Ajax A1-1/2 Piston Pump Installation and Maintenance Manual

Ajax A1-1/2 Piston Pump Installation and Maintenance Manual

Ajax A1-1/2 Piston Pump Installation and Maintenance Manual

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

I<br />

<strong>Ajax</strong> <strong>Pump</strong>s Australia - Location<br />

Page I ofl<br />

AIl,i PUMP INSTALLATION<br />

Locatign / Company History<br />

INSTRUCTIONS<br />

S the 25th of January 2OO7 the mpahy name ofilclally changed frcm KSB AJax tumps Ry Ltd to reB Australla fty Ltd.<br />

reB Alax pumps Pty Ltd tn tustralta has been seilhg ausralla <strong>and</strong> the australian lndusry for mll owr seventy years. w6 employ<br />

Uff ti sales, manuiaCudng, sgtn€edng <strong>and</strong> admlnGtr.don adlvlues thrcughout &stralla <strong>and</strong> Nw Zeal<strong>and</strong>. We have lhe @Fclty<br />

to est, macirhe <strong>and</strong> asserible iumphg equlpment for lo@l <strong>and</strong> expft mark$ whlle ale supPlylng dher 69 oP€ratlons ln the<br />

&la Paclflc reglon,<br />

The ForE€ manufadudng faclllty was also mwed to TotEnham.<br />

LOCATION:<br />

Manufatuing was moved b *ate of the aft premlses ln ToBenham. Melbournc.<br />

l(SB Aax wrs formed bdnghg togdher KSB, me of the rcrld's large* <strong>Pump</strong> <strong>and</strong> valve manufadureB <strong>and</strong> AJax P!mF, the<br />

Australlan oper.tlon.<br />

*b*'dumeiruirirrhA fti ro*o co,rpuov, q(iil"ii"t:establilh;i d::igbil rt":'-r':i d :,<br />

ffiO&iinne iii lp'i*ttr, Quensl<strong>and</strong>, thia dant rpddld rn sMqdble €s9€ pumPs.<br />

ne Alax<br />

pumps Foundry was opened at Kyneton tn rural Vdorla. The bundry had a Gpacity in exces of one hundred tonnes per<br />

month ln a varlety of ferrous <strong>and</strong> mn-ferrcus meEls.<br />

4!x tump Works was esbllshed atTofrenham, vldorln,<br />

l(SB was sbbltshed tn 1871 when thEe Gemans, Johannes Kleln, Fieddch Schanzlln, <strong>and</strong> August Becker declded to Gbblish a<br />

@;pany ln Frankdthal, ermany, KSB <strong>and</strong> has grcm ow the past 13O yeaE to become a world leader ln the manufadure of<br />

pumpa tnd valves.<br />

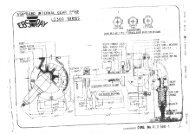

lnstoll the <strong>Pump</strong> os neor fhe source of supply<br />

Never exceed the recommended distonce qnd<br />

the lowest level of fhe source of supply.<br />

should be chosen for ihe inefollotion of o<br />

Unit. Allow sufficient spqce oround fhe<br />

rcpoirs to be corried out when necEssory.<br />

os possible.<br />

height from<br />

A dry ploce<br />

mofor-driven<br />

<strong>Pump</strong> for<br />

The verticol height from the <strong>Pump</strong> level to the lowEst<br />

woter level should not exceed l5 ft. to 20 ft. ond the<br />

suction pipe should be kept os short os possible. ll<br />

the suction lift is neor the moximum, or fhe suction line is<br />

o long one, obfoin our recommendotion before instolling.<br />

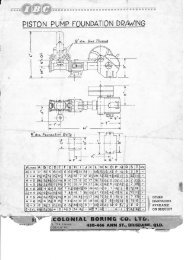

FOUNDATION:<br />

This should bc sufficiently substontiol to support the pump<br />

ond prevent movcmeni"<br />

PIPE SUPPORT:<br />

All piping, should be supported indcpendenfly neor the pump.<br />

Pipes must register with the <strong>Pump</strong> connecions without<br />

being stroined into position.<br />

SUCTION PIPE:<br />

The suction pipe, in porticulor, must be kept oir tight,<br />

os even o smol I leok moy impoir the operotion of the <strong>Pump</strong>.<br />

The pipe should never be smoller thqn the <strong>Pump</strong> connecfion<br />

ond moy, with odvontoge, be o size lorger. Avoid obrupt<br />

t//www.ksb.oom.auAooation/history.htnl<br />

t6t03t20Q8