Nanoprobe Laboratory for Bio- & Nanotechnology and Biomimetics

Nanoprobe Laboratory for Bio- & Nanotechnology and Biomimetics

Nanoprobe Laboratory for Bio- & Nanotechnology and Biomimetics

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

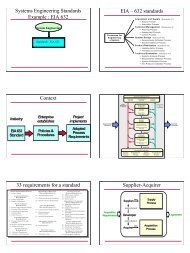

MEMS/NEMS <strong>and</strong> <strong>Bio</strong>MEMS/<strong>Bio</strong>NEMS<br />

Materials <strong>and</strong> Devices <strong>and</strong> <strong>Bio</strong>mimetics<br />

Prof. Bharat Bhushan<br />

Ohio Eminent Scholar <strong>and</strong> Howard D. Winbigler Professor<br />

<strong>and</strong> Director NLBB<br />

Bhushan.2@osu.edu<br />

<strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics<br />

© B. Bhushan<br />

<strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics

Outline<br />

• Background<br />

Definition of MEMS/NEMS <strong>and</strong> characteristic dimensions<br />

Examples of MEMS/NEMS <strong>and</strong> <strong>Bio</strong>MEMS/bioNEMS with nanotribology<br />

<strong>and</strong> nanomechanics issues<br />

<br />

<strong>Bio</strong>mimetics – Lessons from Nature<br />

• Experimental<br />

Atomic <strong>for</strong>ce/Friction <strong>for</strong>ce microscope (AFM/FFM)<br />

• Tribological Studies of Si <strong>and</strong> Related Materials<br />

Virgin, treated/coated silicon; polysilicon films <strong>and</strong> SiC film<br />

• <strong>Bio</strong>adhesion Studies<br />

Surface modification approaches to improve bioadhesion<br />

• Device Level Studies<br />

Nanotribological characterization of digital micromirror devices (DMD)<br />

• Hierarchical Nanostructures <strong>for</strong> Superhydrophobicity, self cleaning <strong>and</strong> low<br />

adhesion (Lotus Effect)<br />

<strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics

Background<br />

Definition of MEMS/NEMS <strong>and</strong> characteristic dimensions<br />

MEMS - characteristic length less than 1 mm,<br />

larger than 100 nm<br />

NEMS - less than 100 nm<br />

Human hair<br />

50-100 μm<br />

500 nm<br />

DMD<br />

12 μm<br />

Quantum-dots transistor<br />

300 nm<br />

Red blood cell<br />

8 μm<br />

Molecular gear<br />

10 nm-100 nm<br />

SWNT chemical sensor<br />

2 nm<br />

C atom<br />

0.16 nm<br />

DNA<br />

2.5 nm<br />

0.1 1 10 100 1000 10000 100000<br />

Size (nm)<br />

Characteristic dimensions in perspective<br />

B. Bhushan, Springer H<strong>and</strong>book of <strong>Nanotechnology</strong>, Springer, 2 nd ed. (2007)<br />

<strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics

Examples of MEMS/NEMS <strong>and</strong> <strong>Bio</strong>MEMS/NEMS<br />

shuttle<br />

springs<br />

gears <strong>and</strong> pin joint<br />

Microgear unit can be driven at speeds up<br />

to 250,000 RPM. Various sliding comp. are<br />

shown after wear test <strong>for</strong> 600k cycles at<br />

1.8% RH (Tanner et al., 2000)<br />

Microengine driven by electrostatically-actuated<br />

comb drive<br />

S<strong>and</strong>ia Summit Technologies (www.mems.s<strong>and</strong>ia.gov)<br />

<strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics<br />

Stuck comb drive

Microfabricated commercial MEMS components<br />

5<br />

<strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics

The generating points of friction <strong>and</strong> wear due to interaction of<br />

a biomolecular layer on a synthetic microdevice with tissue<br />

(Bhushan, Lee et al., 2006)<br />

<strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics<br />

6

Need to address nanotribology <strong>and</strong> nanomechanics issues<br />

• The nanotribology <strong>and</strong> nanomechanics problems can drastically<br />

compromise device per<strong>for</strong>mance <strong>and</strong> reliability. To solve these<br />

problems, there is a need to develop a fundamental underst<strong>and</strong>ing<br />

of adhesion, friction/stiction, wear <strong>and</strong> the role of surface<br />

contamination <strong>and</strong> environment in MEMS/NEMS <strong>and</strong><br />

<strong>Bio</strong>MEMS/NEMS. This can be done by studying<br />

<br />

<br />

<br />

<br />

<br />

Approach<br />

Nanotribology <strong>and</strong> nanomechanics of MEMS/NEMS materials<br />

Lubricant methods <strong>for</strong> MEMS/NEMS<br />

<strong>Bio</strong>adhesion Studies<br />

Development of superhydrophobic surfaces<br />

Device level studies<br />

• Use an AFM/FFM <strong>for</strong> imaging <strong>and</strong> to study adhesion, friction, scratch <strong>and</strong><br />

wear properties of materials <strong>and</strong> lubricants, which better simulates<br />

MEMS/NEMS <strong>and</strong> <strong>Bio</strong>MEMS/<strong>Bio</strong>NEMS contacts<br />

• Develop <strong>and</strong> employ techniques to measure tribological phenomena in<br />

devices<br />

B. Bhushan et al., Nature 374, 607 (1995); B. Bhushan, H<strong>and</strong>book of Micro/Nanotribology, second ed., CRC Press, 1999;<br />

B. Bhushan, Introduction to Tribology, Wiley, NY, 2002; B. Bhushan, Springer H<strong>and</strong>book of <strong>Nanotechnology</strong>, 2 nd ed., 2007;<br />

B. Bhushan, Nanotribology <strong>and</strong> Nanomechanics – An Introduction, Springer, 2005.<br />

<strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics

Lessons From Nature (<strong>Bio</strong>mimetics)<br />

<strong>Bio</strong>mimetics<br />

• <strong>Bio</strong>mimetics means mimicking biology or nature. It is derived from a<br />

Greek word “biomimesis.” Other words used include bionics, biomimicry<br />

<strong>and</strong> biognosis.<br />

• <strong>Bio</strong>mimetics involves taking ideas from nature <strong>and</strong> implementing them in<br />

an application.<br />

• Nature has gone through evolution over 3.8 billion years. It has evolved<br />

objects with high per<strong>for</strong>mance using commonly found materials.<br />

• <strong>Bio</strong>logical materials have hierarchical structure, made of commonly<br />

found materials.<br />

• It is estimated that the 100 largest biomimetic products had generated<br />

$1.5 billion over 2005-08. The annual sales are expected to continue to<br />

increase dramatically.<br />

M. Nosonovsky <strong>and</strong> B. Bhushan (2008), Multiscale Dissipative Mechanisms <strong>and</strong> Hierarchical Surfaces: Friction, Superhydrophobicity,<br />

<strong>and</strong> <strong>Bio</strong>mimetics, Springer-Verlag, Heidelberg, Germany; B. Bhushan (2007), Springer H<strong>and</strong>book of <strong>Nanotechnology</strong>, second ed.,<br />

Springer-Verlag, Heidelberg, Germany; B. Bhushan, Phil. Trans. R. Soc. A 367, 1445-1486 (2009).<br />

<strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics<br />

8

Montage of some<br />

examples from nature.<br />

B. Bhushan, Phil. Trans. R. Soc. A 367, 1445-1486 (2009).).<br />

<strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics<br />

9

Experimental<br />

Atomic <strong>for</strong>ce/Friction <strong>for</strong>ce microscope (AFM/FFM)<br />

