Download PDF - Olyset Net

Download PDF - Olyset Net

Download PDF - Olyset Net

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Registered trademark of Sumitomo Chemical Co. Ltd.<br />

The Next-Generation <strong>Net</strong> with Added Protection<br />

<strong>Olyset</strong> ® Plus is a durable long-lasting<br />

mosquito net with fast action against<br />

mosquitoes and additional efficacy<br />

against Pyrethroid-resistant mosquitoes.

<strong>Olyset</strong> Plus – meeting the world’s changing needs.<br />

Contents<br />

Introduction and Background....................................................................1<br />

Controlled Release Technology ................................................................5<br />

Biological Efficacy ......................................................................................6<br />

Technical Specifications ..........................................................................10<br />

Usage and Safety ......................................................................................12

Introduction and Background<br />

Introduction<br />

Mosquito nets have a long history of protecting people<br />

from malarial mosquitoes but it was not until the introduction<br />

of treating nets with pyrethroid insecticides that<br />

bed nets changed from being a physical barrier to being<br />

an insecticidally active tool which both deters and kills<br />

mosquitoes. The original method of dipping nets in<br />

insecticide solution was very labour intensive and<br />

logistically difficult in the field and the treatment rarely<br />

survived more than three washes. The situation changed<br />

dramatically with the introduction of factory-treated,<br />

wash-proof, long lasting insecticide treated nets (LLINs)<br />

in which the insecticide is either bound to the surface of<br />

the net fibre or incorporated inside the fibre itself.<br />

<strong>Olyset</strong> ® <strong>Net</strong> – Pioneering Technology with Added Durability<br />

Sumitomo Chemical was the first company to develop and<br />

pioneer fibre incorporation technology. We realised that<br />

incorporation of insecticide into the fibre, using controlled<br />

release technology that allows insecticide to migrate to<br />

the surface and maintain a regular supply, is better than<br />

`gluing` to the fibre surface which leaves the insecticide<br />

vulnerable to removal by abrasion or washing. In addition,<br />

the use of high-density polyethylene (HDPE) rather than<br />

polyester as the fibre material gives major advantages in<br />

both the strength and durability of the net. <strong>Olyset</strong> Plus,<br />

like the original <strong>Olyset</strong> <strong>Net</strong>, has a denier of >150 whereas<br />

commonly available polyester nets are 75 – 100 denier. As<br />

denier is one of the major contributors to strength and<br />

durability in the field, <strong>Olyset</strong> Plus is therefore approximately<br />

1.5 - 2 times stronger than typical 75 – 100 denier<br />

polyester LLINs.<br />

<strong>Olyset</strong> <strong>Net</strong> was the first LLIN to pass the World Health<br />

Organization Pesticide Evaluation Scheme (WHOPES).<br />

Since then, many more nets have passed WHOPES with<br />

either interim or full recommendation. However, all these<br />

nets—including <strong>Olyset</strong> <strong>Net</strong>—are manufactured using a<br />

single class of insecticides known as pyrethroids, on<br />

account of their excellent activity against mosquitoes and<br />

low mammalian toxicity.<br />

Emerging insecticide resistance – a real threat<br />

Due to the excellent results from using LLINs, donors<br />

campaigned and advocated for mass distribution of bednets<br />

throughout Africa and in many other endemic countries.<br />

Universal coverage (at least 80% coverage with LLINs of<br />

at-risk populations) was achieved in many African<br />

countries by early 2011. The pressure of only using<br />

pyrethroids in LLINs, and their extensive use in indoor<br />

residual spraying programs as well as in agriculture, has<br />

resulted in insecticide resistance in mosquito vector<br />

populations in some parts of the world, particularly in<br />

Africa. ‘At the time of this report, resistance to at least<br />

one insecticide has been identified in 64 countries with<br />

on-going malaria transmission. Resistance to pyrethroids<br />

Key Features<br />

• Fine mesh.<br />

• Softer feel.<br />

• Excellent biological performance<br />

against mosquitoes.<br />

• Enhanced knockdown and kill<br />

against pyrethroid-resistant<br />

mosquitoes.<br />

• Contains the synergist –<br />

piperonyl butoxide (PBO) on<br />

all surfaces.<br />

• Insecticide and synergist<br />

incorporated inside fibres.<br />

• Insecticide and synergist<br />

migrate to fibre surface<br />

continuously over many years.<br />

• Re-generation of both<br />

active ingredients.<br />

• Unique to market.<br />

• A second generation of the<br />

well proven <strong>Olyset</strong> <strong>Net</strong>.<br />

• Japanese technology.<br />

seems to be the most widespread.*’ The extent and<br />

threat of resistance to the use of LLINs and on actual<br />

malaria cases is not well understood and there are large<br />

programmes planned to monitor and check the impact<br />

on transmission.<br />

* WHO Global Plan for Insecticide Resistance Management in malaria<br />

vectors (GPIRM), 2012<br />

1

Figure 1. Possible scenario for resistance development<br />

in a mosquito population.<br />

Reproduced by kind permission of IRAC<br />

Figure 2. Distribution of pyrethroid resistance in Africa using<br />

data collected between 2000 to 2010.<br />

Sumitomo Chemical’s original <strong>Olyset</strong> <strong>Net</strong> remains one<br />

