Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

g -E<br />

.: a' ,.<br />

#<br />

#d<br />

<strong>F@RREmS</strong><br />

.,,. r:r<br />

f1&<br />

iJ::<br />

".;, . j.., !<br />

t<br />

\:.<br />

':<br />

'<br />

:!:'1 Pun'tps<br />

\.<br />

and<br />

Engineering<br />

ri<br />

F9RREAS PTY. LTD.<br />

FORRER PAfiO PTY. LTD.<br />

MANUFAeruft,ras & DrsrRrEuroRs oF puMps FoR EVERv sERvteE<br />

I i<br />

I<br />

I

*"j<br />

{,)<br />

AUTOMATIC LUBRICATION<br />

DOUBLE ACTING<br />

HIGI"I PRESSURE<br />

EFFICIENT<br />

ECONOMICAL<br />

These are highly efficient pumps<br />

and are ideally suited for pumping<br />

over long distances and against<br />

heads up to 700 feet and over.<br />

They are positive acting with low<br />

horsepower requirement and<br />

operate silently, economically -<br />

and ef f iciently with very little<br />

ma intenance.<br />

Single Cylinder 2-Lx3<br />

Pump with Motor mounts<br />

tt<br />

it<br />

DURABLE<br />

LOW HORSEPOWER<br />

MINIMUM MAINTENANCE<br />

FULI.Y ENCLOSED<br />

GEAR DRIVE<br />

Available in Single and Duplex<br />

cylinders and having capacities<br />

up to 26,500 g.p.m. and pressures<br />

up to 300 p.s.i. Bigger<br />

pumps have large free f lowing<br />

waterways and are especially<br />

suitable for handling viscous<br />

liquids. All pumps can have the<br />

motor or engine mounted on<br />

top. thereby preserving space.<br />

Duplex Cylinder,<br />

6x8 Pump, mount3d with electric motor

FEATURES<br />

GEAR CASE:<br />

The gear box consists of a one-piece casting which forms the base of the pump<br />

and oil reservoir. A cast iron lid encloses all working parts protecting them f rom<br />

dirt or damage, and securing safe operation. The casting is completely machined<br />

at one setting for all bearings, the cross - head, cylinder head, and shaft<br />

bearings, assuring alignment of all working parts.<br />

LUBRICATION :<br />

The pump is.entirely self-lubricating. Th.e. driving gear. carries the oil from the<br />

reservoir and distributes it to every working part of the gear case.<br />

DRIVE :<br />

Centre line drive by machine cut gear and pinion eliminates side thrust.'These<br />

are supported between wide replacable bearings.<br />

GEAR RATIO :<br />

<strong>Pumps</strong> are back geared 5 to l.<br />

I'IPING:<br />

Suction and delivery piping may be taken from either side of the pump.<br />

ROTATION :<br />

The pulley can be transferred to the opposite side of the pump from that<br />

illustrated. An eccentric cast integral with the main gear operatesthe crosshead<br />

through a connecting rod which is fitted with a replaceabie bronze bush at<br />

the crosshead end.<br />

PISTON ROD :<br />

Made of solid manganese bronze (stainless steel if required) and is fitted with<br />

Water Def lector ai a special guard against leakage fiom a loose packing box.<br />

PISTON :<br />

Comprises selected hydraulic leather cups with brass spacer and backing plates.<br />

PACKING BOX:<br />

Adjustable brass gland type .packing box of adequate depth, f itted with greasy<br />

hemp packing.<br />

CYLINDER BODY :<br />

One piece close grained casting forms the cylinder and valve chambers. This is<br />

fitted with a removable brass liner in which the piston operates.<br />

VALVES :<br />

Rubber Disc type valves with bronze seats, stems and springs are fitted to<br />

standard pumps and are all located above the cylinder. They are easily accessible<br />

for inspection, repair or replacement without disturbing pipe connections.<br />

Special valves can be supplied for specific applications.<br />

AIR CHAMBER :<br />

A cast iron air chamber is f itted as standard equipment on the discharge side of<br />

all pumps. This evens the flow of water through the pipe lines and prevents<br />

shock loads from causing damage to the pump.<br />

MOTOR MOUNTING :<br />

Cast iron slotted side rails can be supplied for mounting electric motor or<br />

petrol engine on top of the pump. This makes a compact unit and saves considerable<br />

space.

