Closing the Loop on Thermal Solutions - Durex Industries

Closing the Loop on Thermal Solutions - Durex Industries

Closing the Loop on Thermal Solutions - Durex Industries

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

DUREX INDUSTRIES closing <str<strong>on</strong>g>the</str<strong>on</strong>g> loop <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g>rmal soluti<strong>on</strong>s<br />

INDUSTRIES SERVED<br />

<strong>Durex</strong> plant in Cary, IL (Chicago)—Facility houses our foundry and full manufacturing operati<strong>on</strong>s<br />

<str<strong>on</strong>g>Closing</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>Loop</str<strong>on</strong>g> <strong>on</strong> <strong>Thermal</strong> Soluti<strong>on</strong>s<br />

The world of complex <str<strong>on</strong>g>the</str<strong>on</strong>g>rmal processes demands high<br />

quality, precisi<strong>on</strong>-made <str<strong>on</strong>g>the</str<strong>on</strong>g>rmal comp<strong>on</strong>ents and pro-<br />

cess c<strong>on</strong>trol systems. At <strong>Durex</strong> <strong>Industries</strong>, we do this all<br />

day, every day. Our extensive design and manufacturing<br />

capabilities are syn<str<strong>on</strong>g>the</str<strong>on</strong>g>sized to deliver soluti<strong>on</strong>s from<br />

complex and creative to robust and durable. We truly<br />

represent a traditi<strong>on</strong> of excellence in <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g>rmal process<br />

industry.<br />

Headquartered in Cary, Illinois, our<br />

campus now encompasses<br />

145,000 square feet, which<br />

includes additi<strong>on</strong>al capacity for<br />

research and development of new<br />

products for increasingly demanding<br />

applicati<strong>on</strong>s. Our ISO<br />

9001:2008 certificati<strong>on</strong> also<br />

mirrors our commitment to total<br />

customer satisfacti<strong>on</strong>, with<br />

c<strong>on</strong>tinuous improvement<br />

integrated into <str<strong>on</strong>g>the</str<strong>on</strong>g> fiber of our<br />

operati<strong>on</strong>s.

As a vertically integrated manufacturer<br />

based in <str<strong>on</strong>g>the</str<strong>on</strong>g> USA, we<br />

pride ourselves <strong>on</strong> our ability to<br />

quickly deploy our resources to<br />

resolve complex <str<strong>on</strong>g>the</str<strong>on</strong>g>rmal problems,<br />

enhance existing designs,<br />

and provide rapid prototypes.<br />

Our sizeable array of in-house<br />

capabilities gives us a significant<br />

advantage in resp<strong>on</strong>se time and<br />

design opti<strong>on</strong>s, as well as tight<br />

process c<strong>on</strong>trol, undiluted by<br />

outside sourcing.<br />

Our competitive strengths are<br />

leveraged by our customers to<br />

produce soluti<strong>on</strong>s with accuracy,<br />

durability, and dependability – <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

key factors to ensuring your<br />

equipment and instruments<br />

perform as designed. Our aim is<br />

laser focused; to become an<br />

extensi<strong>on</strong> of your organizati<strong>on</strong><br />

…working towards comm<strong>on</strong><br />

goals via design optimizati<strong>on</strong>,<br />

c<strong>on</strong>tinuous process requirements,<br />

and cost minimizati<strong>on</strong>.<br />

This catalog offers you a look at<br />

our depth of products, both<br />

standard and custom designs to<br />

suit virtually any <str<strong>on</strong>g>the</str<strong>on</strong>g>rmal<br />

processing requirement. You<br />

will find our products worldwide<br />

in industries as diverse as<br />

semic<strong>on</strong>ductor processing,<br />

plastics, packaging, medical<br />

equipment, life sciences, foodservice,<br />

military technology,<br />

photovoltaic, and chemical and<br />

petroleum processing.<br />

<strong>Durex</strong> engineered <str<strong>on</strong>g>the</str<strong>on</strong>g>rmal<br />

products are supported through<br />

an internati<strong>on</strong>al network of<br />

expert sales engineers, factory<br />

authorized distributors, and an<br />

inside staff of dedicated engineering<br />

professi<strong>on</strong>als eager for<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> next challenge in <str<strong>on</strong>g>the</str<strong>on</strong>g>rmal<br />

applicati<strong>on</strong>.<br />

We welcome <str<strong>on</strong>g>the</str<strong>on</strong>g> opportunity to<br />

become your valued design<br />

partner. Call direct or visit our<br />

website to get started.<br />

www.durexindustries.com<br />

TABLE OF CONTENTS PG.<br />

Company Overview<br />

Advanced <strong>Thermal</strong> Soluti<strong>on</strong>s for<br />

Semic<strong>on</strong>ductor Processing<br />

M<br />

Durocast Industrial<br />

Cast-In Heaters<br />

High-Performance Mineral-Insulated<br />

Heaters<br />

Formed Tubular and<br />

Immersi<strong>on</strong> Heaters<br />

M<br />

Circulati<strong>on</strong> and DFX Heat<br />

Exchangers<br />

Process Heating Systems<br />

Flexible Kapt<strong>on</strong> and Silic<strong>on</strong>e<br />

Rubber Heaters<br />

High-Temperature<br />

Cartridge Heaters<br />

Industrial ProcessThermocouples<br />

Advanced <strong>Thermal</strong> Sensors<br />

for General Industry<br />

Precisi<strong>on</strong> RTDs and Thermistors<br />

Special Sensor Applicati<strong>on</strong> Products<br />

<strong>Thermal</strong> Process Accessories<br />

Custom Temperature C<strong>on</strong>trols<br />

Stock Temperature C<strong>on</strong>trols and<br />

C<strong>on</strong>trol Panels<br />

<strong>Durex</strong> Capabilities and Services<br />

4-5<br />

6-7<br />

8-9<br />

10-11<br />

12-13<br />

14<br />

15<br />

16-17<br />

18-19<br />

20-21<br />

22-23<br />

24-25<br />

26-27<br />

27<br />

28<br />

29<br />

30-31

4<br />

DUREX INDUSTRIES closing <str<strong>on</strong>g>the</str<strong>on</strong>g> loop <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g>rmal soluti<strong>on</strong>s<br />

At <strong>Durex</strong>, <str<strong>on</strong>g>the</str<strong>on</strong>g>re are several<br />

important reas<strong>on</strong>s why we stay<br />

ahead of our competiti<strong>on</strong>. The<br />

most important reas<strong>on</strong> is our<br />

wide range of capabilities.<br />

For example, our in-house<br />

capabilities include heater<br />

element manufacturing, foundry<br />

operati<strong>on</strong>s, heat treating,<br />

CNC bending, CNC machining,<br />

waterjet cutting, plasma and<br />

orbital welding, anodizing and<br />

passivati<strong>on</strong>, and Class 100 clean<br />

room assembly.<br />

Our quality assurance capabilities<br />

as an ISO 9001:2008 registered<br />

manufacturing operati<strong>on</strong> mirror<br />

our commitment to total customer<br />

satisfacti<strong>on</strong>. These capabilities<br />

include a full service calibrati<strong>on</strong><br />

lab traceable to NIST, digital<br />

in-house x-ray facility, helium leak<br />

test, coordinate measuring<br />

machine, temperature profiling<br />

acquisiti<strong>on</strong> and display, and an<br />

<strong>on</strong>-going accelerated life cycle<br />

testing.<br />

C<strong>on</strong>tact us to find out more about<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> unique capabilities we offer<br />

that can provide you with <str<strong>on</strong>g>the</str<strong>on</strong>g> best<br />

design and product value in<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> industry!<br />

NOTE: The product families and specific<br />

items shown herein are merely representative<br />

of what <strong>Durex</strong> can do. If your process or<br />

producti<strong>on</strong> requirement involves a heat<br />

process in any way, we welcome your call.<br />

Problem Analysis<br />

We assess <str<strong>on</strong>g>the</str<strong>on</strong>g> total envir<strong>on</strong>ment<br />

of <str<strong>on</strong>g>the</str<strong>on</strong>g> applicati<strong>on</strong>, including temperature<br />

range, field of heat required, humidity,<br />

space, <str<strong>on</strong>g>the</str<strong>on</strong>g>rmal dissipati<strong>on</strong> and data<br />

transmissi<strong>on</strong>, as required. We ask all <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

questi<strong>on</strong>s and we listen, as you provide<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> necessary input to guide our internal<br />

processes. If standard products can be<br />

utilized to solve <str<strong>on</strong>g>the</str<strong>on</strong>g> problems, we make<br />

those recommendati<strong>on</strong>s. When <str<strong>on</strong>g>the</str<strong>on</strong>g>y<br />

cannot be used, or when a more costeffective,<br />

space-c<strong>on</strong>taining or materialspecific<br />

product is needed, we find it.<br />

Better designs and <str<strong>on</strong>g>the</str<strong>on</strong>g> most appropriate<br />

soluti<strong>on</strong>s are <str<strong>on</strong>g>the</str<strong>on</strong>g> result.<br />

Design<br />

With state-of-<str<strong>on</strong>g>the</str<strong>on</strong>g>-art CAD and 3-D<br />

Solidificati<strong>on</strong> Modeling, <strong>Durex</strong> engineers<br />

create a <str<strong>on</strong>g>the</str<strong>on</strong>g>rmal processing soluti<strong>on</strong> to<br />

your challenge. Precisely because we<br />

manufacture nearly everything we sell,<br />

<strong>Durex</strong> can draw from a wealth of<br />

experience and in-field successes to<br />

help you generate, sense or c<strong>on</strong>trol<br />

heat in <str<strong>on</strong>g>the</str<strong>on</strong>g> best ways possible. This<br />

catalog dem<strong>on</strong>strates, we have thousands<br />

of proven products to help you, or we can<br />

design a completely new heater, sensor<br />

or c<strong>on</strong>trol to match your requirements,<br />

both envir<strong>on</strong>mental and ec<strong>on</strong>omic.<br />

You get <str<strong>on</strong>g>the</str<strong>on</strong>g> products and profitability<br />

you need.

