CAREER PROFILE CLOTHING ALTERATION HAND - Skillset

CAREER PROFILE CLOTHING ALTERATION HAND - Skillset

CAREER PROFILE CLOTHING ALTERATION HAND - Skillset

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

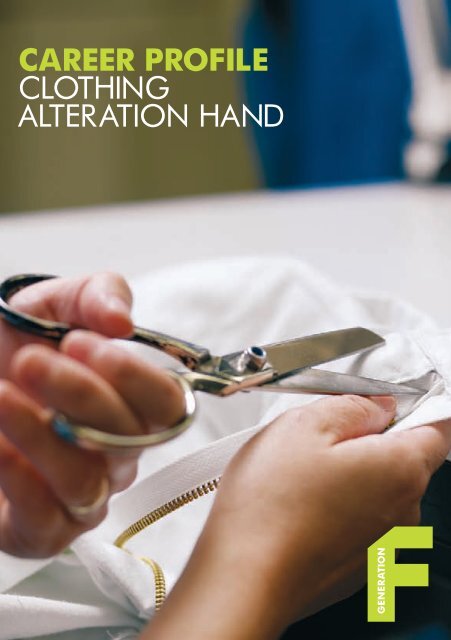

<strong>CAREER</strong> <strong>PROFILE</strong><br />

Clothing<br />

Alteration Hand

Clothing alteration hands<br />

modify and repair items<br />

of clothing. They may use<br />

hand or machine sewing<br />

techniques and will have<br />

expert knowledge of<br />

garment construction.<br />

What does a clothing<br />

alteration hand do<br />

They may be involved in fastening<br />

new zips, taking in or letting out<br />

seams, shortening or lengthening<br />

hems and replacing trims. Clothing<br />

alteration hands may also work<br />

on specialist pieces, such as<br />

bridal gowns.<br />

The salary of a clothing<br />

alteration hand<br />

When starting out, a clothing<br />

alteration hand could expect to be<br />

paid around £11,000 a year with<br />

experience earning up to £16,000.<br />

Supervisors could earn £22,000<br />

a year or more.<br />

Hours and working environment<br />

Alteration hands usually work around<br />

40 hours a week. Saturday work<br />

is common for those employed in<br />

laundries and dry-cleaners.<br />

Part-time work and flexible hours<br />

are very common.<br />

A self-employed alteration hand<br />

may have a small, home-based<br />

workroom. Those based in a laundry<br />

or dry-cleaners may have a small<br />

workroom or working area within<br />

the store. Workrooms are usually<br />

warm and well-lit but can be small<br />

and cramped.<br />

Skills and interests<br />

To have a career as a clothing<br />

alteration hand, it is important to<br />

have good sewing skills. These can<br />

be obtained on a relevant course but<br />

on-the-job experience is also very<br />

valuable. The following skills and<br />

interests would also be useful:<br />

* an interest in fashion and a<br />

knowledge of tends and fabrics<br />

*<br />

*<br />

a focused approach to work with<br />

attention to detail<br />

to be self-motivated and able to<br />

work alone and to deadlines<br />

Entry into a career in<br />

clothing alteration<br />

Work-based learning qualifications<br />

such as apprenticeships or NVQs are<br />

a common way to get started as a<br />

clothing alteration hand and many<br />

companies will prefer candidates<br />

to have a relevant qualification.<br />

Check what options are available<br />

at your local college or visit<br />

www.abcawards.co.uk<br />

Further training to develop a<br />

career in clothing alteration<br />

Mastering different sewing<br />

techniques comes with experience.<br />

It can be useful to work alongside<br />

more experienced alteration hands<br />

to enhance practical knowledge.<br />

A wide range of short courses,<br />

qualifications and workshops in<br />

tailoring and garment production<br />

are also available from the<br />

London College of Fashion<br />

www.fashion.arts.ac.uk.<br />

Opportunities in the field of<br />

clothing alteration<br />

Opportunities for promotion may be<br />

limited, although supervisory posts<br />

may be available in larger companies<br />

to those with the relevant experience.<br />

Experienced alteration hands could<br />

become self-employed and may<br />

combine alteration work with design<br />

and craft roles. Strong business<br />

and marketing skills are useful for<br />

those who become self-employed.<br />

Experienced clothing alteration<br />

hands may also move into teaching.<br />

Case study<br />

Gail Sharlotte has<br />

worked at Johnson<br />

Apparelmaster for 20<br />

years as a clothing<br />

alteration hand and<br />

has always had a<br />

passion for sewing.<br />

When Gail started work,<br />

no formal qualifications<br />

were available in sewing<br />

so learned most of her<br />

skills on-the-job or at<br />

school. Gail says “Don’t be<br />

afraid to ask for help there<br />

will always be someone<br />

around to offer you tips<br />

and advice. You need to<br />

have a good eye for detail,<br />

have an understanding<br />

of garment construction<br />

and be conscientious as<br />

someone will have to wear<br />

the garment you are<br />

working on”.<br />

Gail’s work is varied as she<br />

may be repairing an arm<br />

sleeve one minute and<br />

attaching a new collar<br />

the next. Gail says “I love<br />

the work I do as it’s really<br />

varied and interesting<br />

with every garment<br />

requiring something<br />

different and I really look<br />

forward to coming to work.”<br />

For more information visit<br />

www.skillfast-uk.org/generationf

<strong>CAREER</strong> <strong>PROFILE</strong><br />

Garment<br />

Technologist

Garment technologists<br />

support the design and<br />

buying team through all<br />

stages of garment product<br />

development, from<br />

