Ajax A1-1/2 Piston Pump Installation and Maintenance Manual

Ajax A1-1/2 Piston Pump Installation and Maintenance Manual

Ajax A1-1/2 Piston Pump Installation and Maintenance Manual

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

../...<br />

t" ,,7 I d.-A ,4.-* - 4/6.*,-o-- ,p/f<br />

," 3S o p.-o.--u...-- /z c;,{*-i /.o*d,<br />

^ i<br />

7"_:. "- -ZZ, _--e4_::*___"<br />

) *;:"* . ,' /., )<br />

)/'.:<br />

,l ul"A*-,'("'f Ii G ,,*,2.<br />

AJAX(>*<br />

\ 6 (/at

I<br />

<strong>Ajax</strong> <strong>Pump</strong>s Australia - Location<br />

Page I ofl<br />

AIl,i PUMP INSTALLATION<br />

Locatign / Company History<br />

INSTRUCTIONS<br />

S the 25th of January 2OO7 the mpahy name ofilclally changed frcm KSB AJax tumps Ry Ltd to reB Australla fty Ltd.<br />

reB Alax pumps Pty Ltd tn tustralta has been seilhg ausralla <strong>and</strong> the australian lndusry for mll owr seventy years. w6 employ<br />

Uff ti sales, manuiaCudng, sgtn€edng <strong>and</strong> admlnGtr.don adlvlues thrcughout &stralla <strong>and</strong> Nw Zeal<strong>and</strong>. We have lhe @Fclty<br />

to est, macirhe <strong>and</strong> asserible iumphg equlpment for lo@l <strong>and</strong> expft mark$ whlle ale supPlylng dher 69 oP€ratlons ln the<br />

&la Paclflc reglon,<br />

The ForE€ manufadudng faclllty was also mwed to TotEnham.<br />

LOCATION:<br />

Manufatuing was moved b *ate of the aft premlses ln ToBenham. Melbournc.<br />

l(SB Aax wrs formed bdnghg togdher KSB, me of the rcrld's large* <strong>Pump</strong> <strong>and</strong> valve manufadureB <strong>and</strong> AJax P!mF, the<br />

Australlan oper.tlon.<br />

*b*'dumeiruirirrhA fti ro*o co,rpuov, q(iil"ii"t:establilh;i d::igbil rt":'-r':i d :,<br />

ffiO&iinne iii lp'i*ttr, Quensl<strong>and</strong>, thia dant rpddld rn sMqdble €s9€ pumPs.<br />

ne Alax<br />

pumps Foundry was opened at Kyneton tn rural Vdorla. The bundry had a Gpacity in exces of one hundred tonnes per<br />

month ln a varlety of ferrous <strong>and</strong> mn-ferrcus meEls.<br />

4!x tump Works was esbllshed atTofrenham, vldorln,<br />

l(SB was sbbltshed tn 1871 when thEe Gemans, Johannes Kleln, Fieddch Schanzlln, <strong>and</strong> August Becker declded to Gbblish a<br />

@;pany ln Frankdthal, ermany, KSB <strong>and</strong> has grcm ow the past 13O yeaE to become a world leader ln the manufadure of<br />

pumpa tnd valves.<br />

lnstoll the <strong>Pump</strong> os neor fhe source of supply<br />

Never exceed the recommended distonce qnd<br />

the lowest level of fhe source of supply.<br />

should be chosen for ihe inefollotion of o<br />

Unit. Allow sufficient spqce oround fhe<br />

rcpoirs to be corried out when necEssory.<br />

os possible.<br />

height from<br />

A dry ploce<br />

mofor-driven<br />

<strong>Pump</strong> for<br />

The verticol height from the <strong>Pump</strong> level to the lowEst<br />

woter level should not exceed l5 ft. to 20 ft. ond the<br />

suction pipe should be kept os short os possible. ll<br />

the suction lift is neor the moximum, or fhe suction line is<br />

o long one, obfoin our recommendotion before instolling.<br />

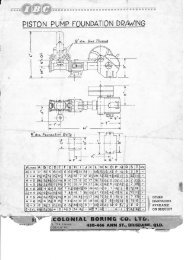

FOUNDATION:<br />

This should bc sufficiently substontiol to support the pump<br />

ond prevent movcmeni"<br />

PIPE SUPPORT:<br />

All piping, should be supported indcpendenfly neor the pump.<br />

Pipes must register with the <strong>Pump</strong> connecions without<br />

being stroined into position.<br />

SUCTION PIPE:<br />

The suction pipe, in porticulor, must be kept oir tight,<br />

os even o smol I leok moy impoir the operotion of the <strong>Pump</strong>.<br />

