RX45 Scissor Lift

RX45 Scissor Lift

RX45 Scissor Lift

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

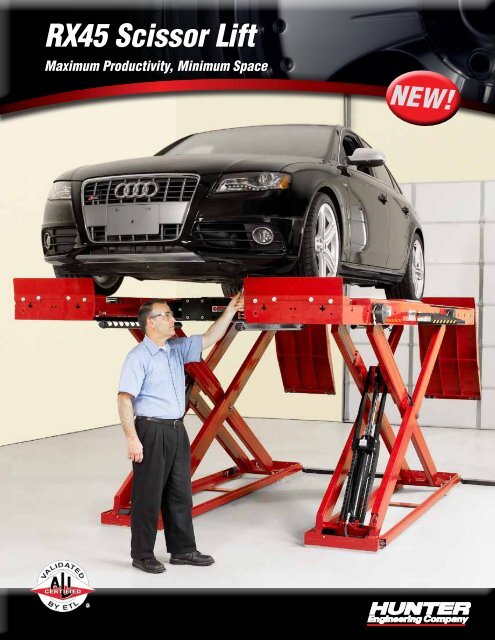

<strong>RX45</strong> <strong>Scissor</strong> <strong>Lift</strong><br />

Maximum Productivity, Minimum Space<br />

NEW!

<strong>RX45</strong> <strong>Scissor</strong> <strong>Lift</strong><br />

Large capacity with a<br />

small footprint<br />

Swing Air Jacks<br />

3 2,722 kg<br />

(6,000-lb.)<br />

capacity<br />

Two Movable Wor<br />

Extra-Wide Runways<br />

3 Technicians’<br />

favorite<br />

610 mm (24 in.)<br />

3 610 mm (24 in.) runways<br />

accept wide vehicles<br />

Integrated Air Line Kit<br />

3 Convenient air source<br />

for tools at front and rear<br />

Sensor Feedback System *<br />

Velocity Safety Fuses<br />

Safety Locks<br />

3 Sensors keep runway level<br />

3 Instantaneous<br />

shutdown<br />

in event of<br />

hydraulic<br />

failure<br />

3 Safely stops if obstructed<br />

* Shown with protective cover removed.

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

k Steps<br />

Low Profile<br />

Louvered Ramps<br />

3 12 secure<br />

positions<br />

3 Lightweight<br />

design<br />

1 10 11 12<br />

8.75 in. (222 mm)<br />

3 222 mm (8.75 in.)<br />

best-in-class<br />

lowered height<br />

Spoiler clearance<br />

Breakover clearance<br />

3 Prevent wheel spin in<br />

wet conditions<br />

3 More effective than<br />

diamond tread or<br />

abrasive strips<br />

Control Panel<br />

3 Complete operation from<br />

the console<br />

3 PowerSlide ® , Inflation<br />

Station and FIA control<br />

Inflation Station (optional)<br />

Pins and Bearings<br />

3 Perform<br />

adjustments at<br />

16 height<br />

positions<br />

3Chromed<br />

pins and<br />

teflon<br />

bearings for<br />

long life<br />

3 Automatically fills or<br />

bleeds each tire<br />

3 No hanging air lines

Hunter offers fully integrated<br />

options to enhance productivity<br />

WinAlign software controls the lift for ultimate<br />

productivity. This patented design offers greater<br />

flexibility and timesaving capabilities.<br />

<strong>RX45</strong> <strong>Scissor</strong> <strong>Lift</strong> shown with optional Swing Air Jacks, AlignLights, Inflation<br />

Station, PowerSlide ® turnplates, WinAlign ® Wheel Aligner and HawkEye ® Sensors.<br />

PowerSlide ® rear slipplates are standard equipment on all <strong>RX45</strong> configurations.

