nozzle</strong>s and manifold. Operating<br />

temperature must first be reached in order to seal the<br />

system. Please provide for adequate screw fixation of<br />

the clamping plate towards the cavity plate close enough<br />

to the manifold with at least 2x M10 per <strong>nozzle</strong> or, based<br />

on the length, 2x M10 per every 80 mm. We recommend<br />

connecting with screws of the 12.9 property class.<br />

Please use a pry bar or a <strong>nozzle</strong> extractor tool to<br />

professionally disassemble the <strong>nozzle</strong> from the gate<br />

bushing and/or cavity plate. See chapter 8.<br />

<strong>Hot</strong> <strong>runner</strong> systems / manifolds<br />

Fig. Manifold with _TT <strong>nozzle</strong> type,<br />

screwed to the<br />

parting line<br />

Advantages:<br />

• For high number of cavities and tight pitch spacing.<br />

• Easy front mounting of the <strong>nozzle</strong>s -<br />

the mold can remain on the machine for maintenance.<br />

• Two fits provide a precise positioning to the pitch<br />

distance.<br />

• Safety due to spatial and thermal separation of the<br />

connecting cable from the manifold.<br />

• Protection against leakage by sealing the manifold<br />

from the cable channels om the cable channels.<br />

www.guenther-hot<strong>runner</strong>.com<br />

Subject to technical changes 7/12

<strong>Hot</strong> <strong>runner</strong> systems / manifolds<br />

Manifold power calculation (230 V)<br />

Power Voltage Current Approximate resistance<br />

Watt Volt A<br />

values to be measured in<br />

Ohm [S]<br />

2300<br />

3680<br />

1500<br />

1400<br />

1100<br />

1000<br />

750<br />

500<br />

630<br />

500<br />

400<br />

250<br />

600 (max.)<br />

600 (max.)<br />

P = U • I<br />

R = U/I<br />

P = U 2 / R<br />

Thermocouple<br />

cable<br />

Red = plus<br />

Blue = minus<br />

www.guenther-hot<strong>runner</strong>.com<br />

7/12 Subject to technical changes<br />

230<br />

230<br />

230<br />

230<br />

230<br />

230<br />

230<br />

230<br />

230<br />

230<br />

230<br />

230<br />

5<br />

24<br />

PE earthed lead<br />

Fig. Manifold - correlation of cables<br />

Example:<br />

P = (230 V) 2 / 23 Ohm<br />

P = 2300 W<br />

10<br />

16<br />

6.5<br />

6.1<br />

4.8<br />

4.4<br />

3.3<br />

2.8<br />

2.2<br />

1.8<br />

1.4<br />

1.1<br />

125 (max.)<br />

25 (max.)<br />

23.0<br />

14.375<br />

35.4<br />

37.7<br />

47.9<br />

52.3<br />

69.1<br />

82.1<br />

104.5<br />

127.8<br />

164.3<br />

209.1<br />

0.1 - 0.2<br />

0.2 - 0.4<br />

Alternating current 230 V<br />

iT<br />

1.4. 54

Assembly of the manifold<br />

1.4. 55<br />

iT<br />

Signs and symbols:<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

23<br />

24<br />

22<br />

21<br />

20<br />

25<br />

Surface mounted thermocouple, chap. 7<br />

Bores in the clamping plate<br />

to fix the <strong>nozzle</strong><br />

26 27<br />

PE-ground cable connection, chap. 7<br />

Connection elements, chap. 6<br />

Pressure pads, chap. 8<br />

Clamping plate<br />

Manifold, chap. 4<br />

Nozzle holding plate<br />

Cable channel<br />

19<br />

Air circulation above and below depending<br />

on the position of the mould<br />

STT SHT<br />

NMT NHF<br />

18<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

17<br />

18<br />

19<br />

20<br />

1 2 3 4<br />

5<br />

17<br />

Nozzle length, chap.2 + 3<br />

Nozzle protrusion<br />

<strong>Hot</strong> <strong>runner</strong> systems / manifolds<br />

16<br />

Cylindrical pin to prevent twisting,<br />

chap. 4.1<br />

<strong>Hot</strong> <strong>runner</strong> <strong>nozzle</strong>, chap. 2 + 3<br />