• At most interfaces of technological relevance, contact occurs at<br />

numerous asperities. It is of importance to investigate a single<br />

asperity contact in the fundamental tribological studies.<br />

Engineering Interface<br />

Tip - based microscope allows<br />

simulation of a single asperity contact<br />

• Nanotribological studies are needed<br />

To develop fundamental underst<strong>and</strong>ing of interfacial phenomena<br />

on a small scale<br />

<br />

To study interfacial i phenomena in micro- or nanostructures t <strong>and</strong><br />

per<strong>for</strong>mance of ultra-thin films used in MEMS/NEMS<br />

components<br />

<strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics

Tribological Studies of Si <strong>and</strong> Related Materials<br />

Macroscale friction <strong>and</strong> wear per<strong>for</strong>mance of silicon<br />

<strong>and</strong> effect of ion implantation<br />

Reciprocating sliding tests against an alumina ball at 1 N load.<br />

V refers to virgin silicon. S <strong>and</strong> P correspond to doped single-crystal<br />

<strong>and</strong> polycrystalline silicon. Ion energy used was 200 keV.<br />

B. K. Gupta, B. Bhushan et al., ASME J. Tribol. 115, 392 (1993); B. K. Gupta, B. Bhushan et al., Tribol. Trans. 37, 601 (1994)<br />

<strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics

Scratch, wear <strong>and</strong> nanoindentation of virgin<br />

<strong>and</strong> treated/coated silicon<br />

Microscale scratch tests using a diamond tip in an AFM<br />

B. Bhushan <strong>and</strong> V. N. Koinkar, J. Appl. Phys. 75, 5741 (1994)<br />

<strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics

Friction, scratch, wear <strong>and</strong> nanoindentation of<br />

polysilicon films <strong>and</strong> SiC film<br />

• Polysilicon films, undoped <strong>and</strong> doped are commonly used as<br />

MEMS materials<br />

• Silicon-based MEMS devices lack high-temperature capabilities<br />

with respect to both mechanical <strong>and</strong> electrical properties<br />

Density<br />

Hardness<br />

Elastic<br />

Fracture<br />

Thermal<br />

Coeff. of<br />

Melting B<strong>and</strong>-<br />

(kg/m 3 ) (GPa) modulus toughness conductivity thermal point gap<br />

(GPa) (MPa m 1/2 ) (W/m K) expansion ( ο C) (eV)<br />

(x 10 -6 / ο C)<br />

• SiC is being gpursued as a material <strong>for</strong> high-temperature<br />

microsensor <strong>and</strong> microactuator applications based on its<br />

successful use in high-power devices<br />

Sample<br />

β-SiC 3210 23.5-26.5 440 4.6 85-260 4.5 - 6 2830 2.3<br />

Si(100) 2330 9-10 130 0.95 155 2 – 4.5 1410 1.1<br />

Selected bulk properties of 3C SiC <strong>and</strong> Si(100)<br />

<strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics

AFM 3D maps <strong>and</strong> average 2D profiles of<br />

scratch marks on various samples<br />

B. Bhushan, Tribology Issues <strong>and</strong> Opportunities in MEMS, Kluwer, 1998; S. Sundararajan <strong>and</strong> B. Bhushan, Wear 217, 251 (1998)<br />

<strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics

Summary of tribological studies of MEMS/NEMS materials<br />

• Tribological properties of silicon are inadequate<br />

• Ion implantation ti <strong>and</strong> oxidation of silicon improve the<br />

tribological properties of silicon<br />

• SiC exhibits significantly better tribological properties than<br />

silicon-based materials <strong>and</strong> is a good c<strong>and</strong>idate <strong>for</strong><br />

MEMS/NEMS devices<br />

<strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics

<strong>Bio</strong>adhesion Studies<br />

• Study surface modification approaches - nanopatterning <strong>and</strong><br />

chemical linker method to improve adhesion of biomolecules on<br />

silicon based surfaces.<br />

B. Bhushan et al., Acta <strong>Bio</strong>materialia 1, 327 (2005) ; ibid 2, 39 (2006); S. C. Lee et al., J. Vac. Sci. Technol. B 23, 1856 (2005) ;<br />