Prototype<br />

You work in a fast-paced, changing<br />

envir<strong>on</strong>ment and so do we. Rapid<br />

prototype development is critical to<br />

market proactivity. As needed, <strong>Durex</strong><br />

engineers can fashi<strong>on</strong> test-ready samples<br />

<strong>on</strong> virtually any design, faster than all<br />

o<str<strong>on</strong>g>the</str<strong>on</strong>g>r suppliers in <str<strong>on</strong>g>the</str<strong>on</strong>g> industry. Once<br />

again, this translates into time and cost<br />

savings for your operati<strong>on</strong>. You have less<br />

downtime or can bring your product to<br />

market faster.<br />

Manufacturing<br />

The <strong>Durex</strong> foundry process guarantees<br />

our heater performance, because it<br />

ensures precise element placement and<br />

minimum porosity <strong>on</strong> each alloy or pure<br />

aluminum casting we produce. Likewise,<br />

our machining and fabricati<strong>on</strong> plant<br />

produces heaters and temp sensors<br />

of unparalleled accuracy and stability<br />

in use. Such tightly c<strong>on</strong>trolled quality is<br />

built into your products.<br />

Validati<strong>on</strong>/QA<br />

Ano<str<strong>on</strong>g>the</str<strong>on</strong>g>r <strong>Durex</strong> advantage for you is<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> validati<strong>on</strong>/quality assurance process<br />

used at our company. Nothing leaves<br />

our dock until it’s been rigorously<br />

tested and certified for use, to your<br />

specificati<strong>on</strong>s. As needed, we have X-ray<br />

inspecti<strong>on</strong>, Helium leak testing, life cycle<br />

testing, surface temperature profiling<br />

and more. Our products undergo this<br />

extensive procedure for just <strong>on</strong>e reas<strong>on</strong>,<br />

namely, our customers’ satisfacti<strong>on</strong>.<br />

www.durexindustries.com<br />

Engineering Process<br />

QUALITY POLICY<br />

When you employ our engineering<br />

process, you enlist a team of experts that<br />

become an integral part of your design<br />

process. Designing and manufacturing<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> optimal <str<strong>on</strong>g>the</str<strong>on</strong>g>rmal comp<strong>on</strong>ents for any<br />

applicati<strong>on</strong> is a process that begins with<br />

analysis and identificati<strong>on</strong>. Overlooking<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g>se two important “first steps” leads to<br />

wasted time, m<strong>on</strong>ey and opportunity.<br />

When you engage our engineering<br />

process, we bring our many years of<br />

applicati<strong>on</strong> expertise to bear <strong>on</strong> your<br />

project. No large bureaucracy, no<br />

middlemen protecting mind share. Our<br />

engineers roll up <str<strong>on</strong>g>the</str<strong>on</strong>g>ir sleeves and get to<br />

work with your staff. If it can be d<strong>on</strong>e, it<br />

will be d<strong>on</strong>e. That is our attitude and<br />

commitment to our valued partners.<br />

We are committed to total customer satisfacti<strong>on</strong><br />

through <str<strong>on</strong>g>the</str<strong>on</strong>g> competitive<br />

value of quality products and services, <strong>on</strong>-time<br />

deliveries, and <str<strong>on</strong>g>the</str<strong>on</strong>g> integrity of a total quality<br />

system that promotes c<strong>on</strong>tinuous improvement in<br />

our services and operati<strong>on</strong>s.<br />

DUREX IS AN ISO 9001:2008 REGISTERED FIRM<br />

5

6<br />

DUREX INDUSTRIES closing <str<strong>on</strong>g>the</str<strong>on</strong>g> loop <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g>rmal soluti<strong>on</strong>s<br />

BAKE PLATENS<br />

Utilizing state-of-<str<strong>on</strong>g>the</str<strong>on</strong>g>-art heater<br />

technology, <strong>Durex</strong> manufactures precisi<strong>on</strong><br />

bake platens specifically for processing<br />

200mm and 300mm wafers. These platens<br />

are cast from pure aluminum (99.7%) to<br />

insure maximum operating temperatures<br />

of 450 C (842 F) with minimum risk of<br />

process c<strong>on</strong>taminati<strong>on</strong>. The casting<br />

process is c<strong>on</strong>trolled to eliminate any<br />

defects in <str<strong>on</strong>g>the</str<strong>on</strong>g> machined surface or<br />

casting body caused by porosity. A<br />

mineral-insulated heating element<br />

distributed throughout <str<strong>on</strong>g>the</str<strong>on</strong>g> casting<br />

provides surface temperature uniformity<br />

to _+ 1% or better of <str<strong>on</strong>g>the</str<strong>on</strong>g> process operating<br />

temperature. A hard-anodized finish<br />

provides an abrasi<strong>on</strong>-resistant dielectric<br />

barrier <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> working surface.<br />

BAKE/CHILL PLATENS<br />

<strong>Durex</strong> bake/chill platens have<br />

essentially <str<strong>on</strong>g>the</str<strong>on</strong>g> same operating<br />

specificati<strong>on</strong>s as our bake platens,<br />

with <str<strong>on</strong>g>the</str<strong>on</strong>g> additi<strong>on</strong> of a cooling functi<strong>on</strong>.<br />

A precisi<strong>on</strong> formed cooling tube is added<br />

as an integral comp<strong>on</strong>ent to <str<strong>on</strong>g>the</str<strong>on</strong>g> heater<br />

assembly in <str<strong>on</strong>g>the</str<strong>on</strong>g> body of <str<strong>on</strong>g>the</str<strong>on</strong>g> casting.<br />

This functi<strong>on</strong> can be used to rapidly<br />

cool <str<strong>on</strong>g>the</str<strong>on</strong>g> working surface of <str<strong>on</strong>g>the</str<strong>on</strong>g> platen<br />

or to act as a heat exchanger for liquids<br />

and gases. A pressure test <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

finished part assures <str<strong>on</strong>g>the</str<strong>on</strong>g> integrity<br />

of <str<strong>on</strong>g>the</str<strong>on</strong>g> cooling tube after <str<strong>on</strong>g>the</str<strong>on</strong>g> casting<br />

process. The platen can also include<br />

an integral temperature sensor as part<br />

of <str<strong>on</strong>g>the</str<strong>on</strong>g> assembly.

PEDESTAL HEATERS<br />

These pedestals comprise a bake or chill<br />

platen with an aluminum "shaft" attached<br />

to <str<strong>on</strong>g>the</str<strong>on</strong>g> underside of <str<strong>on</strong>g>the</str<strong>on</strong>g> platen by electr<strong>on</strong><br />

beam welding. A helium leak test insures<br />

a vacuum tight assembly. The surface of<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> pedestal is precisi<strong>on</strong> machined with<br />

a flatness of _+ 0.0005" and includes lift<br />

pin holes and proximity pins to customer<br />

specificati<strong>on</strong>s. Various terminati<strong>on</strong><br />

opti<strong>on</strong>s are available to customize<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> cooling tube exits for new or<br />

existing applicati<strong>on</strong>s.<br />

HOT CHUCKS<br />

Hot chucks or "heated tools" deliver precise<br />

heat to wafers during <str<strong>on</strong>g>the</str<strong>on</strong>g> manufacturing<br />

process. These platens are individually<br />

customized with vacuum channels <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

working surface, as well as specific pin hole<br />

locati<strong>on</strong>s and o<str<strong>on</strong>g>the</str<strong>on</strong>g>r surface or backside<br />

mounting holes. Manufactured from pure<br />

aluminum (99.7%), <str<strong>on</strong>g>the</str<strong>on</strong>g>se hot chucks have a<br />

temperature uniformity of better than _+ 1%<br />

of <str<strong>on</strong>g>the</str<strong>on</strong>g> process temperature and a flatness<br />

tolerance of _+ 0.0005" across <str<strong>on</strong>g>the</str<strong>on</strong>g> entire surface.<br />

A precisi<strong>on</strong> lapped surface is standard, with<br />

a hardcoat anodized finish available.<br />

www.durexindustries.com<br />

GAS and PUMP LINE HEATERS<br />

Gas and pump line heaters are turnkey<br />

soluti<strong>on</strong>s that reduce c<strong>on</strong>densati<strong>on</strong> from<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> gas cylinder to a vacuum chamber,<br />

and sublimati<strong>on</strong> of nitrides and o<str<strong>on</strong>g>the</str<strong>on</strong>g>r<br />

materials in <str<strong>on</strong>g>the</str<strong>on</strong>g> exhaust lines from <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

vacuum chamber to <str<strong>on</strong>g>the</str<strong>on</strong>g> scrubber.<br />

