Equipment Performance Module 2.0 - Control System

Equipment Performance Module 2.0 - Control System

Equipment Performance Module 2.0 - Control System

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Equipment</strong> <strong>Performance</strong> <strong>Module</strong> <strong>2.0</strong><br />

Real-time <strong>Equipment</strong> Downtime and Efficiency Tracking<br />

The Wonderware ® <strong>Equipment</strong> <strong>Performance</strong> <strong>Module</strong><br />

powered by Wonderware Factelligence ® technology helps<br />

companies quickly capture critical plant information<br />

and deliver it to anyone throughout the organization for<br />

immediate action to improve overall plant performance.<br />

This real-time equipment-performance and plantefficiency<br />

information therefore enables operators and<br />

other decision-makers to:<br />

<br />

<br />

<br />

<br />

Reduce capital expenditures by identifying the most<br />

productive assets for continued operation<br />

Cut down on production costs by decreasing labor<br />

costs, scrap and rework<br />

Decrease time-to-market by identifying production<br />

bottlenecks more quickly and increasing supplier<br />

accountability<br />

Increase the capacity of existing assets by pinpointing<br />

the causes of unplanned downtime and improving<br />

operational efficiency<br />

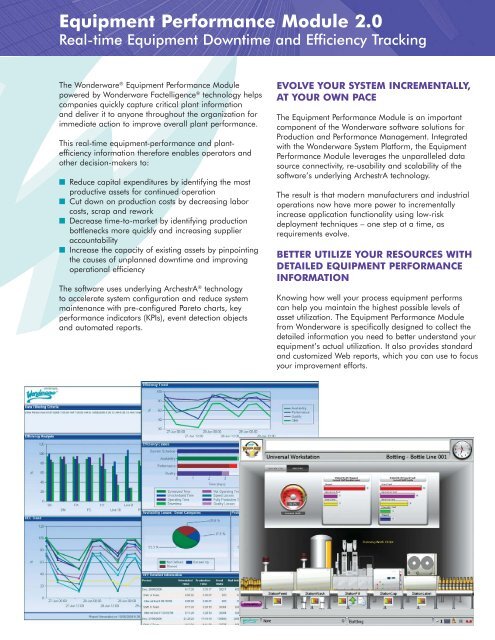

The software uses underlying ArchestrA ® technology<br />

to accelerate system configuration and reduce system<br />

maintenance with pre-configured Pareto charts, key<br />

performance indicators (KPIs), event detection objects<br />

and automated reports.<br />

EVOLVE YOUR SYSTEM INCREMENTALLY,<br />

AT YOUR OWN PACE<br />

The <strong>Equipment</strong> <strong>Performance</strong> <strong>Module</strong> is an important<br />

component of the Wonderware software solutions for<br />

Production and <strong>Performance</strong> Management. Integrated<br />

with the Wonderware <strong>System</strong> Platform, the <strong>Equipment</strong><br />

<strong>Performance</strong> <strong>Module</strong> leverages the unparalleled data<br />

source connectivity, re-usability and scalability of the<br />

software’s underlying ArchestrA technology.<br />

The result is that modern manufacturers and industrial<br />

operations now have more power to incrementally<br />

increase application functionality using low-risk<br />

deployment techniques – one step at a time, as<br />

requirements evolve.<br />

BETTER UTILIZE YOUR RESOURCES WITH<br />

DETAILED EQUIPMENT PERFORMANCE<br />

INFORMATION<br />

Knowing how well your process equipment performs<br />

can help you maintain the highest possible levels of<br />

asset utilization. The <strong>Equipment</strong> <strong>Performance</strong> <strong>Module</strong><br />

from Wonderware is specifically designed to collect the<br />

detailed information you need to better understand your<br />

equipment’s actual utilization. It also provides standard<br />

and customized Web reports, which you can use to focus<br />

your improvement efforts.

