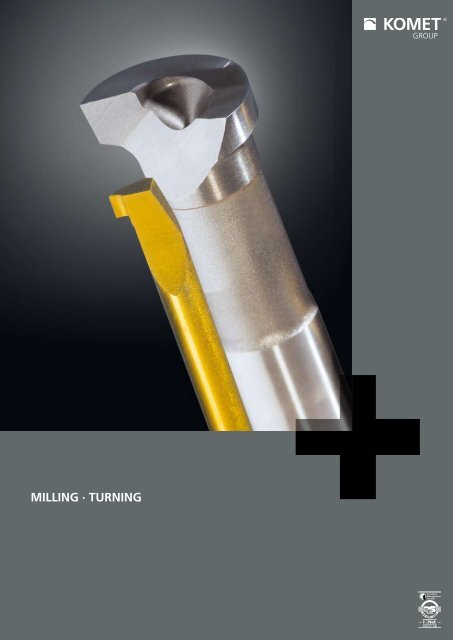

Milling · Turning - Komet Group

Milling · Turning - Komet Group

Milling · Turning - Komet Group

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Milling</strong> · <strong>Turning</strong>

Established in 1918, the KOMET GROUP has developed into a worldwide partner in technology and<br />

supplier of complete systems and tool concepts for boring, thread cutting and reaming by being constantly<br />

ready for innovation and optimisation of structures and strategies. Under the product names<br />

of KOMET, JEL, Dihart and their own product management company X3-Solutions, the KOMET GROUP<br />

focuses on demanding bore machining and holds a leading international market position.<br />

With the programme of innovative tools in this brochure for<br />

milling and turning operations<br />

we open up new perspectives for you for economic production.<br />

w w w . k o m e t g r o u p . c o m

Index<br />

Chapter<br />

1<br />

<strong>Milling</strong><br />

2<br />

Countersinking and Chamfering<br />

3<br />

<strong>Turning</strong><br />

4<br />

Adaptors<br />

5<br />

Index of Order Numbers<br />

International Agencies

<strong>Milling</strong><br />

Our comprehensive milling programme provides the guarantee for creating<br />

optimum surfaces, both in quality and output. Thanks to the highest level<br />

of production reliability, these form the basis of economic production for<br />

our customers.

<strong>Milling</strong><br />

Circular milling cutter<br />

Page<br />

6 – 11<br />

1<br />

End milling cutter<br />

12 – 15<br />

Chamfer milling cutter<br />

16<br />

T-slot milling cutter<br />

17<br />

Shell end face milling cutter<br />

18 – 20<br />

90° face milling cutter<br />

21<br />

Face milling cutter<br />

22 – 23<br />

Slot milling cutter<br />

24 – 25<br />

HSC milling cutter<br />

26 – 27<br />

PCD slot milling cutter<br />

28 – 29<br />

PCD end milling cutter<br />

30

Programme summary – adaptors<br />

Adaptors<br />

<strong>Milling</strong> Tools<br />

Collet holder ABS ® SZV<br />

Catalogue "KomPass – Drilling" chapter 5<br />

Taper shanks<br />

Catalogue "KomPass – Drilling" chapter 5<br />

ABS ® Extension<br />

Catalogue "KomPass – Drilling" chapter 5<br />

<br />

<br />

<br />

<br />

<br />

Adaptor sleeve Weldon<br />

ABS ® HWD<br />

Catalogue "KomPass – Drilling" chapter 5<br />

Spindle adaptor flange<br />

Catalogue "KomPass – Drilling" chapter 5<br />

ABS ® Reducer<br />

Catalogue "KomPass – Drilling" chapter 5<br />

<br />

<br />

<br />

<br />

<br />

Schrumpftechnik<br />

Catalogue "KomPass – Drilling" chapter 5<br />

HSK Adaptor<br />

Catalogue "KomPass – Drilling" chapter 5<br />

<br />

<br />

<br />

<br />

<br />

<strong>Milling</strong> cutter arbor<br />

<br />

ABS-FA<br />

E 116<br />

<br />

HSK-FA<br />

E 100<br />

<br />

<br />

ABS-FAM<br />

E 117<br />

HSK-FAM<br />

E 100<br />

<br />

ABS-FAK<br />

<br />

E 118<br />

HSK-FAK<br />

<br />

E 101<br />

<br />

EP 0 547 049 and other patents (ABS ® )

Programme summary – milling<br />

<strong>Milling</strong> Tools<br />

1<br />

Page<br />

<br />

Circular milling cutter<br />

X 10, 16, 25, 40 mm<br />

6 – 7<br />

<br />

End milling cutter<br />

X 9,5-40 mm<br />

12 – 14<br />

<br />

Chamfer milling cutter<br />

X 19,6 / 27,6 mm<br />

16<br />

<br />

T-slot milling cutter<br />

X 17,5-47 mm<br />

17<br />

<br />

Shell end face milling cutter<br />

X 20, 25, 32 mm<br />

18<br />

<br />

Countersinking tool KWZ<br />

X 10-48 mm<br />

Chapter 2<br />

<br />

Countersinking tool KWS<br />

X 16,5-37 mm<br />

Chapter 2<br />

<br />

PCD slot milling cutter<br />

X 6-20 mm 28 – 29<br />

<br />

PCD end milling cutter<br />

X 12-25 mm 30<br />

<br />

Circular milling cutter<br />

X 63, 80 mm<br />

8<br />

<br />

Shell end face milling cutter<br />

X 63, 80 mm<br />

1.24<br />

<br />

90° face milling cutter<br />

X 40-125 mm<br />

21<br />

<br />

Face milling cutter<br />

X 40, 50, 63, 80 mm<br />

22<br />

<br />

HSC milling cutter<br />

X 63-100 mm<br />

26<br />

<br />

Slot milling cutter<br />

X 63-125 mm<br />

25<br />

Slot milling cutter<br />

X 63-125 mm 24

Circular milling cutter<br />

Cylindrical shank to DIN 1835 T1 B<br />

Calculations for circular milling see page 10-11<br />

Central coolant supply<br />

L<br />

b H13<br />

L1<br />

a<br />

d h6<br />

d2<br />

d1<br />

y = number of inserts = 1<br />

z = effective number of teeth for calculating vf = 3<br />

Basic recommendation<br />

Insert<br />

for<br />

workpiece material<br />

Assembly parts<br />

Clamping screw<br />

Accessories<br />

Screwdriver<br />

Order No.<br />

d1<br />

b<br />

a<br />

d2<br />

d h6<br />

L<br />

L1<br />

Order No.<br />

Size<br />

ISO-Code<br />

P M K<br />

N S H<br />

Order No.<br />

Article<br />

Order No.<br />

Article<br />

F51 70050<br />

10<br />

1,1<br />

0,9<br />

8,2<br />

16<br />

84<br />

24<br />

Q12 18000.1003 TPAX1102ZZ R-110 P25M<br />

0,09 Q12 18000.1022 TPAX1102ZZ R-110 K20<br />

Q12 18000.108425 TPAX1102ZZ R-110 BK8425<br />

N00 57221<br />

S2553-7IP<br />

0,9 Nm<br />

L05 00820<br />

7IP<br />

F51 70080<br />

16<br />

1,1<br />

1,3<br />

1,6<br />

0,9<br />

1,3<br />

1,4<br />

13<br />

16<br />

84<br />

24<br />

Q12 32000. ..03<br />

0,11 Q12 32000. ..22<br />

TCAX16T3ZZ R-...P25M<br />

TCAX16T3ZZ R-...K20<br />

Q12 32000. ..8425TCAX16T3ZZ R-...BK8425<br />

<br />

<br />

15 for b = 1,1 mm 110<br />

16 for b = 1,3 mm 130<br />

17 for b = 1,6 mm 160<br />

N00 57281<br />

S3598-15IP<br />

2,8 Nm<br />

For further details on selecting insert types,<br />

see KomPass chapter 7<br />

L05 00860<br />

15IP<br />

Design:<br />

The dimension b is determined by the slot widths with H13 tolerance for holding rings to DIN 471 and DIN 472; this is the<br />

higher tolerance limit for the slot widths which can be produced.<br />

Supply includes: Circular milling cutter with assembly parts. Please order insert and accessories separately.<br />

Copaslip grease for screw should be included in first order. Order No. 4700100100.