FORRERS PTY. LTD. LEAFLET F 9690<br />

POWER PUMP<br />

MODEL 2x2XL<br />

OPERATING HEADS TO 5OOfI.<br />

RELIABLE<br />

ECONOMICAL<br />

-<br />

LOW H.P.<br />

-**;ii<br />

t'l<br />

EFFICIENT<br />

LOW MAINTENANCE<br />

CAPACITY<br />

-<br />

400 G.P.H. at 600 R P"M<br />

PERFORMANCE<br />

50' I 00' 200' 250' 300' 400' 500'<br />

H.P. AT VARYING HEADS -lb h p l r+<br />

The 2x2XL FORRERS Double Acting Pump is selfoiling<br />

and has been proven a most reliable and<br />

efficient unit. lt is extremely compact as engine or<br />

electric motor can be mounted on top of pump.<br />

It is used extensively for dairying and agricultural<br />

purposes, pressure systems, domestic water supply,<br />

and for industrial high pressure service such as<br />

boiler feeding, hot water pumping, etc.<br />

Maintenance is kept to a minimum and many hours<br />

cf unattended operation can be expected<br />

2x2Xu Pump Mounted With Petrol Motor

FORRERS PTY. LTD.<br />

INSTRUCTION SHEET<br />

FORRERS<br />

SELF - OILINS POWER PUMPS<br />

2*x3 PUMP WITH MOTOR MOUNT AND PULLEY<br />

INSTALLATION<br />

SITE<br />

Pump should be as close to water supply as possible. Suction lift including pipe friction<br />

should not exceed 24 feet at sea level. For each 1200 feet altitude, deduct 1 foot for practical<br />

suction lift.<br />

Should pump become flooded, drain oil fro'm crankcase, replace oil and check pump over<br />

generally.<br />

FOUNDATION<br />

lnstall pump on firm foundation, preferably concrete. Pump should be set level.<br />

SUCTION LINE<br />

Suction line should<br />

is not trapped in line.<br />

Keep suction line as<br />

Pipe diameter should<br />

lines where a large volume<br />

rise towards pump at all times. Avoid high points so as to ensure air<br />

free of bends as possible.<br />

be no sm,aller than that for which the pump is screwed. On long pipe<br />

is pumped, a size larger is pieferable.

s<br />

to<br />

INSTALLATION CONTINUED<br />

Make sure all joints are air tight.<br />

A foot valve should always be fitted where water level is below the pump. When water level<br />

higher than the pump, install a gate valve so that water may be shut off if it becomes necessary<br />

work on the pump.<br />

DISCHARGE LINE<br />

The diameter of the discharge line will depend on the work the pump has to perform, including<br />

friction in that line. The smaller the pipe ihe higher the friction load and power consumption.<br />

A check valve fitted in the discharge line as close to the pump as possible, protects the pump<br />

from water hammer and from damage through flow back of water. This also holds back this<br />

water when maintenance is being carried out on the pump.<br />

Both suction and discharge piping must be supported independently of the pump.<br />

Should a gate valve be installed in the delivery, this MUST BE OPENED before starting<br />

pLlmp. lt is always advisable in installations where a gate valve is {itied to have a relief valve<br />

between purmp and gate valve to protect pump from damage in case line is shut off or becomes<br />

blocked.<br />

GLAND PACKING<br />

Packing should be renewed periodically to protect excessive leakage from the gland and<br />

prevent damage to the piston rod. When replacing, insert each ring separately, seating it firmly<br />

and staggering ihe joints. The last ring of packing should not protrude beyond the stuffing box.<br />

lnstall the gland and tighten the nuts evenly by hand. Allow a slight leakage at all times as this<br />

is necessary to cool and lubricate the packing. Wait until the pump is running before making the<br />

final adjustment.<br />

Unduly tight packing increases power consurmption and causes wear on piston rod.<br />

PRIMING PUMP<br />

Pump can be primed by removing plug from the top of ihe suction chamber and filling the<br />

chamber and suction line completely with water. Before replacing plug, watch water level for short<br />

time to see if the footvalve is holding.<br />

, IRATION<br />

Before starting pump ensure<br />

the oil return channel. SAE 140 Oil<br />

gear case is filled with<br />

is recommended.<br />

oil to a point level with the bottom of<br />

It is advisable after the f irst<br />

place with fresh. Oil level should be<br />

48 hours of actual pumping to drain the original oil and reinspected<br />

every few months,<br />

Before starting turn the pump by hand and ensure all suction, bypass, and discharge valves<br />

are open.<br />

TROUBLE SHOOTTNG<br />

<strong>Piston</strong> pumps are noted for long operation periods with little more than routine lubrication<br />

and inspection. However, like all other pumps, these units can develop trouble. These are usually<br />

hydraulic troubles, or troubles connected with the installation of the complete unit. Some of these<br />

are analysed below.

