You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

In the Lab<br />

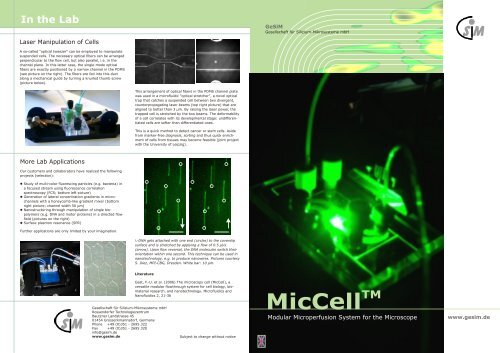

Laser Manipulation of Cells<br />

A so-called "optical tweezer" can be employed to manipulate<br />

suspended cells. The necessary optical fibers can be arranged<br />

perpendicular to the flow cell, but also parallel, i.e. in the<br />

channel plane. In this latter case, the single-mode optical<br />

fibers are exactly positioned by a narrow channel in the PDMS<br />

(see picture on the right). The fibers are fed into this duct<br />

along a mechanical guide by turning a knurled thumb screw<br />

(picture below).<br />

More Lab Applications<br />

Our customers and collaborators have realized the following<br />

projects (selection):<br />

� Study of multi-color fluorescing particles (e.g. bacteria) in<br />

a focused stream using fluorescence correlation<br />

spectroscopy (FCS; bottom left picture)<br />

� Generation of lateral concentration gradients in microchannels<br />

with a honeycomb-like gradient mixer (bottom<br />

right picture; channel width 50 µm)<br />

� Nanostructuring through manipulation of single biopolymers<br />

(e.g. DNA and motor proteins) in a directed flow<br />

field (pictures on the right)<br />

� Surface plasmon resonance (SPR)<br />

Further applications are only limited by your imagination.<br />

This arrangement of optical fibers in the PDMS channel plate<br />

was used in a microfluidic "optical stretcher", a novel optical<br />

trap that catches a suspended cell between two divergent,<br />

counterpropagating laser beams (top right picture) that are<br />

aligned to better than 3 µm. By raising the laser power, the<br />

trapped cell is stretched by the two beams. The deformability<br />

of a cell correlates with its developmental stage: undifferentiated<br />

cells are softer than differentiated ones.<br />

This is a quick method to detect cancer or stem cells. Aside<br />

from marker-free diagnosis, sorting and thus quick enrichment<br />

of cells from tissues may become feasible (joint project<br />

with the University of Leipzig).<br />

�-DNA gets attached with one end (circles) to the coverslip<br />

surface and is stretched by applying a flow of 0.5 µl/s<br />

(arrow). Upon flow reversal, the DNA molecules switch their<br />

orientation within one second. This technique can be used in<br />

nanotechnology, e.g. to produce nanowires. Pictures courtesy<br />

S. Diez, MPI-CBG, Dresden. White bar: 10 µm.<br />

Literature<br />

Gast, F.-U. et al. (2006) The microscopy cell (<strong>MicCell</strong>), a<br />