design to manufacture.<br />

Garment technologists<br />

can be employed by<br />

manufacturers or large,<br />

high-street retailers.<br />

What does a garment<br />

technologist do<br />

The garment technologist would be<br />

involved in choosing an appropriate<br />

fabric and design, which will be<br />

in budget. They would then work<br />

with the pattern graders to oversee<br />

the sizing, fitting and testing of the<br />

pre-production garments. A garment<br />

technologist would also analyse<br />

product returns and faults.<br />

The salary of a<br />

garment technologist<br />

A garment technologist may be paid<br />

between £15,000 and £18,000 a<br />

year when starting out. This could<br />

increase to around £25,000 a year<br />

with experience. Senior garment<br />

technologists can earn around<br />

£50,000 a year.<br />

Hours and working environment<br />

A garment technologist would<br />

typically work around 38 hours<br />

a week, this can increase during<br />

busy times and when deadlines<br />

have to be met.<br />

For the majority of the time, a<br />

garment technologist is office-based<br />

and the job can involve working<br />

in a design studio. A garment<br />

technologist may be required to<br />

travel for work, both within the<br />

UK and overseas.<br />

Skills and interests<br />

It may be useful for someone<br />

considering a career in garment<br />

technology to have some of the<br />

following skills and interests:<br />

* an understanding of manufacturing<br />

processes and textile properties<br />

*<br />

*<br />

the ability to work well alone<br />

or as part of a team<br />

the ability to work under pressure<br />

and to tight deadlines<br />

For more information visit<br />

www.skillfast-uk.org/generationf<br />

Entry into a career in<br />

garment technology<br />

A relevant degree is usually preferred<br />

on entry to this industry. Relevant<br />

degrees are available in clothing<br />

technology and production from<br />

a number of universities, visit the<br />

UCAS website: www.ucas.com<br />

for more information.<br />

Work experience is also a good<br />

way of gaining experience of the<br />

industry and making contacts.<br />

Further training to develop a<br />

career in garment technology<br />

On-the-job development of practical<br />

knowledge and skills is critical<br />

to this role. Experience and skills<br />

development will lead to promotion<br />

opportunities.<br />

Short and part-time courses are<br />

also available which may be suitable<br />

for those already working in the<br />

industry. Other qualifications<br />

are available from ABC awards,<br />

visit www.abcawards.co.uk<br />

The Textile Institute also covers<br />

the apparel industry and offers<br />

a range of qualifications, for<br />

more information see the website:<br />

www.texi.org<br />

Opportunities in the field<br />

of garment technology<br />

Graduates will usually join a<br />

company in a junior role, working<br />

their way up through the areas<br />

of product development, quality<br />

control or buying before becoming<br />

a garment technologist.<br />

With experience, it may be possible<br />

to gain promotion into more senior<br />

positions, such as senior technologist<br />

or technical manager. It may also<br />

be possible for a senior garment<br />

technologist to progress into a role<br />

in research within a university or<br />

similar institution.<br />

Case study<br />

Peter Capewell has<br />

worked for Simon Jersey,<br />

a leading corporate<br />

and workwear specialist<br />

based near Accrington,<br />

for two years as a<br />

garment technologist.<br />

Peter started his career as<br />

a pattern cutter working<br />

for numerous companies<br />

including a bespoke tailor<br />

and a mail order company.<br />

He has taken a variety of<br />

qualifications to develop<br />

his skills and gain a better<br />

understanding of fabrics<br />

and garment construction.<br />

Peter had some great<br />

mentors over the years<br />

that encouraged his<br />

development and provided<br />

him with experience to move<br />

into garment technology.<br />

Peter says “Having worked<br />

extensively with a variety<br />

of products means I have<br />

a great deal of knowledge<br />

and understanding of<br />

garment construction which<br />

is essential for my job.”<br />

Team working with the<br />

textile technologist and<br />

pattern cutter ensures the<br />

best product is made for<br />

the customer and allows<br />

maximum creativity.<br />

Peter’s job has allowed<br />

for extensive travel as<br />

many fabrics and finished<br />

garments are made now<br />

overseas. Peter says “Good<br />

all round knowledge of<br />

clothing and fabrics makes<br />

my job easier especially<br />

when working with overseas<br />

companies but seeing a new<br />

product developed from<br />

start to finish is fantastic.”