PUMP DOES NOT DISCHAR,GE<br />

Suction Lift too High: At sea level a pump hand!ing water should not have a suction lift<br />

greater than 24 feet.<br />

Pump<br />

^ Not Primed: Prime pump by filling the suction line above foot valve with liquid.<br />

Open any vents on discharge side io free pump of air while filling.<br />

Suction Air Bound: Checks for leaks in suction pipe.<br />

Obstructions in Suction Line: Check suction pipe and strainer to see that they are free of<br />

rust, debris, and other obstructions<br />

Worn Parts: Worn valves, piston rod packing and piston buckets can cause a pump to lose<br />

suction. Replace as necessary.<br />

PIPING VIBR.ATES<br />

Undersize Discharge Pipe: Use a larger size of discharge line, if it is possible to change the<br />

piping. lf this cannot be done, install an air chamber in the discharge line, close to the pump.<br />

This will red'uce the pressure surges in the pipe.<br />

On Forrers Power <strong>Pumps</strong> an air chamber is supplied as standard equipment.<br />

Undersize Suction Pipe: lncrease size of piping or reduce its length. lnstall a suction air<br />

chamber close to the pump to reduce pressure surge pulsations during operation. On sizes up to<br />

and including 6in. bore x 6in. stroke this chamber is supplied.<br />

POWER END NOISY<br />

Crosshead, Bearings or Gears Worn or Loose: Check and replace as necessary.<br />

Speed ioo High: Lower pump speed to recommended level.<br />

LTQUTD END NOISY<br />

Excessive Suction Lift: This has been dealt with earlier.<br />

Gas or Air in Liquid: Inspect the suction piping for leaks at joints, around valve stems, and<br />

at other points where air can enter the system.<br />

Valve Troubles: Weak or broken springs lead to pounding of valves. Valve chatter and other<br />

noises are usually caused by operating pump at too high a speed.<br />

EXCESSIVE PACKING WEAR<br />

<strong>Piston</strong> Rod Defects: <strong>Piston</strong> rod may be worn or bent causing uneven wear of the packing.<br />

Check also for burrs on the rod. Replace badly damaged rods with new ones.<br />

POWER INPUT EXCESSIVE<br />

High Discharge Prdssure: lnspect piping for closed valve, increase in relief valve setting or<br />

.<br />

an obstruction in the piping. Where additional piping has been installed, check friction loss-has<br />

not increased the duty above the rated m.aximum head of the pump.<br />

MANUFACTURED BY<br />

Carberry Street,<br />

FORRERS PTY. LTD.<br />

lpswich, Qld.