SAVE TIME WITH PRE-CONFIGURED<br />

APPLICATION EXAMPLES<br />

The <strong>Equipment</strong> <strong>Performance</strong> <strong>Module</strong> provides preconfigured<br />

equipment event objects, which empower<br />

plant personnel to quickly capture asset-utilization data.<br />

Pre-configured web-based reports are also included to<br />

swiftly give you the information you need to optimize<br />

your plant’s equipment utilization without the need to<br />

create custom reports.<br />

MINIMIZE EQUIPMENT DOWNTIME<br />

AND UNLOCK HIDDEN PRODUCTION<br />

CAPACITY<br />

Every minute that your critical equipment is down, your<br />

productivity suffers. By systematically analyzing your<br />

equipment’s downtime or slowdowns with the <strong>Equipment</strong><br />

<strong>Performance</strong> <strong>Module</strong>, you can identify and eliminate<br />

the true causes of your lost production, and unlock the<br />

hidden production capacity in your plant.<br />

The <strong>Equipment</strong> <strong>Performance</strong> <strong>Module</strong> leverages your<br />

existing system to collect highly accurate and timely<br />

information related to downtime events — without the<br />

need to modify your PLC programming.<br />

Pareto and other charts give decision-makers a clear<br />

view into which downtime events occur most frequently,<br />

and how much production time has actually been lost<br />

– in an actionable format.<br />

In essence, the Wonderware <strong>Equipment</strong> <strong>Performance</strong><br />

<strong>Module</strong> provides precisely the information you need to<br />

make the most out of your process improvement efforts.<br />

IMPROVE EQUIPMENT EFFECTIVENESS<br />

WITH OEE METRICS AND NEW<br />

ARCHESTRA GRAPHICS<br />

Overall <strong>Equipment</strong> Effectiveness (OEE) is a well-accepted<br />

metric for comparing the efficiency of equipment, lines<br />

or entire plants. OEE combines equipment availability,<br />

performance and product-quality information into a<br />

single, easy-to-understand metric.<br />

The Wonderware <strong>Equipment</strong> <strong>Performance</strong> <strong>Module</strong><br />

automatically collects near real-time OEE information<br />

with easy-to-configure efficiency objects. You can<br />

easily combine efficiency data from the <strong>Equipment</strong><br />

<strong>Performance</strong> <strong>Module</strong> with vibrant ArchestrA graphics<br />

in Wonderware InTouch ® 10.0 HMI to quickly build<br />

stunning OEE dashboard displays for operators. You can<br />

also produce a wide variety of OEE charts and reports,<br />

which you can then distribute via the Web to decisionmakers<br />

throughout the plant.<br />

COLLECT OPERATOR FEEDBACK TO<br />

IMPROVE PLANT EFFICIENCY AND<br />

PRODUCTIVITY<br />

Using pre-configured InTouch 10.0 HMI screens loaded<br />

with equipment efficiency metrics, gives operators the<br />

ability to “steer” equipment efficiency in real time. They<br />

can input feedback on equipment events in a structured<br />

way that equipment deviations can be quantified and<br />

properly classified. This approach enables operators<br />

to focus on their most important job: running the<br />

equipment. The ability to collect operator feedback<br />

also gives context to equipment performance reports,<br />

empowering plant decision-makers to develop more<br />

effective process improvement strategies. The end result<br />

is improved plant efficiency and productivity.<br />

KEY CAPABILITIES<br />

Data Collection<br />

Operator Involvement<br />

Event Detection<br />

ADVANTAGES<br />

The Wonderware <strong>Equipment</strong> <strong>Performance</strong> <strong>Module</strong> leverages industryleading<br />

data source connectivity and the powerful integration capabilities of<br />

the Wonderware <strong>System</strong> Platform. The powerful Wonderware Factelligence<br />

technology automatically collects event and process data, helping to ensure<br />

accurate, consistent and timely information.<br />

The <strong>Equipment</strong> <strong>Performance</strong> <strong>Module</strong> facilitates the collection of structured<br />

operator feedback on production events and their causes via the.NET<br />

based Utilization/OEE control. This valuable information is made available<br />

to plant decision-makers through a range of reports and data displays such<br />

as Pareto charts and ArchestrA graphics in InTouch.<br />

ArchestrA Event Objects are easy to create and deploy. Display the<br />

frequency and type of equipment events in context with the production<br />

schedule, production order or production shift.

