Sulphur Cored Wires - Minex

Sulphur Cored Wires - Minex

Sulphur Cored Wires - Minex

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Sulphur</strong> <strong>Cored</strong> <strong>Wires</strong><br />

SULPHUR ADDITION IN STEEL<br />

Many steel specifications require significant alloying quantities of sulphur, primarily for its ability to improve<br />

machinability of the final product. Indeed, in some applications such as forging dies, the product may be<br />

ordered to any one of a number of machinability ratings as well as hardenability and other factors.<br />

<strong>Sulphur</strong> is used as an alloying addition to improve machinability. Increasing the sulphur content from nominal<br />

say 0.008% to 0.060% lowers the charpy upper shelf level, thereby raising the transition temperature as fixed by<br />

a given impact energy.<br />

ADDITION PRACTICE<br />

The addition of sulphur, and close control over the degree of addition, is an important step in the steelmaking<br />

process. There is various ways to add sulphur into steel melt. Usually the sulphur is added in steel melt<br />

(temperature 1500 - 1600°C) the form of stick sulphur which is, essentially, elemental sulphur. From experience<br />

it has been determined that recovery of about 40 - 50% can be expected from stick sulphur. The<br />

non-recovered sulphur easily ignites in air to form sulphur dioxide, a noxious gas with a strong, pungent<br />

objectionable odor. Since the density of the stick sulphur (2.08 gm/cc) is low and the boiling point (444.72°C)<br />

is also low, this sulphur vapor generation, and subsequent sulphur dioxide fume generation, occurs before<br />

molten steel reactions involving sulphur can reach completion. As those skilled in the art will appreciate, the<br />

steel reactions are essentially the formation of Mn S in the steel which is non-odorous coupled with the<br />

vaporization of uncombined sulphur, which vaporization causes environmental conditions to become very<br />

objectionable.<br />

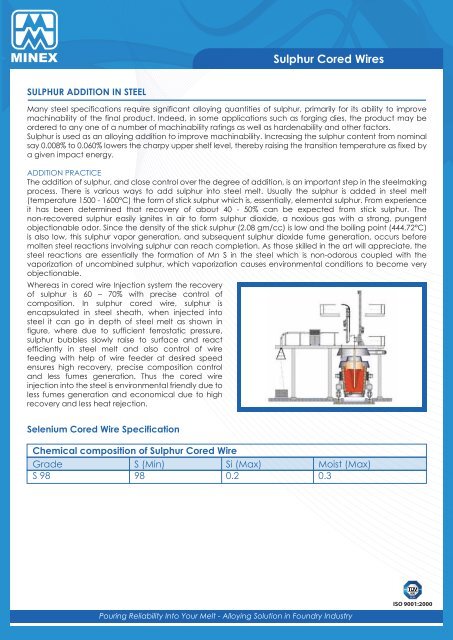

Whereas in cored wire Injection system the recovery<br />

of sulphur is 60 – 70% with precise control of<br />

composition. In sulphur cored wire, sulphur is<br />

encapsulated in steel sheath, when injected into<br />

steel it can go in depth of steel melt as shown in<br />

figure, where due to sufficient ferrostatic pressure,<br />

sulphur bubbles slowly raise to surface and react<br />

efficiently in steel melt and also control of wire<br />

feeding with help of wire feeder at desired speed<br />

ensures high recovery, precise composition control<br />

and less fumes generation. Thus the cored wire<br />

injection into the steel is environmental friendly due to<br />

less fumes generation and economical due to high<br />

recovery and less heat rejection.<br />

Selenium <strong>Cored</strong> Wire Specification<br />

Chemical composition of <strong>Sulphur</strong> <strong>Cored</strong> Wire<br />

Grade S (Min) Si (Max) Moist (Max)<br />

S 98 98 0.2 0.3<br />

Pouring Reliability Into Your Melt - Alloying Solution in Foundry Industry