D. Tokachichu <strong>and</strong> B. Bhushan, IEEE Trans. Nanotech. 5, 228 (2006); E. Eteshola et al., J. Royal Soc. Interf. 5, 123 (2008); B.<br />

Bhushan et al., J. Royal Soc. Interf. 5(in press)<br />

<strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics

Sample preparation<br />

STA: Streptavidin<br />

t APTES:Aminopropyltriethoxysilane<br />

NHS: N-hydroxysuccinimido<br />

BSA: Bovine serum albumin<br />

<strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics

Schematic representation of deposition of streptavidin (STA) by chemical<br />

linker method<br />

<strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics

Adhesion measurements in PBS with functionalized tips<br />

Patterned silica surface exhibits higher adhesion compared to<br />

unpatterned silica surface. <strong>Bio</strong>tin coated surface exhibits even higher<br />

adhesion.<br />

<strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics

Device Level Studies<br />

Device level studies - digital micromirror devices (DMD)<br />

AFM images of the arrays which were<br />

removed by ultrasonic method<br />

<strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics

Surface height<br />

ht<br />

The stuck mirror can be identified <strong>and</strong> removed by AFM.<br />

“Hard” stuck micromirror<br />

H. Liu <strong>and</strong> B. Bhushan, Ultramicroscopy 100, 391 (2004)<br />

<strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics

The adhesive <strong>for</strong>ce of FP larger than no FP region on the l<strong>and</strong>ing site.<br />

Roughness <strong>and</strong> adhesion of l<strong>and</strong>ing sites<br />

<strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics

Weak bonds exist<br />

close to the<br />

uncovered sites<br />

Wear could initiate if<br />

contact occurs at the<br />

defects sites<br />

PFDA delaminated<br />

from the interface<br />

Formation of high energy surface<br />

increases the water adsorption,<br />

which in turn leads to large adhesion<br />

Assembled<br />

molecules<br />

Defects<br />

in PFDA<br />

Uncovered<br />

sites<br />

Residual Molecular<br />

head groups<br />

fragments<br />

Water<br />

molecule<br />

Mechanisms <strong>for</strong> Wear <strong>and</strong> Stiction<br />

<strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics

The “soft” stuck micromirror (S) contains the debris at the edges<br />

“Soft” Stuck Micromirror<br />

H. Liu <strong>and</strong> B. Bhushan, J. Vac. Sci. Technol. A 22, 1388 (2004)<br />

<strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics

“Soft” stuck mechanisms<br />

<strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics

H. Liu <strong>and</strong> B. Bhushan, <strong>Nanotechnology</strong> 15, 1246 (2004)<br />

<strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics

Hiearchical Nanostructures <strong>for</strong> Superhydrophobicity,<br />

self-cleaning <strong>and</strong> low adhesion<br />

One of the crucial property p in wet<br />

environments is non-wetting or<br />

superhydrophobicity <strong>and</strong> self cleaning.<br />

These surfaces are of interest in various<br />

applications, e.g., self cleaning windows,<br />

windshields, exterior paints <strong>for</strong> buildings,<br />

navigation-ships <strong>and</strong> utensils, roof tiles,<br />

textiles <strong>and</strong> reduction of drag in fluid flow,<br />

e. g. in micro/nanochannels. Also,<br />

superhydrophobic surface can be used <strong>for</strong><br />

energy conservation <strong>and</strong> energy<br />

conversion such as in the development elopment of<br />

a microscale capillary engine.<br />

Reduction of wetting is also important in<br />

reducing meniscus <strong>for</strong>mation,<br />

consequently reducing stiction.<br />

SEM of Lotus leaf showing bump structure.<br />

Various natural surfaces, including various<br />

leaves, e. g. Lotus, are known to be<br />

superhydrophobic, due to high roughness<br />

<strong>and</strong> the presence of a wax coating<br />

(Neinhuis <strong>and</strong> Barthlott, 1997)<br />

NY Times, 1/27/05; ABCNEWS.com, 1/26/05; Z. Burton <strong>and</strong> B. Bhushan, Ultramicroscopy 106, 709 (2006); B. Bhushan <strong>and</strong> Y. C. Jung,<br />