KEY CAPABILITIES<br />

Real-Time Visibility<br />

Total Cost of Ownership<br />

ADVANTAGES<br />

ArchestrA graphics displaying event data can be easily assembled into<br />

equipment performance KPI dashboards, which can then be deployed to<br />

InTouch 10.0 operator screens or the Web. Operators can track and display<br />

information related to production efficiency by product, equipment, line<br />

or shift. Production targets can be easily configured and displayed relative<br />

to actual production. Powerful real-time dashboards are visible to virtually<br />

anyone in the plant — saving time and money.<br />

ArchestrA application object technology facilitates quick changes or<br />

additions to system capabilities, without extensive engineering changes.<br />

This approach decreases implementation and maintenance costs, and<br />

accelerates project schedules. The pre-configured data and graphical<br />

objects delivered with the <strong>Equipment</strong> <strong>Performance</strong> <strong>Module</strong> provide a<br />

powerful head-start in creating an equipment performance management<br />

solution for your facility.<br />

ARCHITECTURE<br />

The <strong>Equipment</strong> <strong>Performance</strong> <strong>Module</strong> runs on the<br />

Wonderware <strong>System</strong> Platform, the common strategic<br />

platform for networked Supervisory HMI, SCADA, and<br />

Production and <strong>Performance</strong> Management solutions and<br />

Wonderware Factelligence technology. It is composed of<br />

the following major components.<br />

FACTELLIGENCE EQUIPMENT<br />

PERFORMANCE SERVICES<br />

Utilization Manager<br />

<br />

<br />

<br />

<br />

<br />

The Utilization Manager provides:<br />

<strong>Equipment</strong> event definitions and categories<br />

Powerful logic engine which automatically captures<br />

information on equipment performance and<br />

downtime events<br />

OEE calculations and information on equipment<br />

performance, availability and quality<br />

Enhanced Localization — Configuration, Reason<br />

Codes, Local Nomenclature<br />

Factelligence Utilization/OEE <strong>Control</strong>s are customizable<br />

.NET controls which can be integrated into Wonderware<br />

InTouch 10.0 HMI screens to provide an easy and<br />

convenient way for collecting operator feedback and<br />

qualifying and categorizing slowdowns and stoppages.<br />

EQUIPMENT PERFORMANCE EXAMPLES<br />

<strong>Equipment</strong> <strong>Performance</strong> Event Capture Library<br />

A library of pre-configured Event Capture Objects for<br />

the <strong>System</strong> Platform 3.0 facilitates rapid configuration<br />

and deployment of an equipment performance system.<br />

Event objects can be quickly adapted to capture almost<br />

any equipment performance event or efficiency metric.<br />

The objects can be easily modified and re-deployed<br />

— saving time and maintenance costs.<br />

Factelligence<br />

Utilization/OEE <strong>Control</strong>

<strong>Equipment</strong> <strong>Performance</strong> ArchestrA<br />

Graphic Library<br />

A collection of pre-configured InTouch 10.0 ArchestrA<br />

graphics easily links important process parameters<br />

to graphical indicators of equipment performance,<br />

including OEE metrics and other KPIs. ArchestrA graphics<br />

can be embedded into InTouch 10.0 screens to inform<br />

operators of critical equipment performance information.<br />

They can also scale up to enterprise-wide HMI solution<br />

to apprise an entire production team of important<br />

equipment performance issues and events.<br />

ArchestrA <strong>Equipment</strong> <strong>Performance</strong> Reports<br />

Pre-configured reports and integration with Microsoft ®<br />

SQL Server 2005 Reporting Services provide customized<br />

equipment performance reports that can be viewed via<br />

the Web-based Wonderware Information Server.<br />

Wonderware • 26561 Rancho Parkway South, Lake Forest, CA 92630 • Tel: (949) 727-3200 • Fax: (949) 727-3270<br />

www.wonderware.com<br />

© 2007 Invensys <strong>System</strong>s, Inc. All rights reserved. No part of the material protected by this copyright may be reproduced or utilized in any form<br />

or by any means, electronic or mechanical, including photocopying, recording, broadcasting, or by any information storage and retrieval system,<br />

without permission in writing from Invensys <strong>System</strong>s, Inc.<br />

Invensys, Wonderware, ArchestrA, Factelligence, InTouch, InBatch, In<strong>Control</strong>, IndustrialSQL Server, InSQL, InTrack, QI Analyst, SCADAlarm,<br />

SuiteLink, SuiteVoyager, WindowMaker, WindowViewer are trademarks and registered trademarks of Invensys plc, its subsidiaries and affiliated<br />

companies. All other brands and product names may be the trademarks or service marks of their respective owners.<br />

PN 15-0214 Rev 12/07