Height temperature insulating plate, optional<br />

Support piece, chap. 8<br />

Gate bushing, chap. 2.2 + 3.2<br />

Tempering<br />

Cavity plate<br />

Height of the <strong>nozzle</strong> head<br />

A B C<br />

Needle adjustment from outside Protected heating conductor<br />

connection in the manifold<br />

B<br />

C<br />

15<br />

21<br />

22<br />

23<br />

24<br />

25<br />

26<br />

27<br />

Needle guide and sealing<br />

in the manifold<br />

A<br />

14<br />

13<br />

Manifold height<br />

19<br />

12<br />

Recess for the hot <strong>runner</strong> system in the tool<br />

www.guenther-hot<strong>runner</strong>.com<br />

Subject to technical changes 7/12<br />

7<br />

8<br />

9<br />

10<br />

11<br />

Installation height of the hot<strong>runner</strong> without<br />

pressure pad<br />

Heat expansion gap dimension K, chap. 4.1<br />

Pressure pad height<br />

Protection against leakage:<br />

The manifold area is sealed off from the<br />

cable ducts<br />

Melt direction element<br />

6

<strong>Hot</strong> <strong>runner</strong> systems / manifolds<br />

Complete “<strong>Hot</strong> Halves”<br />

The hot half is delivered as a <strong>nozzle</strong>side<br />

mold half without cavity plates.<br />

The <strong>nozzle</strong> overhang over the supporting<br />

plate can be set individually.<br />

The height-matched hot <strong>runner</strong> is<br />

completely wired and functionally<br />

tested. This ready-to-install solution<br />

eliminates extensive design matching<br />

work and possible installation errors.<br />

Prior to delivery, hot halves are<br />

subjected to a functional test which is<br />

documented according to DIN EN<br />

ISO 9001:2000.<br />

Complete “<strong>Hot</strong> Halves” normally<br />

guarantee a smooth production<br />

start-up.<br />

Fig. Complete mold half “<strong>Hot</strong> Half”, valve gate system<br />

www.guenther-hot<strong>runner</strong>.com<br />

7/12 Subject to technical changes<br />

Fig. Cross section of a mold<br />

iT<br />

1.4. 56

Service program<br />

Our comprehensive program of services<br />

is meant to provide you with the<br />

service you need, from consul-tation<br />

and layout for hot <strong>runner</strong> systems to<br />

practice-oriented seminars for users<br />

and designers.<br />

On the GÜNTHER website you will<br />

find many tools and programs to<br />

make your work easier.<br />

You can now configure your hot<br />

<strong>runner</strong> system individually via the<br />

GÜNTHER Internet platform. 3-D CAD<br />

data including negative volume and<br />

drawings are available for downloading<br />

for each hot <strong>runner</strong> system.<br />

To round this service off, price<br />

information (as a PDF file) is also<br />

provided.<br />

Once you have configured your<br />

individual hot <strong>runner</strong> system, you<br />

can select various data formats. The<br />

„CADHOC V2“ System Designer and<br />

the systems running in the background<br />

generate the required data.<br />

All files are then compressed and<br />

made available for downloading.<br />

You will be notified by e-mail a few<br />

minutes later.<br />

This e-mail will contain a link to the<br />

product data for the configured hot<br />

<strong>runner</strong> system.<br />

With its high functionality, the system<br />

is designed to suit the requirements<br />

of our customers, first of all<br />

designers of injection molds and<br />

sales personnel, to meet the desire<br />

for quicker availability of complete<br />

hot <strong>runner</strong> systems including negative<br />

volumes.<br />

www.guenther-hot<strong>runner</strong>.com<br />

7/12 Subject to technical changes<br />

iT<br />

Register once on our Internet platform „www.guenther-hot<strong>runner</strong>.com“ and<br />

