Separator's Digest 2009/1 min. - GEA Westfalia Separator Group

Separator's Digest 2009/1 min. - GEA Westfalia Separator Group

Separator's Digest 2009/1 min. - GEA Westfalia Separator Group

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

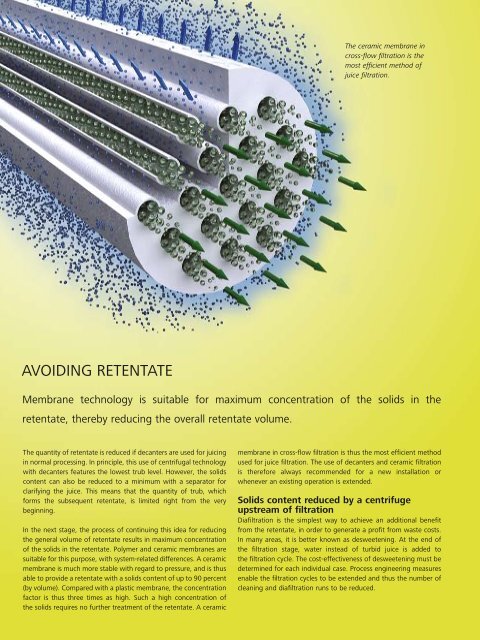

The ceramic membrane in<br />

cross-flow filtration is the<br />

most efficient method of<br />

juice filtration.<br />

Avoiding retentate<br />

Membrane technology is suitable for maximum concentration of the solids in the<br />

retentate, thereby reducing the overall retentate volume.<br />

The quantity of retentate is reduced if decanters are used for juicing<br />

in normal processing. In principle, this use of centrifugal technology<br />

with decanters features the lowest trub level. However, the solids<br />

content can also be reduced to a <strong>min</strong>imum with a separator for<br />

clarifying the juice. This means that the quantity of trub, which<br />

forms the subsequent retentate, is limited right from the very<br />

beginning.<br />

In the next stage, the process of continuing this idea for reducing<br />

the general volume of retentate results in maximum concentration<br />

of the solids in the retentate. Polymer and ceramic membranes are<br />

suitable for this purpose, with system-related differences. A ceramic<br />

membrane is much more stable with regard to pressure, and is thus<br />

able to provide a retentate with a solids content of up to 90 percent<br />

(by volume). Compared with a plastic membrane, the concentration<br />

factor is thus three times as high. Such a high concentration of<br />

the solids requires no further treatment of the retentate. A ceramic<br />

membrane in cross-flow filtration is thus the most efficient method<br />

used for juice filtration. The use of decanters and ceramic filtration<br />

is therefore always recommended for a new installation or<br />

whenever an existing operation is extended.<br />

Solids content reduced by a centrifuge<br />

upstream of filtration<br />

Diafiltration is the simplest way to achieve an additional benefit<br />

from the retentate, in order to generate a profit from waste costs.<br />

In many areas, it is better known as desweetening. At the end of<br />

the filtration stage, water instead of turbid juice is added to<br />

the filtration cycle. The cost-effectiveness of desweetening must be<br />

deter<strong>min</strong>ed for each individual case. Process engineering measures<br />

enable the filtration cycles to be extended and thus the number of<br />

cleaning and diafiltration runs to be reduced.<br />

24<br />

<strong>Separator</strong>’s <strong>Digest</strong> 1 | <strong>2009</strong><br />

<strong>GEA</strong> <strong>Westfalia</strong> <strong>Separator</strong> Process