The pipe should never be smoller thqn the <strong>Pump</strong> connecfion<br />

ond moy, with odvontoge, be o size lorger. Avoid obrupt<br />

t//www.ksb.oom.auAooation/history.htnl<br />

t6t03t20Q8

2<br />

chonges in pipe diometers. The suction line must be os<br />

shori ond direct os possible. Avoid shorp turns, use bends<br />

rother fhon elbows. When loying the line, o uniform grode<br />

should be mointoined, rising towords the <strong>Pump</strong> the whole<br />

woy.<br />

When instolling for outomotic operotion by Floot Switch cnd<br />

fhe woter level is below the <strong>Pump</strong>, obtoin on instollotion<br />

sketch from us, os speciol fittings ore required<br />

FOOTVALVE:<br />

Where the woter level is below the <strong>Pump</strong>, o Footvolve or<br />

Check Volve should be used. The lotter is only used with<br />

Speor Points. The Volve should hove on oreo ot leost one<br />

ond o holf times thof of ihe suction pipe. The sfroiner<br />

should hove o cleor oreo three io four times thot of ihe suction<br />

pipe.<br />

r<br />

STARTING:<br />

3<br />

For the initiol sfort it is necessory to prime the <strong>Pump</strong>. This<br />

con be done by removing the plug on the <strong>Pump</strong> body iusf over<br />

fhe top of the suction pipe connection ond filling the whole<br />

of the suction pipe with woter lt sometimes becomes necessory<br />

to ol so remove the top cover of the <strong>Pump</strong> ond fi ll wiih woter.<br />

This is removed by undoing the one bolt on the top.<br />

VALVES:<br />

Volves moy be inspected by removing fhe volve covers for<br />

the suction volves ond the oir chomber for the delivery volves.<br />

The volves con be removed from the <strong>Pump</strong> by unscrewing the<br />

volve sfem with o screwdriver. Volves should not be disturbod<br />

unless trouble is suspected, ond if the rubbers ore disturbed<br />

they should be removed from the <strong>Pump</strong> ond rubbed ogoinst o<br />

piece of emery poper supported on o flot surfoce until they<br />

ore perfectly flot. lf excessively pitted, the rubbers moy be<br />

reversed ond the other side used; or reploced i{ necessory.<br />

DELIVERY PIPE:<br />

The size of the delivery pipe should be selected so fhot the<br />

friction heod is not excessive. lf delivery pipe is too smoll<br />

frictionol heod is very greotly increosed, consequently more<br />

power is reguired to drive the <strong>Pump</strong>. 'Avoid<br />

shorp furns'<br />

use bends rother ihon elbows. lt is odvisoble for del ivery<br />

piping to ri se ol lthe woy to the point of dischorge'<br />

Unions or flonges should be used fo connect the piping to<br />

the pump, so thot the pipes con be disconnected, if necessory,<br />

without disturbing the whole instollotion'<br />

A relief Volve must be fitted to delivery line neor <strong>Pump</strong> if<br />

ony Gote Volves or Tops ore in it to guord ogoinst domoge<br />

to the pumps or motor in the event of the outlet being closed<br />

whilst the pump is oPeroting.<br />

PLUNGER LEATHERS:<br />

Will possibly need replocing obout every eighieen months or<br />

so. By removing the Cylinder Heod (held down by rwo bolts)<br />

the Plunger con then be unscrewed by meons of the slot in<br />

the centre of the Plunger Assembly. When removed from the<br />

<strong>Pump</strong>, the Plunger con hen be token oporf ond new leofhers<br />

fitted.<br />

Moke sure thot fhey ore well oiled ond soft ond thot the<br />

Cylinder Liner is not excessively scored. Turn the <strong>Pump</strong><br />

by hond to bring the Plunger well forword in the Cylinder.<br />

lf the <strong>Pump</strong> hos been stonding for some time the Plunger<br />

Leothers moy become hord ond dry. This will greotly impoir<br />

.,re oporotion of the <strong>Pump</strong>. The leothers should be removed<br />

from the <strong>Pump</strong> ond sooked in coslrqr or neoisfoot oil,<br />

or, if this not ovoiloble, woter, for some hours. They<br />

should then be worked with the fingers until soft, ond repfoced<br />

in the <strong>Pump</strong>.