of the best and most durable LLINs on the market.<br />

However, Sumitomo recognised that for some markets<br />

improvements could be made by increasing the speed of<br />

action and efficacy against both susceptible and resistant<br />

mosquitoes. This led to the development of <strong>Olyset</strong> Plus.<br />

<strong>Olyset</strong> Plus introduces many new features, including<br />

the addition of piperonyl butoxide (PBO), a synergist<br />

which increases the performance of the active ingredient<br />

Permethrin and in particular enhances activity against<br />

pyrethroid-resistant mosquitoes (see below for more<br />

information on PBO).<br />

<strong>Olyset</strong> Plus is the first and only net on the market to<br />

incorporate PBO into every fibre and all surfaces of the<br />

net, providing enhanced knockdown and kill against<br />

pyrethroid-resistant mosquitoes.<br />

Insecticide Resistance<br />

Insecticide resistance is defined by the Insecticide<br />

Resistance Action Committee (IRAC) as: ‘a heritable change in<br />

the sensitivity of a pest population that is reflected in the repeated<br />

failure of a product to achieve the expected level of control when used<br />

according to the label recommendation for that pest species.’<br />

The development of insecticide resistance occurs for the<br />

following reasons:<br />

Key:<br />

An. pharoensis<br />

An. labranchiae<br />

An. funestus<br />

An. gambiae s.l.<br />

An. arabiensis<br />

An. gambiae s.s.<br />

Resistant<br />

Resistance suspected<br />

Susceptible<br />

Ranson et al, Trends in Parasitology, February 2011, Vol. 27, No. 2.<br />

• Natural selection allows pre-adapted insects with<br />

resistance genes to survive and pass this resistance trait<br />

onto off-spring.<br />

• As more product is applied, the resistant population<br />

keeps growing while the susceptible individuals are<br />

eliminated by the insecticide. The product therefore<br />

is no longer fully effective.<br />

Other key points to note :<br />

• Speed of resistance development depends on speed of<br />

reproduction, the persistence of the insecticide applied<br />

and the proportion of susceptible species.<br />

• Resistance has appeared in a wide range of public<br />

health vectors to most chemical classes of insecticides.<br />

• The resistance problem in vector control is exacerbated<br />

2

y extensive use and misuse of the same classes of<br />

insecticides in agriculture.<br />

The map (see Figure 2) indicates that there is a spread of<br />

pyrethroid resistance into many areas of Africa where<br />

LLINs are being deployed. While the impact of this resistance<br />

on the efficacy of LLINs and malaria transmission is<br />

still unknown, there is a growing consensus that high<br />

levels of resistance may in the future result in operational<br />

failure of mass LLIN distribution programmes. Insecticide<br />

resistance in malaria vectors is therefore one of the major<br />

issues concerning stakeholders today.<br />

There are several types of resistance mechanism:<br />

• Metabolic resistance.<br />

• Target site resistance (Knockdown resistance (Kdr)<br />

or nerve insensitivity).<br />

• Behavioural resistance.<br />

• Reduced penetration resistance.<br />

Amongst these mechanisms, metabolic resistance is<br />

probably the most important, although the impact of Kdr<br />

resistance is also significant. The only chance to overcome<br />

most types of resistance is by using a totally new class of<br />

insecticide which as yet is not available. Ideally, a new<br />

insecticide would have all the attributes of pyrethroids:<br />

<strong>Olyset</strong> Plus is the first and only net on the market to<br />

incorporate PBO into every fibre and all surfaces of<br />

the net, providing enhanced knockdown and kill<br />

against pyrethroid-resistant mosquitoes.<br />

fast action, high intrinsic activity against target insects,<br />

and low mammalian toxicity combined with ease of<br />

formulation. These characteristics make the task of<br />

identifying suitable chemistry an extremely challenging,<br />

costly and long-term undertaking.<br />

While companies such as Sumitomo Chemical are<br />

playing a leading role in the synthesis, screening and<br />

development of new chemistry for use in disease vector<br />

control, the best solution in the interim is to continue to<br />

formulate LLINs with pyrethroids and to use the synergistic<br />

properties of PBO to improve insecticidal activity<br />

against both susceptible and resistant mosquitoes.<br />

For further information on insecticide resistance,<br />

monitoring and management strategies see `Prevention<br />

and Management of Insecticide Resistance in Vectors of<br />

Public Health Importance` published by IRAC (CropLife<br />

International) – see (www.irac-online.org)<br />

What is <strong>Olyset</strong> Plus<br />

<strong>Olyset</strong> Plus is a durable polyethylene net containing 2%<br />

permethrin and 1% of the synergist piperonyl butoxide<br />

(PBO) which are incorporated in all fibres. In this way,<br />

all sides and also the roof are treated. Using Sumitomo<br />

Chemical’s unique <strong>Olyset</strong> controlled-release technology, net<br />