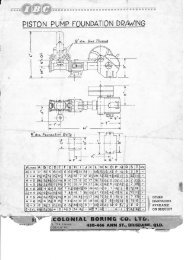

FOUNDATION DRAWINGS<br />

-<br />

STANDARD PUMPS<br />

sl<br />

o<br />

-T+_<br />

z<br />

8"5<br />

6+<br />

ct<br />

'4<br />

t3* 88<br />

6+<br />

;F o<br />

v<br />

t<br />

F<br />

I ọ<br />

t,<br />

-<br />

-td<br />

D E F G H J K L M N o P o R S T I ns.<br />

4 6 at '2 3 24 at 6i 7 3* 6<br />

3<br />

6 3* 6+<br />

6i t0+ 5 6* 34t s+ 8+ lt 27;] s* 13 3i 9 r*<br />

I<br />

2<br />

5 9<br />

6i t2+ 7 8+ 42 7 t2 t2+ 29 7* 3 r4 4i l0* r+<br />

I<br />

2<br />

si il*<br />

t0* t4+ 9 t0 53 8 t2 t7 35 7+ 6+ 6 t3+ 2<br />

I<br />

2 7 ts*<br />

t0* t4+ 9 l0 55 9 t4 l7 36 7+ 6* 5 t3* 7+<br />

I<br />

2<br />

7 ts+<br />

8 ts* 7 il+ 63+ l0i t5 t9 42 il* 6 7 t6+ 3<br />

5<br />

a 7+ t8 ,)<br />

6i t2+ 7 8* 42 7 8+ t2+ 27 7+ 13 4+ t0i t+<br />

I<br />

2<br />

q3<br />

il+<br />

t0* t4+ 9 t0 54 8+ il+ l7 38* 7+ 3* 6 t3* r+ l_ 2<br />

7 ts+ tt<br />

5<br />

I ts+ 7 il+ 62 t0 t5 t9 46 il+ 5 8+ t6+ 2+ a 7+ t8<br />

6i t0+ 6 6* 34i; (r<br />

8 ll 712 st ')r 3 .4 9 *ll<br />

I<br />

2 5 9<br />

(OTHER DIMENSIONS AVAILABLE ON REQUEST)

PUMPING TABLLJ<br />

FORRERS STANDARD PUMPS<br />

Pump<br />

N,o.<br />

Strokes ,Pump<br />

(lnches)<br />

pet Pulley Galls.<br />

Bore Stroke Suction minute R.P,M. Per Hr, sofr. loofr. l f<br />

HORSEPOWER. REQU!RED AT THESE HEADS<br />

Pulley<br />

Dia.<br />

XL<br />

(FA) 2 2 I I<br />

100 _r_<br />

300 263 4<br />

-l_<br />

-t,<br />

4 4<br />

I I<br />

3 7 3_<br />

4<br />

150 4s0 3s0<br />

,|<br />

4<br />

_l_<br />

4 i-<br />

J.<br />

2<br />

3_<br />

4 I<br />

3_ 4 4 I t+<br />

200 600 400 ,L 4 -l4 + + t 4 4 I r+<br />

9t2F<br />

(FB) 2+<br />

3 r+ l*<br />

70 350 436<br />

I<br />

4<br />

I 2 , 4 I<br />

BO 400 500 -L 4 + +<br />

3<br />

4 4<br />

12x2<br />

I<br />

l0s 525 650 + + 4 I l+<br />

9t3F<br />

(FD) 3 4 r+ r+<br />

50 250 597 -l_ 4 L a<br />

70 350 834 + r+ r+<br />

e<br />

4<br />

14 x 2+<br />

80 400 95s + t r+ r+ r+<br />

9t 4F<br />

(FF) 4 5 2 2<br />

50 250 r 300 + I ll4 ra 2 3<br />

60 300 1566 3 4 l+ loa 2+ 3 4<br />

16x4<br />

70 350 1827 I r+<br />

al<br />

L4 3 4 5<br />

9l5F<br />

(FG) 5 5 2+ 2I<br />

922F<br />

(FN) 5 6 3 3<br />

30 150 1240<br />

3_<br />

r+ ri 2<br />

50 250 2000 3 4 r* 2 3 3+<br />

65 325 2691 r* 2 3+ 4+ 6<br />

40 200 1775 1*<br />

al<br />

ZA- t 4+ s+ 6 7*<br />

50 250 2200 r+<br />

at<br />

z-2 4 5 6+ 7+ e+<br />

60 300 2675 l+ 3 4+ 6 7+ 8+ n+<br />

l6x4<br />

24x4<br />

!<br />

G g<br />

!<br />

z a<br />

-l<br />

9l6F<br />

(FJ) 6 6 3 3<br />

30 r50 2160 r+ 2 3 I<br />

50 250 3600 r+ 2+ 3+ 5 7<br />

60 300 4300 2 4 s+ 7 t0<br />

24x4<br />

E<br />

F<br />

m<br />

Vl

FORRERS. HEAVY DUTY AND HIGH PRESSURE PUMPS<br />

Pump<br />

No.<br />

(lnches)<br />

Strokes<br />

per<br />

minute<br />

Pump<br />

Pulley<br />

R.P.M.<br />

Galls.<br />

Per Hr.<br />

HOR.SEPOWER REQUTRED AT TI{ESE HEADS<br />

Bore I Stroke I Suction lDischa.ge 50ft. I 00ft. I 5oft. 200ft. 300fr. 400ft. 500ft. 600ft, 70ofr.<br />

