Orthodontic Screw System Orthodontic Screw System - Osstem.

Orthodontic Screw System Orthodontic Screw System - Osstem.

Orthodontic Screw System Orthodontic Screw System - Osstem.

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Osstem</strong> <strong>Osstem</strong> <strong>Orthodontic</strong> <strong>Screw</strong> Catalog & User Manual<br />

New Surgical Design Instrument Quality Feature<br />

Good Initial Stability<br />

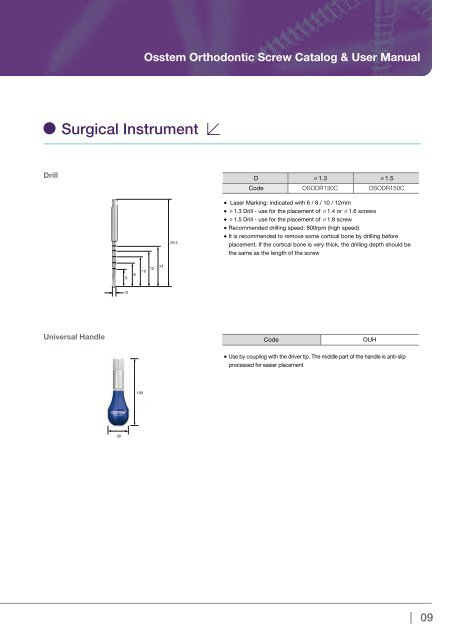

Drill<br />

D ∅1.3 ∅1.5<br />

The initial stability of the orthodontic screw is mainly provided<br />

by the cortical bone. With this new product, the initial stability is<br />

Code OSODR130C OSODR150C<br />

● Laser Marking: indicated with 6 / 8 / 10 / 12mm<br />

effectively improved by increasing the taper Body.<br />

● ∅1.3 Drill - use for the placement of ∅1.4 or ∅1.6 screws<br />

Therefore, sufficient final torque for placement and less possibility ● ∅1.5 Drill - use for the placement of ∅1.8 screw<br />

● Recommended drilling speed: 800rpm (high speed)<br />

of displacement can be achieved when applied with orthodontic force.<br />

● It is recommended to remove some cortical bone by drilling before<br />

placement. If the cortical bone is Resistance very thick, of the the thread drilling against depth external should loadbe<br />

Resistance against <strong>Orthodontic</strong> Forces<br />

the same as the length of the 50 screw<br />

6<br />

To use orthodontic screws as a stable anchorage, the screw thread<br />

and bone must have sufficient Dresistance against orthodontic forces.<br />

The screw thread and body shape of the new product are designed<br />

to be highly rigid against orthodontic forces.<br />

Universal Handle<br />

Stress Distribution<br />

8<br />

29.4<br />

10 12 14<br />

Load(N)<br />

40<br />

30<br />

20<br />

10<br />

New<br />

Conventional<br />

Competitor<br />

Code<br />

0<br />

0.00 0.05 0.10OUH<br />

Displacement(mm)<br />

0.15 0.20<br />

● Use by coupling with the driver tip. The middle part of the handle is anti-slip<br />

processed for easier placement<br />

The body and thread of the new orthodontic screw are designed to<br />

facilitate stress distribution.<br />

Thus, long-term orthodontic force does not give excessive stress to<br />

the bone with the new orthodontic screw<br />

30<br />

100<br />

Conventional : 35.3Mpa<br />

New : 23.8Mpa<br />

Driver Tip<br />

Enhanced Body Strength<br />

80<br />

Hex<br />

Type<br />

Cross<br />

70 Short LongNew<br />

L 48 70 69<br />

The fracture strength is improved by increasing the upper diameter.<br />

60<br />

Code OSDTS OSDT OCDT<br />

50<br />

Competitor<br />

The strength is far superior to the conventional products to improve<br />

● Use for the placement of orthodontic screws by coupling with the<br />

40<br />

the safety of the placement.<br />

Universal Handle<br />

Conventional<br />

30<br />

However, the Ø1.4 diameter size has low<br />

L<br />

body strength<br />

● The set consists of Hex and Cross types. Use the Hex type for applying<br />

torque, and use Cross 20 type for correcting the through hole path of the<br />

So requires careful placement.<br />

screw part<br />

Torque(Ncm)<br />

10<br />

Comparison of Fracture Strength of <strong>Orthodontic</strong> <strong>Screw</strong>s<br />

(Hex)<br />

(Hex)<br />

(Cross)<br />

0<br />

(Caution) Do not apply excessive 0 1torque 2 with 3 the 4 cross 5 6type 7 driver 8 9 10<br />

-10<br />

Placement Depth<br />

03 09