fibres have been designed to release the two ingredients at<br />

a constant ratio of 2:1 thus ensuring enhanced efficacy for<br />

the life of the net against all mosquitoes, including those<br />

which are resistant.<br />

It has been shown that while many mosquitoes<br />

approach the roof of the LLINs a similar proportion go to<br />

the sides to get at the sleeping host. (Ref. Severin, L.<br />

University d` Abomey – Calavi Calvi, pers. comm.)<br />

Based on the above, it is clear that any net seeking to<br />

provide enhanced levels of protection from susceptible and<br />

3

esistant insects should have PBO on all surfaces so that<br />

the mosquitoes cannot avoid contacting both insecticide<br />

and synergist at the same time.<br />

What is Piperonyl Butoxide<br />

Piperonyl butoxide (PBO) is a synergist which has long<br />

been used to improve the performance of pyrethroid<br />

insecticides especially household aerosols. Synergists are<br />

chemicals that lack insecticidal activity of their own but<br />

enhance the insecticidal performance of other chemicals.<br />

How does Piperonyl Butoxide combat resistance<br />

All insects, whether susceptible or resistant, have enzymes<br />

that can metabolise insecticides into harmless components.<br />

Some of these enzymes, known as cytochrome P450s, are<br />

powerful oxidising agents that can detoxify an active<br />

ingredient before the desired effect is achieved; PBO is a<br />

powerful inhibitor of these enzymes and therefore blocks<br />

this action.<br />

In resistant insects the activity of these enzymes can<br />

be greatly enhanced which can significantly reduce the<br />

efficacy of an insecticide. PBO acts on these enzymes in<br />

resistant insects and inhibits the breakdown or the<br />

metabolism of insecticides, rendering the insecticide more<br />

effective. PBO also increases the activity of pyrethroids to<br />

susceptible insects, so adding PBO to an LLIN has a benefit<br />

even in areas where there is no resistance.<br />

There are many scientific papers which demonstrate<br />

the impact of PBO on pyrethroid resistance, and some<br />

specifically highlight the impact on permethrin resistance.<br />

See for example: Evidence of multiple pyrethroid resistance<br />

mechanisms in the malaria vector Anopheles gambiae sensu stricto<br />

from Nigeria. Awolola, T.S. et al., Transactions of the Royal Society<br />

of Tropical Medicine and Hygiene Vol: 103, Issue: 11, Pages: 1139-<br />

1145 (2009).<br />

Piperonyl Butoxide Key Points:<br />

• Inhibitor of P450 enzymes.<br />

• Enhances insecticide penetration.<br />

• Used in many household aerosols and space sprays<br />

products.<br />

• Not an insecticide but a synergist.<br />

• Low mammalian toxicity.<br />

• Known and used for >50 years.<br />

<strong>Olyset</strong> Plus Regeneration<br />

Rapid regeneration of surface active ingredients after<br />

washing -- and therefore the provision of an almost<br />

continuously available insecticide plus PBO barrier against<br />

mosquitoes -- is required to maximise the protective effect.<br />

This is especially important in areas where resistant mosquitoes<br />

have been found. The rate at which permethrin<br />

and PBO migrate from the internal reservoir in the fibre<br />

to the surface of the net (known as the ‘bleed rate’) has<br />

been adjusted in <strong>Olyset</strong> Plus to provide a rapid rate of<br />

regeneration, making the net active again within 1 – 2<br />

days after washing.<br />

Full efficacy in less than 2 days after washing.<br />

4

Controlled Release Technology<br />

Incorporated Polyethylene Controlled-Release Fibres vs “Coated” Polyester Fibre<br />

Permethrin and PBO<br />

Year 1 Year 2 Year 3<br />

Standard <strong>Net</strong><br />

Above: <strong>Olyset</strong> Plus, permethrin and piperonyl<br />

butoxide migrate to the surface of the net fibre over<br />

a period of three years or longer, maintaining a<br />

biologically effective surface concentration.<br />

Insecticide particles<br />

“glued” to net surface<br />

Left: For “coated” LLINs, surface concentration<br />

of insecticide declines over time.<br />

Year 1 Year 2 Year 3

Biological Efficacy<br />

The objectives of testing <strong>Olyset</strong> Plus were as follows:<br />

• Confirm efficacy meets WHOPES standards.<br />

• Confirm the regeneration time for insecticide and<br />

synergist is rapid.<br />

• Evaluate efficacy against susceptible mosquitoes.<br />

• Evaluate efficacy against pyrethroid resistant<br />

mosquitoes.<br />

% mortality<br />

% KD at 60 minutes<br />

%<br />

Figure 3. <strong>Olyset</strong> Plus tested unwashed and at intervals after<br />

three times washing — mortality at 24 hours.<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

100<br />

64<br />

74<br />

85 85 87 87 84<br />

0 1 2 3 4 5 6 7<br />

Days post-washing<br />

Rossignol, B. Luce, MN Lacroix and F. Chandre, DOC/LIN/IRD/01/11<br />

Figure 4. Effect of washing <strong>Olyset</strong> Plus net (WHO cone test)<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