<strong>Nanotechnology</strong> 17, 2758 (2006); B. Bhushan <strong>and</strong> Y. C. Jung, J. Phys.: Condens. Matter 20, 225010 (2008)<br />

<strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics

Rolling off liquid droplet over superhydrophobic Lotus leaf<br />

with self cleaning ability<br />

<strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics

Roughness optimization model <strong>for</strong> superhydrophobic <strong>and</strong> self<br />

cleaning surfaces<br />

Complete wetting<br />

Composite interface<br />

In fluid flow, another property of<br />

interest is contact angle<br />

hysteresis (θ H )<br />

α : Tilt angle<br />

Cassie-Baxter equation:<br />

cosθ<br />

= R f cosθ<br />

− f<br />

Droplet of liquid in contact with<br />

f<br />

SL 0 LA<br />

a smooth <strong>and</strong> rough surface<br />

Wenzel’s equation:<br />

cos<br />

θ<br />

= R<br />

cos<br />

θ<br />

R f o<br />

θ<br />

H<br />

= θ<br />

adv<br />

− θ<br />

rec<br />

R<br />

≈<br />

f<br />

1−<br />

f<br />

LA<br />

2( R<br />

(cosθθ<br />

f<br />

rec0<br />

cosθ<br />

<strong>for</strong> high contact angle<br />

(θ 180°)<br />

0<br />

− cosθθ<br />

f<br />

f<br />

= Rf<br />

cos θ0 − fLA( Rf<br />

cosθ0<br />

+ 1) Increase in f LA <strong>and</strong> reduction<br />

http://lotus-shower.isunet.edu/the_lotus_effect.htm<br />

+ 1)<br />

in R f decrease θ H<br />

M. Nosonovsky <strong>and</strong> B. Bhushan, Microsyst. Tech. 11, 535 (2005); ibid, 231 (2006); Microelectronic Eng. 84, 387 (2007); Ultramicroscopy 107, 969<br />

(2007); Nano Letters 7, 2633 (2007); J. Phys.: Condens. Matter 20, 225009 (2008); US Patent pending (2005); Y.C. Jung <strong>and</strong> B. Bhushan,<br />

<strong>Nanotechnology</strong> 17, 4970 (2006); B. Bhushan <strong>and</strong> Y.C. Jung, J. Phys.: Condens. Matter 20, 225010 (2008)<br />

<strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics<br />

adv0<br />

)

Structure t of ideal hierarchical surface<br />

• Based on the modeling <strong>and</strong> observations made on leaf surfaces, hierarchical<br />

surface is needed d to develop composite interface with high h stability.<br />

• Proposed transition criteria can be used to calculate geometrical parameters <strong>for</strong><br />

a given droplet radius. For example, , <strong>for</strong> a droplet on the order of 1 mm or<br />

larger, a value of H on the order of 30 μm, D on the order of 15 μm <strong>and</strong> P on the<br />

order of 130 μm is optimum.<br />

• Nanoasperities should have a small pitch to h<strong>and</strong>le nanodroplets, less than 1<br />

mm down to few nm radius. The values of h on the order of 10 nm, d on the<br />

order of 100 nm can be easily fabricated.<br />

<strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics

Fabrication <strong>and</strong> characterization of hierarchical surface<br />

Fabrication of microstructure<br />

• Microstructure<br />

Replication of Lotus leaf <strong>and</strong> micropatterned silicon surface using<br />

an epoxy resin <strong>and</strong> then cover with the wax material<br />

B. Bhushan et al., Soft Matter 4, 1799 (2008); Appl. Phys. Lett. 93, 093101 (2008); Ultramicroscopy (in press); Langmuir 25, 1659-1666 (2009);<br />

Koch et al., Soft Matter 5, 1386-1393 (2009) <strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics

Fabrication of nanostructure <strong>and</strong> hierarchical structure<br />

Recrystallization of wax tubules<br />

• Nanostructure<br />

Self assembly of the Lotus wax deposited by thermal evaporation<br />

• Expose to a solvent in vapor phase <strong>for</strong> the mobility of wax molecules<br />

• Hierarchical structure<br />

Lotus <strong>and</strong> micropatterned epoxy replicas <strong>and</strong> covered with the tubules of Lotus wax<br />

B. Bhushan et al., Soft Matter 4, 1799 (2008); Appl. Phys. Lett. 93, 093101 (2008); Ultramicroscopy (in press); Langmuir 25, 1659-1666 (2009);<br />

Koch et al., Soft Matter 5, 1386-1393 (2009) <strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics

Static contact angle, contact angle hysteresis, tilt angle <strong>and</strong> adhesive <strong>for</strong>ce on<br />

various structures<br />

• Nano- <strong>and</strong> hierarchical structures with tubular wax led to high static contact<br />

angle of 167º <strong>and</strong> 173º <strong>and</strong> low hysteresis angle on the order of 6º <strong>and</strong> 1º.<br />

• Compared to a Lotus leaf, hierarchical structure showed higher static<br />

contact angle <strong>and</strong> lower contact angle hysteresis.<br />

B. Bhushan, Y. C. Jung, A. Niemietz, <strong>and</strong> K. Koch, Langmuir (in press)<br />

<strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics

Self-cleaning efficiency of various surfaces<br />

• As the impact pressure of the droplet is zero or low, most of particles on<br />

nanostructure were removed by water droplets, resulting from geometrical scale<br />

effects.<br />

• As the impact pressure of the droplet is high, h all particles which h are sitting at the<br />

bottom of the cavities between the pillars on hierarchical structure were removed by<br />

the water droplets.<br />

<strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics

Summary of nanotribology of bioadhesion <strong>and</strong> device level studies as<br />

well as hierarchical surfaces<br />

• <strong>Bio</strong>adhesion studies<br />

Adhesion between silica surfaces <strong>and</strong> biomolecules using chemical linker<br />

method is stronger than by direct adsorption<br />

• Device level studies<br />

Wear of the SAMs lubricant at the defects region can lead to the increase of<br />

surface energy which causes the increase of adhesion <strong>and</strong> lead to “hard”<br />

stiction.<br />

Micromirror sidewall contamination particles could cause micromirror “soft”<br />

stiction.<br />

• Hierarchical surfaces<br />

Optimum roughness distribution can be used to generate superhydrophobic<br />

surfaces.<br />

<strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics

Acknowledgements<br />

• Financial support has been provided by the National Science Foundation<br />

(Contract No. ECS-0301056 ), the <strong>Nanotechnology</strong> Initiative of the National<br />

Institute of St<strong>and</strong>ards <strong>and</strong> Technology in conjunction with Nanotribology<br />

Research Program (Contract No. 60 NANB1D0071), <strong>and</strong> Texas Instruments,<br />

Intel Corp <strong>and</strong> Nanochip Inc.<br />

• Polysilicon <strong>and</strong> SiC work was per<strong>for</strong>med in collaboration with Prof. M.<br />

Mehregany <strong>and</strong> Dr. C. A. Zorman at Case Western Reserve University<br />

• The <strong>Bio</strong>MEMS/<strong>Bio</strong>NEMS studies were carried out in collaboration with Prof.<br />

S. C. Lee of OSU Medical School <strong>and</strong> Prof. D. Hans<strong>for</strong>d of <strong>Bio</strong>medical Eng.<br />

• DMD chips were supplied by Dr. S. Joshua Jacobs of Texas Instruments<br />

<strong>Nanoprobe</strong> <strong>Laboratory</strong> <strong>for</strong> <strong>Bio</strong>- & <strong>Nanotechnology</strong> <strong>and</strong> <strong>Bio</strong>mimetics