POWERSLIDE EDITION<br />

4 Slipplates and optional turnplates lock<br />

with the touch of a button or automatically<br />

through an FIA-equipped aligner**<br />

4 No more struggles with lock pins<br />

4 Avoid wear and tear and extend the life of<br />

your turnplates<br />

Yesterday's<br />

Technology<br />

Minimize trips around the car<br />

1 Mount Targets<br />

2 Make Adjustments<br />

3 Remove Targets<br />

4 Jack Vehicle and Compensate Sensors 8 Trips<br />

5 Lower Leveling Legs (if equipped)<br />

2<br />

Only<br />

3 Trips!<br />

6<br />

Remove Slipplate and Turnplate Pins<br />

7 Replace Slipplate and Turnplate Pins<br />

8<br />

Raise Leveling Legs (if equipped)<br />

INFLATION STATION EDITION<br />

4 Automatically inflate or deflate all four tires<br />

simultaneously to the specified tire pressure<br />

4 Record starting and final pressure**<br />

4 Hose recoils to keep work area clear<br />

Printouts show starting and<br />

final tire pressures. **<br />

** Requires WinAlign ® 10.x software or greater.

<strong>RX45</strong>F Flush-Mount <strong>Scissor</strong> <strong>Lift</strong><br />

The RX <strong>Scissor</strong> <strong>Lift</strong> may also be flush-mounted in<br />

a shallow recess. No more worries about lowered<br />

vehicles or expensive spoilers! This very tidy<br />

installation is ideal for “showcase” shops.<br />

See site requirements for installation details.<br />

No additional charge for flush-mount option, see<br />

Hunter Sales Representative for details.<br />

Add -F to any RX model.<br />

Swing Air Jacks<br />

Hunter Swing Air Jacks add capabilities<br />

for lifting vehicles off the runways during alignment<br />

procedures and other service operations.<br />

The Swing Air Jack has a capacity of 2,722 kg<br />

(6,000 lbs.) Swing Jacks combine low drive-on<br />

height with high lift capacity needed to handle wide<br />

range of vehicles.<br />

133-69-1 – 2,722 kg (6,000-lb.) Capacity Swing Air Jack<br />

Optional AlignLights Accessory<br />

Hunter’s AlignLights lighting accessory provides an<br />

efficient light source underneath the vehicle.<br />

Lights automatically shut off as the lift is lowered to<br />

the ground and turn on when raised.<br />

AlignLights are powered by the main lift power<br />

source and require no additional or exposed<br />

electrical cords.<br />

For All RX Models: 20-2173-1

Turnplates<br />

All <strong>RX45</strong> models have 50mm deep turnplate pockets.<br />

20-2076-1 – PowerSlide ® Turnplates with Automatic Bridges<br />

Stainless steel turnplates for camera-sensor-based systems.<br />

20-2075-1 – PowerSlide ® Turnplates without Automatic Bridges<br />

Stainless steel turnplates for conventional CCD sensors.<br />

20-2114-1 – 50mm Stainless Steel Turnplate Kit<br />

20-2113-1 – 50mm Low-Friction Stainless Turnplate Kit<br />

Integrated bridge lowers and raises as plates<br />

are locked, making rolling compensation a<br />

snap. Air-operated control system ties directly<br />

into PowerSlide ® lifts.<br />

Approach Ramp Extensions<br />

For high floor slope installs or specialty vehicles, sometimes approach ramp extensions are needed.<br />

Several choices are available.<br />

147-104-1 – Adds 324 mm / 12.75 in. (2 required)<br />

147-113-1 – Adds 451 mm / 17.75 in. (2 required)<br />

Conventional Sensor Extension<br />

Required when using conventional sensors with<br />

toe arms. Provides more room for toe arms<br />

during use.<br />

20-2169-1 – Adds 1,016 mm / 40 in. (1 required)<br />

20-2189-1 – Adds 1,270 mm / 50 in. (1 required)<br />

Drive-Thru Kit<br />

For surface-mount, drive-thru application. Use<br />

standard kit for camera sensors and extended kit<br />

for conventional sensors.<br />

20-2497-1<br />

20-2498-1 – Std. Drive-Thru<br />

20-2501-1 – Ext. Drive-Thru

<strong>RX45</strong> Specifications<br />

<strong>RX45</strong><br />

<strong>RX45</strong>L<br />

Max. Vehicle Gross Weight: 4,536 kg (10,000 lbs.) 4,536 kg (10,000 lbs.)<br />

Max. Wheelbase: General service 4,547/4,445 mm (179/175 in.) 4,877/4,775 mm (192/188 in.)<br />