100 100 100 99 99<br />

0 3 5 10 15 20 25<br />

Number of washes<br />

Rossignol, B. Luce, MN Lacroix and F. Chandre, DOC/LIN/IRD/01/11<br />

Figure 5. Speed of regeneration of <strong>Olyset</strong> Plus against field<br />

caught pyrethroid resistant mosquitoes (WHO cone test).<br />

100<br />

100<br />

<strong>Olyset</strong> Plus<br />

unwashed<br />

100<br />

73.2<br />

<strong>Olyset</strong> Plus<br />

washed<br />

KD<br />

Mortality<br />

Ref. Sumitomo Chemical Health and Crop Sciences Laboratory Report, 2011<br />

95 95<br />

1. Regeneration, wash resistance and efficacy of <strong>Olyset</strong> Plus against<br />

susceptible Anopheles gambiae.<br />

To evaluate speed of regeneration, <strong>Olyset</strong> Plus was tested<br />

unwashed and then washed and dried 3 times and tested<br />

each day afterwards. Results (Figure 3) demonstrate that<br />

the net rapidly recovers killing efficacy and retained 100%<br />

knockdown activity after washing. From this (noting the<br />

fact that confidence intervals for mortality between day 2<br />

and 7 overlapped) regeneration time was determined to be<br />

2 days.<br />

To evaluate wash resistance nets were tested after<br />

repeated washing using the cone test. From the data<br />

generated above the interval between washes was set at 2<br />

days to allow the net to fully regenerate. Results indicate<br />

that knockdown (KD) of mosquitoes exposed to <strong>Olyset</strong><br />

Plus hardly changes over 25 washes. As these tests were<br />

conducted only 24 hours after each washing, the rapid<br />

regeneration of active ingredient on the fibre surface is<br />

clearly shown (See Figure 4).<br />

2. Evaluation of <strong>Olyset</strong> Plus vs. <strong>Olyset</strong> Plus without PBO unwashed<br />

and one day post washing against field caught pyrethroid resistant<br />

mosquitoes.<br />

Tests were conducted using the World Health Organisation<br />

(WHO) cone method (3 minute exposure) against field<br />

caught Anopheles arabiensis which were metabolic mechanism<br />

pyrethroid resistant. <strong>Olyset</strong> Plus was very effective<br />

unwashed and had regenerated very rapidly after 1 day to<br />

give 100% KD and 73.2% mortality (See Figure 5).<br />

3. Evaluation of <strong>Olyset</strong> Plus two days after 20 washes against<br />

pyrethroid resistant mosquitoes using the WHO tunnel test.<br />

<strong>Olyset</strong> Plus was washed 20 times using the standard<br />

WHO method and then tested in the WHO tunnel test only<br />

2 days after the last wash against Anopheles gambiae G3<br />

strain (moderately metabolic resistant to pyrethroids).<br />

Mosquitoes were introduced at one end of the tunnel and<br />

a small animal at the other end. The netting sample was<br />

placed in between with nine holes cut in it according to<br />

the WHO protocol. If mosquitoes can pass through the<br />

holes in the net this indicates the net has little repellency<br />

6

or killing effect. Blood Feeding Inhibition (BFI) shows the<br />

percentage of mosquitoes prevented from reaching the animal<br />

and feeding. Mortality is the total number of mosquitoes<br />

killed in their attempts to feed.<br />

Figure 6. <strong>Olyset</strong> Plus 2 days after 20 washes against<br />

pyrethroid-resistant mosquitoes (WHO Tunnel test).<br />

100<br />

80<br />

94.6<br />

79.6<br />

Sumitomo Chemical was the first company to develop<br />

and pioneer fibre incorporation technology.<br />

%<br />

60<br />

40<br />

20<br />

0<br />

BFI<br />

Mortality<br />

Results (Figure 6) show that blood feeding inhibition<br />

was very high and mortality was almost 80% despite the<br />

mosquitoes being pyrethroid resistant. This test demonstrates<br />

how quickly efficacy is restored to <strong>Olyset</strong> Plus<br />

following 20 washes and only 2 days regeneration time.<br />

4. <strong>Olyset</strong> Plus vs. a Polyester LLIN against field caught pyrethroid<br />

resistant mosquitoes.<br />

These tests were conducted against field caught Anopheles<br />

arabiensis which are pyrethroid metabolic resistant. Both<br />

nets were new and unwashed. The polyester LLIN used was<br />

a commercially available net treated with deltamethrin,<br />

widely used in malaria control programmes.<br />

The standard WHO cone test (3 minute exposure) was<br />

used. The results (Figure 7) show that the resistant<br />

Anopheles were knocked down and killed by <strong>Olyset</strong> Plus<br />

but the impact of the commercially available pyrethroid<br />

net was much less, demonstrating the superior efficacy<br />

of <strong>Olyset</strong> Plus against resistant mosquitoes.<br />

5. Impact of the addition of PBO on <strong>Olyset</strong> Plus and performance after<br />

1 day post-wash against resistant mosquitoes.<br />

Tests were conducted against field caught Anopheles<br />

arabiensis which were pyrethroid metabolic resistant.<br />

To evaluate the impact of PBO, an experimental <strong>Olyset</strong> Plus<br />

net was made with no synergist present. Both nets were<br />

washed once and tested after 1 day using the WHO cone<br />

test (3 minute exposure).<br />

The results (Figure 8) show showed that while there<br />

was no noticeable impact on knockdown there was a<br />

dramatic difference in mortality as a result of the action<br />

of PBO blocking the metabolic resistance mechanism.<br />

%<br />

Figure 7. <strong>Olyset</strong> Plus vs. a Polyester LLIN against field<br />

caught resistant mosquitoes (WHO cone test).<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

