Vol 3 - Cont J Pharm Sci - Wilolud Journals

Vol 3 - Cont J Pharm Sci - Wilolud Journals

Vol 3 - Cont J Pharm Sci - Wilolud Journals

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

A. K. Jain et al: <strong>Cont</strong>inental J. <strong>Pharm</strong>aceutical <strong>Sci</strong>ences 3: 1 - 6, 2009<br />

EXPERIMENTAL<br />

Materials and Apparatus<br />

Famotidine was obtained as a gift sample from Intas <strong>Pharm</strong>aceutical, Ahmedabad. Polyvinyl alcohol was obtained<br />

from S.D. Fine Chemicals Ltd. Mumbai. Dichloromethane, ethyl acetate, acetone, acrycoat S100, chitosan were<br />

obtained from Central Drug House (Pvt) Ltd. Delhi. All other chemicals/reagents were used of analytical grade.<br />

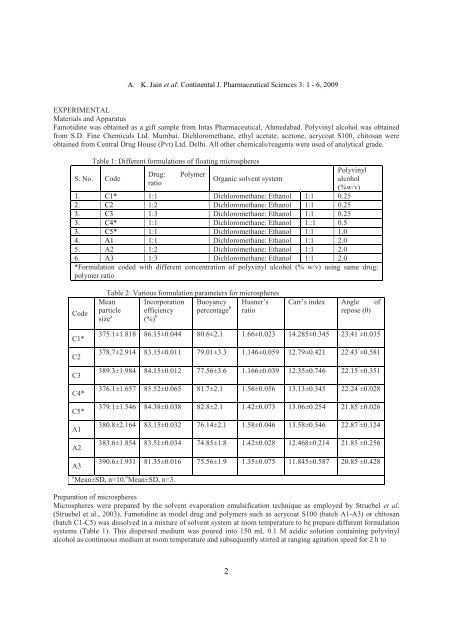

Table 1: Different formulations of floating microspheres<br />

S. No. Code<br />

Drug:<br />

ratio<br />

Polymer<br />

Organic solvent system<br />

Polyvinyl<br />

alcohol<br />

(%w/v)<br />

1. C1* 1:1 Dichloromethane: Ethanol 1:1 0.25<br />

2. C2 1:2 Dichloromethane: Ethanol 1:1 0.25<br />

3. C3 1:3 Dichloromethane: Ethanol 1:1 0.25<br />

3. C4* 1:1 Dichloromethane: Ethanol 1.:1 0.5<br />

3. C5* 1:1 Dichloromethane: Ethanol 1:1 1.0<br />

4. A1 1:1 Dichloromethane: Ethanol 1:1 2.0<br />

5. A2 1:2 Dichloromethane: Ethanol 1:1 2.0<br />

6. A3 1:3 Dichloromethane: Ethanol 1:1 2.0<br />

*Formulation coded with different concentration of polyvinyl alcohol (% w/v) using same drug:<br />

polymer ratio<br />

Code<br />

Buoyancy<br />

Table 2: Various formulation parameters for microspheres<br />

Mean Incorporation<br />

Husner’s<br />

size a (%) b<br />

particle efficiency percentage b ratio<br />

Carr’s index Angle of<br />

repose (θ)<br />

C1*<br />

375.1±1.818 86.15±0.044 80.6±2.1 1.66±0.023 14.285±0.345 23.41 ° ±0.035<br />

C2<br />

378.7±2.914 83.15±0.011 79.01±3.3 1.146±0.059 12.79±0.421 22.43 ° ±0.581<br />

C3<br />

389.3±1.984 84.15±0.012 77.56±3.6 1.166±0.039 12.35±0.746 22.15 ° ±0.351<br />

C4*<br />

376.1±1.657 85.52±0.065 81.7±2.1 1.56±0.056 13.13±0.345 22.24 ° ±0.028<br />

C5*<br />

379.1±1.546 84.38±0.038 82.8±2.1 1.42±0.073 13.06±0.254 21.85 ° ±0.026<br />

A1<br />

380.8±2.164 83.15±0.032 76.14±2.1 1.58±0.046 13.58±0.546 22.87 ° ±0.124<br />

A2<br />

383.6±1.854 83.51±0.034 74.85±1.8 1.42±0.028 12.468±0.214 21.85 ° ±0.256<br />

A3<br />

390.6±1.931 81.35±0.016 75.56±1.9 1.35±0.075 11.845±0.587 20.85 ° ±0.428<br />

a Mean±SD, n=10. b Mean±SD, n=3.<br />

Preparation of microspheres<br />

Microspheres were prepared by the solvent evaporation emulsification technique as employed by Struebel et al.<br />

(Struebel et al., 2003). Famotidine as model drug and polymers such as acrycoat S100 (batch A1-A3) or chitosan<br />

(batch C1-C5) was dissolved in a mixture of solvent system at room temperature to be prepare different formulation<br />

systems (Table 1). This dispersed medium was poured into 150 mL 0.1 M acidic solution containing polyvinyl<br />

alcohol as continuous medium at room temperature and subsequently stirred at ranging agitation speed for 2 h to<br />

2