<strong>CAREER</strong> <strong>PROFILE</strong><br />

Laundry<br />

Maintenance<br />

Engineer

A laundry maintenance<br />

engineer is responsible for<br />

ensuring machinery and<br />

equipment at the laundry<br />

plant runs efficiently<br />

and smoothly. They must<br />

have expert knowledge<br />

in mechanical, electrical,<br />

hydraulic, pneumatic and<br />

computerised systems.<br />

What does a laundry<br />

maintenance engineer do<br />

Their work revolves around ensuring<br />

machinery for washing and drying<br />

clothes for a commercial laundry is<br />

working efficiently and effectively.<br />

They are also responsible for testing<br />

the water used by washing machines<br />

to make sure it is balanced correctly<br />

for clothes washing.<br />

Senior engineers and managers will<br />

also be involved with administration<br />

work to ensure systems and<br />

procedures are adhered to.<br />

The salary of a laundry<br />

maintenance engineer<br />

A laundry maintenance engineer<br />

could expect to be paid around<br />

£16,000 per year as an apprentice<br />

engineer, with experience this can<br />

rise to £21,000. Supervisors will<br />

earn around £18,000 to £25,000.<br />

Managers could earn up to £30,000<br />

per year or more.<br />

Hours and working environment<br />

Laundry maintenance engineers<br />

usually work around 39 hours a<br />

week. Although weekend work is<br />

not common in a commercial<br />

laundry, you will be required to<br />

be ‘on-call’ occasionally in case<br />

of emergency breakdowns.<br />

Laundry maintenance engineers<br />

working environment is on the plant<br />

floor and will be working closely<br />

with machinery so it can be noisy.<br />

Due to working with water and<br />

steam it can be hot.<br />

Skills and interests<br />

You will need to be multi-skilled<br />

with electrical and mechanical<br />

qualifications and knowledge.<br />

A good understanding of maths<br />

and science is also essential.<br />

* an interest in machinery<br />

and fixing equipment<br />

*<br />

*<br />

to be logical, practical<br />

and adaptable<br />

to be self-motivated to work<br />

alone or as part of a team<br />

* physically fit<br />

Entry into a career in laundry<br />

maintenance engineering<br />

You will need some qualifications<br />

to become an engineer and passes<br />

in maths and science GCSE are a<br />

must. Work-based apprenticeships<br />

are a common route for many<br />

entering engineering. For more<br />

information on apprenticeships,<br />

visit the apprenticeship website:<br />

www.apprenticeships.org.uk.<br />

The Institution of Engineering and<br />

Technology website has details<br />

of UK colleges offering<br />

engineering courses.<br />

Further training to develop<br />

a career in laundry<br />

maintenance engineering<br />

As technology changes and becomes<br />

more efficient, many engineers find<br />

they need to do short courses to keep<br />

their skills and knowledge up to date.<br />

Many businesses will assist with this<br />

element of further training and it will<br />

often be tailored to suit the business<br />

you work for.<br />

Opportunities in the field of a<br />

laundry maintenance engineer<br />

Once you have an engineering<br />

qualification you can move into<br />

many sectors not just laundry and<br />

dry cleaning. There are opportunities<br />

to develop your skills and training<br />

and you can work your way up to<br />

supervisor or managerial levels in<br />

some companies.<br />

Case study<br />

Andy Pitts has worked at<br />

Johnson Apparelmaster<br />

for almost two years<br />

and has recently been<br />

promoted to senior<br />

maintenance engineer at<br />

the commercial laundry<br />

based in Hull.<br />

Andy worked while studying<br />

for his marine engineering<br />

apprenticeship. This led him<br />

to do engineering work in<br />

many areas including boiler<br />

maintenance and laundry.<br />

Andy says “To become a<br />

maintenance engineer you<br />

need to be multi-skilled with<br />

electrical and mechanical<br />

training. You need to be<br />

able to think problems<br />

through logically and have<br />

a good head for numbers.<br />

Being physically fit is also<br />

an advantage.”<br />

Andy’s job is not just about<br />

working with hand tools,<br />

many of the machines are<br />

computerised so expertise<br />

in electronics and electrics<br />

are essential. There is also<br />

a very scientific element<br />

involved to make the water<br />

soft for washing clothes.<br />

Andy says “My work is<br />

really varied as every<br />

problem is different so<br />

it makes it interesting.<br />

Technology is always<br />

changing so I am always<br />

learning something new.”<br />

For more information visit<br />

www.skillfast-uk.org/generationf

<strong>CAREER</strong> <strong>PROFILE</strong><br />

Pattern Cutter<br />

or Grader

A pattern cutter is<br />

responsible for turning<br />

a designer’s sketch into<br />

a working pattern,<br />

which can be used when<br />

constructing the garment.<br />

A pattern grader takes<br />

a pattern and produces<br />

scaled-up and scaleddown<br />

versions, to enable<br />

manufacturers to reproduce<br />

the same garment,<br />

but in different sizes.<br />

These roles will often be<br />

combined together.<br />

What does a pattern cutter<br />

or grader do<br />

A pattern cutter takes a designer’s<br />

drawing or modifies existing patterns<br />

to create a prototype pattern<br />

template. A typical technique is to<br />

cut pieces of fabric, which are then<br />

draped and pinned over a dummy<br />

until they hang correctly. Each piece<br />

is then used to create a cut-out card<br />

or paper template.<br />

Using this prototype pattern, pattern<br />

graders produce different pattern<br />

sizes so that clothing manufacturers<br />

can re-create one design in a variety<br />

of different sizes. They alter the<br />

proportions digitally or by hand.<br />

The different pattern grades are<br />

then sent to clothing manufacturers,<br />

enabling them to produce the<br />

finished garments.<br />

The salary of a pattern<br />

cutter or grader<br />

The starting salary of a pattern cutter<br />

or grader can be between £11,000<br />

and £18,000 a year. Experienced<br />

cutters/grader can earn over<br />

£20,000 a year.<br />

Hours and working environment<br />

Pattern cutters and graders normally<br />

work between 37 and 39 hours<br />

a week. Overtime hours may<br />

be required when working to<br />

deadlines and part-time hours<br />

may be available.<br />

They would normally be based in<br />

a studio or workroom; this space<br />

will be light and well lit. It will also<br />