917Ht<br />

(FC) r* 3 I 4<br />

gIBH<br />

(FE)<br />

:'-"'<br />

2* 4 r* r+<br />

9l9Hr<br />

(FH) 3 5 1+ r+<br />

94 al<br />

J2 5 l+ r+<br />

(FK) 3 6 2+ 2+<br />

92tHt<br />

(FL) 4 6 2+ L2 al<br />

923Ht<br />

(FO) 4 8 3 3<br />

924H 4+ 8 3 3<br />

(FM) 5 8 3 3<br />

60 300 170<br />

_t<br />

4<br />

BO 400 230 -t-<br />

4 + + +<br />

'I<br />

4<br />

Fulley<br />

Dia.<br />

1<br />

I<br />

4 l 2 + 4 4<br />

I<br />

12x2<br />

2 * I I r*<br />

105 525 300 + t t 4 I r* r+ r* 2<br />

40 200 260 I 4<br />

'L 4 + + +<br />

3 4 I I<br />

60 300 390 + + t * A r1- r{-<br />

BO 400 s2B + t<br />

3<br />

^1<br />

r+ r+ 2 2+<br />

40 200 560<br />

'|<br />

2 t 4 3 I r+ r+ 2+<br />

55 275 780 + 3 I r+ tz 2+ 3<br />

65 325 924 + I r+ r+ 2<br />

,)l<br />

LA 4<br />

40 200 760 -3,<br />

4 ri r+ 2.0 L4<br />

1 3+ 4+<br />

55 275 I 060 1l- ')l 2Z 3; 5 6<br />

65 325 1 250 li t; 2+ 2l<br />

J4<br />

+)<br />

A1<br />

JZ 7<br />

40 200 660 I 1 I I r+ 2 2+ 3 3i<br />

60 300 I 000 I I r+ r+ 2 3 3' 5 6<br />

70 350 I 134 I I r* lo3 2+ J2<br />

t1 4+ 5 7<br />

40 200 I 320 I I r* 2 3 4 5<br />

60 300 r 980 I r+ 2 3 4+ 6 7t<br />

70 350 2192 I 2 3 4 s+ 7+ l0<br />

30 150 I 190 I l+ r+ 2 3 4 5 6 7+<br />

40 200 I 590 I r+ 2 234 4 s+ 7 B l0<br />

60 300 2340 I 2 3 4 s+ 7+ 10 t2 15<br />

30 ls0 I 540 1+ 2 2Z 4 trl J2 7 B 7*<br />

40 200 2000 r+ 2 3 4 s+ 7+ l0 lt 12<br />

60 300 3080 r+ 3 4 5+ 7+ e+ ll+ t5 t5<br />

30 r50 I 900 l1- 2 3 4 5 7+ l0<br />

40 200 2550 l+ 2+ 3+ 4+ 6+ B+ t2<br />

50 300 3600 2 3 4 6 9 12 l5<br />

14 x2*<br />

l6x4<br />

l6x4<br />

24x4<br />

24x4<br />

30x6<br />

30x6<br />

30x6

1<br />

Pump<br />

No.<br />

Strokes Pu,mp<br />

(lnches)<br />

HORSEPOWER REQUIRED AT THESE HEADS<br />

Per Pulley Galls.<br />

Bore Stroke Suction Dischargr minute R.P.M. Per Hr. 50ft. t OOfr. I 5oft. 200ft. 300fr. 400fr. 500fr. 600ft, 7OOfr.<br />

