ROSTA OSCILLATING MOUNTINGS - Jens S Transmisjoner

ROSTA OSCILLATING MOUNTINGS - Jens S Transmisjoner

ROSTA OSCILLATING MOUNTINGS - Jens S Transmisjoner

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>ROSTA</strong><br />

Technology<br />

3. Terminology and Calculation (Crank Shaft Driven Systems)<br />

3.1. Terminology<br />

Symbol Unit Term<br />

a m/s 2 Acceleration<br />

A mm Center distance rockers<br />

c d N/mm Dynamic spring value (rocker)<br />

c t N/mm Total spring value (system)<br />

f e Hz Natural frequency (elements)<br />

f err Hz Excitation frequency<br />

F N Force<br />

g 9.81m/s 2 Gravitational acceleration<br />

K<br />

machine acc.<br />

grav. acc.<br />

Oscillating machine factor<br />

Symbol Unit Term<br />

m kg Mass<br />

n err min –1 Revolutions per minute<br />

R mm Crank radius<br />

S – Center of gravity<br />

sw = 2 · R mm Throw (peak to peak)<br />

v th<br />

m/min cm/s Theoretical velocity (material)<br />

z – Quantity (number)<br />

W % Degree of isolation<br />

α ° Oscillation angle<br />

β ° Rocker angle (inclination)<br />

3.2. Calculation<br />

Formulas for calculating oscillating machines based on the fundamental knowledges about oscillation theories.<br />

Total spring value (system)<br />

Exitation frequency<br />

c t = m · ( 2π · n err ) 2 · 0.001<br />

60<br />

f err = 1 c ·<br />

t · 1000<br />

2π<br />

m<br />

[N/mm]<br />

[Hz]<br />

Oscillating Mountings<br />

Number of rockers for resonance operation<br />

Oscillating machine factor (g-factor of acceleration)<br />

Acceleration force<br />

c t<br />

z =<br />

0.9 · c d<br />

K = (2π · n err ) 2<br />

60<br />

·R<br />

9810<br />

F = K · m · g<br />

[piece]<br />

[–]<br />

[N]<br />

Required driving power (approximation)<br />

P ≈ R · K · m · g · nerr<br />

9550 · 1000 · 2<br />

[kW]<br />

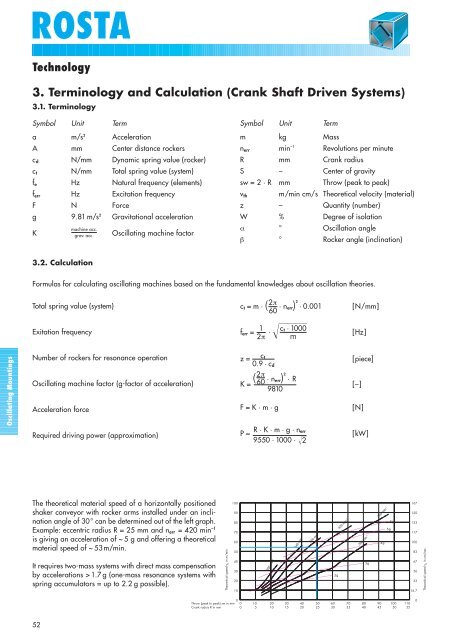

The theoretical material speed of a horizontally positioned<br />

shaker conveyor with rocker arms installed under an inclination<br />

angle of 30° can be determined out of the left graph.<br />

Example: eccentric radius R = 25 mm and n err = 420 min –1<br />

is giving an acceleration of ~ 5 g and offering a theoretical<br />

material speed of ~ 53 m/min.<br />

It requires two-mass systems with direct mass compensation<br />

by accelerations > 1.7 g (one-mass resonance systems with<br />

spring accumulators = up to 2.2 g possible).<br />

Theoretical speed v th in m/min<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

600 min -1<br />

-1<br />

540 min<br />

-1<br />

480 min<br />

2g<br />

-1<br />

420 min<br />

-1 360 min<br />

300 min -1<br />

4g<br />

3g<br />

6g<br />

5g<br />

167<br />

150<br />

133<br />

117<br />

100<br />

83<br />

67<br />

50<br />

33<br />

16.7<br />

Theoretical speed v th in cm/sec<br />

Throw (peak to peak) sw in mm<br />

Crank raduis R in mm<br />

0<br />

0<br />

0<br />

10<br />

5<br />

20<br />

10<br />

30<br />

15<br />

40<br />

20<br />

50<br />

25<br />

60<br />

30<br />

70<br />

35<br />

80<br />

40<br />

90<br />

45<br />

100<br />

50<br />

110<br />

55<br />

0<br />

52