Circular milling cutter<br />

Cylindrical shank to DIN 1835 T1 B<br />

Calculations for circular milling see page 10-11<br />

Central coolant supply<br />

1<br />

L<br />

L1<br />

0,05× 0,05× 0,05×<br />

45° 45° 45° b H13<br />

b H13<br />

a<br />

R<br />

a<br />

R<br />

d h6<br />

d2<br />

d1<br />

Q12 18000.36..<br />

Q12 32000.38..<br />

y = number of inserts = 3<br />

z = effective number of teeth for calculating vf = 3<br />

Basic recommendation<br />

Insert<br />

for<br />

.36.. workpiece material<br />

Assembly parts<br />

Clamping screw<br />

Accessories<br />

Screwdriver<br />

Order No.<br />

d1<br />

b<br />

a<br />

R<br />

d2<br />

d h6<br />

L<br />

L1<br />

Order No.<br />

Size<br />

ISO-Code<br />

P M K<br />

N S H<br />

Order No.<br />

Article<br />

Order No.<br />

Article<br />

F51 70121<br />

F51 70140<br />

1,6 1,0 0,1<br />

25<br />

20,5 25<br />

1,851,25<br />

0,1<br />

2,15 1,5 0,1<br />

25<br />

20,5 25<br />

2,651,75<br />

0,2<br />

100<br />

100<br />

42 0,35<br />

Q12 18000. ..03 TNAX1103ZZ R-...P25M<br />

Q12 18000. ..22 TNAX1103ZZ R-...K20<br />

Q12 18000. ..8425 TNAX1103ZZ R-...BK8425<br />

42 0,30<br />

N00 57221<br />

S2553-7IP<br />

0,9 Nm<br />

L05 00820<br />

7IP<br />

<br />

<br />

31 for b = 1,6 mm 160<br />

32 for b = 1,85 mm 185<br />

33 for b = 2,15 mm 215<br />

34 for b = 2,65 mm 265<br />

36 for b = 2,65 mm 265<br />

For further details on selecting insert types,<br />

see KomPass chapter 7<br />

Basic recommendation<br />

Insert<br />

.38..<br />

for<br />

workpiece material<br />

Assembly parts<br />

Clamping screw<br />

Accessories<br />

Screwdriver<br />

Order No.<br />

d1<br />

b a R d2 d h6<br />

L L1<br />

Order No.<br />

Size<br />

ISO-Code<br />

P M K<br />

N S H<br />

Order No.<br />

Article<br />

Order No.<br />

Article<br />

F51 70201<br />

2,651,75<br />

0,2<br />

40 3,151,75<br />

0,2 33<br />

Q12 32000. ..03<br />

32 110 49,50,65<br />

Q12 32000. ..22<br />

TNAX1604ZZ R-...P25M<br />

TNAX1604ZZ R-...K20<br />

4,15 2,5 0,3<br />

Q12 32000. ..8425 TNAX1604ZZ R-...BK8425<br />

<br />

<br />

41 for b = 2,65 mm 265<br />

42 for b = 3,15 mm 315<br />

43 for b = 4,15 mm 415<br />

38 for b = 4,15 mm 415<br />

N00 57281<br />

S3598-15IP<br />

2,8 Nm<br />

For further details on selecting insert types,<br />

see KomPass chapter 7<br />

Design:<br />

The dimension b is determined by the slot widths with H13 tolerance for holding rings to DIN 471 and DIN 472; this is the<br />

higher tolerance limit for the slot widths which can be produced.<br />

Supply includes: Circular milling cutter with assembly parts. Please order insert and accessories separately.<br />

Copaslip grease for screw should be included in first order. Order No. 4700100100.<br />

L05 00860<br />

15IP<br />

Important: See page 10 for more application details !

Circular milling cutter<br />

Location to DIN 6358 A<br />

Calculations for circular milling see page 10-11<br />

L<br />

0,05× 0,05× 0,05×<br />

45° 45° 45° b H13<br />

b H13<br />

a<br />

R<br />

a<br />

R<br />

d2<br />

d1<br />

Q12 32000.38..<br />

Q12 44000.87..<br />

y = number of inserts = 6<br />

z = effective number of teeth for calculating vf = 6<br />

Basic recommendation<br />

Insert<br />

for<br />

.38.. workpiece material<br />

Assembly parts<br />

Clamping screw<br />

Accessories<br />

Screwdriver<br />

Order No.<br />

d1<br />

b<br />

a<br />

R<br />

d2<br />

d H7<br />

L<br />

Order No.<br />

Size<br />

ISO-Code<br />

P M K<br />

N S H<br />

Order No.<br />

Article<br />

Order No.<br />

Article<br />

d H7 N S H<br />

2,65 1,75 0,2<br />

Q12 32000. ..03<br />

TNAX1604ZZ R-...P25M<br />

F51 71031 63 3,15 1,75 0,2 55 22 40 0,63 Q12 32000. ..22 TNAX1604ZZ R-...K20<br />

4,15 2,5 0,3<br />

Q12 32000. ..8425 TNAX1604ZZ R-...BK8425<br />

<br />

<br />

41 für b = 2,65 mm 265<br />

42 für b = 3,15 mm 315<br />

43 für b = 4,15 mm 415<br />

38 für b = 4,15 mm 415<br />

Basic recommendation<br />

Insert<br />

.87..<br />

N00 57281<br />

S3598-15IP<br />

2,8 Nm<br />

For further details on selecting insert types,<br />

see KomPass chapter 7<br />

for<br />

workpiece material<br />

Assembly parts<br />

Clamping screw<br />

L05 00860<br />

15IP<br />

Accessories<br />

Screwdriver<br />

Order No.<br />

d1<br />

b<br />

a<br />

R<br />

d2<br />

d H7<br />

L<br />

Order No.<br />

Size<br />

ISO-Code<br />

P M K<br />

Order No.<br />

Article<br />

Order No.<br />

Article<br />

4,15 2,5 0,3<br />

Q12 44000. ..03 TNAX1604ZZ R-...P25M<br />

F51 71101 80 4,65 3,4 0,3 68 27 50 1,25 Q12 44000. ..22 TNAX1604ZZ R-...K20<br />

5,15 4,0 0,3<br />

Q12 44000. ..8425 TNAX1604ZZ R-...BK8425<br />

<br />

<br />

84 für b = 4,15 mm 415<br />

85 für b = 4,65 mm 465<br />

86 für b = 5,15 mm 515<br />

87 für b = 5,15 mm 515<br />

N00 57301<br />

S45100-20IP<br />

6,25 Nm<br />

For further details on selecting insert types,<br />

see KomPass chapter 7<br />

L05 00870<br />

20IP<br />

Design:<br />

The dimension b is determined by the slot widths with H13 tolerance for holding rings to DIN 471 and DIN 472; this is the<br />

higher tolerance limit for the slot widths which can be produced.<br />

Supply includes: Circular milling cutter with assembly parts. Please order insert and accessories separately.<br />

Copaslip grease for screw should be included in first order. Order No. 4700100100.

Fax to +49(0)7143.373-577<br />

1<br />

Inquiry<br />

Purchase order<br />

Purcase order no._________________<br />

This purchase order underlie the terms and<br />

conditions of sale by KOMET GROUP GmbH.<br />

Required purchase quantity<br />

Company name __________________________________________<br />

Adress _________________________________________________<br />

_______________________________________________________<br />

Contact name ____________________________________________<br />

Fon ________________________ Fax _______________________<br />

Date _______________________ Signature ____________________<br />

Material to be machined: _____________________________________<br />

Special Grooving Inserts<br />

symmetrical<br />

b<br />

R<br />

Table of<br />

parameters<br />

Insert size<br />

groove<br />

width<br />

b<br />

groove<br />

depth<br />

a<br />

radius<br />

R<br />

chamfer<br />

angle<br />

<br />

a<br />

<br />

XQ12 18...<br />

XQ12 32...<br />

XQ12 44...<br />

1,60 – 2,65<br />

2,65 – 4,15<br />

4,15 – 5,80<br />

max. 2,2<br />

max. 3,2<br />

max. 5,2<br />

0,1 – 0,5<br />

30° – 60°<br />

max. 0,2<br />

Note: Dimensional relationship between width of groove,<br />

depth and chamfer angle.<br />

asymmetrical<br />

R1<br />

b<br />

R2<br />

Table of<br />

parameters<br />

Insert size<br />

groove<br />

width<br />

b<br />

groove<br />

depth<br />

a1 a2<br />

radius<br />

R1 / R2<br />

chamfer<br />

angle<br />

1 / 2<br />

a1<br />

1<br />

a2<br />

2<br />

XQ12 18...<br />

XQ12 32...<br />

XQ12 44...<br />

1,60 – 2,65<br />

2,65 – 4,15<br />

4,15 – 5,80<br />

2,5<br />

3,5<br />

5,5<br />

2,2<br />

3,2<br />

5,2<br />

0,0 –<br />

b<br />

2<br />

15° – 75°<br />

We require a cutting body with the following profile:<br />

symmetrical<br />

b = ________<br />

a = ________<br />

R = ________<br />

= ________<br />

asymmetrical<br />

b = ________<br />

a1 = ________<br />

a2 = ________<br />

R1 = ________<br />

R2 = ________<br />

1 = ________<br />

2 = ________<br />

Important: See page 10 for more application details !

Calculations for circular milling<br />

Note:<br />

The calculation for hm is made on the basic of the workpiece/tool geometry.<br />

The total cutting time must allow for the entry and exit times. Axial "chambering"<br />

is also possible with these interpolating milling cutters.<br />

The application details shown depend on the environmental and application<br />

conditions (e.g. machine, ambient temperature, use of lubricant/coolant and the<br />

machining result required). These are subject to correct operating conditions, correct<br />

application and compliance with the spindle speed limits given for the tools.<br />