Standard designs for regulators,<br />

filters, mass flow c<strong>on</strong>trollers (MFC)<br />

and piping<br />

Clean silic<strong>on</strong>e rubber heater<br />

c<strong>on</strong>structi<strong>on</strong><br />

Process temperatures to 200 C<br />

Integrated temperature assemblies<br />

Meets SEMI safety guidelines<br />

Integrated high limit protecti<strong>on</strong><br />

7

8<br />

DUREX INDUSTRIES closing <str<strong>on</strong>g>the</str<strong>on</strong>g> loop <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g>rmal soluti<strong>on</strong>s<br />

TM<br />

M<br />

LIQUID-COOLED BARRELS<br />

A heating element and an integral<br />

cooling tube are cast into <str<strong>on</strong>g>the</str<strong>on</strong>g>se<br />

heaters for uniform process c<strong>on</strong>trol.<br />

Cooling tube sizes of 3/8" and 1/2"<br />

are available in stainless steel or<br />

Incoloy®. Dual cooling tubes are<br />

also available to eliminate downtime<br />

associated with clogged cooling lines.<br />

Various electrical and cooling tube<br />

terminati<strong>on</strong>s are offered by <strong>Durex</strong>.<br />

Strap-<strong>on</strong> and bolt-<strong>on</strong> designs are<br />

standard. Cast materials can<br />

accommodate temperatures to<br />

750 F (400 C) aluminum, 1100 F<br />

(595 C) br<strong>on</strong>ze.<br />

AIR-COOLED BARRELS<br />

These heater designs incorporate<br />

a variety of cast fin patterns to<br />

circulate forced air across <str<strong>on</strong>g>the</str<strong>on</strong>g> body<br />

of <str<strong>on</strong>g>the</str<strong>on</strong>g> casting. Specific fin patterns<br />

are used to maximize <str<strong>on</strong>g>the</str<strong>on</strong>g> airflow for<br />

efficient cooling. Low profile fin<br />

patterns are used when restricted<br />

space or rapid cooling requirements<br />

are present. <strong>Durex</strong> can also integrate<br />

cast-in cooling tubes to augment<br />

cooling capacity <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g>se designs.

AIR-COOLED BARRELS WITH<br />

SHROUD AND BLOWER<br />

<strong>Durex</strong> designs cast shrouds as integral<br />

comp<strong>on</strong>ents <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g>se air-cooled styles.<br />

The shroud fits tightly over <str<strong>on</strong>g>the</str<strong>on</strong>g> fin<br />

pattern and features a throat secti<strong>on</strong><br />

for mounting a forced air blower to direct<br />

airflow across <str<strong>on</strong>g>the</str<strong>on</strong>g> entire body of <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

casting. This system optimizes <str<strong>on</strong>g>the</str<strong>on</strong>g> air<br />

cooling functi<strong>on</strong> of individual heater<br />

z<strong>on</strong>es through <str<strong>on</strong>g>the</str<strong>on</strong>g> dedicated operati<strong>on</strong><br />

of individual blowers.<br />

L-SHAPED PLATENS<br />

For rectangular barrels or squared<br />

surfaces, maximum c<strong>on</strong>tact is achieved<br />

with this cast heater design. Usually<br />

c<strong>on</strong>structed of a br<strong>on</strong>ze alloy because of<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> high-temperature c<strong>on</strong>diti<strong>on</strong>s of <str<strong>on</strong>g>the</str<strong>on</strong>g>ir<br />

applicati<strong>on</strong>, <str<strong>on</strong>g>the</str<strong>on</strong>g>se heaters can also be<br />

cast from aluminum, where lower watt<br />

densities are acceptable. The most<br />

comm<strong>on</strong> electrical terminati<strong>on</strong> for this<br />

type of heater includes a vented tower<br />

protecting <str<strong>on</strong>g>the</str<strong>on</strong>g> heating elements as<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g>y exit <str<strong>on</strong>g>the</str<strong>on</strong>g> back of <str<strong>on</strong>g>the</str<strong>on</strong>g> casting, with<br />

a moisture-resistant terminal housing.<br />

CAST-IN PLATENS<br />

Universal style platens are <str<strong>on</strong>g>the</str<strong>on</strong>g> primary<br />

source for heat in <str<strong>on</strong>g>the</str<strong>on</strong>g> foodservice,<br />

packaging, heat transfer, die heating,<br />

hot stamping and many o<str<strong>on</strong>g>the</str<strong>on</strong>g>r industries.<br />

Cast-in elements provide uniform heating,<br />

rapid delivery time and rugged c<strong>on</strong>tinuous<br />

service. <strong>Durex</strong> designs and casts such<br />

heaters for large volume producti<strong>on</strong>,<br />

guaranteed to perform, heat after heat.<br />

Mounting opti<strong>on</strong>s and heating surface<br />

features to fit any applicati<strong>on</strong>. We work<br />

with equipment builders, product design<br />

firms, commercial/instituti<strong>on</strong>al and end<br />

users alike to create <str<strong>on</strong>g>the</str<strong>on</strong>g> best soluti<strong>on</strong> for<br />

your heating needs.<br />

HOT MELT ADHESIVE HEATERS<br />

Hot melt adhesive delivery systems<br />

require very complex cast-in heater<br />

designs to simultaneously optimize melt<br />

flow and evenly distribute heat throughout<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> process. <strong>Durex</strong> engineers have <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

experience to design <str<strong>on</strong>g>the</str<strong>on</strong>g> ideal unit for your<br />

applicati<strong>on</strong>. Our heaters are found<br />

throughout <str<strong>on</strong>g>the</str<strong>on</strong>g> automotive, packaging and<br />

o<str<strong>on</strong>g>the</str<strong>on</strong>g>r high-volume markets, where l<strong>on</strong>g<br />

service life, uniform performance and<br />

cost-effectiveness are all demanded.<br />

www.durexindustries.com<br />

CUSTOM APPLICATION HEATERS<br />

When you have <str<strong>on</strong>g>the</str<strong>on</strong>g> breadth of<br />

experience and skills of <strong>Durex</strong>, <str<strong>on</strong>g>the</str<strong>on</strong>g>re<br />

is literally no applicati<strong>on</strong> for which we<br />

cannot design a <str<strong>on</strong>g>the</str<strong>on</strong>g>rmal processing<br />

soluti<strong>on</strong>. We specialize in <str<strong>on</strong>g>the</str<strong>on</strong>g> design<br />

and casting of various heating<br />

comp<strong>on</strong>ents for <str<strong>on</strong>g>the</str<strong>on</strong>g> most unusual<br />

applicati<strong>on</strong>s in industries and<br />

commercial operati<strong>on</strong>s worldwide.<br />

From <str<strong>on</strong>g>the</str<strong>on</strong>g> processing of syn<str<strong>on</strong>g>the</str<strong>on</strong>g>tic<br />

fibers to <str<strong>on</strong>g>the</str<strong>on</strong>g> laminati<strong>on</strong> of multi-layered<br />

derivative materials, from solvent reclaim<br />

equipment to petrochemical processing<br />

pipelines, <strong>Durex</strong> has <str<strong>on</strong>g>the</str<strong>on</strong>g> soluti<strong>on</strong> you<br />

need in a cast-in heater.<br />

9

10<br />

DUREX INDUSTRIES closing <str<strong>on</strong>g>the</str<strong>on</strong>g> loop <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g>rmal soluti<strong>on</strong>s

IMMERSION CABLE HEATERS<br />

<strong>Durex</strong> can also modify any cable heater<br />

with special sheath materials, sheath<br />

seals and protective c<strong>on</strong>necti<strong>on</strong> housings<br />

for immersi<strong>on</strong> heating in a gas or liquid<br />

envir<strong>on</strong>ment. Shown here is a fully<br />

grounded, helical wound screw-type<br />

c<strong>on</strong>nector heater. Flange and<br />

over-<str<strong>on</strong>g>the</str<strong>on</strong>g>-side designs, as well as many<br />

o<str<strong>on</strong>g>the</str<strong>on</strong>g>r styles, are also available.<br />