versatile modular flowthrough system for cell biology, biomaterial<br />

research, and nanotechnology. Microfluidics and<br />

Nanofluidics 2, 21-36<br />

Gesellschaft für Silizium-Mikrosysteme <strong>mbH</strong><br />

Rossendorfer Technologiezentrum<br />

Bautzner Landstrasse 45<br />

01454 Grosserkmannsdorf, Germany<br />

Phone +49 (0)351 - 2695 322<br />

Fax +49 (0)351 - 2695 320<br />

info@gesim.de<br />

www.gesim.de Subject to change without notice<br />

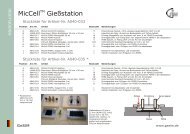

<strong>GeSiM</strong><br />

Gesellschaft für Silizium-Mikrosysteme <strong>mbH</strong><br />

<strong>MicCell</strong><br />

<strong>TM</strong><br />

Modular Microperfusion System for the Microscope<br />

www.gesim.de

<strong>TM</strong><br />

The <strong>MicCell</strong><br />

Possible Applications<br />

The study of biomolecules or cells often includes their immobilization<br />

on surfaces. Microfluidic flowthrough systems are only<br />

suited if the channels can be opened and closed reversibly, if<br />

possible without tinkering with adhesive tape. Highly desirable<br />

would be a modular fluidic system that can be easily adapted to<br />

diverse analytical methods (e.g. electrochemical or optical) and<br />

also efficiently cleaned.<br />

For this purpose, <strong>GeSiM</strong> has developed microperfusion chambers<br />

with removable coverslip for the microscope. By using a novel,<br />

patented setup, these flow cells are mounted in seconds and can<br />

be applied in cell imaging or single-molecule fluorescence experiments.<br />

If needed, electrical signals can be processed or optical<br />

fibers mounted. The system is completed by a computer-controlled<br />

macrofluidic environment.<br />

Layout and assembly of the system can be modified in a wide<br />

range. So a bunch of different materials can be used and microvalves<br />

and microelectrodes can be integrated. Due to the easy<br />

and modular setup, even the most complicated method in<br />

screening, diagnostics, and nanotechnology can be realized in a<br />

customer-specific way.<br />

Semi-automatic drug screening using adherent cells or tissue slices in<br />

the microscope<br />

Interaction of cells with immobilized proteins, oligosaccharides, lipids,<br />

and other ligands<br />

Viability testing (e.g. for cancer cells) and other cell-based tests<br />

Cell adhesion tests with prepared surfaces<br />

Laser manipulation of cells in the flow: e.g. with the "optical stretcher"<br />

(for cancer diagnosis and to isolate stem cells)<br />

DNA transfection in the flow<br />

Measurement of the homogeneity of microbeads and size sorting<br />

Single-molecule detection unsing fluorescent biomolecules (fluorescence<br />

correlation spectroscopy in the flow, receptor-ligand binding studies,<br />

motor protein kinetics, hybridization kinetics on microarrays, etc.)<br />

Capillary electrophoresis (CE)<br />

Application of hydrodynamic flow fields (e.g. to align macromolecules,<br />

nanotechnology)<br />

Generation of lateral concentration gradients in a microchannel<br />

Activity measurment of electrically active cells on microelectrode arrays<br />

Rapid prototyping of microsystems (e.g. for "stopped flow" or for<br />

chemical synthesis) by use of PDMS<br />

Study of non-transparent substrates in the flow with the fully revolvable<br />

"sample carrier", etc.<br />

Microelectrodes<br />

Microelectrodes for heating and sensing are microstructured<br />

in our cleanroom and those regions that must not come in<br />

contact with the medium are passivated by vapor deposition<br />

of SiO .<br />

2<br />

In the assembled <strong>MicCell</strong>, electrode pads are contacted by<br />

spring contacts and the signals are then conducted to a<br />

socket via a printed circuit board (shown in green). If<br />

coverslip and channel plate are from glass, electrodes can be<br />

present at both the top and the bottom of the channels.<br />

Examples shown were<br />

performed in cooperation<br />

with Fraunhofer-IBMT,<br />

Berlin, and Max-Planck<br />

Institute for Polymer<br />

Research, Mainz<br />

Sample Carrier for Opaque Objects<br />

The <strong>MicCell</strong> channel is normally translucent and thus allows<br />

sample illumination from the rear side. Opaque objects can<br />

be introduced into the channel with a pivotable sample carrier<br />

(orange in the schematic drawing below) and observed in the<br />

flow, e.g. for material testing.<br />

<strong>GeSiM</strong> offers such a flowthrough cell that can hold objects up<br />