you can then start the CADHOC V2 system designer to configure your own<br />

individual hot-<strong>runner</strong> system.<br />

Advantages of the new CADHOC system-designers version 2:<br />

• optimised calculation of the <strong>nozzle</strong> size<br />

• extensive choice of types of plastic<br />

• two different methods of configuration<br />

- application-specific by entering processing parameters<br />

- direct configuration without entering processing parameters<br />

• shorter waiting periods during the configuration process<br />

1.4. 60

Fig. Delta Tool calculation program<br />

Fig. Application database with many applications already implemented<br />

1.4. 61<br />

iT<br />

Service program<br />

Reworking the 1.2 mm gate<br />

For gate diameters smaller than ØD<br />

= 1.2 mm, the <strong>nozzle</strong> must be<br />

installed further back from the gate.<br />

You will find a Delta Tool calculation<br />

program on our homepage at<br />

www.guenther-hot<strong>runner</strong>.com under<br />

the menu item “Service” available<br />

for download free of charge.<br />

Application database<br />

The application database is a program<br />

for selecting from design proposals<br />

and machine parameter data.<br />

Following the entry of simple search<br />

criteria for hot <strong>runner</strong> requirements<br />

and material compa-tibility, the<br />

program makes available a selection<br />

of systems which have already been<br />

implemented along with their results.<br />

You can also enter your own applications<br />

directly into the data-base.<br />

The application will be reviewed and<br />

subsequently released under the<br />

menu item “Service”.<br />

The registration is free of charge.<br />

www.guenther-hot<strong>runner</strong>.com<br />

Subject to technical changes 7/12

Service program<br />

Download / catalog<br />

Under the menu item Catalog you<br />

will find all hot <strong>runner</strong> components<br />

with their relevant data available as a<br />

PDF file.<br />

The online catalog provides you with<br />

the newest version of the technical<br />

information.<br />

Pressure drop /<br />

Filling analysis<br />

The melt channels are dimensioned<br />

by GÜNTHER on the basis of application-specific<br />

rheologic calculations,<br />

with pressure drop, shear<br />

and dwell time standing in the foreground.<br />

Our calculations can be expanded to<br />

include the filling analysis of plastic<br />

parts per Moldflow. This is particularly<br />

advisable when laying out family<br />

molds with different cavities. By<br />

performing this calcu-lation, we offer<br />

you support in determining an optimal<br />

gate position and demon-strate the<br />

flow front course for the ideal part<br />

filling along with anticipated air<br />

pockets and the course of the weld<br />

line.<br />

www.guenther-hot<strong>runner</strong>.com<br />

7/12 Subject to technical changes<br />

Fig. Online catalog<br />

Fig. Filling analysis<br />

Fig. BlueFlow®<br />

Energie cost comparsion<br />

iT<br />

Here you can find GÜNTHER hot <strong>runner</strong><br />

components with all the relevant information<br />

as a PDF file. Make use of extensive<br />

TM<br />

Acrobat Reader features, such as shortcuts,<br />

bookmarks and icons, for a comfortable and<br />

quick search for information!<br />

1.4. 62

Fig. Seminars for designers and users<br />

1.4. 63<br />

iT<br />

Service program<br />

Seminars for users and designers<br />

Topics, such as layout, smooth<br />

running operation and professional<br />

maintenance of GÜNTHER hot <strong>runner</strong><br />

systems, are handled in a comprehensive<br />

manner.<br />

Additional services in our program<br />

include performing injection molding<br />

experiments in our in-house labora-<br />

tory as well as conducting external<br />

seminars. Please look for dates and<br />

locations on our website<br />

www.guenther-hot<strong>runner</strong>.com under<br />

the menu item ”Seminars” or ask by<br />

phone at<br />

+49 (0) 64 51 - 5008-0.<br />

Webinar, what's that?<br />

Webinar is an acronym formed from<br />

the words web (world wide web) and<br />

seminar.<br />

In short, it is a seminar held over the<br />

Internet.<br />

Advantages for you:<br />

• concise and specific information<br />

• no travelling and overnight accommodation<br />

expenses,<br />

• no loss of working days!<br />

See website<br />

www.guenther-hot<strong>runner</strong>.com<br />

www.guenther-hot<strong>runner</strong>.com<br />

Subject to technical changes 7/12