Circular milling, internal<br />

R+ar–r<br />

ar<br />

s' 1<br />

180°–<br />

<br />

R<br />

r<br />

L<br />

AZ<br />

AT<br />

R = workpiece radius in mm<br />

r = milling cutter radius in mm<br />

ar = radial cutting depth in mm<br />

= approach angle in °<br />

hm = average chip thickness in mm<br />

n = spindle speed in min –1<br />

z = number of teeth (effectively cutting)<br />

cos (180° – ) =<br />

r 2 + (R + ar – r) 2 – R 2<br />

2r (R + ar –r)<br />

180° – <br />

L<br />

=<br />

× 2r × <br />

360°<br />

(mm)<br />

Approach length<br />

AZ<br />

=<br />

L × hm<br />

(mm 2 )<br />

Chip cross section<br />

AT<br />

=<br />

[ ( R + ar ) 2 – R 2 ]<br />

(mm 2 )<br />

Total surface cut<br />

t<br />

s' 1<br />

=<br />

=<br />

AT<br />

n × z × AZ<br />

× 2 ( R + ar – r )<br />

t<br />

(min)<br />

(mm/min)<br />

Cutting time for AT<br />

Feed speed tool centre<br />

10

1<br />

Circular milling, external<br />

AT<br />

s' 1<br />

AZ<br />

R<br />

r<br />

<br />

ar<br />

R+r–ar<br />

R = workpiece radius in mm<br />

r = milling cutter radius in mm<br />

ar = radial cutting depth in mm<br />

= approach angle in °<br />

hm = average chip thickness in mm<br />

n = spindle speed in min –1<br />

z = number of teeth (effectively cutting)<br />

cos () =<br />

r 2 + ( R + r – ar ) 2 – R 2<br />

2r ( R + r – ar )<br />

<br />

L<br />

=<br />

× 2r × <br />

360°<br />

(mm)<br />

Approach length<br />

AZ<br />

=<br />

L × hm<br />

(mm 2 )<br />

Chip cross section<br />

AT = [ R 2 – ( R – ar ) 2 ]<br />

AT<br />

t =<br />

n × z × AZ<br />

× 2 ( R + r – ar )<br />

s' 1<br />

=<br />

t<br />

(mm 2 )<br />

(min)<br />

(mm/min)<br />

Total surface cut<br />

Cutting time for AT<br />

Feed speed tool centre<br />

11

End milling cutter<br />

Cylindrical shank to DIN 1835 T1 B<br />

Instructions for slot milling see page 15<br />

Central coolant supply<br />

L<br />

L1<br />

a<br />

d h6<br />

d1<br />

y = number of inserts<br />

z = effective number of teeth for calculating vf<br />

Basic recommendation<br />

Insert<br />

for<br />

workpiece material<br />

Assembly parts<br />

Clamping screw<br />

Accessories<br />

Screwdriver<br />

Order No.<br />

F51 50251<br />

F51 50052<br />

F51 50062<br />

F51 50072<br />

F51 50082<br />

F51 50102<br />

d1<br />

9,5<br />

10,0<br />

12,0<br />

14,0<br />

16,0<br />

20,0<br />

d h6<br />

16<br />

16<br />

16<br />

16<br />

16<br />

20<br />

a<br />

9<br />

9<br />

9<br />

9<br />

9<br />

9<br />

L<br />

80<br />

80<br />

80<br />

80<br />

85<br />

90<br />

L1<br />

17<br />

17<br />

21<br />

23<br />

26<br />

26<br />

y<br />

1<br />

1<br />

1<br />

1<br />

2<br />

3<br />

z<br />

1<br />

1<br />

1<br />

1<br />

2<br />

3<br />

0,09<br />

0,09<br />

0,09<br />

0,10<br />

0,10<br />

0,18<br />

Order No.<br />

Size<br />

Q36 18000.01..<br />

ISO-Code<br />

APKT 1003PD-R ...<br />

P M K<br />

N S H<br />

Order No.<br />

Article<br />

N00 57321<br />

S2556-8IP<br />

1,28 Nm<br />

Order No.<br />

Article<br />

L05 00830<br />

8IP<br />

F51 50122<br />

F51 50162<br />

25,0<br />

32,0<br />

25<br />

25<br />

11<br />

11<br />

100<br />

100<br />

32<br />

42<br />

3<br />

4<br />

3<br />

4<br />

0,31<br />

0,35<br />

Q36 24000.02..<br />

APKT 1203PD-R ...<br />

N00 57341<br />

S3066-9IP<br />

2,25 Nm<br />

L05 00840<br />

9IP<br />

F51 50181<br />

40,0<br />

32<br />

15<br />

115<br />

40<br />

3<br />

3<br />

0,57<br />

Q36 38000.07..<br />

APKT 1605PD-R ...<br />

N00 57411<br />

S40101-15IP<br />

4,3 Nm<br />

L05 00860<br />

15IP<br />

For further details on selecting insert types, see KomPass chapter 7<br />

Supply includes: End milling cutter with assembly parts. Please order insert and accessories separately.<br />

Copaslip grease for screw should be included in first order. Order No. 4700100100.<br />

12

End milling cutter<br />

Cylindrical shank to DIN 1835 T1 B<br />

Instructions for slot milling see page 15<br />

Central coolant supply<br />

1<br />

L<br />

L1<br />

a<br />

d h6<br />

d1<br />

y = number of inserts<br />

z = effective number of teeth for calculating vf<br />

Basic recommendation<br />

Insert<br />

for<br />

workpiece material<br />

Assembly parts<br />

Clamping screw<br />

Accessories<br />

Screwdriver<br />

Order No.<br />

d1<br />

d h6<br />

a<br />

L<br />

L1<br />

y<br />

z<br />

Order No.<br />

Size<br />

ISO-Code<br />

P M K<br />

N S H<br />

Order No.<br />

Article<br />

Order No.<br />

Article<br />

F51 50410<br />

F51 50420<br />

F51 50460<br />

20<br />

25<br />

32<br />

20<br />

25<br />

32<br />

11<br />

11<br />

11<br />

126<br />

142<br />

182<br />

75<br />

85<br />

120<br />

2<br />

3<br />

3<br />

2<br />

3<br />

3<br />

0,24<br />

0,44<br />

0,91<br />

Q36 24000.02..<br />

APKT 1203PD-R ...<br />

N00 57341<br />

S3066-9IP<br />

2,25 Nm<br />

L05 00840<br />

9IP<br />

For further details on selecting insert types, see KomPass chapter 7<br />

Supply includes: End milling cutter with assembly parts. Please order insert and accessories separately.<br />

Copaslip grease for screw should be included in first order. Order No. 4700100100.<br />

Important: See page 57 for more application details !<br />

13

Copying End <strong>Milling</strong> Cutters<br />

Cylindrical shank to DIN 1835 T1 B<br />

L<br />

L1<br />

a<br />

d h6<br />

d1<br />

y = number of inserts<br />

z = effective number of teeth for calculating vf<br />

Basic recommendation<br />

Insert<br />

for<br />

workpiece material<br />

Assembly parts<br />

Clamping screw<br />

Accessories<br />

Screwdriver<br />

Order No.<br />

d1<br />

d h6<br />

a<br />

L<br />

L1<br />

y<br />

z<br />

Order No.<br />

Size<br />

ISO-Code<br />

P M K<br />

N S H<br />

Order No.<br />

Article<br />

Order No.<br />

Article<br />

F51 50620<br />

F51 50660<br />

25<br />

32<br />

25<br />

25<br />

11<br />

11<br />

100<br />

100<br />

32<br />

42<br />

3<br />

4<br />

3<br />

4<br />

0,30<br />

0,37<br />

Q36 24000.04..<br />

Q36 24000.05..<br />

Q36 24000.06..<br />

APKT 120316PD-R ...<br />

APKT 120324PD-R ...<br />

APKT 120332PD-R ...<br />

N00 57341<br />

S3066-9IP<br />

2,25 Nm<br />

L05 00840<br />

9IP<br />

For further details on selecting insert types, see KomPass chapter 7<br />

Supply includes: Copying end milling cutter with assembly parts. Please order insert and accessories separately.<br />

Copaslip grease for screw should be included in first order. Order No. 4700100100.<br />

14

Instructions for slot milling into the solid<br />

Because of the design of the end milling cutter and the special geometry of the insert,<br />

this tool is particularly suitable for producing feather key slots to DIN 138 and DIN 6885.<br />

For this purpose the tools are arranged with an allowance below the nominal diameter.<br />

The angles of entry given in the table are maximum values and should not be exceeded.<br />

1<br />

Two versions are used according to the slot length<br />

Single angled entry<br />

It it is not possible to obtain the required slot depth<br />

by a single entry, this is achieved by entering more<br />

than once.<br />

<br />

<br />

a<br />

<br />

<br />

<br />

d1<br />

slot length<br />

L<br />

Multiple entry<br />

It should be noted that there must be an allowance<br />

of 0,8 mm when the milling cutter is reversed. If this<br />

allowance is not made, the tool may be damaged or<br />

destroyed.<br />

0,8<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

a –0,8<br />

<br />

<br />

<br />

Max. angle of entry in<br />

relation to diameter d1<br />

d1<br />

L<br />

a<br />

max<br />

<br />

max<br />

9,5<br />

10,0<br />

11,5<br />

12,0<br />

13,5<br />

14,0<br />

15,5<br />

16,0<br />

17,5<br />

18,0<br />

19,5<br />

20,0<br />

25,0<br />

32,0<br />

32,0 (für F51 50171)<br />

40,0 (für F51 50181)<br />

91,5<br />

14,4<br />

12,8<br />

33,6<br />

56,8<br />

128,7<br />

128,7<br />

343,0<br />

156,0<br />

186,0<br />

8<br />

9<br />

9<br />

9<br />

9<br />

9<br />

9<br />

9<br />

15<br />

15<br />

5°<br />

32°<br />

35°<br />

15°<br />

9°<br />

4°<br />

4°<br />

1,4°<br />

5,5°<br />

3°<br />

Important: See page 57 for more application details !<br />

15

Chamfer milling cutter<br />

Cylindrical shank to DIN 1835 T1 B<br />

Reverse circular milling possible<br />

Central coolant supply<br />

L<br />

L1<br />

90°<br />

d h6<br />

d3<br />

d2<br />

d1<br />

y = number of inserts<br />

z = effective number of teeth for calculating vf<br />

Basic recommendation<br />

Insert<br />

for<br />

workpiece material<br />

Assembly parts<br />

Clamping screw<br />

Accessories<br />

Screwdriver<br />

Order No.<br />

d1<br />

d2<br />

d3<br />

d h6<br />

L<br />

L1<br />

y<br />

z<br />

Order No.<br />

Size<br />

ISO-Code<br />

P M K<br />

N S H<br />

Order No.<br />

Article<br />

Order No.<br />

Article<br />

F53 30110<br />

F53 30191<br />

19,6 11,5<br />

27,6 19,5<br />

11<br />

19<br />

16<br />

25<br />

80<br />

90<br />

29<br />

31<br />

1<br />

2<br />

1<br />

2<br />

0,10<br />

0,28<br />

Q09 18000.1703<br />

Q09 18000.1722<br />

Q09 18000.1787<br />

SPMT060304 P25M<br />

SPMT060304 K20<br />

SPMT060304 BK87<br />

N00 57221<br />

S2553-7IP<br />

0,9 Nm<br />

L05 00820<br />

7IP<br />

Supply includes: Chamfer milling cutter with assembly parts. Please order insert and accessories separately.<br />