to a size of 2.5x2.5 mm. As sample and sample holder are<br />

intransparent, the sample must be illuminated from the<br />

objective side, i.e. along the optical path. Its specialty: the<br />

specimen can be rotated a full 360° around the optical axis of<br />

the microscope, such that objects can be exposed to the flow<br />

at an arbitrary angle.<br />

Optional Design<br />

Microelectrode Arrays (MEAs)<br />

To measure signals of muscle or nerve cells, these cells can<br />

be grown on coverslips containing microelectrode arrays (see<br />

bottom picture) that are then mounted into a flow channel.<br />

The flow system shown can process electrical potentials while<br />

the cells are being inspected under a microscope.<br />

Potential (mV)<br />

1.0<br />

0.5<br />

0.0<br />

-0.5<br />

0 50 100 150 200<br />

t (msec)

Accessories<br />

Hydrogel Microvalve<br />

To add liquids to the main channel, e.g. to start and stop<br />

reactions, a dead volume-free microvalve must be placed in<br />

the flow channel. The patented <strong>GeSiM</strong> hydrogel valve contains<br />

hydrogel particles that dramatically swell by hydration<br />

when the temperature drops below 34 °C, hence blocking the<br />

channel. Warming above this transition temperature opens<br />

the valve immediately, which allows the aspiration of<br />

substances into the main channel.<br />

Several versions of this valve exist (see separate brochure),<br />

but in the <strong>MicCell</strong> only those are used where the fluid passes<br />

vertically through holes etched into the heated actuator<br />

chamber. This very small device can be built into a standard<br />

UNF 1/4-28 fitting that can be screwed into a <strong>MicCell</strong> inlet<br />

hole.<br />

Actuator Specifications<br />

Scanning EM picture<br />

of an opened actuator<br />

chamber with<br />

dehydrated hydrogel<br />

particles<br />

� Hydrogel polymerized from purified N-isopropylacrylamide<br />

(PNIPAAm)<br />

� Standard transition temperature 34 °C (can be adjusted),<br />

more than tenfold volume increase upon cooling ("normally<br />

closed valve")<br />

� Heating power max. 250 mW at 3.5 - 5 V, heating and<br />

temperature measurement via sputtered platinum electrodes<br />

� Switching period ca. 1 - 3 seconds; if Peltier cooling is<br />

used, closing about as fast<br />

5<br />

� Watertight up to a pressure of ~ 6·10 Pa (6 bar)<br />

� Needs aqueous solutions, but tolerates<br />

< 15 % methanol, ethanol, acetone<br />

< 5 % 1-propanol<br />

Hydrogel valve PV7 without<br />

printed circuit board (thus<br />

autoclavable) in the <strong>MicCell</strong><br />

Sample injection into T and K-channel. The inlet and outlet of<br />

the main channel are marked green. After blocking the main<br />

inlet, samples can be sucked into the channel via the red<br />

hydrogel valve. The K-channel (right panel) has an extra<br />

outlet (white circle) to flush the dead volume between microvalve<br />

and T-junction.<br />

Microvalve filled with hydrogel particles, before (left) and<br />

after (right) packaging<br />

Hydrogel valve<br />

Electrical<br />

connection<br />

Standard fitting<br />

(to microstructure)<br />

Hydrogel particle actuator with small dead volume (PV6) in<br />

standard UNF fitting. Left: injector for manual sample addition<br />

via a microfunnel, right: automatic sample injection<br />

through capillary (inner diameter 25 - 762 µm).<br />

Hydrodynamic flow chamber with eight hydrogel valves<br />

(arrows) to generate flow in various directions (in collaboration<br />

with the University of Technology Dresden and Namos<br />

G<strong>mbH</strong>, Dresden)<br />

Assembly<br />

The <strong>MicCell</strong> microsystem consists of<br />

� the channel plate from PDMS or glass that contains the<br />

microstructured channel system<br />

� the coverslip<br />

The microchannel is covered by a coverslip that is firmly<br />

pressed onto the channel plate as it is mounted between the<br />

lid (polycarbonate, on the top) and support (metal, on the<br />

bottom). Feeding and draining of the fluid is achieved by<br />

openings in the channel plate.<br />

The easy fluidic connection of the microchannel via standard<br />

fittings in the <strong>MicCell</strong> lid is groundbreaking. The flow is generated<br />

