22000111333 PPRRRIIICCCEEE LLLIIISSSTTT - Pumps and Controls

22000111333 PPRRRIIICCCEEE LLLIIISSSTTT - Pumps and Controls

22000111333 PPRRRIIICCCEEE LLLIIISSSTTT - Pumps and Controls

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Page 04<br />

LMI METERING PUMPS<br />

Each LMI Metering Pump series is designed to meet user needs for specific application <strong>and</strong> installation requirements. Within each<br />

series there are a number of options for controls, liquid end designs <strong>and</strong> materials, power, <strong>and</strong> various other accessories <strong>and</strong><br />

features.<br />

The following price pages are presented in four groups so each can be described by the features offered:<br />

ROYTRONIC ® Series A - LMI's pump line with new control <strong>and</strong> liquid end features.<br />

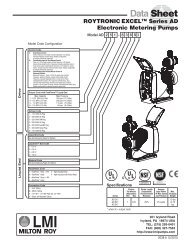

ROYTRONIC EXCEL Series AD - LMI's all new digital pump line with new control <strong>and</strong> liquid end features.<br />

B, C, E, HH <strong>and</strong> J - All share common drives, control, or liquid end features.<br />

P Series - LMI P series with new liquid end features applied to a familiar pump series.<br />

Each section has a page in the beginning that describes the features <strong>and</strong> options available.<br />

Note: All st<strong>and</strong>ard plastic liquid ends are shipped with PE tubing. PE tubing is not recommended for all applications,<br />

therefore, please refer to LMI Chemical Resistance chart (1100.F) for material compatibility. When PE tubing is not suitable for the<br />

application, please contact your local master distributor for alternative tubing materials.<br />

Application Notes<br />

● Off-gassing Fluids (such as Sodium Hypochlorite) - Each pump series that offers special designs for these fluids has a<br />

separate selection table at the end of the pricing section (reference AUTOPRIME Liquid Ends). <strong>Pumps</strong> designed to h<strong>and</strong>le<br />

these fluids are specially designed to automatically bleed a portion of the process chemical in order to eliminate gas binding of<br />

the liquid end. The pump capacity ratings take into account the continuous bleed. For applications of off-gassing liquids such<br />

as sodium hypochlorite or hydrogen peroxide, "AI" or "HI" liquid ends with AUTOPRIME heads or valves are recommended.<br />

An "HI" liquid end adds a 4FV to the "AI" liquid end. AUTOPRIME is available on PVC <strong>and</strong> Acrylic heads. A 4FV on the "HI"<br />

head enables safe pressure release of process fluid.<br />

● Explosion-Proof Applications - The "E" series pumps are designed to operate in hazardous areas requiring explosion proof<br />

equipment.<br />

● ROYTRONIC EXCEL AD Series High Viscosity Liquid Ends - Use Liquid End Assemblies 624XX, 626XX, 634XX, 636XX,<br />

644XX <strong>and</strong> 646XX with corresponding size drive assembly.<br />

● Slurry Feeds with Abrasive Solids - Use Liquid End Assemblies 29, 79 or 89 with corresponding size drive assembly.<br />

(Max. solids 5% by weight)<br />

● High Viscosity Fluids, Polymers - Use Liquid End Assemblies 20HV, 25HV, 75HV, 76HV, 85HV, 86HV, 155HV or 156HV<br />

with corresponding size drive assembly. Pump output may be reduced in some applications. Also, please note that no foot<br />

valve is included with HV liquid ends. HV liquid ends are available on AA, B, C, E, <strong>and</strong> J series pumps.<br />

● Stainless Steel Liquid Ends - Liquid End Assemblies with a "7" in the second or third position. Please note no foot valve or<br />

injection valves are included with these Stainless Steel liquid ends. 316ss liquid ends are only available in NPT connections<br />

<strong>and</strong> without 4 function valves. Separate back pressure <strong>and</strong> safety valves are available in the accessory section.<br />

● Accessories - Reference Bulletin 1951 <strong>and</strong> contact your LMI distributor to discuss the variety of LMI accessories designed to<br />

make the installation <strong>and</strong> operation of your LMI pump easier <strong>and</strong> more efficient.<br />

● Hastelloy® C Head Screws - are available for pumps that will be used with strong acids or other applications where<br />

Hastelloy® C will provide better results than the st<strong>and</strong>ard 316 S.S. head screws. Please refer to the LMI Chemical Resistance<br />

chart <strong>and</strong> to your chemical supplier for suggested materials. See head screw kits: #37144 <strong>and</strong> #38735.<br />

● Series HH <strong>Pumps</strong> - are for high pressure applications only. For low output at pressures below 250 psi, select ROYTRONIC<br />

EXCEL Series AD9 pumps. The minimum system pressure necessary for an HH9 application is 100 psi.<br />

Pressure Prime or Flush - Use Primer/Flush Kit:<br />

#37393 for .375" tubing (300 & 400 Series LE's) #37399 for .5" tubing (300 & 400 Series LE's)<br />

#26220 for .375" tubing (except 300 & 400 Series LE's)<br />

#26221 for .5" tubing (70 & 80 Series LE's)<br />

#26708 for .5" tubing (20 & 30 Series LE's)<br />

All information <strong>and</strong> prices herein are subject to change without notice.<br />

www.lmipumps.com