be spacious so that patterns can be<br />

laid out. Those using computerised<br />

programmes may also be based in<br />

front of a computer screen.<br />

Skills and interests<br />

It may be useful for someone<br />

considering a career as a pattern<br />

cutter or grader to have some<br />

of the following skills and interests.<br />

* an interest in fashion and trends<br />

* the ability to interpret a designer’s<br />

working drawing<br />

*<br />

knowledge of garment construction<br />

and pattern cutting techniques<br />

* good IT and numeracy skills<br />

* the ability to work quickly and<br />

accurately within a team<br />

Entry into a career in pattern<br />

cutting or grading<br />

There is a strong demand for pattern<br />

cutters and graders with the relevant<br />

technical skills and so employers<br />

usually look for people who have<br />

some form of relevant training.<br />

The usual route into this work is<br />

to begin as a pattern cutting or<br />

grading assistant. With training<br />

and experience it is possible to<br />

progress into the role of pattern<br />

cutter or grader.<br />

For more information on the ABC<br />

qualifications, visit the website:<br />

www.abcawards.co.uk<br />

Some fashion design degree courses<br />

incorporate the key technical<br />

elements needed for a career in this<br />

area. For more information about<br />

university courses, visit the UCAS<br />

website: www.ucas.co.uk<br />

Further training to develop<br />

a career in pattern cutting<br />

or grading<br />

It may be possible for those working<br />

in the sector to work towards the<br />

following qualifications whilst<br />

on the job.<br />

Several institutions, such as the<br />

London College of Fashion www.<br />

fashion.arts.ac.uk offer short courses<br />

in pattern cutting. The Textile<br />

Institute www.texi.org also offer a<br />

range of professional qualifications.<br />

Opportunities in the field of<br />

pattern cutting or grading<br />

A pattern cutter or grader with the<br />

relevant experience can expect to be<br />

promoted to head pattern cutter or<br />

grader overseeing a team of pattern<br />

cutters/graders. They may also be<br />

able to move into a career in design<br />

or buying.<br />

Case study<br />

Mary Aspinall is a<br />

pattern cutter and grader<br />

for Simon Jersey, a<br />

leading corporate and<br />

workwear specialist<br />

based near Accrington.<br />

Mary has seventeen<br />

years pattern cutting<br />

and grading experience.<br />

Mary completed a fashion<br />

design course which covered<br />

some pattern cutting. Upon<br />

graduating, she decided<br />

that a hands-on role would<br />

suit her best and chose to<br />

become a pattern cutter.<br />

Making clothes into different<br />

sizes, known as grading, is<br />

a skill she has learnt during<br />

her working life and the use<br />

of computers is essential for<br />

this element of the job.<br />

Mary’s has developed an<br />

eye for what is a good fit<br />

and cut, Mary says “My<br />

experience means that<br />

without looking too closely<br />

at a garment I can see<br />

how well it’s been cut. It’s<br />

particularly important that<br />

corporate wear is made<br />

well and comfortable as<br />

it represents a brand, is<br />

sometimes worn for long<br />

periods of time and needs<br />

to last.”<br />

Mary adds “There’s always<br />

a new challenge with my<br />

job, turning a design into<br />

a finished garment that’s<br />

wearable, looks good<br />

and meets the design<br />

expectations is really<br />

rewarding.”<br />

For more information visit<br />

www.skillfast-uk.org/generationf

<strong>CAREER</strong> <strong>PROFILE</strong><br />

Sample Machinist

Sample machinists are<br />

a key part of the clothing<br />

design team. They work<br />

closely with designers,<br />

garment technologists<br />

and pattern cutters<br />

to create the first<br />

made-up sample<br />

of a garment design.<br />

What does a sample<br />

machinist do<br />

A sample machinist will follow the<br />

instructions of the designer, pattern<br />

cutter and garment technologist<br />

when sewing the sample together.<br />

They may occasionally use handsewing<br />

techniques but their work<br />

most commonly requires the use of<br />

a sewing machine. They will also<br />

be involved in the pressing of the<br />

finished garment.<br />

An experienced sample machinist<br />

may also be involved in making<br />

quality control checks during<br />

production and helping the other<br />

machinists during busy periods.<br />

The salary of a sample machinist<br />

The starting salary for a sample<br />

machinist may be between £11,000<br />

and £18,000 a year. This may<br />

increase with experience to around<br />

£20,000 a year. Very experienced<br />

and senior sample machinists may<br />

earn around £30,000 a year.<br />

Hours and working environment<br />

A sample machinist would typically<br />

work between 37 and 40 hours<br />

a week, additional hours may be<br />

required when deadlines need<br />

to be met.<br />

A sample machinist is usually based<br />

in an office environment where they<br />

are sat alongside the design team<br />

so that questions can be answered<br />

quickly. This environment will be<br />

clean and well-lit with plenty of<br />

room for laying out patterns and<br />

experimenting with material.<br />

Skills and interests<br />

It may be useful for a person<br />

considering a career as a sample<br />

machinist to have some of the<br />

following skills and interests:<br />

* excellent sewing skills (both<br />

hand and machine)<br />

*<br />

*<br />

knowledge on production<br />

methods and fabric types<br />

basic knowledge of design<br />

and the ability to advise on<br />

garment construction<br />

Entry into a career as<br />

a sample machinist<br />

Work-based learning such as an<br />

apprenticeship or NVQ qualification<br />

would be useful for this job, however,<br />

it is usual to progress into this<br />

role after gaining the relevant<br />

experience as a sewing machinist<br />

on a production line. Check<br />

what options are available<br />

at your local college or visit<br />

www.abcawards.co.uk.<br />

Further training to develop a<br />

career as a sample machinist<br />

Once working, it is usual for the<br />

employer to provide on-the-job<br />

training on different production<br />

methods, techniques and fabric<br />

and product types.<br />

It may be possible for someone<br />

already in the industry to work<br />

towards vocational qualifications<br />

which will help with career prospects.<br />

Opportunities for a<br />

sample machinist<br />