Copaslip grease for screw should be included in first order. Order No. 4700100100.<br />

16

T-slot milling cutter<br />

Cylindrical shank to DIN 1835 T1 B and D<br />

Central coolant supply<br />

1<br />

L<br />

L1<br />

h<br />

d h6<br />

d2<br />

d1<br />

y = number of inserts<br />

z = effective number of teeth for calculating vf<br />

Basic recommendation<br />

Insert<br />

for<br />

workpiece material<br />

Assembly parts<br />

Clamping screw<br />

Accessories<br />

Screwdriver<br />

Order No.<br />

Article<br />

d1<br />

d2<br />

F51 60081<br />

17,5 9<br />

TNS.010.001.00<br />

F51 60101<br />

20,5 11<br />

TNC.012.001.00<br />

F51 60121<br />

23,5 13<br />

TNC.014.001.00<br />

F51 60151<br />

30,5 17<br />

TNC.018.001.00<br />

F51 60191<br />

37,5 21<br />

TNC.022.001.00<br />

F51 60231<br />

47,0 27<br />

TNC.028.001.00<br />

d h6<br />

h -0,1<br />

L<br />

16<br />

16<br />

25<br />

8,0<br />

9,0<br />

10,0<br />

80<br />

85<br />

95<br />

25<br />

32<br />

11,6 105<br />

16,0 115<br />

32 20,0 125<br />

L1<br />

25<br />

30<br />

32<br />

40<br />

50<br />

60<br />

y<br />

2<br />

2<br />

2<br />

4<br />

4<br />

4<br />

z<br />

1<br />

1<br />

1<br />

2<br />

2<br />

1<br />

0,09<br />

0,10<br />

0,26<br />

0,30<br />

0,53<br />

0,65<br />

Order No.<br />

Size<br />

Q09 13000.0103<br />

Q09 13000.0122<br />

Q15 18000.01..<br />

Q15 18000.0261<br />

Q15 32000.04..<br />

Q15 32000.0322<br />

Q09..<br />

Q15..<br />

ISO-Code<br />

SPGW050204 P25M<br />

SPGW050204 K20<br />

CPMT060304 ...<br />

CPMW060304 BK61<br />

CPMT09T308 ...<br />

CPMW09T308 K22<br />

P M K<br />

N S H<br />

Order No.<br />

Article<br />

N00 57221<br />

S2553-7IP<br />

0,9 Nm<br />

N00 57221<br />

S2553-7IP<br />

0,9 Nm<br />

N00 57261<br />

S3575-15IP<br />

2,8 Nm<br />

Order No.<br />

Article<br />

L05 00820<br />

7IP<br />

L05 00820<br />

7IP<br />

L05 00860<br />

15IP<br />

For further details on selecting insert types, see KomPass chapter 7<br />

Supply includes: T-slot milling cutter with assembly parts. Please order insert and accessories separately.<br />

Copaslip grease for screw should be included in first order. Order No. 4700100100.<br />

Important: See page 57 for more application details !<br />

17

Shell end face milling cutter<br />

Cylindrical shank to DIN 1835 T1 B<br />

Central coolant supply<br />

L<br />

L1<br />

a<br />

d h6<br />

d1<br />

y = number of inserts<br />

z = effective number of teeth for calculating vf<br />

Basic recommendation<br />

Insert<br />

for<br />

workpiece material<br />

Assembly parts<br />

Clamping screw<br />

Accessories<br />

Screwdriver<br />

Order No. d1 d h6<br />

a L L1<br />

F51 40300*<br />

F51 40310<br />

F51 40320<br />

F51 40360<br />

20<br />

20<br />

25<br />

32<br />

25<br />

25<br />

25<br />

32<br />

27<br />

18<br />

27<br />

26<br />

100<br />

90<br />

100<br />

110<br />

33<br />

24<br />

41<br />

49<br />

* only suitable for edge cutting<br />

y<br />

6<br />

4<br />

6<br />

12<br />

z<br />

2<br />

2<br />

2<br />

3<br />

0,26<br />

0,25<br />

0,29<br />

0,53<br />

Order No.<br />

Size<br />

Q36 18000.01..<br />

ISO-Code<br />

APKT 1003PD-R ...<br />

P M K<br />

N S H<br />

Order No.<br />

Article<br />

N00 57321<br />

S2556-8IP<br />

1,28 Nm<br />

For further details on selecting insert types, see KomPass chapter 7<br />

Order No.<br />

Article<br />

L05 00830<br />

8IP<br />

Supply includes: Shell end face milling cutter with assembly parts. Please order insert and accessories separately.<br />

Copaslip grease for screw should be included in first order. Order No. 4700100100.<br />

18

Grade Application<br />

Cutting Data<br />

With coated cutting materials we recommend the higher cutting speeds given.<br />