100<br />

80<br />

60<br />

%<br />

40<br />

Ref. Sumitomo Chemical Health and Crop Sciences Laboratory Report, 2011<br />

20<br />

0<br />

100<br />

73.2 75.6<br />

KD<br />

24.4<br />

Mortality<br />

Polyester LLIN<br />

<strong>Olyset</strong> Plus<br />

Ref. Sumitomo Chemical Health and Crop Sciences Laboratory Report, 2011<br />

Figure 8. Impact of PBO in <strong>Olyset</strong> Plus against resistant<br />

mosquitoes 1 day after washing (WHO cone test).<br />

100<br />

KD<br />

100<br />

14.6<br />

73.2<br />

Mortality<br />

Ref. Sumitomo Chemical Health and Crop Sciences Laboratory Report, 2011<br />

<strong>Olyset</strong> Plus without PBO<br />

<strong>Olyset</strong> Plus with PBO

%<br />

Figure 9. Blood Feeding Inhibition in hut trials against resistant<br />

mosquitoes in Benin.<br />

100<br />

90<br />

80<br />

70<br />

60<br />

100<br />

80<br />

60<br />

%<br />

40<br />

%<br />

100 100<br />

Kisumu before<br />

washing<br />

100<br />

95.1<br />

Kisumu after<br />

washing<br />

(3x+7 days)<br />

84.6<br />

82<br />

70.2<br />

KDR +<br />

Metabolic<br />

before<br />

washing<br />

Ref: C.Pennetier, V.Corbel et al. DOC/IRD/CREC/02/10<br />

20<br />

0<br />

87.1<br />

KDR +<br />

Metabolic<br />

after washing<br />

(3x+7 days)<br />

97.4 100 88<br />

Metabolic<br />

before<br />

washing<br />

BFI<br />

<strong>Olyset</strong> <strong>Net</strong><br />

<strong>Olyset</strong> Plus<br />

96.1<br />

Metabolic<br />

after washing<br />

(3x+7 days)<br />

Figure 10. Experimental hut trials in Cameroon: <strong>Olyset</strong> <strong>Net</strong> and<br />

<strong>Olyset</strong> Plus<br />

.6<br />

Control<br />

97.4<br />

75.8<br />

<strong>Olyset</strong> <strong>Net</strong><br />

Unwashed<br />

100 97.5<br />

<strong>Olyset</strong> Plus<br />

Ref: C.Pennetier, V.Corbel et al. DOC/IRD/CREC/02/10<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

.5<br />

Control<br />

88.0<br />

38.0<br />

<strong>Olyset</strong> <strong>Net</strong><br />

3 washes + 7 days<br />

Figure 11. WHOPEs Phase II experimental hut trials,<br />

Malanville, Benin.<br />

83.2<br />

80.6<br />

<strong>Olyset</strong> Plus<br />

unwashed<br />

79.4<br />

67.3<br />

<strong>Olyset</strong> Plus 20<br />

times washed<br />

Ref: CREC/IRD WHOPES Phase II report 31/1/2012<br />

81.6<br />

Blood Feeding Inhibition<br />

Mortality corrected<br />

for control<br />

41.7<br />

<strong>Olyset</strong> <strong>Net</strong><br />

unwashed<br />

59.9<br />

36.3<br />

<strong>Olyset</strong> <strong>Net</strong> 20<br />

times washed<br />

Mortality<br />

96.1<br />

68.6<br />

<strong>Olyset</strong> Plus<br />

These studies also demonstrated that <strong>Olyset</strong> Plus<br />

regenerated very rapidly and was active again 1 day after<br />

washing.<br />

6. <strong>Olyset</strong> Plus compared with <strong>Olyset</strong> <strong>Net</strong> in experimental huts – Benin.<br />

Trials were conducted in Cotonou, Benin using experimental<br />

huts to compare activity of <strong>Olyset</strong> <strong>Net</strong> and <strong>Olyset</strong> Plus.<br />