There may be opportunities for a<br />

sample machinist to progress to<br />

a higher-level technical role, such<br />

as garment technologist or quality<br />

control inspector.<br />

It may also be possible for a sample<br />

machinist to extend their role to<br />

include the design of garments.<br />

Case study<br />

Cath Rawse is sample<br />

machinist at Simon<br />

Jersey, a leading<br />

corporate and workwear<br />

specialist based near<br />

Accrington, she has<br />

worked for the company<br />

for seventeen years.<br />

Over the length of her<br />

career, Cath has worked<br />

for a various clothing<br />

manufacturers as a sewing<br />

machinist and has been<br />

involved with making a<br />

range of clothes from<br />

menswear, childrenswear,<br />

workwear and exclusive<br />

bridal wear. With the<br />

exception of bridal wear,<br />

much of this work was<br />

piece-work meaning she<br />

was involved with making<br />

one element of the garment.<br />

Cath says “All my previous<br />

experience really benefits<br />

me in my current role –<br />

making full garments is<br />

great because it pulls all<br />

the different sewing and<br />

making skills together.”<br />

Whilst at Simon Jersey,<br />

Cath completed her Level<br />

2 NVQ in Manufacturing<br />

Sewn Products. She really<br />

enjoyed this as she<br />

learnt new knowledge<br />

around health and safety<br />

and she produced her<br />

own portfolio of work.<br />

Cath adds “I really enjoy<br />

my work as there’s always<br />

something new to do and a<br />

new challenge to overcome.<br />

It’s really great when you<br />

see the finished garment<br />

you’ve made up and<br />

the customer loves it.”<br />

For more information visit<br />

www.skillfast-uk.org/generationf

<strong>CAREER</strong> <strong>PROFILE</strong><br />

Textile Technologist

Textile technologists<br />

are concerned with the<br />

scientific make-up of<br />

fabrics. They may work in<br />

production, quality control,<br />

sourcing or research and<br />

development teams.<br />

What does a textile<br />

technologist do<br />

Textile technologists often work<br />

in-house for clothing companies,<br />

conducting research and sourcing<br />

fabrics to meet a brief. They may<br />

also support the buying, marketing<br />

and sales teams within the company.<br />

Duties will include sourcing<br />

fabrics that are fit for purpose,<br />

conducting quality control tests for<br />

properties such as crease resistance.<br />

Experimenting with dyeing or<br />

production processes and liaising<br />

with suppliers to get the right fabric<br />

at the right price.<br />

Textile technologists often work in<br />

a supervisory or management<br />

capacity, overseeing the running<br />

of a team of people.<br />

The salary of a fabric technologist<br />

Starting salary is usually around<br />

£21,000 a year. This will increase to<br />

between £25,000 and £35,000 a<br />

year with experience. A research and<br />

development textile technologist or<br />

those with management duties may<br />

earn up to £45,000 a year.<br />

Hours and working environment<br />

Textile technologists usually work<br />

around 40 hours a week. Early<br />

morning or late night work may be<br />

required when liaising with overseas<br />

suppliers or overseeing production<br />

runs. Travel within the UK and<br />

overseas may also be required.<br />

Textile technologists are usually<br />

based in an office within the<br />

production facility. They will also<br />

spend much of their time in a<br />

laboratory environment when<br />

conducting fabric testing.<br />

Skills and interests<br />

It may be useful for someone<br />

considering a career as a textile<br />

technologist to have some of the<br />

following skills and interests:<br />

* able to lead a team and<br />

prioritise workloads<br />

*<br />

*<br />

*<br />

have excellent communication<br />

and organisation skills<br />

be knowledgeable of production<br />

processes and textile fabrics<br />

interested in solving problems and<br />

experimenting with new ideas<br />

Entry into a career in<br />

textile technology<br />

Most employers in this area will<br />

expect candidates to have a degree<br />

or a HND in a relevant subject, such<br />

as chemistry, physics, maths, textile<br />

science or textile management.<br />

There are a wide variety of courses<br />

available at this level, for more<br />

information, visit the UCAS website:<br />

www.ucas.co.uk<br />

Promotion without degree from a<br />

relevant position, such as a textile<br />

technician, may also be possible.<br />

Further training to develop a<br />

career in textile technology<br />

Further training is usually carried<br />

out on the job under the supervision<br />

of more experienced colleagues.<br />

Large companies may also offer<br />

management training schemes<br />

for their textile technologists.<br />

The Textile Institute offers a range<br />

of qualifications for those working in<br />

this area. For more information on<br />

these, visit the website: www.texi.org<br />

Opportunities in the field of<br />

textile technology<br />

With experience, it is possible for a<br />

textile technologist to take on wider<br />

responsibilities within technical<br />

management, production and<br />

quality control.<br />

Those with the relevant skills and<br />

experience may also be able to<br />

work on a self-employed basis,<br />

providing consultations for a<br />

variety of different companies.<br />

Case study<br />

Cheryl Murray has<br />

worked for Simon Jersey,<br />

a leading corporate and<br />

workwear specialist<br />

based near Accrington,<br />

for two years as a textile<br />

technologist. Cheryl<br />

has twenty four years<br />

experience in the job for<br />

a number of companies.<br />

Cheryl completed an<br />

Associateship of the Textile<br />

Institute that gave her a<br />

good understanding of the<br />

scientific make-up of fibres<br />

and the processes they go<br />

through to become finished<br />

fabrics. Cheryl says “The<br />

course gave me a great<br />

base but you can’t fully<br />

appreciate fabrics and<br />

the processes they go<br />

through until you are<br />

working in industry.”<br />

A large part of Cheryl’s<br />

job is ensuring fabrics are<br />

fit for purpose, this is<br />

especially important when<br />

producing workwear.<br />

Cheryl adds “Consistency<br />

of quality and knowledge<br />

of fabrics is imperative for<br />

corporate wear so a good<br />

eye for detail, listening<br />

to the customer and the<br />

designer are essential<br />

parts of my job.”<br />

Cheryl really enjoys her job<br />

and loves watching fabrics<br />