WEDGE-LOCK MINI-COIL HEATERS<br />

Designed for <str<strong>on</strong>g>the</str<strong>on</strong>g> specific applicati<strong>on</strong><br />

of injecti<strong>on</strong> nozzle heating, this unique<br />

<strong>Durex</strong> product features a unique clamping<br />

band that allows <str<strong>on</strong>g>the</str<strong>on</strong>g> heating element to<br />

maintain full clamping force at elevated<br />

temperatures. Unlike c<strong>on</strong>venti<strong>on</strong>al<br />

M<br />

cam-locking designs, <str<strong>on</strong>g>the</str<strong>on</strong>g> Wedge-Lock<br />

mini-coil heater mechanism compensates<br />

for <str<strong>on</strong>g>the</str<strong>on</strong>g>rmal expansi<strong>on</strong> during <str<strong>on</strong>g>the</str<strong>on</strong>g> molding<br />

operati<strong>on</strong>. The heating element is<br />

c<strong>on</strong>structed within a rectangular profiled<br />

sheath, providing ten times <str<strong>on</strong>g>the</str<strong>on</strong>g> surface<br />

c<strong>on</strong>tact area of a round sheath. Using<br />

<strong>on</strong>ly an Allen wrench, quick installati<strong>on</strong><br />

<strong>on</strong> multi-gate molds is possible. Flexible<br />

M<br />

72" Tefl<strong>on</strong> leadwires. The Wedge-Lock<br />

coil heater is offered with an opti<strong>on</strong>al<br />

internal Type J or K <str<strong>on</strong>g>the</str<strong>on</strong>g>rmocouple for<br />

integral temperature c<strong>on</strong>trol. Direct<br />

replacements for Husky systems.<br />

NOZZLE AND SPRUE-BUSHING HEATERS<br />

Ano<str<strong>on</strong>g>the</str<strong>on</strong>g>r <strong>Durex</strong> innovati<strong>on</strong> for <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

hot runner molding industry, <str<strong>on</strong>g>the</str<strong>on</strong>g>se<br />

heaters comprise a hollow cast copper<br />

alloy and stainless steel outer shell for<br />

optimum heat transfer with extra<br />

protecti<strong>on</strong>. Precisi<strong>on</strong> machined I.D.<br />

www.durexindustries.com<br />

FIELD FORMABLE TRACE HEATERS<br />

Shown here is a sample of a <strong>Durex</strong> pipe<br />

trace heater assembly, with a swaged<br />

stainless steel flex hose c<strong>on</strong>necti<strong>on</strong> and<br />

Heliarc welded end. Pipelines, fuel lines,<br />

gas lines, food processing lines and o<str<strong>on</strong>g>the</str<strong>on</strong>g>r<br />

l<strong>on</strong>g runs, where evenly distributed heat<br />

is required to maintain temperature<br />

or prevent freezing, are all typical<br />

applicati<strong>on</strong>s for <str<strong>on</strong>g>the</str<strong>on</strong>g>se <strong>Durex</strong> products.<br />

Various terminati<strong>on</strong>s are available, as<br />

well as fiberglass leadwires, fiberglass<br />

sleeving, stainless steel overbraid and<br />

o<str<strong>on</strong>g>the</str<strong>on</strong>g>r shielding. Applicati<strong>on</strong> engineering<br />

assistance is provided by <strong>Durex</strong> to help<br />

you integrate <str<strong>on</strong>g>the</str<strong>on</strong>g>se products into your<br />

piping c<strong>on</strong>figurati<strong>on</strong>s, whe<str<strong>on</strong>g>the</str<strong>on</strong>g>r OEM,<br />

process, producti<strong>on</strong> or lab.<br />

for a press fit installati<strong>on</strong>. The copper<br />

alloy achieves maximum temperatures to<br />

1200 F (649 C). Sealed heater c<strong>on</strong>structi<strong>on</strong><br />

eliminates failures due to c<strong>on</strong>taminati<strong>on</strong><br />

and moisture. An opti<strong>on</strong>al internal<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g>rmocouple is offered for integral<br />

temperature c<strong>on</strong>trol.<br />

11

12<br />

These <strong>Durex</strong> products all feature <str<strong>on</strong>g>the</str<strong>on</strong>g> following:<br />

FINNED TUBULAR HEATERS<br />

Select high quality sheath materials to suit <str<strong>on</strong>g>the</str<strong>on</strong>g> applicati<strong>on</strong><br />

Precisi<strong>on</strong> wound helical Nichrome resistance wire<br />

Higher watt densities and increased heat<br />

transfer characteristics are achieved using<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> finned tubular heater design. The<br />

c<strong>on</strong>tinuous spiral fins are attached to <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

heater sheath promoting rapid heat<br />

dispersi<strong>on</strong> in air or liquids. The fins are<br />

c<strong>on</strong>structed of steel, stainless steel, or<br />

Incoloy depending <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> applicati<strong>on</strong><br />

requirements. All standard element<br />

diameters can be adapted to <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

finned c<strong>on</strong>structi<strong>on</strong>.<br />

High purity MgO (magnesium oxide) powder insulati<strong>on</strong> compacted<br />

to provide maximum heat c<strong>on</strong>ductivity and dielectric strength<br />

Integral cold pin fusi<strong>on</strong> welded to helical resistance wire<br />

for optimum current carrying capability<br />

FORMED MANIFOLD HEATERS<br />

Durotube tubular heating elements<br />

can be provided to any length, formed<br />

into any c<strong>on</strong>figurati<strong>on</strong> and shea<str<strong>on</strong>g>the</str<strong>on</strong>g>d in<br />

a dozen different materials to suit your<br />

applicati<strong>on</strong>. Likewise, <str<strong>on</strong>g>the</str<strong>on</strong>g> c<strong>on</strong>necti<strong>on</strong>/<br />

terminati<strong>on</strong> possibilities are limited <strong>on</strong>ly<br />

by your imaginati<strong>on</strong> and <str<strong>on</strong>g>the</str<strong>on</strong>g> availability<br />

of comp<strong>on</strong>ents. Typical terminati<strong>on</strong>s<br />

include threaded stud, threaded bulk-head,<br />

screw lug, quick disc<strong>on</strong>nect spade,<br />

ceramic-to-metal hermetic, molded rubber<br />

lead, c<strong>on</strong>venti<strong>on</strong>al lead-wire terminal<br />

assembly and more. <strong>Durex</strong> frequently<br />

fabricates custom manifold heaters in<br />

c<strong>on</strong>juncti<strong>on</strong> with an OEM’s design staff,<br />

both for prototype and producti<strong>on</strong>. We<br />

welcome all challenges.<br />

CUSTOM FORMED ELEMENTS<br />

When special c<strong>on</strong>necti<strong>on</strong>s, shapes,<br />

sheathing or o<str<strong>on</strong>g>the</str<strong>on</strong>g>r design elements require<br />

it, <strong>Durex</strong> engineers can produce a dozen<br />

or a thousand of <str<strong>on</strong>g>the</str<strong>on</strong>g> custom formed<br />

elements you need. Once again, you benefit<br />

from <str<strong>on</strong>g>the</str<strong>on</strong>g> "under <strong>on</strong>e roof" philosophy that<br />

has made and keeps our company ahead<br />

of <str<strong>on</strong>g>the</str<strong>on</strong>g> pack, in heater design, engineering<br />

and fabricati<strong>on</strong>. This is your <strong>Durex</strong><br />

guarantee of quality at every bend!

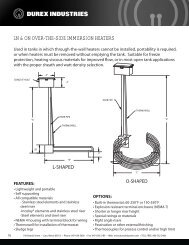

OVER-THE-SIDE IMMERSION HEATERS<br />

L-shaped and O-shaped immersi<strong>on</strong><br />

heaters are offered with standard NEMA 4<br />

waterproof enclosure; Incoloy® sheath;<br />

all welded c<strong>on</strong>structi<strong>on</strong> between <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

element housing and <str<strong>on</strong>g>the</str<strong>on</strong>g> riser pipes;<br />

stainless steel riser pipes and manifold<br />

housing; <str<strong>on</strong>g>the</str<strong>on</strong>g>rmostat protecti<strong>on</strong> tube; 3/4"<br />

NPT waterproof wiring hub; 4" high sludge<br />

legs and welded c<strong>on</strong>necti<strong>on</strong>s between <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

leadwires and element jumpers. Opti<strong>on</strong>al<br />

NEMA 7 explosi<strong>on</strong>-proof enclosure,<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g>rmocouples for c<strong>on</strong>trol or high limit<br />

protecti<strong>on</strong>, alternate sheath materials such<br />

as Carpenter 20, M<strong>on</strong>el 400, Inc<strong>on</strong>el 600,<br />

Hastelloy and Titanium are available.<br />

FLANGED IMMERSION HEATERS<br />

Flanged immersi<strong>on</strong> heaters are<br />

offered in hundreds of styles and sizes,<br />

with 150 lb. rated flanges from 3-14" with<br />

integral <str<strong>on</strong>g>the</str<strong>on</strong>g>rmowells. Welded c<strong>on</strong>structi<strong>on</strong><br />

<strong>on</strong> steel flanges and silver braze<br />

c<strong>on</strong>structi<strong>on</strong> <strong>on</strong> n<strong>on</strong>-ferrous flanges.<br />

All <strong>Durex</strong> immersi<strong>on</strong> heaters feature<br />

recompacted bends to restore MgO<br />

density throughout. Copper, Incoloy®<br />

or steel sheaths. All heating elements<br />

moisture sealed for l<strong>on</strong>g life.<br />

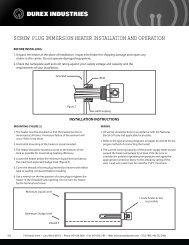

SCREW PLUG IMMERSION HEATERS<br />

Hundreds of styles and sizes are available<br />

for use in virtually any media, including<br />

water, mild soluti<strong>on</strong>s, detergents, vegetable<br />

oil, aqueous soluti<strong>on</strong>s, tar, asphalt,<br />

petroleum products, plating chemicals,<br />

molten salt baths, grease, gas or grape<br />

juice. Various sheath, screw plug and<br />

corrosi<strong>on</strong>-resistant hardware materials are<br />

available. NEMA enclosures for all moisture<br />

and explosi<strong>on</strong>-proof c<strong>on</strong>diti<strong>on</strong>s, as well.<br />