The washing methodology and experimental protocol<br />

followed the WHO Guidelines for testing long lasting nets<br />

(WHO/CDS/WHOPES/GCDPP/2005.11). Both LLINs had six<br />

holes cut in them to simulate torn nets and a volunteer<br />

slept under the nets. Mosquitoes therefore had access to a<br />

blood meal or were inhibited from feeding and exited the<br />

hut to a veranda trap. Three An. gambiae strains were used<br />

– susceptible (Kisumu), Kdr + metabolic resistant and<br />

metabolic only resistant. The mosquitoes were released<br />

into the hut in known numbers on different nights and<br />

Blood Feeding Inhibition (BFI) recorded to demonstrate<br />

the varying degrees of protection the test nets provided.<br />

The results are shown in Figure 9 where it can be seen<br />

that with susceptible mosquitoes there was little difference<br />

before washing, while after washing the <strong>Olyset</strong> Plus<br />

The unwashed <strong>Olyset</strong> <strong>Net</strong> performed well especially<br />

considering the resistance present but <strong>Olyset</strong> Plus gave<br />

better mosquito mortality.<br />

was slightly more effective due to faster regeneration and<br />

also to the additional performance enhancement that<br />

comes from the synergistic effects of PBO. When both nets<br />

were tested against Kdr + metabolic resistant mosquitoes<br />

the performance was not dissimilar before washing but<br />

after washing there was a dramatic difference as the BFI<br />

was far higher with <strong>Olyset</strong> Plus showing a protective<br />

effect. The BFI in this <strong>Olyset</strong> Plus treatment was 87.1%<br />

which is good considering that with Kdr resistance<br />

(caused by insensitivity of the insect nervous system to<br />

insecticide) PBO would be expected to add little benefit.<br />

When tested against metabolic only resistant mosquitoes<br />

8

<strong>Olyset</strong> Plus gave very good BFI that was superior to <strong>Olyset</strong><br />

<strong>Net</strong> due to the presence of PBO.<br />

7. <strong>Olyset</strong> Plus compared with <strong>Olyset</strong> <strong>Net</strong> in experimental huts –<br />

Cameroon.<br />

Experimental hut trials to compare <strong>Olyset</strong> <strong>Net</strong> and <strong>Olyset</strong><br />

Plus were conducted in Pitoa, Cameroon. As above, the<br />

washing methodology and protocol followed WHO<br />

Guidelines. The local population of An. gambiae were<br />

pyrethroid metabolic mechanism resistant.<br />

Blood Feeding Inhibition (BFI) rates were recorded to<br />

demonstrate the varying degrees of protection the test<br />

nets provided. The results (Figure 10) demonstrate that<br />

the untreated control nets gave little protection before<br />

washing.<br />

The unwashed <strong>Olyset</strong> <strong>Net</strong> performed well especially<br />

considering the resistance present but <strong>Olyset</strong> Plus gave<br />

better mosquito mortality. After 3 washes and 7 days<br />

<strong>Olyset</strong> <strong>Net</strong> gave good levels of BFI (88%) while <strong>Olyset</strong> Plus<br />

gave even better protection with 96% BFI. <strong>Olyset</strong> Plus also<br />

had a better overall impact on mortality (69% vs 38% for<br />

<strong>Olyset</strong> <strong>Net</strong>).<br />

8. WHO Phase II Evaluation of <strong>Olyset</strong> Plus – Benin.<br />

As part of the evaluation of <strong>Olyset</strong> Plus, Phase II experimental<br />

hut trials were conducted in Benin by WHOPES.<br />

These were carried out in Malanville, in an area where<br />

increased resistance of malaria vectors to pyrethroids<br />

(22% mortality to 0.75% permethrin) has been recently<br />

reported. Results for wild, free flying An.gambiae are<br />

shown in Figure 11. These show that while both nets have<br />

given good initial levels of protection from blood feeding<br />

before washing, <strong>Olyset</strong> Plus continues to give excellent<br />

protection after 20 washes. Levels for <strong>Olyset</strong> <strong>Net</strong> while<br />

still good, have declined. Mortality data follows a similar<br />

trend, indicating that <strong>Olyset</strong> Plus is likely to have a<br />

greater mass killing effect on these resistant populations<br />

over time compared with <strong>Olyset</strong> <strong>Net</strong>.