1<br />

Tool<br />

Carbide grade<br />

Unalloyed steel<br />

f z<br />

(mm)<br />

v c<br />

(m/min)<br />

Steel<br />

to 800 N/mm²<br />

f z<br />

(mm)<br />

v c<br />

(m/min)<br />

Steel<br />

over 800 N/mm²<br />

f z<br />

(mm)<br />

v c<br />

(m/min)<br />

Cast iron<br />

mid hardness<br />

f z<br />

(mm)<br />

v c<br />

(m/min)<br />

f z<br />

(mm)<br />

Aluminium<br />

v c<br />

(m/min)<br />

P25M, BK85<br />

0,08 - 0,35<br />

120 - 180<br />

0,08 - 0,30<br />

100 - 160<br />

0,05 - 0,20<br />

80 - 150<br />

Face milling cutter<br />

P40, BK87, BK64<br />

K20<br />

CK37<br />

SK44<br />

0,10 - 0,40<br />

0,10 - 0,25<br />

90 - 160<br />

180 - 350<br />

0,10 - 0,35<br />

0,10 - 0,35<br />

90 - 160<br />

160 - 280<br />

0,08 - 0,30<br />

55 - 100<br />

0,08 - 0,40<br />

0,07 - 0,40<br />

60 - 140<br />

250 - 500<br />

0,05 - 0,30<br />

0,10 - 0,15<br />

300 - 800<br />

300 -1000<br />

BK89<br />

0,05 - 0,60<br />

20 - 70<br />

0,05 - 0,50<br />

20 - 70<br />

0,05 - 0,30<br />

15 - 60<br />

90° Face milling<br />

cutter<br />

P25M, BK78, BK64<br />

BK68<br />

K10<br />

0,08 - 0,35<br />

0,08 - 0,35<br />

100 - 180<br />

100 - 180<br />

0,08 - 0,30<br />

0,08 - 0,30<br />

90 - 160<br />

90 - 160<br />

0,05 - 0,25<br />

0,05 - 0,25<br />

70 - 120<br />

70 - 120<br />

0,06 - 0,40<br />

0,06 - 0,40<br />

60 - 140<br />

60 - 140<br />

0,05 - 0,25<br />

0,05 - 0,25<br />

250 - 700<br />

250 - 700<br />

End<br />

milling cutter<br />

P25M, BK78, BK64<br />

BK68<br />

K10<br />

0,06 - 0,20<br />

0,06 - 0,20<br />

100 - 190<br />

100 - 190<br />

0,06 - 0,18<br />

0,06 - 0,18<br />

100 - 170<br />

100 - 170<br />

0,05 - 0,15<br />

0,05 - 0,15<br />

70 - 130<br />

70 - 130<br />

0,06 - 0,20<br />

0,06 - 0,20<br />

70 - 110<br />

70 - 110<br />

0,05 - 0,30<br />

0,05 - 0,30<br />

300 - 900<br />

300 - 900<br />

T-Slot milling<br />

cutter<br />

P25M<br />

P40, BK87<br />

K20<br />

0,04 - 0,10<br />

0,04 - 0,12<br />

100 - 180<br />

80 - 140<br />

0,04 - 0,10<br />

0,04 - 0,12<br />

90 - 150<br />

70 - 130<br />

0,05 - 0,12<br />

70 - 120<br />

0,10 - 0,30<br />

150 - 300<br />

Circular<br />

mill.cutter<br />

P25M<br />

K20<br />

0,08 - 0,25<br />

100 - 180<br />

0,08 - 0,20<br />

90 - 160<br />

0,06 - 0,15<br />

50 - 90<br />

0,10 - 0,25<br />

70 - 120<br />

0,08 - 0,30<br />

120 - 250<br />

Slot mill.<br />

cutter<br />

P25M, BK85<br />

K20<br />

0,07 - 0,17<br />

100 - 180<br />

0,07 - 0,15<br />

100 - 160<br />

0,05 - 0,15<br />

80 - 120<br />

0,08 - 0,25<br />

70 - 130<br />

0,07 - 0,25<br />

120 - 350<br />

Shell end face<br />

milling cutter<br />

P25M, BK78, BK64<br />

BK64<br />

K10<br />

0,08 - 0,35<br />

0,08 - 0,35<br />

100 - 180<br />

100 - 180<br />

0,08 - 0,30<br />

0,08 - 0,30<br />

90 - 160<br />

90 - 160<br />

0,05 - 0,25<br />

0,05 - 0,25<br />

70 - 120<br />

70 - 120<br />

0,06 - 0,40<br />

0,06 - 0,40<br />

60 - 140<br />

60 - 140<br />

0,05 - 0,25<br />

0,05 - 0,25<br />

250 - 700<br />

250 - 700<br />

P25M, BK60<br />

0,10 - 0,25<br />

100 - 200<br />

0,10 - 0,20<br />

100 - 180<br />

Countersinking<br />

tool<br />

P40, BK64<br />

K10<br />

BK61 (not for Al)<br />

0,10 - 0,25<br />

100 - 180<br />

0,10 - 0,20<br />

100 - 160<br />

0,10 - 0,15<br />

0,10 - 0,15<br />

100 - 160<br />

100 - 140<br />

0,15 - 0,30<br />

0,10 - 0,25<br />

80 - 140<br />

160 - 250<br />

0,10 - 0,25<br />

160 - 250<br />

Important: See page 57 for more application details !<br />

19

Shell end face milling cutter<br />

Location to DIN 6358 A<br />

Central coolant supply<br />

L<br />

L1<br />

d H7<br />

d1<br />

y = number of inserts<br />

z = effective number of teeth for calculating vf<br />

Basic recommendation<br />

Insert<br />

for<br />

workpiece material<br />

Assembly parts<br />

Clamping screw<br />

Accessories<br />

Screwdriver<br />

Order No.<br />

d1<br />

d H7<br />

L<br />

L1<br />

y<br />

z<br />

Order No.<br />

Size<br />

ISO-Code<br />

P M K<br />

N S H<br />

Order No.<br />

Article<br />

Order No.<br />

Article<br />

F51 42060<br />

F51 42080<br />

63<br />

80<br />

27<br />

32<br />

60<br />

70<br />

42<br />

55<br />

9<br />

16<br />

3<br />

4<br />

0,71<br />

0,39<br />

Q36 38000.07..<br />

APKT 1605PD-R ...<br />

N00 57411<br />

S40101-15IP<br />

4,3 Nm<br />

L05 00860<br />

15IP<br />

For further details on selecting insert types, see KomPass chapter 7<br />

Supply includes: Shell end face milling cutter with assembly parts. Please order insert and accessories separately.<br />

Copaslip grease for screw should be included in first order. Order No. 4700100100.<br />

20

90° Face milling cutter<br />

Location to DIN 6358 A<br />

1<br />

h<br />

a<br />

d H7<br />

d1<br />

y = number of inserts<br />

z = effective number of teeth for calculating vf<br />

Basic recommendation<br />

Insert<br />

for<br />

workpiece material<br />

Assembly parts<br />

Clamping screw<br />

Accessories<br />

Screwdriver<br />

Order No.<br />

F51 12040<br />

F51 12050<br />

F51 12060<br />

F51 12180<br />

d1<br />

40<br />

50<br />

63<br />

80<br />

d H7<br />

22<br />

22<br />

22<br />

27<br />

h<br />

40<br />

40<br />

40<br />

50<br />

a<br />

11<br />

11<br />

11<br />

11<br />

y<br />

4<br />

4<br />

5<br />

6<br />

z<br />

4<br />

4<br />

5<br />

6<br />

0,18<br />

0,28<br />

0,54<br />

1,19<br />

Order No.<br />

Size<br />

Q36 24000.02..<br />

ISO-Code<br />

APKT 1203PD-R ...<br />

P M K<br />

N S H<br />

Order No.<br />

Article<br />

N00 57341<br />

S3066-9IP<br />

2,25 Nm<br />

Order No.<br />

Article<br />

L05 00840<br />

9IP<br />

F51 12080<br />

F51 12100<br />

F51 12120<br />

80<br />

100<br />

125<br />

27<br />

32<br />

40<br />

50<br />

50<br />

63<br />

15<br />

15<br />

15<br />

5<br />

6<br />

7<br />

5<br />

6<br />

7<br />

1,13<br />

1,91<br />

4,00<br />

Q36 38000.07..<br />

APKT 1605PD-R ...<br />

N00 57411<br />

S40101-15IP<br />

4,3 Nm<br />

L05 00860<br />

15IP<br />

For further details on selecting insert types, see KomPass chapter 7<br />

Supply includes: Face milling cutter with assembly parts. Please order insert and accessories separately.<br />

Copaslip grease for screw should be included in first order. Order No. 4700100100.<br />

Important: See page 57 for more application details !<br />

21

Face milling cutter 45°<br />

Location to DIN 6358 A and B<br />

h<br />

45°<br />

a<br />

d H7<br />

d1<br />

d2<br />

y = number of inserts<br />

z = effective number of teeth for calculating vf<br />

Basic recommendation<br />

Insert<br />

for<br />

workpiece material<br />

Assembly parts<br />

Clamping screw<br />

Accessories<br />

Screwdriver<br />

Order No.<br />

Article<br />

F51 01040<br />

PFS.040.001.79<br />

F51 01050<br />

PFS.050.001.79<br />

F51 01060<br />

PFS.063.001.79<br />

F51 01080<br />

PFS.080.001.79<br />

d1<br />

40<br />

50<br />

63<br />

80<br />

d2<br />

53<br />

63<br />

76<br />

93<br />

d H7<br />

16<br />

22<br />

22<br />

27<br />

h<br />

40<br />

40<br />

40<br />

50<br />

a<br />

6<br />

6<br />

6<br />

6<br />

y<br />

3<br />

4<br />

4<br />

5<br />

z<br />

3<br />

4<br />

4<br />

5<br />

0,38<br />

0,46<br />

0,67<br />

1,17<br />

Order No.<br />

Size<br />

Q09 44000. ..<br />

ISO-Code<br />

SEHW 1204 ...<br />

P M K<br />

N S H<br />

Order No.<br />

Article<br />

N00 57301<br />

S45100-20IP<br />

6,25 Nm<br />

Order No.<br />

Article<br />

L05 00870<br />

20IP<br />

For further details on selecting insert types, see KomPass chapter 7<br />

Supply includes: Face milling cutter with assembly parts. Please order insert and accessories separately.<br />

Copaslip grease for screw should be included in first order. Order No. 4700100100.<br />