come alive when being<br />

made in to a garment.<br />

Cheryl adds “My job is really<br />

exciting and there are many<br />

opportunities, particularly<br />

overseas, for young people<br />

coming through.”<br />

For more information visit<br />

www.skillfast-uk.org/generationf

<strong>CAREER</strong> <strong>PROFILE</strong><br />

Leather Technologist

Leather technologists<br />

supervise and manage<br />

the process of the<br />

conversion of raw hides<br />

and skins into leather<br />

used to make a variety of<br />

products, including shoes,<br />

accessories and upholstery.<br />

What does a leather<br />

technologist do<br />

A leather technologist’s work is<br />

both scientific and technical. They<br />

may be involved in the process of<br />

turning the raw animal hides and<br />

skins into leather. Technologists<br />

will also be involved in the scientific<br />

side of leather production, including<br />

developing the appropriate dyes<br />

and finishes and experimenting<br />

with new techniques.<br />

The salary of a leather<br />

technologist<br />

The starting salary for a leather<br />

technologist may be around £14,000<br />

a year. This would increase to around<br />

£20,000 a year with experience. At<br />

senior level, a leather technologist<br />

could earn over £30,000 a year.<br />

Hours and working environment<br />

Leather technologists employed in a<br />

tannery would work around 40 hours<br />

a week. Shift work may be involved<br />

and overtime and part-time hours<br />

may be available.<br />

Some technologists work in a tannery<br />

environment, which can be dirty<br />

and smelly. They may have a small<br />

laboratory attached to the tannery<br />

where they can perform experiments.<br />

Other technologists work in a factory<br />

environment or workshop.<br />

Skills and interests<br />

To have a career as a leather<br />

technologist, it may be useful to<br />

have some of the following skills<br />

and interests:<br />

* to be good at science, particularly<br />

chemistry and have good<br />

numeracy and IT skills<br />

*<br />

*<br />

*<br />

to be able to plan projects and<br />

communicate ideas effectively<br />

to be able to manage and<br />

supervise others and work<br />

as part of a team<br />

have some knowledge of<br />

mechanics and engineering<br />

Entry into a career in<br />

leather technology<br />

A wide range of qualifications are<br />

available in the field of leather<br />

technology and entry into a job in<br />

this area is possible in a variety of<br />

different ways. Apprenticeship and<br />

NVQs in footwear and leather goods<br />

offer a route in, however the main<br />

qualifications for leather technology<br />

are awarded by the British School of<br />

Leather Technology at the University<br />

of Northampton.<br />

Further training to develop a<br />

career in leather technology<br />

Continued professional development<br />

is very important in this area and<br />

there are a number of professional<br />

courses available, which will help an<br />

experienced technologist progress<br />

their career.<br />

The British School of Leather<br />

Technology at the University of<br />

Northampton, The Society of Dyers<br />

and Colourists (SDC) and The BLC<br />

Leather Technology Centre all offer<br />

a wide range of training courses for<br />

the leather industry.<br />

Opportunities in the field<br />

of leather technology<br />

It may be possible to move from<br />

work as a leather technologist to<br />

other jobs in production, quality<br />

control, research or technical<br />

management. Technologists can<br />

also move into related areas such<br />

as buying, sales or marketing. There<br />

are good opportunities for leather<br />

technologists to work abroad or set<br />

up their own consultancy business.<br />

Case study<br />

Amanda Michel is a<br />

leather technologist<br />

for her own company,<br />

Leather Wise Ltd, offering<br />

problem solving and<br />

training services to the<br />

leather supply chain.<br />

Amanda is involved with<br />

virtually every aspect of<br />

the leather business from<br />

the animal on the farm,<br />

through each stage of the<br />

leather making process,<br />

onto product design and<br />

manufacture. Amanda<br />

says “My core business is<br />

to do with helping people<br />

with problems they may<br />

have with their leather. For<br />

example, if someone has<br />

bought a leather sofa and<br />

the colour is coming off, I<br />

can run a series of tests such<br />

as rub fastness or looking<br />

at it under a microscope.<br />

This will determine whether<br />

the customer is entitled to<br />

a replacement or their<br />

money back.”<br />

Amanda has acted as an<br />

expert witness for trading<br />

standards and is also an<br />

information resource for<br />

all aspects of the leather<br />

supply chain. She has<br />

articles regularly published<br />

in the trade press. Amanda<br />

adds “I really enjoy my job<br />

as every day is different<br />

and each day brings a<br />

new challenge!”<br />

For more information visit<br />

www.skillfast-uk.org/generationf

<strong>CAREER</strong> <strong>PROFILE</strong><br />

Footwear<br />

Manufacturing<br />

Operative

Footwear manufacturing<br />

operatives use a range<br />

of handcraft tools and<br />

semi-automated equipment<br />

to create footwear<br />

products. They may<br />

produce many different<br />

types of footwear from<br />

fashion shoes to trainers<br />

and safety footwear.<br />

What does a footwear<br />

manufacturing operative do<br />

A footwear manufacturing operative<br />

will usually be involved in each<br />

stage of the production process.<br />

This includes cutting the leather,<br />

stitching the pattern pieces together<br />

and moulding the shoe into shape.<br />

They would also be involved in<br />

creating a ‘last,’ which is the mould<br />

that the shoe will be formed around.<br />

They would use the last to stitch the<br />

pattern pieces together in the correct<br />

shape, before fitting soles and heels<br />

to the finished product. The shoe<br />

would then be stained, polished<br />

and buffed and the lasts removed.<br />

The salary of a footwear<br />

manufacturing operative<br />

A footwear manufacturing operative<br />

can expect to earn between<br />

£12,000 and £14,000 a year when<br />

starting out. With experience, this<br />

may increase to between £15,000<br />

and £22,000 a year. Those with<br />

considerable experience and more<br />

responsibilities could earn around<br />

£25,000 a year.<br />

Hours and working environment<br />

Footwear manufacturing operatives<br />

normally work between 37 and 40<br />