Opti<strong>on</strong>al <str<strong>on</strong>g>the</str<strong>on</strong>g>rmocouples for c<strong>on</strong>trol or<br />

high limit protecti<strong>on</strong>, plus a full range<br />

of <str<strong>on</strong>g>the</str<strong>on</strong>g>rmostatic c<strong>on</strong>trols, can also be<br />

provided with <str<strong>on</strong>g>the</str<strong>on</strong>g>se immersi<strong>on</strong> heaters.<br />

IMMERSION TUBULARS<br />

When c<strong>on</strong>venti<strong>on</strong>al immersi<strong>on</strong> heaters<br />

w<strong>on</strong>’t do <str<strong>on</strong>g>the</str<strong>on</strong>g> job right, you can look to<br />

<strong>Durex</strong> for a combinati<strong>on</strong> of our Durotube<br />

element design al<strong>on</strong>g with <str<strong>on</strong>g>the</str<strong>on</strong>g> necessary<br />

hardware and safety devices required for<br />

immersi<strong>on</strong> heating.<br />

BOLT HEATERS<br />

Designed for <str<strong>on</strong>g>the</str<strong>on</strong>g> purpose of preheating<br />

hollow holding bolts or studs used for <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

assembly, installati<strong>on</strong> and servicing of<br />

hydraulic presses, steam or pressure<br />

vessels, turbines, boilers and o<str<strong>on</strong>g>the</str<strong>on</strong>g>r<br />

heavy-duty equipment. When <str<strong>on</strong>g>the</str<strong>on</strong>g> heater<br />

is inserted, <str<strong>on</strong>g>the</str<strong>on</strong>g> bolt or stud leng<str<strong>on</strong>g>the</str<strong>on</strong>g>ns,<br />

thus allowing tighter nut fixing. Units<br />

feature swaged cartridge heater, c<strong>on</strong>duit<br />

box with ground c<strong>on</strong>necti<strong>on</strong>, insulated<br />

handle, 3-wire cord and plug assembly.<br />

Dozens of standard diameters and lengths<br />

available.<br />

13

16<br />

DUREX INDUSTRIES closing <str<strong>on</strong>g>the</str<strong>on</strong>g> loop <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g>rmal soluti<strong>on</strong>s<br />

KAPTON ® FLEXIBLE HEATERS<br />

Kapt<strong>on</strong> flexible heaters offer superior<br />

tensile strength and tear resistance,<br />

with precisi<strong>on</strong> heat distributi<strong>on</strong>.<br />

They are ideal for extreme<br />

temperature envir<strong>on</strong>ments, from<br />

-319ºF to +392ºF (-195ºC to +200ºC).<br />

Standard sizes start at .007" (0.2mm)<br />

thick and up to 20" x 26" (.508m x<br />

.660m) areas. Watt density is 5W/in 2<br />

(0.8W/cm 2) standard, with units<br />

available to 50W/in 2 (7.8W/cm 2).<br />

Kapt<strong>on</strong> is an organic polymer with<br />

very high dielectric capabilities, while<br />

providing superior resistance to<br />

most solvents, oils, even radiati<strong>on</strong>.<br />

With low outgassing, <str<strong>on</strong>g>the</str<strong>on</strong>g>se heaters<br />

are useful in vacuum envir<strong>on</strong>ments.<br />

Etched foil heating elements, with<br />

12" (305mm) l<strong>on</strong>g Kapt<strong>on</strong> or Tefl<strong>on</strong>®<br />

leads, are standard. Silic<strong>on</strong>e leads,<br />

as well as custom lengths, cord and<br />

plug sets available. Being<br />

transparent, Kapt<strong>on</strong> film also allows<br />

easy visual inspecti<strong>on</strong> of <str<strong>on</strong>g>the</str<strong>on</strong>g> internal<br />

structures. Pressure-sensitive<br />

adhesive (PSA) backing surface is<br />

standard, but <strong>Durex</strong> will customize<br />

your Kapt<strong>on</strong> heaters with special<br />

adhesives or mounting holes, as <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

applicati<strong>on</strong> requires. Mechanical<br />

fasteners such as hooks, grommets,<br />

spring-loaded latches, snaps and<br />

Velcro® patches are also available.<br />

Minimum radius flexibility is 1/32"<br />

(0.88mm) standard with weight of<br />

1-1/2oz/ft 2 (0.05g/cm 2).<br />

MEDICAL DESIGN KAPTON<br />

KAPTON WITH TAB TERMINATION<br />

CUSTOM DESIGNED KAPTON

www.durexindustries.com<br />

FLEXIBLE WRAP AROUND<br />

HEATER WITH THERMOSTAT<br />

CUSTOM SHAPED ELEMENTS<br />

17

18<br />

DUREX INDUSTRIES closing <str<strong>on</strong>g>the</str<strong>on</strong>g> loop <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g>rmal soluti<strong>on</strong>s<br />

M<br />

M<br />

These <strong>Durex</strong> products all<br />

feature <str<strong>on</strong>g>the</str<strong>on</strong>g> following:<br />

High-temperature fiberglass<br />

flexible leadwire<br />

Protective ceramic or lava end seal<br />

High-temperature alloy<br />

sheath material<br />

Nichrome resistance wire allows<br />

even heat distributi<strong>on</strong> and more<br />

efficient heat transfer<br />

Welded end disc seals out moisture<br />

and c<strong>on</strong>taminati<strong>on</strong><br />

NOTE The following are representative terminati<strong>on</strong><br />

selecti<strong>on</strong> opti<strong>on</strong>s. More opti<strong>on</strong>s are available, so please<br />

c<strong>on</strong>tact <strong>Durex</strong> with your specific requirement.<br />

M<br />

NON-STICK CARTRIDGE HEATERS<br />

Using a patented process, <strong>Durex</strong> can<br />

provide a high temperature n<strong>on</strong>-stick<br />

coating to any cartridge heater sheath.<br />

The Duraslik coating eliminates <str<strong>on</strong>g>the</str<strong>on</strong>g> need<br />

for additi<strong>on</strong>al release agents to be applied<br />

to <str<strong>on</strong>g>the</str<strong>on</strong>g> heater prior to <str<strong>on</strong>g>the</str<strong>on</strong>g> inserti<strong>on</strong>. The<br />

coating acts as a corrosi<strong>on</strong> inhibitor and a<br />

solid lubricant <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> inner diameter of <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

drilled hole when <str<strong>on</strong>g>the</str<strong>on</strong>g> heater is energized,<br />

allowing for reduced downtime caused by<br />

"sticky" heaters during replacement.<br />

STANDARD LEADS<br />

Fiberglass insulated leadwires are<br />

externally c<strong>on</strong>nected to nickel pins.<br />

The c<strong>on</strong>necti<strong>on</strong> area is electrically<br />

insulated with heavy wall fiberglass<br />

sleeving. 12" leads standard.<br />

SWAGED-IN FLEXIBLE LEADS<br />

Fiberglass insulated leadwires are<br />

internally c<strong>on</strong>nected to nickel pins. This<br />

design allows for much greater flexibility<br />

at <str<strong>on</strong>g>the</str<strong>on</strong>g> lead exit point from <str<strong>on</strong>g>the</str<strong>on</strong>g> heater.

INTERNAL THERMOCOUPLE<br />

A Type J <str<strong>on</strong>g>the</str<strong>on</strong>g>rmocouple provides integral<br />

temperature c<strong>on</strong>trol. The reference<br />

juncti<strong>on</strong>, grounded or ungrounded, can be<br />

located at <str<strong>on</strong>g>the</str<strong>on</strong>g> end disc, center or lead end.<br />

O<str<strong>on</strong>g>the</str<strong>on</strong>g>r <str<strong>on</strong>g>the</str<strong>on</strong>g>rmocouple Types are available.<br />

RIGHT ANGLE LEADS<br />

Fiberglass insulated leads exit <str<strong>on</strong>g>the</str<strong>on</strong>g> heater<br />

sheath at a right angle for easier access<br />

and routing. Includes stainless steel end<br />

cap and high-temperature potting.<br />

STRAIGHT BRAID<br />

LEAD PROTECTION<br />

Stainless steel braid over fiberglass insulated<br />

leadwires exits straight from heater sheath for<br />

abrasi<strong>on</strong> resistance.<br />

RIGHT ANGLE BRAID PROTECTION<br />

Stainless steel braid over fiberglass insulated<br />

leadwires exits at right angle from heater<br />

sheath. Includes stainless steel end cap.<br />

STRAIGHT FLEX CABLE<br />

Stainless steel flex cable over fiberglass<br />

insulated leadwires exits straight from<br />

heater sheath for maximum lead protecti<strong>on</strong>.<br />

Galvanized or stainless steel armor.<br />

RIGHT ANGLE FLEX CABLE<br />

Stainless steel flex cable over fiberglass<br />

insulated leadwires exits at right angle<br />

from heater sheath. Includes stainless<br />

steel end cap. Galvanized or stainless<br />

steel armor.<br />

IMMERSION PIPE FITTING<br />

Cartridge heater supplied with threaded<br />

NPT pipe fitting, silver brazed or welded to<br />

heater sheath for immersed applicati<strong>on</strong>s.<br />

Fiberglass insulated leadwires exit<br />

high-temperature cement potting. 3/4"<br />

cold secti<strong>on</strong> required before fitting.<br />

www.durexindustries.com<br />

MOUNTING FLANGE<br />

Stainless steel flange welded directly<br />

to heater sheath. Fiberglass insulated<br />

leadwires are standard. Assorted sizes<br />

and opti<strong>on</strong>s available.<br />

BOLT HEATERS<br />

Bolt Heaters are used to tighten large<br />

bolts that secure heavy machinery and<br />

equipment. The shaft of <str<strong>on</strong>g>the</str<strong>on</strong>g> heater is<br />

inserted into <str<strong>on</strong>g>the</str<strong>on</strong>g> hollow bolt and energized<br />

to expand it, which allows fur<str<strong>on</strong>g>the</str<strong>on</strong>g>r<br />

tightening of <str<strong>on</strong>g>the</str<strong>on</strong>g> nut. This heater design<br />

is manufactured with specific diameter<br />

sheaths to fit industry standard hollow<br />

bolts. High watt densities with special<br />

heated lengths distribute heat evenly to<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> surrounding bolt.<br />