I<br />

@P,<br />

4<br />

This should be iust right enough to permit o slow drip from<br />

the glond when the <strong>Pump</strong> is operoting. lf the glond is too<br />

rightl the <strong>Pump</strong> will use excgssive power ond fie plunger<br />

rod will weor roPidlY.<br />

When oll the odiustment hos been token up, the Glond Nut<br />

should be unscrewed ond withdrown, thence the smoll ferrule'<br />

The old pocking should be scroped out with o noil or piece<br />

of wire qnd new pocking (6" - 9" ol 3/16" grophited Volve<br />

f*ist) wropped oround ih" Plung"t Rod ond pressed into the<br />

Glond.<br />

Aftcr the Glond Nut hos been tightened il compressgs the<br />

po"ting ond usuolly I or 2 more turns of pocking con then be<br />

fitted.<br />

ir<br />

i<br />

,<br />

i<br />

SPEED:<br />

200 r.p.m.<br />

LUBRICATION:<br />

Provided thot the sump is kept filled with oil, lubricotion is<br />

guite outomotic. Oil level in the sump when the <strong>Pump</strong> is<br />

sfotionory should never foll below the bottom of the filler<br />

plug hole.<br />

The Filling Plug con be found on the bock of the Cronkcose,<br />

while o dioin plug is underneoth for periodicol replocement<br />

of the oil.<br />

sufficienr sAE 20-40 Engine oil should be odded to fill the<br />

cronkcose to fhe fi ller plug level. core should be tokcn thqt<br />

the sump is reolly full, os sometimes o smol I bubble qcrossthe<br />

Ltto, of the fil'ler hole gives the impression thqt it is full<br />

when such is not the cose. About every six months the sump<br />

should be droined ond refilled with new oil.<br />

I<br />

I<br />

f

\ '\ \v{/<br />

>a<br />

\v, -'.,ti,<br />

@<br />

\\\@r<br />

Jaa/e<br />

Fu // Jtzel

i<br />

I<br />

t<br />

I<br />

i<br />

5<br />

EMERGENCY HINTS<br />

i<br />

I<br />

ffi<br />

.61f<br />

].IO WATER DELIVERED:<br />

Check suction line fittings for blockoge or leoks. Check<br />

Plunger- Leothers ond Volves for excessive weor. Sucfion<br />

lift moy be excessive.<br />

UNEVEN FLOW:<br />

Check Plunger Leother for weor; see thot the surfoce of the<br />

leother is not scored. Check Volves, if foce of rubber is<br />

worn oi deformed, rub volve foce ogoinst emery cloth supported<br />

on o flot surfoce until foce is perfectly flot. Check lhct volvc<br />

springs

6<br />

GLAND LEAKS EXCESSIVELY:<br />

Tighten glond, repock if necessory.<br />

Check plunger rod for weor.<br />

Part No.<br />

l.<br />

7<br />

LIST OF AIZ PIST()}| PUTP PARTS:<br />

N ame<br />

Base<br />

2.<br />

ilotor Plate<br />

3.<br />

Short Bearing<br />

lr in doubt obout ony<br />

or phone ond we sholl<br />

to odvise you.<br />

point, write<br />

be pleoscd<br />

4.<br />

E<br />

0.<br />

Long Bearing<br />

Eccentric<br />

Crank Case<br />

1.<br />

Pulley ttheel<br />

8.<br />

Connect i ng Rod<br />

g.<br />

Va lve H $s ing<br />

10.<br />

ll.<br />

Va I ve Hous i ng Cove r<br />

Ya I ve Cove r Cl amP<br />

12.<br />

Ya I ve Cove r<br />

13.<br />

Cyl inder Head<br />

14.<br />

G l<strong>and</strong> l{u t<br />

15.<br />

10.<br />

Gl <strong>and</strong> Sl eeve<br />

,<br />

, "'..,I1r,<br />

Bucket Bolt<br />

17.<br />

Pi ston Plate<br />

18.<br />

Bucket llut<br />

lg.<br />

Ya I ve 0i sc.<br />

20.<br />

Plug for Short Bearings<br />

21,<br />

Ya lve Stem<br />

22.<br />

C rosshead

I<br />

i<br />

l<br />

i<br />

Part No.<br />

B.<br />

Name<br />

ffiTL."<br />

23.<br />

Pi ston I{ashers<br />

24.<br />

Gl<strong>and</strong> Plate<br />

25.<br />

Cyl inder Liner<br />

I<br />

21.<br />

Valve Seat<br />

28.<br />

lllain Shaf t<br />

29.<br />

Gudgeon P i n<br />

30.<br />

Pivot Pin<br />

31.<br />

Pi ston Rod<br />

33.<br />

Comp ress i on Sn r i ng<br />

4&<br />

34.<br />

35.<br />

Va I ve Rubber<br />

Leather Bucket<br />

Centre Plate<br />

Gasket Gl<strong>and</strong> Plate<br />

0asket Cylinder Head<br />

0asket Crank Case<br />

Priming plug N', B.S.p.<br />

Gasket Valve Housing Cover<br />

0i I LeveI plug \" B.S.p.<br />

0 ra i n P lug, t/g' B. S. p.<br />

Gasket Valve Cover<br />

Baf f le I{asher<br />

*********

'"/ lf-f .'<br />

I<br />

r' , '-/ ,T:<br />

'::r<br />

:-L I<br />

)t\<br />

\ .",<br />

'-<br />

\_r<br />

.'.....< \.<br />

r,t<br />

j*<br />

( -