22

Calculation Information / Specific Cutting Force<br />

1<br />

Calculation Information<br />

ae = <strong>Milling</strong> width in mm<br />

ap = Cutting depth in mm<br />

b = Chip width in mm<br />

d1 = Tool diameter in mm<br />

fz = Feed/Tooth in mm<br />

n = Speed in min –1<br />

kc = Specific cutting force in N/mm²<br />

Pe = Power requirement in KW<br />

vc = Cutting speed in m/min<br />

vf = Feed rate in mm/min<br />

z = Tooth load<br />

= Working angle<br />

d1<br />

n<br />

f z<br />

v f<br />

b<br />

a p<br />

a e<br />

Feed rate:<br />

v f<br />

= f z<br />

× z × n (mm/min)<br />

Spindle speed:<br />

v<br />

n = c<br />

× 1000<br />

(min –1 )<br />

p × d<br />

Cutting speed:<br />

n × p × d1<br />

v c<br />

=<br />

1000<br />

Power requirement:<br />

a p<br />

× a e<br />

× v f<br />

× k<br />

P<br />

c<br />

e<br />

=<br />

60 × 10 6 × <br />

(m/min)<br />

(kW)<br />

Specific Cutting Force kc (N/mm²)<br />

Workpiece material<br />

Carbon steel 0,2% C<br />

0,45% C<br />

0,83% C<br />

Alloy steel<br />

Stainless steel ferritic<br />

martensitic<br />

austenitic<br />

Cast steel<br />

carbon<br />

alloy<br />

Malleable iron ferritic<br />

perlitic<br />

Grey cast iron low tensile strengh<br />

high tensile strengh alloy<br />

Spheroidal ferritic<br />

graphite cast iron perlitic<br />

Chill cast iron<br />

Brinell-hardness<br />

HB<br />

150<br />

190<br />

250<br />

up to 200<br />

200 - 250<br />

275 - 325<br />

325 - 375<br />

375 - 425<br />

425 - 475<br />

135 - 175<br />

175 - 225<br />

275 - 325<br />

375 - 425<br />

135 - 175<br />

up to 150<br />

150 - 200<br />

200 - 250<br />

250 - 300<br />

110 - 145<br />

200 - 250<br />

180<br />

250<br />

160<br />

250<br />

400<br />

Feed per tooth<br />

fz (mm)<br />

0,1 0,2<br />

0,3 0,4<br />

3200<br />

2700<br />

2450<br />

2300<br />

3550<br />

3000<br />

2750<br />

2550<br />

3900<br />

3300<br />

3000<br />

2800<br />

3550<br />

3000<br />

2750<br />

2550<br />

3900<br />

3300<br />

3000<br />

2800<br />

4300<br />

3600<br />

3300<br />

3100<br />

4600<br />

3900<br />

3600<br />

3300<br />

4850<br />

4100<br />

3750<br />

3500<br />

5000<br />

4300<br />

3900<br />

3700<br />

3100<br />

3600<br />

2350<br />

2200<br />

4150<br />

3500<br />

3200<br />

3000<br />

4700<br />

4000<br />

3650<br />

3400<br />

5300<br />

4500<br />

4100<br />

3850<br />

4150<br />

3500<br />

3200<br />

3000<br />

2850<br />

2400<br />

2200<br />

2050<br />

3150<br />

2650<br />

2400<br />

2250<br />

3400<br />

2900<br />

2650<br />

2450<br />

3700<br />

3200<br />

2900<br />

2700<br />

2000<br />

2000<br />

1400<br />

1800<br />

1500<br />

2250<br />

3500<br />

Important: See page 57 for more application details !<br />

23

Slot <strong>Milling</strong> Cutter<br />

Location hole to DIN 138<br />

Cutting width b<br />

adjustable from 7 mm +0,16 !<br />

b h11<br />

Base of slot<br />

straight<br />

d1<br />

F51 22041<br />

SFT.063.002.70<br />

F51 22051<br />

SFT.063.003.70<br />

F51 22111<br />

SFT.080.002.70<br />

F51 22121<br />

SFT.080.003.70<br />

F51 22171<br />

SFT.100.002.70<br />

F51 22181<br />

SFT.100.003.70<br />

F51 22191<br />

SFT.100.004.70<br />

F51 22221<br />

SFT.100.007.70<br />

d1<br />

63<br />

63<br />

80<br />

80<br />

100<br />

100<br />

100<br />

100<br />

125<br />

d2 d H7 b1 b2 C11 y<br />

b h11<br />

±0,02<br />

55<br />

55<br />

40<br />

40<br />

46<br />

46<br />

46<br />

46<br />

46<br />

22<br />

22<br />

27<br />

27<br />

32<br />

32<br />

32<br />

32<br />

32<br />

5<br />

6<br />

5<br />

6<br />

5<br />

6<br />

7<br />

10<br />

12<br />

5<br />

6<br />

5<br />

6<br />

5<br />

6<br />

8<br />

10<br />

12<br />

6<br />

6<br />

7<br />

7<br />

8<br />

8<br />

7<br />

8<br />

8<br />

8<br />

8<br />

10<br />

10<br />

14<br />

14<br />

10<br />

10<br />

12<br />

z<br />

4<br />

4<br />

5<br />

5<br />

7<br />

7<br />

5<br />

5<br />

6<br />

0,07<br />

0,09<br />

0,11<br />

0,14<br />

0,19<br />

0,24<br />

0,25<br />

0,31<br />

0,82<br />

b2 C11 d2 d H7 L05 00820<br />

b1 ±0,02<br />

y = number of inserts<br />

z = effective number of teeth for calculating vf<br />

Basic recommendation<br />

Insert<br />

for<br />

workpiece material<br />

Assembly parts Accessories<br />

Clamping Screwdriver<br />

screw<br />

Order No.<br />

F51 22331<br />

SFT.125.007.70<br />

Order No. No. of Base<br />

Size<br />

inserts of<br />

slot<br />

Q12 18000.01.. 4<br />

Q12 18000.02..<br />

Q12 18000.03..<br />

Q12 18000.04..<br />

Q12 18000.01..<br />

Q12 18000.02..<br />

Q12 18000.03..<br />

Q12 18000.04..<br />

Q12 18000.01..<br />

Q12 18000.02..<br />

Q12 18000.03..<br />

Q12 18000.04..<br />

Q12 32000.05..<br />

Q12 32000.06..<br />

Q12 32000.08..<br />

Q12 32000.09..<br />

Q12 32000.08..<br />

Q12 32000.09..<br />

4<br />

4<br />

4<br />

5<br />

5<br />

5<br />

5<br />

7<br />

7<br />

7<br />

7<br />

5<br />

5<br />

5<br />

5<br />

6<br />

6<br />

ISO-Code<br />

TCAA 1102ZZ R<br />

TCAA 1102ZZ L<br />

TCAA 1103ZZ R<br />

TCAA 1103ZZ L<br />

TCAA 1102ZZ R<br />

TCAA 1102ZZ L<br />

TCAA 1103ZZ R<br />

TCAA 1103ZZ L<br />

TCAA 1102ZZ R<br />

TCAA 1102ZZ L<br />

TCAA 1103ZZ R<br />

TCAA 1103ZZ L<br />

TNAA 16T3ZZ R<br />

TNAA 16T3ZZ L<br />

TNAA 1606ZZ R<br />

TNAA 1606ZZ L<br />

TNAA 1606ZZ R<br />

TNAA 1606ZZ L<br />

P M K<br />

N S H<br />

Order No.<br />

Article<br />

N00 57211<br />

S2542-8IP<br />

1,28 Nm<br />

N00 57221<br />

S2553-7IP<br />

0,9 Nm<br />

N00 57211<br />

S2542-8IP<br />

1,28 Nm<br />

N00 57221<br />

S2553-7IP<br />

0,9 Nm<br />

N00 57211<br />

S2542-8IP<br />

1,28 Nm<br />

N00 57221<br />

S2553-7IP<br />

0,9 Nm<br />

N00 57231<br />

S3056-8IP<br />

2,25 Nm<br />

N00 57271<br />

S3585-15IP<br />

2,8 Nm<br />

N00 57271<br />

S3585-15IP<br />

2,8 Nm<br />

Order No.<br />

Article<br />

L05 00830<br />

8IP<br />

7IP<br />

L05 00830<br />

8IP<br />

L05 00820<br />

7IP<br />

L05 00830<br />

8IP<br />

L05 00820<br />

7IP<br />

L05 00830<br />

8IP<br />

L05 00860<br />

15IP<br />

L05 00860<br />

15IP<br />

For further details on selecting insert types, see KomPass chapter 7<br />

Supply includes: Slot milling cutter with assembly parts.<br />

Please order insert, accessories, adjusting screw (Order no N00 70740) and hexagonal key (Order No. 1805007015) separately.<br />

Copaslip grease for screw should be included in first order. Order No. 4700100100.<br />

24

Slot <strong>Milling</strong> Cutter<br />

Location hole to DIN 138<br />

1<br />

Base of slot<br />

angled<br />

Base of slot<br />

straight<br />

L<br />

b h11<br />

Cutting width b<br />

adjustable from 8 mm +0,16 !<br />

Q12 32000.07..<br />

d1<br />

y = number of inserts<br />

z = effective number of teeth for calculating vf<br />

Order No.<br />

F51 21031<br />

SFT.063.006.01<br />

F51 21061<br />

SFT.080.015.01<br />

*F51 21071<br />

SFT.080.015.02<br />

F51 21111<br />

SFT.100.025.01<br />

*F51 21121<br />

SFT.100.025.02<br />

F51 21131<br />

SFT.100.025.03<br />

F51 21141<br />

SFT.100.025.04<br />

F51 21191<br />

SFT.125.035.01<br />

*F51 21201<br />

SFT.125.035.02<br />

d1<br />

63<br />

80<br />

80<br />

100<br />

100<br />

100<br />

100<br />

125<br />

125<br />

d2 d H7 L y<br />

b h11<br />

32<br />

40<br />

40<br />

48<br />

48<br />

48<br />

48<br />

58<br />

58<br />

16<br />

22<br />

22<br />

27<br />

27<br />

27<br />

27<br />

32<br />

32<br />

6<br />

6<br />

8<br />

6<br />

8<br />

10<br />

12<br />

6<br />

8<br />

32<br />

40<br />

40<br />

45<br />

45<br />

45<br />

45<br />

50<br />

50<br />

8<br />

10<br />

8<br />

14<br />

10<br />

10<br />

10<br />

18<br />

12<br />

z<br />

4<br />

5<br />

4<br />

7<br />

5<br />

5<br />

5<br />

9<br />

6<br />

0,20<br />

0,39<br />

0,41<br />

0,63<br />

0,67<br />

0,73<br />

0,20<br />

1,02<br />

1,23<br />

d2 d H7 L05 00820<br />

Basic recommendation<br />

Insert<br />

for<br />

workpiece material<br />

Assembly parts Accessories<br />

Clamping Screwdriver<br />

screw<br />

Order No. No. of Base ISO-Code P M K N S H Order No.<br />

inserts of<br />

Size<br />

slot<br />

Article<br />

Q12 18000.03.. 4 TCAA 1103ZZ R<br />

N00 57221<br />

Q12 18000.04.. 4 TCAA 1103ZZ L<br />

S2553-7IP<br />

0,9 Nm<br />

Q12 18000.03.. 5 TCAA 1103ZZ R<br />

N00 57221<br />

Q12 18000.04.. 5 TCAA 1103ZZ L<br />

S2553-7IP<br />

0,9 Nm<br />

Q12 32000.52.. 4 TNAA 1604ZZ R<br />

N00 57431<br />

Q12 32000.53.. 4 TNAA 1604ZZ L<br />

S3066-8IP<br />

2,25 Nm<br />

N00 57241<br />

Q12 32000.07.. 8 TNAA 1604ZZ N<br />

S3070-8IP<br />

2,25 Nm<br />

Q12 18000.03.. 7 TCAA 1102ZZ R<br />

N00 57221<br />

Q12 18000.04.. 7 TCAA 1102ZZ L<br />

S2553-7IP<br />

0,9 Nm<br />

Q12 32000.52.. 5 TNAA 16T3ZZ R<br />

N00 57431<br />

Q12 32000.53.. 5 TNAA 16T3ZZ L<br />

S3066-8IP<br />

2,25 Nm<br />

N00 57241<br />

Q12 32000.07.. 10 TNAA 1604ZZ N<br />

S3070-8IP<br />

2,25 Nm<br />

Q12 32000.08.. 5 TNAA 1606ZZ R<br />

N00 57271<br />

Q12 32000.09.. 5 TNAA 1606ZZ L<br />

S3585-15IP<br />

2,8 Nm<br />

Q12 32000.08.. 5 TNAA 1606ZZ R<br />

N00 57281<br />

Q12 32000.09.. 5 TNAA 1606ZZ L<br />

S3598-15IP<br />

2,8 Nm<br />

Q12 18000.03.. 9 TCAA 1102ZZ R<br />

N00 57221<br />

Q12 18000.04.. 9 TCAA 1102ZZ L<br />

S2553-7IP<br />

0,9 Nm<br />

Q12 32000.52.. 6 TNAA 16T3ZZ R<br />

N00 57431<br />

Q12 32000.53.. 6 TNAA 16T3ZZ L<br />

S3066-8IP<br />

2,25 Nm<br />

N00 57241<br />

Q12 32000.07.. 12 TNAA 1604ZZ N<br />

S3070-8IP<br />

2,25 Nm<br />

For further details on selecting insert types, see KomPass chapter 7<br />

Order No.<br />

Article<br />

7IP<br />

L05 00820<br />

7IP<br />

L05 00830<br />

8IP<br />

L05 00830<br />

8IP<br />

L05 00820<br />

7IP<br />

L05 00830<br />

8IP<br />

L05 00830<br />

8IP<br />

L05 00860<br />

15IP<br />

L05 00860<br />

15IP<br />

L05 00820<br />

7IP<br />

L05 00830<br />

8IP<br />

L05 00830<br />

8IP<br />

*Standard delivery: Screw N00 57431 for insert for straight base of slot<br />

Supply includes: Slot milling cutter with assembly parts.<br />

Please order insert, accessories, adjusting screw (Order no N00 70740) and hexagonal key (Order No. 1805007015) separately.<br />