Pulley<br />

Dia.<br />

926H1<br />

(FP) 6 8 4 4<br />

927F<br />

(rQl 7 B 4 4<br />

928F B 8 4 4<br />

929H\<br />

(FR) 5 l0 4 4<br />

930H<br />

(FS) 6 t0 4 4<br />

93I HI<br />

(FT) 7 l0 4 4<br />

932F 8 r0 4 4<br />

933F l0 r0 6 6<br />

25 125 23s0 r+ 2+ '" 4 5 7+<br />

3s 175 3250 r-a 3 / sl B+ lt<br />

55 275 4950 2 4 6 B+ 12+ l5<br />

25 125 3200 re 3 A<br />

trl<br />

J2<br />

35 17s 4500 2 4 6 7+<br />

55 :27s 6900 2 6 10 t5<br />

25 125 4200 2 3+ 5<br />

35 175 5900 2+ 5 7+<br />

45 225 7s60 3 6 l0<br />

30 r50 2300 1+ 2+ 3 4 5 7+ l0 12<br />

50 i250 3800 2 3+ 5 6J, r0 l3 l6 20<br />

40 1200 3100 r* 3 4 s+ 8+ ll r3 l5<br />

30 150 3400 r+ J 4+ 6 B+ t2 l5<br />

40 200 4600 2 4 6 8 ll+ l4 IB<br />

50 250 5700 2+ 5 7+ l0 12+ l5 20<br />

25 125 3900 2 3+ 5 6+ l0 r3 l6<br />

35 175 5500 ,2+ 5 7 8 12 14 24<br />

45 )225 7000 i3 6 B+ 12 l8 24 30<br />

25 125 4700 2 4 6 B 12<br />

35 itts 6600 3 s+ B lt l5<br />

45 i225 9440 4 8 12 l5 20<br />

20 Ir oo 6600 r3 sl o ll<br />

30 Lt 50 9900 i4 B t2+ 17<br />

40 200<br />

I 3200 r5+ l1 l5 20<br />

30x6<br />

30x6<br />

30x6<br />

Pulley<br />

to size<br />

Specified<br />

94 2+ 6<br />

al z2 2t 40 200 420<br />

TOOI| 800ft. i 900{r. r000 fr<br />

l<br />

JZ 4 4+ 5<br />

24x4

FORRERS DUPLEX PUMPS<br />

umP<br />

0Nc HES)<br />

Bore Stroke Suction Discharge<br />

PUMP PULLEY<br />

R.P.M.<br />

GALTONS<br />

PER HOUR<br />

MAXIMUM HEAD<br />

FEET<br />

MAXI,MUM<br />

H.P.<br />

934F 4 5 3 3 3s0 3600 250 7<br />

935F 5 5 3 3 325 5200 250 l0<br />

936HD 3+ 6 3 3 3s0 3300 600 l5<br />

937F 5 6 3 3 325 6400 250 l3<br />

93BHD 4 8 4 4 300 4600 600 20<br />

939HD 4+<br />

o 4 4 300 6000 500 25<br />

94OHD 5 B 4 4 300 7000 500 30<br />

94I HD 6 B 5 4 275 9800 500 40<br />

942HD 7 o I 6 6 275 r 3600 200 30<br />

943HD 8 B 6 6 225 I 5000 150 20<br />

944HD 7 t0 6 4 225 I 4000 500 50<br />

945HD B t0 B 6 225 r 8600 300 40<br />

946F l0 l0 B B 200 26500 200 30<br />

rPswrcH<br />

MANUFACTURED BY<br />

FORRERS PTY. LTD.<br />

QUEENSLA.ND

FORRERS FARTS LIST<br />

t$ll I<br />

NAME oF PARI<br />

tftLt<br />

l<br />

NAME oF PARI<br />

PART<br />

No.<br />

NAME OF PART<br />

I<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

l0<br />

ll<br />

t2<br />

t3<br />

t4<br />

t5<br />

t6<br />

l7<br />

t8<br />

r9<br />

20<br />

2l<br />

22<br />

Gear and Eccentric Case<br />

Gear Case Lid<br />

Gear and Eccentric<br />

Connecting Link<br />

Connecfing Link Bush<br />

Retaining Ring<br />

Locking Screws Ret. Ring<br />

Locking Screw Gear Shaft<br />

Locking Nut Gear Shaft<br />

Gear Shaft<br />

Gear Shaft Bearing<br />

Pacl

FOR,RERS PARTS LIST<br />

STANDARD PUMP: MKS FB,FD' FF' FG' FJ'<br />

FK, FL, FM fO, FP, FQ,<br />

FR, F5, FT.<br />

46<br />

45<br />

44<br />

42<br />

40<br />

60<br />

l6<br />

8<br />

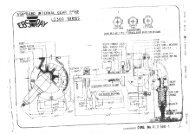

Gear Box ends in all F series pumps are<br />

similar in design to that shown above<br />

Only the Pump Ends (illustrated at left)<br />

differ