by external syringe pumps ("macrofluidics") that are<br />

much more reliable than integrated microfluidic pumps.<br />

A light microscope is not included in the shipment.<br />

Components<br />

� Working plate: metal adapter to hold the <strong>MicCell</strong> support in<br />

practically all inverted and many upright and stereomicroscopes<br />

(required)<br />

� Fluid processor: computer-controlled flow control box containing<br />

one or more syringe pumps, multi-port distribution<br />

valve, 2/2-way valve, and controller for hydrogel valve<br />

(recommended)<br />

� Tubing with small inner diameter (0.3 mm, 0.5 mm etc.),<br />

UNF fittings (1/4-28), O-rings<br />

� Hydrogel microvalves (see below)<br />

� Windows control software (see below) for interactive operation<br />

and process automation with the fluid processor<br />

(flow ramps, valve control, temperature control)<br />

� Optional integrated devices: micromixer, thin film heater<br />

and thermosensor, calorimetric flow sensor (<strong>GeSiM</strong> specialty,<br />

see extra brochure), pressure sensor, microelectrode<br />

array, impedance sensor, "sample carrier"<br />

<strong>MicCell</strong> Control Software<br />

For rinsing, precincuation, and the timely starting and stopping<br />

of reactions, all devices (syringe pumps, valves), plus<br />

the velocity and direction of the flow, can be interactively<br />

controlled via a Windows software. In addition, complex<br />

procedures from several single functions (pumps and valves,<br />

delay time, repeats) can be automated using an easy<br />

scripting language (example in the bottom right figure).<br />

Of course, price-concious researchers can use their own fluidic<br />

periphery, but will then lose all the comfort of a graphic<br />

user interface and programmable operation.<br />

Principle<br />

Zuleitungen<br />

Channel plate<br />

with microchannel<br />

Coverslip<br />

Metal support<br />

<strong>MicCell</strong> assembly. One can see a channel plate of glass with a<br />

polymer channel structured on it; normally it consists of<br />

molded PDMS. Fastening elements and the working plate<br />

(adapter to the microscope) are not shown.<br />

Control software for two syringe<br />

pumps, 6/1 distribution valve ,<br />

and hydrogel valve. On the right:<br />

programming example<br />

Lid<br />

<strong>MicCell</strong> in an inverted<br />

microscope with fluid<br />

processor (on the left),<br />

controlled by a notebook.<br />

Standard fluid processor<br />

with syringe pump (left<br />

side), hydrogel valve<br />

controller and 2/2 valve<br />

(middle), and 4/1 distribution<br />

valve (right). In<br />

front of the fluid processor,<br />

a <strong>MicCell</strong>, complete<br />

with hydrogel valve and<br />

blue metal support, is<br />

mounted in the black<br />

working adapter plate.

PDMS Flow Cell<br />

PDMS Channel Plate<br />

Although the channel plate can be made of various materials<br />

(glass, silicon, ceramics), a good and easy-to-handle material<br />

is PDMS (polydimethylsiloxane), a two-component silicone.<br />

The PDMS mixture is poured onto a master tool of silicon and<br />

cured to form a soft polymer block that seals tightly against<br />

the coverslip.<br />

PDMS molding is a well established lab technique, however it<br />

is often rather bricolage than anything else. <strong>GeSiM</strong> has<br />

developed a professional casting station in which the inlet<br />

and outlet holes are kept open by "channel spacers" (see<br />

picture on the right). The specialty: the lid not only defines<br />

the PDMS thickness during molding, but is also the lid in the<br />

fully assembled flow cell; it presses together coverslip and<br />

microchannel and contains all fluidic connections. So all you<br />

need to do after curing is to replace the master with the<br />

coverslip, screw in the right fittings, and start your experiments.<br />

The channel plate can be used several times, by the<br />

way.<br />

Instead of purchasing the casting station, you can let <strong>GeSiM</strong><br />