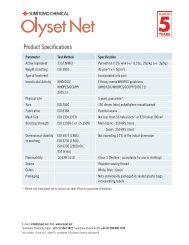

Technical Specifications<br />

<strong>Olyset</strong> Plus – meeting the world’s changing needs.<br />

Specifications<br />

Category<br />

Odour<br />

Colour<br />

Shape<br />

Dimensional Stability to<br />

washing (ISO 5077)<br />

<strong>Net</strong> attachment<br />

Active ingredient<br />

Packaging<br />

Synergist<br />

Insecticide and<br />

synergist location<br />

Storage stability<br />

Duration of Insecticide<br />

& Synergist efficacy<br />

from first use<br />

Specification<br />

Odourless<br />

Blue or white<br />

Rectangular or Conical<br />

Not exceeding 5% of the initial dimension<br />

Rectangular – A minimum of 6 suspension<br />

points (one at each of the four corners of<br />

the top panel and one equidistant at each of<br />

the sides) attached by fabric loops.<br />

Conical – single suspension point<br />

Permethrin 2.0% w/w (+/- 0.5%w/w),<br />

20g/kg (+/- 5g/kg)<br />

<strong>Net</strong>s individually packaged in sealed and<br />

tamper proof polypropylene bags<br />

incorporating a label<br />

Piperonyl Butoxide 1.0% w/w<br />

(+/- 0.25%w/w), 10g/kg (+/- 2.5g/kg)<br />

Incorporated into yarn<br />

In storage tests, net material contains<br />

>95% of the original a.i. content after<br />

2 weeks at 54ºC<br />

3 years (minimum)<br />

Fire Safety Classification Class 1<br />

16CFR 1610<br />

(Textiles – acceptable for use in clothing)<br />

Yarn<br />

150 denier (+/- 30) high density polyethylene<br />

monofilament fibre<br />

Mesh Size (holes/inch²) Not less than 80 holes per inch 2<br />

Weight of netting 40 g/m 2 (+/- 10g/m 2 )<br />

Weave type<br />

Raschel<br />

Bursting strength Main Fabric: 250KPa (min)<br />

Seam: 250KPa (min)<br />

Seams<br />

Polyester sewing thread<br />

Fabrication<br />

Warp Knitted<br />

ISO 13938-1-1999<br />

Sizes Available (cm)<br />

Rectangular <strong>Net</strong>s<br />

Description Length Width Height Number of<br />

Loops (min)<br />

Double 180 100 150 6<br />

Family 180 130 150 6<br />

Large Family/High 180/180 160/160 150/210 6<br />

Extra Family/High 190/190 180/180 150/210 6<br />

Conical <strong>Net</strong>s<br />

Description Circumference Height Roof Top Ring<br />

(diameter)<br />

Small 850 220 56 Flexible metal<br />

Medium 1050 220 56 Flexible metal<br />

Large 1250 250 65 Flexible metal<br />

Note : Rectangular and conical net sizes +/- 10% measured hanging up<br />

Active Ingredient Content of <strong>Olyset</strong> Plus<br />

Permethrin (Ref VBC/DS/84.51)<br />

The following information refers to permethrin, the active<br />

ingredient in <strong>Olyset</strong> Plus. Permethrin has been used for<br />

public health and agricultural insect control for over 30<br />

years and has an excellent track record. Registered uses of<br />

Permethrin include human skin applications for scabies<br />

control and as an insect repellent.<br />

SYNOPSIS: Permethrin is a broad spectrum, non-cumulative<br />

synthetic pyrethroid; and is a fast acting neurotoxin<br />

with good contact, limited stomach and no fumigant<br />

action. It is moderately stable in the environment and has<br />

good residual action on inert surfaces. Permethrin is<br />

non-systemic in plants; of low mammalian toxicity, and is<br />

readily metabolised with immediate loss of toxicity.<br />

Common name: Permethrin (ISO, BSI, ANSI)<br />

Identity:<br />

IUPAC: 3-Phenoxybenzyl(1RS)-cis,trans-3-(2,2-<br />

dichlorovinyl)-2,2-dimethylcyclopropanecarboxylate.<br />

Molecular Formula: C21H20Cl2O3<br />

Molecular weight: 391.3<br />

10

Structural formula:<br />

Piperonyl Butoxide content<br />

Permethrin content<br />

Declared content is 20g/kg (+/-5g/kg, 2% w/w (1.5-2.5%<br />

limits), cis:trans isomer ratio 50/50 to 30/70).<br />

Ecotoxicology<br />

Exposure of non-target organisms to permethrin in <strong>Olyset</strong><br />

Plus is unlikely when used in accordance with the label<br />

instructions. Permethrin is toxic to fish under laboratory<br />

conditions, so contamination of fish-bearing water should<br />

be avoided. <strong>Net</strong>s should be gently washed in containers<br />

using a mild soap as necessary, and not in natural water<br />

sources such as streams, rivers, ponds and lakes.<br />

Piperonyl Butoxide<br />

The following information refers to piperonyl butoxide<br />

(PBO) a synergist used in <strong>Olyset</strong> Plus. PBO has been used for<br />