Two-wheel alignment 4,216/4,115 mm (166/162 in.) 4,547/4,445 mm (179/175 in.)<br />

Four-wheel alignment 4,013 mm (158 in.) 4,013 mm (158 in.)<br />

Min. 4-Wheel Alignment: 2,235 mm (88 in.) 2,235 mm (88 in.)<br />

Runway Width: 609 mm (24 in.) 609 mm (24 in.)<br />

Lowered Height: 222 mm (8.75 in.) 222 mm (8.75 in.)<br />

surface/flush<br />

Alignment height<br />

Max. lifting height<br />

Tread width<br />

Min. inside<br />

Max. outside<br />

Air Pressure<br />

Raise Time<br />

Models<br />

All lock positions<br />

1,829 mm (72 in.)<br />

1,016 mm (40 in.)<br />

2,235 mm (88 in.)<br />

90-150 psi<br />

55 seconds<br />

<strong>RX45</strong>: Surface mounted standard lift with PowerSlide<br />

rear slipplates<br />

<strong>RX45</strong>F: Flush mounted standard lift with PowerSlide<br />

rear slipplates<br />

<strong>RX45</strong>IS: Surface mounted standard lift with Inflation<br />

Station & PowerSlide rear slipplates<br />

<strong>RX45</strong>FIS: Flush mounted standard lift with Inflation<br />

Station & PowerSlide rear slipplates<br />

<strong>RX45</strong>L: Surface mounted long deck lift with<br />

PowerSlide rear slipplates<br />

<strong>RX45</strong>LF: Flush mounted long deck lift with PowerSlide<br />

rear slipplates<br />

<strong>RX45</strong>LIS: Surface mounted long deck lift with Inflation<br />

Station & PowerSlide rear slipplates<br />

<strong>RX45</strong>LFIS: Flush mounted long deck lift with Inflation<br />

Station & PowerSlide rear slipplates.<br />

Add one of the following suffixes to the desired model<br />

number listed above (Example: <strong>RX45</strong>-435E):<br />

Suffix Power Configuration<br />

-435E 208/230/400/460V, 3PH, 50HZ<br />

-215E 230V, 1PH, 50Hz<br />

-216E 230V, 1PH, 60Hz<br />

Standard Equipment<br />

Two Movable Work Steps (not included with flush model)<br />

Front Wheel Stops<br />

Two Wheel Chocks<br />

Air Line Kit<br />

Full-Floating Rear Wheel Slipplates<br />

Louvered Ramps with Built-In Wheel Stops<br />

OPTIONAL<br />

EXTENDED<br />

WHEEL STOP<br />

295 mm<br />

(11 5/8 in.)<br />

406 mm<br />

(16 in.)<br />

559 mm<br />

(22 in.)<br />

406 mm<br />

(16 in.)<br />

991 - 1,372 mm<br />

(39 - 54 in.)<br />

610 mm<br />

(24 in.)<br />

<strong>RX45</strong> Plan View<br />

2,248 mm<br />

(7 ft. - 4 1/2 in.)<br />

RX10<br />

6,128 mm<br />

(20 ft. - 1 1/4 in.)<br />

RX10L<br />

6,458 mm<br />

(21 ft. - 2 1/4 in.)<br />

101 mm (4 in.) RECOMMENDED MIN.<br />

See Hunter Sales Representative for details<br />

on site requirement.<br />

0411BH<br />

The Hunter <strong>RX45</strong> Series <strong>Scissor</strong> <strong>Lift</strong> has been<br />

certified under the program conducted by<br />

Automotive <strong>Lift</strong> Institute (ALI) and ETL Testing<br />

Laboratories to comply with Safety Standard ANSI/<br />

ALI, ALCTV and Electrical Standard ANSI/UL 201.<br />

11250 Hunter Drive, Bridgeton, MO 63044 U.S.A.<br />

Tel: 1-314-731-3020 • Fax: 1-314-731-0132<br />

E-mail: international@hunter.com<br />

Copyright © 2011, Hunter Engineering Company<br />

Form 6284-TE-05, 04/11<br />

Supersedes Form 6284-TE-05, 03/11