manufacture the PDMS channel plate, even hundred units per<br />

month. The lids will be reused.<br />

Due to its easy handling and flexible use, the PDMS channel<br />

plate can be an ideal tool for rapid prototyping: to make a<br />

new channel, only a new master is required.<br />

Casting stations for coverslips of size 22 x 22 and 22 x 50<br />

mm, with metal base plate, silicon master (black), Teflon<br />

case (white), polycarbonate lid (transparent), and channel<br />

spacer (brown)<br />

Advantages of PDMS<br />

� Transparent, with no background fluorescence<br />

� Easy to cast<br />

� Sealing without problems<br />

� Biocompatible (at least after plasma treatment)<br />

� Covalent bonding by plasma treatment<br />

Disadvantages of PDMS<br />

� Faint background in transmitted light<br />

� Permeable for small molecules such as gases (O , CO ),<br />

2 2<br />

alcohols, etc. (actually an advantage in cell biology)<br />

Principle<br />

Inlet<br />

Lid<br />

Channel spacers Master<br />

Silicon molding<br />

master<br />

Casting of the<br />

PDMS channel<br />

plate (top) and<br />

use as flow cell<br />

(bottom)<br />

PDMS<br />

Coverslip<br />

PDMS molding in the<br />

casting station. The<br />

silicon master is under<br />

the transparent lid.<br />

Please note the channel<br />

spacers (brown<br />

fittings).<br />

Demolded PDMS<br />

channel plate with<br />

coverslip. The channel<br />

spacers were replaced<br />

with green fittings.<br />

PDMS channel plate,<br />

mounted with coverslip<br />

on a metal support,<br />

with hydrogel valve<br />

microinjector<br />

Customized Solutions<br />

<strong>GeSiM</strong>'s great specialty is to care for individual needs of<br />

customers. Aside from the numerous possible channel geometries<br />

and materials, the entire setup can also vary in a wide<br />

range. Solutions have been devised for many problems,<br />

among them flowthrough cells that are used without microscope,<br />

e.g. with heating plate for microarray hybrization or to<br />

measure surface plasmon resonance (SPR). Variants for other<br />

microscopes (such as stereomicroscopes) and the integration<br />

of microelectrodes are also possible.<br />

It is therefore a rather rare event that two <strong>MicCell</strong>s are absolutely<br />

identical when they leave the factory.<br />

With polymer walls and microelectrodes...<br />

For SPR...<br />

Flow Cells of Different Size<br />

For channel systems that are larger than a classical coverslip<br />

(22 x 22 mm), up to the size of a slide, the arrangement of<br />

the <strong>MicCell</strong> is somewhat different, as shown in these examples.<br />

Standard PDMS <strong>MicCell</strong>s with coverslips of size 22 x 50 mm<br />

(top) and 22 x 22 mm (bottom)<br />

Variations on a Theme...<br />

With optical fibers...<br />

In a stereomicroscope (see<br />

also below)...<br />

With glass flow cell<br />

and electrodes on<br />

both sides of the<br />

channel...<br />

With glass T-channel and<br />

hydrogel valve injector<br />

(arrow)...<br />

To heat slides...<br />

Coverslip 50<br />

x 22 mm on<br />

a polymer<br />

channel<br />

structured on<br />

a slide.<br />

Sealing is<br />

achieved by<br />

a layer of<br />

silicone<br />

rubber that<br />

was screenprinted<br />

onto<br />

the channel<br />

walls.<br />

Large PDMS<br />

channel plate<br />

used in a<br />

stereomicroscope.<br />

The<br />

channel is<br />

covered by a<br />

slide.