CUSTOM DESIGNS<br />

Magnum cartridge heaters from <strong>Durex</strong><br />

can be supplied with <str<strong>on</strong>g>the</str<strong>on</strong>g> following<br />

enhancements:<br />

-Distributed wattage-Centerless grinding<br />

-Tefl<strong>on</strong> coating -Ground leadwire<br />

-Special c<strong>on</strong>nectors<br />

19

20<br />

DUREX INDUSTRIES closing <str<strong>on</strong>g>the</str<strong>on</strong>g> loop <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g>rmal soluti<strong>on</strong>s<br />

parameters of measurement and<br />

degrees of c<strong>on</strong>trol accuracy in<br />

a manner few can match. This<br />

translates into a supplier who knows<br />

your business, who knows <str<strong>on</strong>g>the</str<strong>on</strong>g> latest<br />

soluti<strong>on</strong>s for your process problems<br />

and has <str<strong>on</strong>g>the</str<strong>on</strong>g> manufacturing muscle<br />

to resp<strong>on</strong>d. These factors, coupled<br />

with <str<strong>on</strong>g>the</str<strong>on</strong>g> <strong>Durex</strong> network of quality<br />

distributors and sales<br />

representatives, work to keep<br />

your producti<strong>on</strong> and your process<br />

running with greater efficiency and<br />

profitability…exactly what you<br />

expect from your best suppliers.<br />

For all your <str<strong>on</strong>g>the</str<strong>on</strong>g>rmocouple needs,<br />

c<strong>on</strong>tact <strong>Durex</strong>.

MINERAL INSULATED<br />

THERMOCOUPLES<br />

We currently manufacture and market<br />

every ANSI industrial <str<strong>on</strong>g>the</str<strong>on</strong>g>rmocouple type<br />

in use, as well as hundreds of variati<strong>on</strong>s<br />

for <str<strong>on</strong>g>the</str<strong>on</strong>g> different juncti<strong>on</strong> types, sheath<br />

materials, sheath diameters and overall<br />

lengths required. Our calibrati<strong>on</strong><br />

services, as well as our physical,<br />

electrical and ASTM testing procedures<br />

are <str<strong>on</strong>g>the</str<strong>on</strong>g> envy of <str<strong>on</strong>g>the</str<strong>on</strong>g> industry. Base metal<br />

and Noble metal <str<strong>on</strong>g>the</str<strong>on</strong>g>rmocouples in bare<br />

and ceramic insulated designs are offered<br />

with every possible c<strong>on</strong>necti<strong>on</strong> needed for<br />

temperatures to 2400 F (1316 C.) Better<br />

still, <strong>Durex</strong> engineers custom temperature<br />

sensors every day, so call <strong>on</strong> us to help<br />

with any requirement.<br />

THERMOWELL ASSEMBLIES<br />

<strong>Durex</strong> offers 1/2", 3/4" and 1" NPT drilled bar<br />

stock <str<strong>on</strong>g>the</str<strong>on</strong>g>rmowells in standard, flanged and<br />

lagging or VanSt<strong>on</strong>e well extensi<strong>on</strong> designs,<br />

with stepped, straight or tapered shanks and<br />

a variety of terminal head designs and<br />

materials to match your requirement.<br />

EXTREME SERVICE PLATINUM<br />

THERMOCOUPLES<br />

For extreme high-temperature ranges<br />

to 3092 F (1700 C) with ultra high purity<br />

MgO or alumina oxide insulati<strong>on</strong>, <str<strong>on</strong>g>the</str<strong>on</strong>g>se<br />

<strong>Durex</strong> platinum <str<strong>on</strong>g>the</str<strong>on</strong>g>rmocouples provide<br />

accurate readings in <str<strong>on</strong>g>the</str<strong>on</strong>g> most hostile<br />

envir<strong>on</strong>ments, such as steel processing,<br />

commercial heat treating and furnace<br />

manufacturing. Protecti<strong>on</strong> tubes of ceramic,<br />

silic<strong>on</strong> carbide and o<str<strong>on</strong>g>the</str<strong>on</strong>g>r materials available.<br />

MINIATURE THERMOCOUPLES<br />

<strong>Durex</strong> offers a complete line of<br />

miniature <str<strong>on</strong>g>the</str<strong>on</strong>g>rmocouples for applicati<strong>on</strong>s<br />

with tight space requirements, limited<br />

access or o<str<strong>on</strong>g>the</str<strong>on</strong>g>r c<strong>on</strong>siderati<strong>on</strong>s. Assorted<br />

jack and plug style c<strong>on</strong>necti<strong>on</strong>s available,<br />

as well as miniature glass-filled nyl<strong>on</strong><br />

terminal head rated to 350 F (177 C)<br />

and measuring <strong>on</strong>ly 1-1/2" x 2-1/8".<br />

www.durexindustries.com<br />

PROTECTION TUBE ASSEMBLIES<br />

Protecti<strong>on</strong> tube assemblies<br />

feature various stainless steels,<br />

carb<strong>on</strong> steel or Inc<strong>on</strong>el® materials of<br />

c<strong>on</strong>structi<strong>on</strong>, plus Mullite and Alumina<br />

ceramics for extremely high-temperature<br />

applicati<strong>on</strong>s. For certain applicati<strong>on</strong>s<br />

where needed, <strong>Durex</strong> supplies a unique<br />

double ceramic protecti<strong>on</strong> tube<br />

design. Ask for details.<br />

CUSTOM THERMOCOUPLE DESIGNS<br />

<strong>Durex</strong> puts no limits <strong>on</strong> our<br />

imaginati<strong>on</strong>, so whatever temperature<br />

measurement requirement you have,<br />

bring it our way and a soluti<strong>on</strong> will<br />

be found. Whe<str<strong>on</strong>g>the</str<strong>on</strong>g>r it be a modificati<strong>on</strong><br />

of a standard <str<strong>on</strong>g>the</str<strong>on</strong>g>rmocouple, a particular<br />

arrangement of elements, an envir<strong>on</strong>ment<br />

requiring a unique protecti<strong>on</strong> tube or a<br />

space c<strong>on</strong>straint no o<str<strong>on</strong>g>the</str<strong>on</strong>g>r <str<strong>on</strong>g>the</str<strong>on</strong>g>rmocouple<br />

company can accommodate.<br />

21

22<br />

DUREX INDUSTRIES closing <str<strong>on</strong>g>the</str<strong>on</strong>g> loop <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g>rmal soluti<strong>on</strong>s<br />

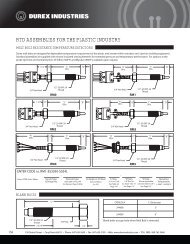

ADJUSTABLE THERMOCOUPLE<br />

WITH SPRING<br />

A compressi<strong>on</strong> spring and bay<strong>on</strong>et<br />

lockcap allow this design to adjust to<br />

holes up to 12" deep. A stainless steel tip<br />

with silver solder juncti<strong>on</strong> provide fast<br />

resp<strong>on</strong>se time. A TIG welded juncti<strong>on</strong> is<br />

also available.<br />

MELT BOLT THERMOCOUPLES<br />

<strong>Durex</strong> melt bolts are designed for<br />

dependable temperature measurement<br />

of <str<strong>on</strong>g>the</str<strong>on</strong>g> plastic melt stream within extruders<br />

and injecti<strong>on</strong> molding equipment. Fixed and<br />

adjustable tip styles to suit any applicati<strong>on</strong>.<br />

Ask us about <strong>Durex</strong>ium, a multi-layer coating<br />

opti<strong>on</strong>. Extends wear life up to 12 times.<br />

ADJUSTABLE THERMOCOUPLE<br />

WITH ARMOR<br />

Flexible stainless steel armor cable<br />

and rotating bay<strong>on</strong>et lockcap <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

outside diameter adjust to various<br />

immersi<strong>on</strong> depths.