Copaslip grease for screw should be included in first order. Order No. 4700100100.<br />

Important: See page 57 for more application details !<br />

25

Finishing, Facing and Corner <strong>Milling</strong> Cutters for HSC Operations<br />

Basic body<br />

Dimensions to DIN 8030<br />

Cartridges<br />

h<br />

Corner cartridge F51 34110<br />

30<br />

max. 4 0,1×45°<br />

10<br />

D<br />

d<br />

d1=<br />

63<br />

80<br />

100<br />

12<br />

6<br />

2<br />

1,8<br />

13,5<br />

15°<br />

1,8<br />

13,5<br />

0°30' +10<br />

15°<br />

Supply of basic body includes:<br />

Basic body incl. balancing screws and clamping screws already fitted.<br />

Cartridges not included.<br />

Facing cartridge F51 34120<br />

30<br />

max. 4<br />

10<br />

2<br />

75°<br />

0,5<br />

12<br />

6<br />

13<br />

75°<br />

0,1×45°<br />

1,8<br />

15° 15° 13<br />

Supply of cartridges includes:<br />

Cartridges without clamping screws.<br />

Clamping screw for cartridges: Order No. 5502406012<br />

Examples for ordering:<br />

Corner mill – complete tool Ø 63 mm, z = 3<br />

1 × basic body F51 02340<br />

3 × corner cartridge F51 34110<br />

Finishing cartridge F51 34130<br />

30<br />

10<br />

2<br />

6<br />

12<br />

75°<br />

13 13,5<br />

15°<br />

45°<br />

0,3<br />

2<br />

13,5<br />

R100<br />

Face milling cutter complete tool Ø 80 mm, z = 5<br />

1 × basic body F51 02350<br />

4 × facing cartridge F51 34120<br />

1 × finishing cartridge F51 34130<br />

Note:<br />

If the basic body and the cartridges are ordered together as shown in the order example, the tool is supplied fully assembled<br />

and adjusted. For safety reasons, only use holding screws as shown.<br />

Basic body<br />

Clamping screw<br />

Torque<br />

setting<br />

Cartridge with PCD insert<br />

Corner<br />

cartridge<br />

Facing<br />

cartridge<br />

Finishing<br />

cartridge<br />

Order No.<br />

F51 02340 1)<br />

F51 02350<br />

F51 02360<br />

d1<br />

63<br />

80<br />

100<br />

d<br />

22<br />

27<br />

32<br />

h<br />

48<br />

50<br />

50<br />

D<br />

61<br />

78<br />

98<br />

z<br />

3<br />

5<br />

6<br />

0,75<br />

0,57<br />

0,95<br />

Size<br />

M10<br />

M12<br />

M16<br />

<strong>Milling</strong> cutter<br />

arbor<br />

Order No.<br />

Order No.<br />

70 Nm F51 34110 F51 34120<br />

Order No.<br />

F51 34130<br />

1)<br />

basic steel body<br />

26

Technical Details<br />

1<br />

Special milling cutter features:<br />

Internal coolant supply<br />

applied with clamping screw provided<br />

Balance<br />

Balanced to DIN 69888 and additional screws for precision balancing<br />

Setting<br />

Secure adjusting screws for setting axial run-out on the milling head<br />

Cartridges<br />

PCD cartridges manufactured to high precision for maximum stability and perfect circular<br />

cutting movement<br />

<strong>Milling</strong> cutter body<br />

Manufactured from special aluminium alloy with high tensile strength, considerably reduced<br />

weight and excellent surface finish (Note 63 mm diameter body in steel)<br />

Secure srews<br />

Strong, high quality screws in hardened threaded inserts and with additional lateral<br />

screws<br />

Setting notes for combination finishing and facing cartridge:<br />

Facing cartridge<br />

Finishing cartridge<br />

Ø d1<br />

0,006 - 0,008<br />

Spindle speeds and cutting speeds<br />

<strong>Milling</strong> cutter diameter (mm)<br />

n (min –1 )<br />

Permissible maximum spindle speed<br />

v c (m/min)<br />

Permissible maximum cutting speed<br />

Important: See page 57 for more application details !<br />

27

PCD Drill Slot <strong>Milling</strong> Tool<br />

Outstanding tool features for maximum quality and long tool life:<br />

• Suitable for: internal circular milling, external circular milling, concentric drilling<br />

• internal coolant supply<br />

• solid carbide body<br />

1×D with solid carbide shank<br />

Drilling/milling depth up to 1×D,<br />

with coolant channels<br />

Shank Ø DIN 6535 Form HA<br />

l3<br />

l1<br />

l2<br />

d2<br />

d1<br />

2 cutting edges, 1 cutting edge over centre, straight fluted<br />

d1 l1 l2 l3 d2<br />

Order No.<br />

6 57 36 6 6 38390000000600<br />

8 63 36 8 8 38390000000800<br />

10 72 40 10 10 38390000001000<br />

12 83 45 12 12 38390000001200<br />

3 cutting edges, 1 cutting edge over centre, straight fluted<br />

16 90 48 16 16 38391000001600<br />

20 104 50 20 20 38391000002000<br />

2×D with solid carbide shank<br />

Drilling/milling depth up to 2×D,<br />

with coolant channels<br />

Shank Ø DIN 6535 Form HA<br />

l3<br />

l1<br />

l2<br />

d2<br />

d1<br />

2 cutting edges, 1 cutting edge over centre, straight fluted<br />

d1 l1 l2 l3 d2<br />

Order No.<br />

6 57 36 12 6 38392057000600<br />

8 63 36 16 8 38392063000800<br />

10 72 40 20 10 38392072001000<br />

12 83 45 24 12 38392083001200<br />

3 cutting edges, 1 cutting edge over centre, straight fluted<br />

16 90 48 32 16 38393090001600<br />

20 104 50 40 20 38393004002000<br />

28<br />

Cutting material: PCD

End mill HF<br />

2xD, 2 cutting edges, face cutting, spiral flutet<br />

1<br />

Drilling/milling depth up to 2×D,<br />

without coolant channels<br />

Shank Ø DIN 6535 Form HA<br />

Cutting material: solid carbide<br />

Cutting material:<br />

solid carbide<br />

ap = max. 1 x D<br />

l1<br />

ap<br />

l3<br />

l2<br />

d1<br />

d2<br />

ae<br />

ap<br />

2xD, 2 cutting edges, face cutting, spiral flutet<br />

DLC - HA<br />

ap = max. 2 x D<br />

ae = max. 0,5 x D<br />

d1 l1 l2 l3 d2<br />

Order No.<br />

6 57 36 12 6 78931057000600<br />

8 63 36 16 8 78931063000800<br />

10 72 40 20 10 78931072001000<br />

12 83 45 24 12 78931083001200<br />

Recommended cutting data<br />

D<br />

Cutting<br />

parameters<br />

Aluminium<br />

alloys<br />

Copper<br />

alloys<br />

Fibre-reinforced<br />

plastics<br />

6 mm<br />

vc ( m/min)<br />

fz ( mm/z)<br />

200 – 800<br />

0,04 – 0,08<br />

200 – 600<br />

0,04 – 0,08<br />

300 – 800<br />

0,04 – 0,10<br />

8 mm<br />

vc ( m/min)<br />

fz ( mm/z)<br />

200 – 800<br />

0,04 – 0,10<br />

200 – 800<br />

0,04 – 0,10<br />

400 – 1000<br />

0,04 – 0,15<br />

10 mm<br />

vc ( m/min)<br />

fz ( mm/z)<br />

400 – 1000<br />

0,04 – 0,12<br />

300 – 800<br />

0,04 – 0,12<br />

500 – 1500<br />

0,04 – 0,20<br />

12 mm<br />

vc ( m/min)<br />

fz ( mm/z)<br />

400 – 1500<br />

0,04 – 0,15<br />

300 – 1000<br />

0,04 – 0,15<br />

500 – 1500<br />

0,04 – 0,25<br />

16 mm<br />

vc ( m/min)<br />

fz ( mm/z)<br />

400 – 1500<br />

0,05 – 0,15<br />

300 – 1000<br />

0,05 – 0,15<br />

500 – 1500<br />

0,05 – 0,26<br />

20 mm<br />

vc ( m/min)<br />

fz ( mm/z)<br />

400 – 1500<br />

0,05 – 0,18<br />

300 – 1000<br />

0,04 – 0,18<br />

500 – 1500<br />

0,05 – 0,28<br />

Application example<br />

Tool:<br />

JEL drill slot milling cutter<br />

<strong>Milling</strong>:<br />

Material: AlZnMgCu 1,5<br />

Drilling:<br />

Coolant: Emulsion<br />

Task:<br />

Slot milling in aluminium profile<br />

Technology: n = 15 000 min -1<br />

Operation:<br />

v c<br />

= 471 m/min<br />

Important: See page 57 for more application details !<br />

f z<br />

= 0,1 mm/tooth<br />

f b<br />

= 0,2 mm/rev<br />

a e<br />

= 10 mm<br />

a p<br />

= 5 mm<br />

concentric boring<br />

followed by circular milling<br />

29

PCD end milling cutters<br />

L1<br />

L2<br />

with internal<br />

coolant supply<br />

d2<br />

D<br />

Shank Ø Tool length Cutt. edge length No. of cutt. edges<br />

D d2 L1 L2 Order. No<br />

12 12 90 18 2 490.05.001<br />

14 16 90 18 2 490.05.002<br />

16 16 100 18 2 490.05.003<br />

20 20 110 24 2 490.05.006<br />

20 20 110 24 4 490.05.004<br />

25 25 120 24 2 490.05.007<br />

25 25 120 24 4 490.05.005<br />

30<br />

Important: See page 57 for more application details !