hours a week. The work may be split<br />

into shifts.<br />

The work is usually factory-based<br />

and an operative will usually spend<br />

much of the day on their feet.<br />

Skills and interests<br />

To become a footwear manufacturing<br />

operative, some of the following skills<br />

and interests would be useful:<br />

* practical skills in tool handling<br />

and using machinery<br />

*<br />

*<br />

*<br />

the ability to follow instructions<br />

quickly and accurately<br />

the ability to work alone or<br />

as part of a team<br />

an awareness of health<br />

and safety issues<br />

Entry into a career in footwear<br />

manufacturing<br />

There are no formal entry<br />

requirements to become a footwear<br />

manufacturing operative, but<br />

good practical skills are essential.<br />

Employers may set a practical<br />

test at the interview stage.<br />

It may also be useful to gain a<br />

relevant qualification and many<br />

companies offer work-based learning<br />

such as apprenticeships or NVQs.<br />

Further training to develop a<br />

career in footwear manufacture<br />

On-the-job training is very important<br />

and skills can be developed by<br />

working alongside more experienced<br />

colleagues. Training is likely to<br />

include production methods,<br />

machine operations and health<br />

and safety.<br />

A footwear manufacturing operative<br />

may be able to move into the related<br />

careers of production management,<br />

footwear design or retail buying.<br />

Some universities offer qualifications<br />

relevant to such a career move,<br />

for more information on university<br />

courses, visit the UCAS website:<br />

www.ucas.com<br />

Opportunities in the field of<br />

footwear manufacture<br />

There may be opportunities for<br />

footwear manufacturing operatives<br />

with the right skills and experience<br />

to progress into supervisory<br />

roles within the company, such<br />

as management, engineering<br />

maintenance and quality control.<br />

It may also be possible to specialise<br />

in custom-made footwear, such as<br />

luxury bespoke shoes, orthopaedic<br />

shoes or specialist historical and<br />

theatrical costume footwear.<br />

Case study<br />

David Preedy works<br />

for Loake Shoemakers,<br />

as part of the<br />

manufacturing process<br />

where he is a back<br />

part moulder. He has<br />

worked for the company<br />

for thirty two years.<br />

David started without any<br />

formal training in shoe<br />

making and has learnt his<br />

skills on-the-job from other<br />

experienced colleagues.<br />

David’s job means he<br />

moulds the heel part of the<br />

shoe by using a specialist<br />

machine, that uses both<br />

heat and freezer moulds<br />

to make the shape. The<br />

uppers are then transferred<br />

to the Muller room where<br />

the leather is softened<br />

so it doesn’t crack when<br />

it goes to be lasted. “You<br />

need to be conscientious<br />

and be prepared to do<br />

a good job. Team work<br />

and communication skills<br />

are essential.”<br />

David has spent most of his<br />

working life doing back part<br />

moulding although he has<br />

worked in other areas of the<br />

factory. He also has the role<br />

of a Union representative<br />

and has a keen interest in<br />

skills development. David<br />

adds “I enjoy the work here<br />

and ensuring the product<br />

made well but the best part<br />

is the people I work with.”<br />

For more information visit<br />

www.skillfast-uk.org/generationf

<strong>CAREER</strong> <strong>PROFILE</strong><br />

Production<br />

Manager

A textiles production<br />

manager is responsible<br />

for overseeing all stages<br />

of the textile manufacturing<br />

process. They make sure<br />

that the products are the<br />

right quality and can be<br />

delivered to a set timescale.<br />

What does a production<br />

manager do<br />

A production manager is likely<br />

to work closely with the planning<br />

manager to discuss working<br />

schedules and plan the work for the<br />

day. It is the production manager’s<br />

responsibility to make sure each<br />

department knows what is expected<br />

of them and find out if there are any<br />

problems with the production plan.<br />

As well as discussing the work with<br />

each section of the production team,<br />

a production manager would also<br />

work closely with suppliers and<br />

machine maintenance technicians.<br />

Hours and working environment<br />

Production managers often work<br />

around 40 hours a week, which is<br />

split into a shift system including<br />

some weekend and evening work.<br />

Production managers are also often<br />

‘on-call’ outside of their working<br />

hours in case there are any issues<br />

holding up production.<br />

Production managers are often<br />

based in an office within a factory<br />

environment, which can be noisy and<br />

dirty. Due to the growth of global<br />

markets, production managers may<br />

be required to manage supply<br />

chains that extend overseas,<br />

involving some travel.<br />

The salary of a<br />

production manager<br />

Starting salaries are likely to be<br />

between £20,000 and £37,000<br />

a year. Experienced production<br />

managers could earn between<br />

£40,000 and £65,000 a year.<br />

For more information visit<br />

www.skillfast-uk.org/generationf<br />

Skills and interests<br />

To become a production manager<br />

some of the following skills and<br />

interests would be useful:<br />

* excellent knowledge of each<br />

part of the production process –<br />

from design to production<br />

*<br />

project and people<br />

management skills<br />

* organisational and planning skills<br />

* the ability to work under pressure<br />

in a demanding environment<br />

*<br />

a willingness to work flexibly<br />

and travel when needed.<br />

Entry and training<br />

There are no formal academic<br />

requirements to become a<br />

production manager, although most<br />

people in this position have worked<br />

their way up through the business.<br />

Production managers need to have<br />

in-depth knowledge of the industry<br />

they are working for, so on-the-job<br />

training is usually provided.<br />

It may also be possible to complete<br />

a BTEC, HND or degree in textiles<br />

production or business, although<br />

extensive experience of the industry<br />

is also usually required.<br />

Further training to develop a<br />

career as a production manager<br />

It is possible to acquire a professional<br />

qualification, such as offered by The<br />

Institute of Operations Management<br />

(IOM) or the Chartered Management<br />