SURFACE MOUNT THERMOCOUPLES<br />

For surface mounting via ring lug or gasket<br />

with bracket, <str<strong>on</strong>g>the</str<strong>on</strong>g>se <strong>Durex</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g>rmocouples<br />

can be provided with various terminati<strong>on</strong>s,<br />

including split leads, spade lugs, standard<br />

plug, standard jack or special c<strong>on</strong>nectors,<br />

as needed.<br />

FIXED BAYONET THERMOCOUPLES<br />

o<br />

o<br />

Straight run, 45 and 90 bend<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g>rmocouples are available in a wide<br />

variety of sizes and styles.<br />

NOZZLE THERMOCOUPLES<br />

o<br />

Rotating bolt, fixed immersi<strong>on</strong>, 90<br />

probe and shim stock pad type nozzle<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g>rmocouples are offered by <strong>Durex</strong> for<br />

virtually any mounting requirement <strong>on</strong> a<br />

plastics machine or auxiliary apparatus.<br />

PIPE CLAMP THERMOCOUPLES<br />

<strong>Durex</strong> offers <str<strong>on</strong>g>the</str<strong>on</strong>g>se <str<strong>on</strong>g>the</str<strong>on</strong>g>rmocouple<br />

styles for temperature measurements <strong>on</strong><br />

pipe ranging from 1/2" to 2-1/4" diameters.<br />

Stainless steel overbraid shield protects<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> element, which senses <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

temperature <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> surface of <str<strong>on</strong>g>the</str<strong>on</strong>g> clamp.<br />

www.durexindustries.com<br />

GENERAL PURPOSE THERMOCOUPLES<br />

Standard Type J <str<strong>on</strong>g>the</str<strong>on</strong>g>rmocouples have<br />

many uses in <str<strong>on</strong>g>the</str<strong>on</strong>g> plastics industry, for<br />

temperatures to 800 F (427 C). Sheath<br />

material is 304 stainless steel, with<br />

standard jack or plug c<strong>on</strong>nectors.<br />

Many o<str<strong>on</strong>g>the</str<strong>on</strong>g>r styles available. Extensi<strong>on</strong><br />

assemblies also offered for any<br />

c<strong>on</strong>necti<strong>on</strong> transiti<strong>on</strong> required.<br />

CUSTOM DESIGNED THERMOCOUPLES<br />

If <str<strong>on</strong>g>the</str<strong>on</strong>g> equipment you’re using or building<br />

requires a particular sensor element,<br />

sheath material, c<strong>on</strong>necti<strong>on</strong> style or<br />

fastening device, please c<strong>on</strong>tact <strong>Durex</strong><br />

with your specificati<strong>on</strong>s. It’s likely we’ve<br />

already built what you need!<br />

<strong>Durex</strong> also offers assorted <str<strong>on</strong>g>the</str<strong>on</strong>g>rmocouple<br />

c<strong>on</strong>nectors, bay<strong>on</strong>et adapters, cable<br />

clamps, panel jack strips, terminal strips,<br />

flexible armor cable, <str<strong>on</strong>g>the</str<strong>on</strong>g>rmocouple<br />

extensi<strong>on</strong> wire and many o<str<strong>on</strong>g>the</str<strong>on</strong>g>r accessory<br />

items specifically for <str<strong>on</strong>g>the</str<strong>on</strong>g> plastics<br />

processor. We welcome <str<strong>on</strong>g>the</str<strong>on</strong>g> opportunity<br />

to service your needs.<br />

23

24<br />

DUREX INDUSTRIES closing <str<strong>on</strong>g>the</str<strong>on</strong>g> loop <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g>rmal soluti<strong>on</strong>s<br />

Standard and custom designed RTD’s<br />

and <str<strong>on</strong>g>the</str<strong>on</strong>g>rmistors are offered for<br />

various industrial and commercial<br />

applicati<strong>on</strong>s. A wide variety of<br />

curves and tolerances is available.<br />

High accuracy RTD’s are provided<br />

with Platinum, Nickel or Nickel Ir<strong>on</strong><br />

elements for temperature ranges up<br />

to 1200 F (649 C). However, <strong>Durex</strong><br />

offers RTD’s for operating tempera<br />

tures to 1500 F 816 C) <strong>on</strong> request. predictable resistance gain that is<br />

2-, 3- and 4-wire styles are available inversely proporti<strong>on</strong>al to change in<br />

with a broad assortment of c<strong>on</strong>nec- ambient temperature. Each of <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

ti<strong>on</strong>s, mounting hardware and enclo- five available standard <str<strong>on</strong>g>the</str<strong>on</strong>g>rmistor<br />

sures. Thermistor assemblies are curves from <strong>Durex</strong> has its own slope<br />

designed to be lower cost probes for over a given temperature range.<br />

surface measurement, liquid immersi<strong>on</strong><br />

or gas temperature readings.<br />

NTC (Negative Temperature Coefficient<br />

) <str<strong>on</strong>g>the</str<strong>on</strong>g>rmistors have a very

CUSTOM RTD’S<br />

Shown here are samples of <str<strong>on</strong>g>the</str<strong>on</strong>g> many<br />

custom designed RTD’s <strong>Durex</strong><br />

manufactures regularly. These include <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

use of special wells, fittings, terminal<br />

blocks, c<strong>on</strong>nector hardware and unique<br />

sheath materials to match <str<strong>on</strong>g>the</str<strong>on</strong>g> specific<br />

needs of our customers. <strong>Durex</strong> can<br />

handle virtually any requirement, so<br />

please bring us yours.<br />

IMMERSION RTD’S<br />

For applicati<strong>on</strong>s requiring immersi<strong>on</strong> into any<br />

liquid or semi-solid, <strong>Durex</strong> will supply RTD’s<br />

in protective <str<strong>on</strong>g>the</str<strong>on</strong>g>rmowells or protecti<strong>on</strong> tubes,<br />

with sealed terminal heads. Assemblies<br />

available for high-pressure applicati<strong>on</strong>s to<br />

5000 PSI. Stainless steel sanitary fittings and<br />

wells are also offered standard for those<br />

applicati<strong>on</strong>s requiring such hardware.<br />

THERMISTOR ASSEMBLIES<br />

10K to 500K ohm elements are<br />

available standard from <strong>Durex</strong> for<br />

accurate temperature measurements of<br />

surfaces, liquid or gas in <str<strong>on</strong>g>the</str<strong>on</strong>g> lower ranges,<br />

down to –50 C (-58 F) with high reliability.<br />

Stainless steel sheath materials, fiberglass<br />

or Tefl<strong>on</strong> leadwires and various fitting/<br />

c<strong>on</strong>nector styles are offered.<br />

www.durexindustries.com<br />

SURFACE MOUNT RTD’S<br />

<strong>Durex</strong> RTD’s can be supplied with block<br />

surface mount, spade type surface mount<br />

or adhesive patch mounting hardware.<br />

Fiberglass, Mica/Fiberglass, Tefl<strong>on</strong> or PVC<br />

leadwires with various braiding or armor<br />

cable shielding opti<strong>on</strong>s are available.<br />

PROCESS RTD’S<br />

<strong>Durex</strong> provides RTD’s for <str<strong>on</strong>g>the</str<strong>on</strong>g> most<br />

challenging process applicati<strong>on</strong>s in <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

industry, from <str<strong>on</strong>g>the</str<strong>on</strong>g> high-corrosi<strong>on</strong> envir<strong>on</strong>s<br />

of <str<strong>on</strong>g>the</str<strong>on</strong>g> petrochem plant to <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

high-precisi<strong>on</strong> of nuclear feedwater to <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

exacting requirements of process air and<br />

gas measurements. Platinum sensors<br />

uniform to DIN 43760, IEC 751 (Class A<br />

and B), as well as JIS 3920 are offered.<br />

For portability, <strong>Durex</strong> also offers a<br />

complete line of hand-held RTD probes.<br />

IC SENSORS<br />

High-precisi<strong>on</strong>, easily calibrated<br />

integrated circuit temperature sensors<br />

operate over a wide current range<br />

with c<strong>on</strong>sistent performance. Operate<br />

in -55 C to +150 C range. Low impedance<br />

and linear output easily interface to readout<br />

or c<strong>on</strong>trol circuitry.<br />

25

26<br />

DUREX INDUSTRIES closing <str<strong>on</strong>g>the</str<strong>on</strong>g> loop <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g>rmal soluti<strong>on</strong>s<br />