public health and agricultural insect control since 1947 and<br />

has an excellent track record. Registered uses of PBO<br />

include consumer aerosols, space sprays, shampoos for head<br />

lice and even skin applications for treatment of scabies.<br />

SYNOPSIS: Piperonyl butoxide is a synergist which<br />

enhances the activity of insecticides by inhibiting or<br />

blocking enzymes in the insect which would de-toxify<br />

the insecticide. It is particularly effective when used in<br />

conjunction with pyrethroids. It has low mammalian<br />

toxicity. It is non-cumulative in the environment.<br />

IUPAC: 5-[2-(2-butoxyethoxy) ethoxymethyl] -6-propyl-1,3-<br />

benzodioxole<br />

Molecular formula: C19H30O5<br />

Molecular weight: 338.438<br />

Declared content is 10g/kg (+/- 2.5g/kg), 1% w/w<br />

(0.75 – 1.25% limits).<br />

Ecotoxicology<br />

Researchers evaluated the disappearance of piperonyl<br />

butoxide in soil and water and determined that the chemical<br />

is short-lived in the environment. Piperonyl butoxide<br />

has a moderate to low potential to contaminate groundwater.<br />

Researchers consider piperonyl butoxide moderately<br />

toxic to fish and highly toxic to other aquatic organisms.<br />

It is not likely to accumulate in fish. Piperonyl butoxide<br />

is low to very low in toxicity when eaten by birds.<br />

Disposal Considerations<br />

The net should be changed when biological performance<br />

declines. Normally this will occur after approximately<br />

3 years. Disposal should conform to recommendations of<br />

International organizations and should comply with all<br />

federal, state and local regulations.<br />

Transport Information<br />

Hazard Class: Not classified as a hazardous material<br />

U.N. Number: Not applicable<br />

Storage<br />

Store in a cool, well-ventilated place away from sources<br />

of ignition and direct sunlight.<br />

Analytical<br />

Full analytical methodology is available for permethrin in<br />

CIPAC/4503/m Permethrin (June 2006). Piperonyl Butoxide<br />

Method extension of CIPAC 32+33+345/TK/M;<br />

Determination of Piperonyl Butoxide in Polyethylene<br />

Matrix by GC-FID 33/LN(M)/-<br />

11

Usage and Safety<br />

Usage and Care of <strong>Olyset</strong> Plus<br />

<strong>Olyset</strong> Plus nets are ready to use. Just unpack and hang<br />

over the bed, using the loops provided to attach string or<br />

cord and suspend from the roof. There is no need to ‘air’<br />

the net before use, unlike some other net products.<br />

Ensure the net hangs over the bed with sufficient netting<br />

hanging below the mattress or mat to tuck under at night.<br />

The net is factory-treated with insecticide and synergist<br />

and never needs re-treatment.<br />

<strong>Olyset</strong> Plus nets may be washed using soap and water to<br />

remove dirt. It is recommended that nets are washed a few<br />

times a year, as if a net becomes really dirty it could<br />

inhibit performance by masking the insecticide.<br />

To avoid damaging the net, gentle washing (with no<br />

bleach) is recommended. After washing the net should be<br />

dried in the shade before re-hanging over the bed. Once<br />

washed, the net will rapidly re-generate insecticide and<br />

synergist to the surface of the fibres, replacing any lost<br />

during washing.<br />

Safety<br />

Permethrin is a pyrethroid insecticide with low<br />

mammalian toxicity. Piperonyl butoxide is a synergist of<br />

low mammalian toxicity. Moreover, the majority of both<br />

chemicals are contained within the fibre matrix. However,<br />

sufficient active ingredient is still available on the net<br />

surface to provide excellent biological performance<br />

against mosquitoes.<br />

The risks from handling the net are negligible.<br />

Permethrin and piperonyl butoxide are virtually<br />

non-irritant, so no adverse effects should result from<br />

contact during handling or while sleeping under the net.<br />

World Health Organization Pesticide Evaluation Scheme (WHOPES)<br />

In accordance with Sumitomo`s ethical policies <strong>Olyset</strong> Plus<br />

has been submitted to WHOPES to be evaluated through<br />

all WHOPES test phases, and results so far are very positive.<br />

The WHOPES Working Group have met and after considering<br />

all the relevant scientific data have granted <strong>Olyset</strong> Plus<br />

an interim recommendation.<br />

WHO Risk Assessment of <strong>Olyset</strong> Plus (abstract)<br />

A risk assessment was conducted according to the WHO<br />

generic risk assessment model to support the use of a<br />

new long lasting insecticidal net (LLINs) to protect against<br />

malaria carried by mosquitoes. The polyethylene net<br />

contains permethrin 2% w/w and piperonyl butoxide<br />

and insecticidal synergist (1% w/w).<br />

Since the nets are manufactured and pre-treated with<br />

permethrin and piperonyl butoxide in the factory, the<br />

treatment of nets by the end user is not required.<br />

Therefore the only relevant exposure scenarios considered<br />

in this risk assessment were exposure during the washing<br />

of nets and exposure while sleeping under the nets,<br />

including exposure from potential oral ingestion by<br />

infants and children sucking or chewing the nets. The<br />

potential exposures of Permethrin and PBO during these<br />

activities were assessed using conservative assumptions,<br />

parameters and default values defined in the WHO model.<br />

All calculated exposures to permethrin and PBO<br />

achieved acceptable margins of safety for adults, children<br />

and infants for the relevant activities noted above.<br />

Therefore the combination of Permethrin and PBO in<br />

LLINs was considered safe.<br />

12

<strong>Olyset</strong> Plus nets are ready to use. Just unpack and hang over<br />

the bed, using the loops provided to attach string or cord and<br />

suspend from the roof. There is no need to ‘air’ the net before<br />

use, unlike some other net products.

Find out more at www.olyset.net<br />

<strong>Olyset</strong> Customer Service Department<br />

Horatio House<br />

77-85 Fulham Palace Road<br />

London W6 8JA<br />

United Kingdom<br />

Tel: +44 (0)208 600 7700<br />

Email: info@olyset.net<br />

<strong>Olyset</strong>® is a Registered trademark of Sumitomo Chemical Co.Ltd