Institute (CMI) and it may be<br />

advantageous to do so. In any<br />

case, managers need to continually<br />

update their knowledge and<br />

experience as new systems and<br />

processes become available.<br />

Opportunities for a<br />

production manager<br />

Some production managers<br />

eventually pursue a more strategic<br />

role and become involved with<br />

long-term planning rather than<br />

day-to-day operations. In larger<br />

organisations, a production<br />

manager may well be responsible<br />

for production on a number of sites,<br />

and opportunities to set up and<br />

manage operations overseas may<br />

arise with multinational firms.<br />

Case study<br />

Michael Cook has worked<br />

in the textile industry all<br />

his working life. He is<br />

currently the production<br />

manager at Pennine<br />

Weavers Ltd, a weaving<br />

mill based in Keighley.<br />

The mill specialises in<br />

creating suiting fabrics<br />

for high-end and<br />

specialist clients.<br />

Michael started his career<br />

in the textile industry as a<br />

mill assistant where he was<br />

responsible for sweeping<br />

the floors. Since then he has<br />

worked his way up through<br />

two textiles companies to<br />

the senior position he is in<br />

now. All Michael’s training<br />

has been on-the-job, where<br />

he has learned from more<br />

experienced colleagues.<br />

As he worked his way<br />

up through the business,<br />

Michael has a good<br />

understanding of each<br />

of the manufacturing<br />

processes. This is essential<br />

for his job, he says: “You<br />

need to know a bit about<br />

every department from<br />

design to final production so<br />

you can step in and sort out<br />

any problems as they occur.”<br />

The job of a production<br />

manager is often very<br />

demanding as they are<br />

responsible for ensuring<br />

all stages of production<br />

run to strict timescales and<br />

quality standards. Michael<br />

says “I enjoy the challenge<br />

of the job the most and the<br />

sense of achievement I get<br />

when the products come<br />

in on time and to the right<br />

standards. This also keeps<br />

the customers happy so<br />

they will come back!”

<strong>CAREER</strong> <strong>PROFILE</strong><br />

Weaver

A weaver works within<br />

the textiles industry, using<br />

highly technical weaving<br />

looms to create fabrics.<br />

What does a weaver do<br />

A weaver may be involved in using<br />

hand-weaving looms, which can be<br />

physically demanding. They may also<br />

be involved in programming and<br />

operating computerised machines.<br />

These are more commonly used in<br />

modern factories today as they can<br />

work to very high specifications.<br />

It is also the weaver’s responsibility<br />

to ensure the machines are running<br />

to capacity and identify any problems<br />

quickly and efficiently.<br />

The salary of a weaver<br />

The starting salary for a weaver<br />

may be between £12,000 and<br />

£15,000 a year. This would<br />

increase with experience to<br />

around £18,000 a year.<br />

Hours and working environment<br />

A weaver usually works between<br />

37 and 40 hours a week, this could<br />

be split into a shift pattern.<br />

Weavers are usually based in a<br />

factory environment, which can be<br />

noisy. Protective ear defenders and<br />

clothing may have to be worn. The<br />

work can be physically demanding<br />

and a weaver will spend a large<br />

portion of the day on their feet.<br />

Skills and interests<br />

It may be useful for a person<br />

considering a career as a weaver to<br />

have some of the following skills and<br />

interests:<br />

* good practical ability and<br />

an understanding of the<br />

machines used<br />

*<br />

*<br />

the ability to concentrate for<br />

long periods of time and do<br />

repetitive work<br />

an understanding of fabric<br />

structure, colour and pattern<br />

* an interest in fabric trends<br />

* an understanding of health<br />

and safety procedures<br />

Entry into a career in weaving<br />

There are no formal entry<br />

requirements to become a weaver<br />

and on the job training will be<br />

provided. Employers usually look<br />

for applicants with good practical<br />

ability and an interest in the area.<br />

Further training to develop<br />

a career in weaving<br />

For those already in employed in<br />

this area, it may be possible to<br />

study towards a relevant vocational<br />

qualification, which contains weaving<br />

units. Check what options are<br />

available at your local college or<br />

visit www.abcawards.co.uk.<br />

Many fashion and textiles courses<br />

at higher education level also offer<br />

weaving modules. This may help<br />

a factory-based weaver to move<br />

more into the creative design side of<br />

weaving. For more information on<br />

university courses, visit the website:<br />

www.ucas.co.uk.<br />

Opportunities in the field<br />

of weaving<br />

Experienced weavers could<br />

progress into the role of team<br />

leader or trainer. They may also<br />

be able to move into related<br />

areas of the industry, such<br />

as the manufacturing side.<br />

Those who have studied towards<br />

a related degree may also be<br />

able to progress into a career in<br />

design or craft weaving. Many<br />

weave designers or craft weavers<br />

are self-employed and sell their<br />

designs to private customers<br />

as well as larger textiles companies.<br />

Case study<br />

Thomas Stockl is a<br />

weaving overlooker<br />

working for Pennine<br />

Weavers Ltd, a weaving<br />

mill based in Keighley.<br />

The mill specialises in<br />

creating suiting fabrics<br />

for high-end and<br />

specialist clients.<br />

Thomas’s job means that<br />

he checks each machine<br />

to make sure it is running<br />

correctly and the cloth being<br />

woven is to the specification<br />

the customer has ordered.<br />

He works in a team with<br />

three other weaving<br />

overlookers and works<br />

shifts. Thomas completed a<br />

three year apprenticeship<br />

whilst working as a weaving<br />

technician and had further<br />

training on-the-job to learn<br />

his role. He also travelled<br />

to Germany for training<br />

on the looms.<br />

Thomas will be required<br />

to fix any breakdowns with<br />

the weaving looms. He says<br />

“Having an understanding<br />

of mechanics is essential<br />

and some metal work<br />

skills as I sometime have<br />

to make my own spare<br />

parts. Knowledge of<br />

electronics and computers<br />

is also helpful.”<br />

For more information visit<br />

www.skillfast-uk.org/generationf