SPECIAL SENSOR<br />

APPLICATION PRODUCTS<br />

One of <str<strong>on</strong>g>the</str<strong>on</strong>g> many benefits of <strong>Durex</strong><br />

is our ability to utilize all our design,<br />

engineering and manufacturing muscle<br />

to bring customers <str<strong>on</strong>g>the</str<strong>on</strong>g>rmal soluti<strong>on</strong>s to<br />

meet <str<strong>on</strong>g>the</str<strong>on</strong>g>ir requirements, <str<strong>on</strong>g>the</str<strong>on</strong>g>ir timetable<br />

and <str<strong>on</strong>g>the</str<strong>on</strong>g>ir budget. Who says you can’t<br />

have quality, service and price from <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

same vendor? The efficiencies <strong>Durex</strong><br />

brings to your <str<strong>on</strong>g>the</str<strong>on</strong>g>rmal process<br />

challenges allow us to provide custom<br />

engineered products, even at lower<br />

volumes, for very competitive prices.<br />

Shown here are just a few samples<br />

of <str<strong>on</strong>g>the</str<strong>on</strong>g> successes we’ve achieved<br />

for customers.<br />

<strong>Durex</strong> begins <str<strong>on</strong>g>the</str<strong>on</strong>g> special sensor<br />

applicati<strong>on</strong> process by listening.<br />

Often, in <str<strong>on</strong>g>the</str<strong>on</strong>g> course of <str<strong>on</strong>g>the</str<strong>on</strong>g> very first<br />

c<strong>on</strong>versati<strong>on</strong>, we’ll hear an aspect of<br />

your situati<strong>on</strong> that sparks an idea or<br />

reminds us of a previous challenge<br />

we’ve overcome. The result is a<br />

better soluti<strong>on</strong> to your problem,<br />

often at a cost savings compared<br />

to "getting by" with some off-<str<strong>on</strong>g>the</str<strong>on</strong>g>-shelf<br />

catalog products.<br />

If something <strong>on</strong> this page sparks<br />

an idea with you, please give<br />

us a call. We’ll be listening!<br />

SANITARY PROBES<br />

In applicati<strong>on</strong>s such as food processing,<br />

semic<strong>on</strong>ductor, medical, cleanroom and<br />

lab applicati<strong>on</strong>s, where sanitary fittings,<br />

terminal heads, wells or o<str<strong>on</strong>g>the</str<strong>on</strong>g>r comp<strong>on</strong>ents<br />

are mandated, <strong>Durex</strong> brings a<br />

wealth of experience to <str<strong>on</strong>g>the</str<strong>on</strong>g> task.<br />

Regardless of <str<strong>on</strong>g>the</str<strong>on</strong>g> temperature ranges or<br />

physical sensing c<strong>on</strong>diti<strong>on</strong>s involved, our<br />

engineers will design (or already have<br />

designed) <str<strong>on</strong>g>the</str<strong>on</strong>g> optimum soluti<strong>on</strong> for you.<br />

HAND-HELD PROBES<br />

When you need <str<strong>on</strong>g>the</str<strong>on</strong>g> portability of a hand-held device for sensing temperature, such<br />

as <strong>on</strong> motor bearings in-plant, <strong>on</strong> process pipelines in <str<strong>on</strong>g>the</str<strong>on</strong>g> field or anywhere in <str<strong>on</strong>g>the</str<strong>on</strong>g> lab,<br />

<strong>Durex</strong> can provide a complete, ready-to-use assembly, matched to <str<strong>on</strong>g>the</str<strong>on</strong>g> ranges and<br />

physical characteristics of <str<strong>on</strong>g>the</str<strong>on</strong>g> job at hand…so to speak. We currently supply such<br />

products to instrument companies, large process end users and labs alike. Thermocouple,<br />

RTD or <str<strong>on</strong>g>the</str<strong>on</strong>g>rmistor elements can be provided with any sheath, leadwire and c<strong>on</strong>nector<br />

c<strong>on</strong>figurati<strong>on</strong> required.<br />

SELF-ADHESIVE RTD’S<br />

If <str<strong>on</strong>g>the</str<strong>on</strong>g> surface being measured for<br />

temperature cannot be penetrated or if<br />

space limitati<strong>on</strong>s require it, <strong>Durex</strong> can<br />

provide an RTD with an adhesive patch<br />

for direct surface mounting. We routinely<br />

provide such sensors with special<br />

adhesives to accommodate temperature<br />

and vapor release requirements.<br />

SILICONE ENCAPSULATED<br />

SURFACE MOUNT RTD<br />

Utilizing <str<strong>on</strong>g>the</str<strong>on</strong>g> same technology as a sealed<br />

silic<strong>on</strong>e rubber heater, <strong>Durex</strong> offers a<br />

surface mount RTD sensor for direct<br />

mounting to flat or curved surfaces. The<br />

design can be manufactured in various<br />

thicknesses and supplied with an adhesive<br />

backing for quick applicati<strong>on</strong>. A thinner<br />

profile can be used to wrap <str<strong>on</strong>g>the</str<strong>on</strong>g> sensor<br />

to curved surfaces such as cooling or<br />

water lines.

MINIATURE RTD’S<br />

<strong>Durex</strong> produces RTD probes down to<br />

0.062" diameter, owing to our unique<br />

manufacturing capability. There is<br />

simply no point of sensing we can’t reach<br />

for you, providing accuracy, reliability and<br />

l<strong>on</strong>g service life with a miniaturized probe<br />

and compatible hardware.<br />

FLEXIBLE RTD’S<br />

When a probe needs to "snake" through an<br />

installati<strong>on</strong> because of space limitati<strong>on</strong>s or<br />

o<str<strong>on</strong>g>the</str<strong>on</strong>g>r factors, <strong>Durex</strong> offers flexible elements<br />

with overbraid shielding or armor to suit <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

specifics of your applicati<strong>on</strong>.<br />

AIR TEMPERATURE RTD<br />

The perforated tip of <str<strong>on</strong>g>the</str<strong>on</strong>g> air temp<br />

RTD sensor is designed for rapid<br />

m<strong>on</strong>itoring of airflow temperature in<br />

various applicati<strong>on</strong>s. Small film elements<br />

used in <str<strong>on</strong>g>the</str<strong>on</strong>g>se housings can detect<br />

incremental changes more quickly than<br />

c<strong>on</strong>venti<strong>on</strong>al housings. This c<strong>on</strong>structi<strong>on</strong><br />

can also be adapted to include special<br />

flanges and fittings, as well as custom<br />

c<strong>on</strong>nector opti<strong>on</strong>s.<br />

THERMAL PROCESS ACCESSORIES<br />

All <str<strong>on</strong>g>the</str<strong>on</strong>g> "extras" needed to complete<br />

your <str<strong>on</strong>g>the</str<strong>on</strong>g>rmal processing installati<strong>on</strong> are<br />

available from <strong>Durex</strong>. Our volume buying<br />

and l<strong>on</strong>g vendor relati<strong>on</strong>ships make <str<strong>on</strong>g>the</str<strong>on</strong>g>se<br />

products easy and affordable to obtain<br />

from <strong>Durex</strong> or our local distributor. We<br />

guarantee <str<strong>on</strong>g>the</str<strong>on</strong>g> same <strong>Durex</strong> applicati<strong>on</strong><br />

assistance and service will support all<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g>se products in use at your company.<br />

TRANSMITTERS<br />

For <str<strong>on</strong>g>the</str<strong>on</strong>g>rmocouples and RTD’s, <str<strong>on</strong>g>the</str<strong>on</strong>g>se 2-wire<br />

transmitters are offered in many styles,<br />

including explosi<strong>on</strong>-proof.<br />

www.durexindustries.com<br />

WIRE<br />

Insulated wire for every Type<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g>rmocouple we offer is available<br />

for your ordering c<strong>on</strong>venience.<br />

PANEL STRIPS<br />

2-12 circuit strips are available standard.<br />

CONNECTORS<br />

Plug, jack, circular panel jack, mini-plug,<br />

mini-jack, mini-circular panel jack and<br />

o<str<strong>on</strong>g>the</str<strong>on</strong>g>r styles are compatible with all<br />

calibrati<strong>on</strong> Type sensors.<br />

TERMINAL HEADS<br />

Cast ir<strong>on</strong>, cast aluminum, cast<br />

anodized, explosi<strong>on</strong>-proof, miniature<br />

glass-filled nyl<strong>on</strong> and o<str<strong>on</strong>g>the</str<strong>on</strong>g>r styles<br />

available for all comm<strong>on</strong> process and<br />

c<strong>on</strong>duit c<strong>on</strong>necti<strong>on</strong>s.<br />

COMPRESSION FITTINGS<br />

Allow for exact immersi<strong>on</strong> depth <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

sensor in-field. Rated up to 10,000 psi.<br />

FLEX CABLE<br />

Stainless steel flex cable is in stock at all<br />

times. Many sizes.<br />

27

28<br />

DUREX INDUSTRIES closing <str<strong>on</strong>g>the</str<strong>on</strong>g> loop <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g>rmal soluti<strong>on</strong>s<br />

CUSTOM TEMPERATURE CONTROLS<br />

<strong>Durex</strong> Temperature C<strong>on</strong>trol Platforms are<br />

a cost savings, fast prototype and<br />

producti<strong>on</strong> soluti<strong>on</strong> for applicati<strong>on</strong>s<br />

requiring combinati<strong>on</strong>s of temperature,<br />

humidity, time, pressure, and logic<br />

process functi<strong>on</strong>s. <strong>Durex</strong>’s c<strong>on</strong>trol<br />

platform leverages proven c<strong>on</strong>trol<br />

designs. Most applicati<strong>on</strong>s <strong>on</strong>ly require<br />

customizati<strong>on</strong> of firmware and hardware<br />

that is unique to <str<strong>on</strong>g>the</str<strong>on</strong>g> applicati<strong>on</strong>. By using<br />

a comm<strong>on</strong> platform <strong>Durex</strong>’s designers<br />

cost effectively achieve <str<strong>on</strong>g>the</str<strong>on</strong>g> distinctive<br />

operati<strong>on</strong> and user interface required for<br />

our customers.<br />

You can get <str<strong>on</strong>g>the</str<strong>on</strong>g> exact c<strong>on</strong>trol you<br />

need…at a price that fits. Time,<br />