1<br />

One standard end milling cutter with four PCD inserts<br />

opens up new dimensions when circular milling a pump<br />

housing in pressure cast aluminium in several planes.<br />

Long tool life increases production output 20-fold<br />

compared to conventional carbide tools. Our customers<br />

are impressed.<br />

With a cutting speed of v c<br />

up to 800 m/min and feeds<br />

per tooth of f z<br />

= 0,125 – 0,18 mm/tooth, central bores/<br />

shoulders and surfaces can be milled in one clamping<br />

set-up in the shortest possible time.<br />

• Suitable for<br />

• external circular milling<br />

• internal circular milling<br />

• machining shoulders and slots<br />

• For pre- and finish machining<br />

• Surfaces achievable up to R z<br />

6,3 µm<br />

• With internal coolant supply<br />

• Double insert tools for slot milling<br />

• Basic body in solid carbide<br />

• Possible cutting data:<br />

v c<br />

up to 5000 m/min<br />

f z<br />

= 0,05 to 0,2 mm/tooth<br />

31

Countersinking and Chamfering<br />

Page<br />

Countersinking Tool KWZ<br />

34 – 35<br />

Countersinking Tool KWS<br />

36 – 37<br />

Countersinking Tool SE<br />

38<br />

Countersinking Tool DSE<br />

38<br />

Countersinking Tool SEA<br />

38<br />

Countersinking Tool SX<br />

39<br />

Countersinking Tool SID<br />

39<br />

32

Programme summary – Countersinking<br />

Adaptors<br />

Catalogue "KomPass – Drilling" chapter 5<br />

Countersinking and Chamfering Tools<br />

Adaptors<br />

Adaptor sleeve HWD<br />

Weldon<br />

<br />

Countersinking Tool KWZ<br />

Page<br />

X 10-48 mm 34<br />

<br />

<br />

<br />

<br />

Countersinking Tool KWS<br />

X 16,5-37 mm 36<br />

2<br />

Spindle adaptor flange<br />

Collet holder SZV<br />

<br />

<br />

<br />

Countersinking Tool SE<br />

HSK Adaptor<br />

X 2-15 mm 38<br />

<br />

Countersinking Tool DSE<br />

X 1-4 mm 38<br />

Countersinking Tool SEA<br />

X 2-30 mm 38<br />

Countersinking Tool SX<br />

X 2,5-25 mm 39<br />

Countersinking Tool SID<br />

X 4,3-20 mm 39<br />

33

Countersinking and Chamfering Tools X 10 – 48 mm<br />

through hole blind hole uneven angled convex cross bore divided cut large hole offset stack plate drilling adjustable<br />

§ § § § § § X § X X<br />

§ very good $ good & possible: see technical notes, chapter 8 X not possible<br />

Countersinking Tool X 10 - 20 mm<br />

• central coolant supply from counterbore<br />

size F10 10040<br />

• shank design to DIN 1835/B T1 A and B.<br />

• for producing 90º counterbores to<br />

DIN 974 T1 for cap head screws.<br />

d<br />

L<br />

L1<br />

d1<br />

d2<br />

y = number of inserts = 1<br />

z = effective number of teeth for calculating v f = 1<br />

Rough bore x<br />

countersink<br />

depth<br />

d1 Article Order No. d2 d L L1 Order No. ISO-Code P M K N S H Order No.<br />

min<br />

max size<br />

Article<br />

10 KWZ-M5K1 F10 10020 5,3 16 80 10 0,09 W28 17010.0464 WOEX040204-01 BK64 §§ §§<br />

N00 55551<br />

M2,5×2,8-8IP<br />

11 KWZ-M6K1 F10 10030 6,4 16 80 11 0,10 W28 17010.0421 WOEX040204-01 K10 §§ 1,28 Nm<br />

15 KWZ-M8K1 F10 10040 8,4 16 80 15 0,10<br />

W29 24010.048425<br />

W29 24010.0421<br />

Basic recommendation Assembly parts Accessories<br />

Insert<br />

for<br />

Clamping Screwdriver<br />

workpiece material screw<br />

WOEX05T304-01 BK8425<br />

WOEX05T304-01 K10<br />

§§<br />

§§<br />

§§<br />

§§<br />

§§<br />

§§<br />

N00 55581<br />

M2,5×4,5-8IP<br />

1,28 Nm<br />

18 KWZ-M10K1 F10 10050 10,4 16 80 18 0,11 W29 24010.048425 WOEX05T304-01 BK8425<br />

N00 57511<br />

S/M2,5×7,2-8IP<br />

20 KWZ-M12K1 F10 10060 13 25 100 20 0,28 W29 24010.0421 WOEX05T304-01 K10<br />

1,28 Nm<br />

Supply includes: Countersinking tool with clamping screw. Please order inserts and accessories separately.<br />

Order No.<br />

Article<br />

L05 00830<br />

8IP<br />

L05 00830<br />

8IP<br />

L05 00830<br />

8IP<br />

Countersinking Tool X 24 - 48 mm<br />

• central coolant supply<br />

• shank design to DIN 1835/B T1 A and B.<br />

• for producing 90º counterbores to<br />

DIN 974 T1 for cap head screws.<br />

L<br />

L1<br />

d<br />

d1<br />

d2<br />

y = number of inserts = 2<br />

z = effective number of teeth for calculating v f = 2<br />

Rough bore x<br />

countersink<br />

depth<br />

Basic recommendation Assembly parts Accessories<br />

Insert<br />

for<br />

Clamping Screwdriver<br />

workpiece material screw<br />

d1 Article Order No. d2 d L L1 Order No. ISO-Code P M K N S H Order No.<br />

min<br />

max size<br />

Article<br />

24 KWZ-M14K2 F10 11070 15 25 100 24 0,29 W29 24010.048425 WOEX05T304-01 BK8425 §§ §§<br />

N00 57511<br />

S/M2,5×7,2-8IP<br />

26 KWZ-M16K2 F10 11080 17 25 100 26 0,31 W29 24010.0421 WOEX05T304-01 K10 §§ 1,28 Nm<br />

W29 34010.048425 WOEX06T304-01 BK8425<br />

30 KWZ-M18K2 F10 11090 19 25 100 30 0,34<br />

§§ §§<br />

N00 57521<br />

S/M3,5×7,3-10IP<br />

W29 34010.0421 WOEX06T304-01 K10 §§ 2,8 Nm<br />

Order No.<br />

Article<br />

L05 00830<br />

8IP<br />

L05 00850<br />

10IP<br />

33 KWZ-M20K2 F10 11100 21 25 100 33 0,36<br />

W29 42010.048425 WOEX080404-01 BK8425<br />

36 KWZ-M22K2 F10 11110 21 25 100 36 0,39<br />

W29 42010.0421 WOEX080404-01 K10<br />

40 KWZ-M24K2 F10 11120 25 25 100 40 0,45<br />

48 KWZ-M30K2 F10 11130 28 32 120 48 0,85<br />

W29 50010.048425<br />

W29 50010.0421<br />

WOEX100504-01 BK8425<br />

WOEX100504-01 K10<br />

§§<br />

§§<br />

§§<br />

§§<br />

§§<br />

§§<br />

Supply includes: Countersinking tool with clamping screw. Please order inserts and accessories separately.<br />

N00 57531<br />

S/M4,5×9-15IP<br />

6,25 Nm<br />

L05 00860<br />

15IP<br />

34

Technical Notes<br />

Guideline values for countersinking/chamfering<br />

Material group<br />

1.0<br />

2.0<br />

2.1<br />

P<br />

3.0<br />

4.0<br />

Strength Rm<br />

(N/mm 2 )<br />

# 500<br />

500-900<br />

< 500<br />

> 900<br />

> 900<br />

Hardness HB<br />

Material<br />

non-alloy steels<br />

non-alloy /<br />

low alloy steels<br />

lead alloys<br />

non alloy /<br />

low alloy steels: heat<br />

resostant structural,<br />

heat treated, nitride<br />

and tools steels<br />

high alloy steels<br />

F10 (KWZ)<br />

Material example<br />

material code/DIN<br />

St37-2/1.0037;<br />

9SMn28/1.0715;<br />

St44-2/1.0044<br />

St52-2 / 1.0050,<br />

C55 / 1.0525,<br />

16MnCr5 / 1.7131<br />

9SMnPb28 / 1.0718<br />

42CrMo4 / 1.7225,<br />

CK60 / 1.1221<br />

X6CrMo4 / 1.2341,<br />

X165CrMoV12/1.2601<br />

Cutting speed<br />

vc (m/min)<br />

180-240<br />

180-240<br />

160<br />

140<br />

120<br />

x 10 – 15<br />

0,06-0,12<br />

0,06-0,12<br />

0,06-<br />

0,12<br />

0,06-0,10<br />

0,04-<br />

0,08<br />

Max. feed<br />

f (mm/rev)<br />

x 18 – 20<br />

0,12-0,20<br />

0,12-0,20<br />

0,20<br />

0,18<br />

0,15<br />

x 24 – 30<br />

0,15-0,25<br />

0,25-0,40<br />

x 33 – 48<br />

0,20-0,30<br />

0,25-0,40<br />

0,20-<br />

0,30<br />

0,20-<br />

0,40<br />

0,20-0,35<br />

0,25-0,40<br />