Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

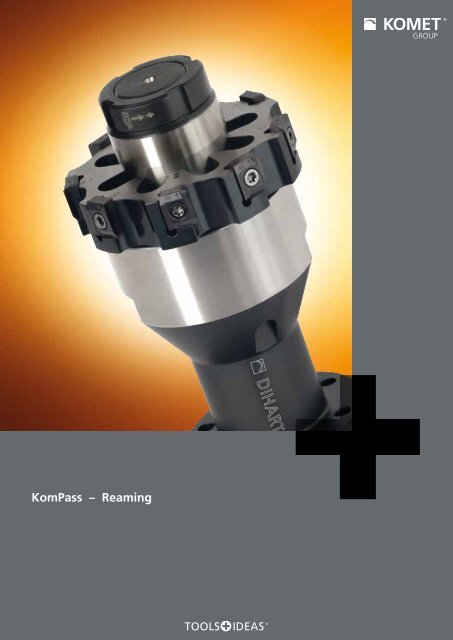

<strong>KomPass</strong> <strong>Reaming</strong> – Benefits for youAs a brand of the KOMET GROUP,DIHART® is convincing for its perfect reaming technologyto new dimensions.For the economic fine machining of bores, the comprehensivetool programme of standardised Monomax® monoblock tools,PCD reamers and tailor-made multiblade stepped reamers and onto customer-specific special tools, guarantees accurate, economicand reliable machining.Innovative solutions for fine bore machining:- Reamax® TS – Modular reaming system- <strong>Reaming</strong> with indexable insert technology- Compensating holder DAH® for µ-accurate concentricity

Programme Summary · Tool Selection4 – 9Reamax® TS10 – 211Reamax®22 – 292Monomax®30 – 393Solid Carbide Reamers40 – 454Duomax Cutting Ring46 – 615Special ToolsInsert <strong>Reaming</strong> TechnologyMicroSet System62 – 716DAH® Compensating HolderTaper shanks · HSK · ABS® · DPS72 – 837Informations, Cutting Data, Performance dataNumerical Index, KOMET SERVICE®84 – 10738

DIHART® – Innovative Solutions for Precision Finishing of BoresThe KOMET GROUP is a leading global provider of DIHART® reaming tools for the economical ultraprecisionmachining of bores. Our innovative solution potential, comprehensive performance range and personalcommitment are the basis for successful partnerships with our customers.For more than 60 years DIHART® has been synonymousfor high-precision reaming. We are successfully meetingthe increasing demand for customer-specific special solutionsand flexible standard tools we have been continuouslyexpanding our solution competency and our innovativeedge. Our leading market position is the result of consistentlyhigher quality and continuous development.The KOMET GROUP also offers the complete range of servicesinternationally. You can find us wherever you manufactureyour products with an exacting claim for quality.The standardised tool range and the customer-specificspecial tools guarantee precise, economical and reliablemachining.With new product and logistics concepts such as themodular high-speed reaming tools Reamax® TS, setsstandards especially in the standard range. Our knowledgeof customer-specific solutions offers unique perspectives.DIHART® is the brand of the KOMET GROUP for perfectreaming in new dimensions.4

DIHART® Tool SelectionThis selection aid guides you quicklyand easily to the tool system that issuitable for you requirements.DIHART® Tool SelectionExampleOur recommendation for a toolsystem suitable for you, whichtakes tolerance and diameter intoconsideration, can be found onpage 7.IT-ToleranceIT 5 – IT 6Tool recommendation 1,40 – 5,59 mm 5,60 – 11,99 mm 12,00 – 17,99 mm 18 – 40 mm 40 – 65 mm 65 – 110 mm1Example: Diameter 20 H7 to bemachined leads to Reamax® TStooling systemIT 7Solid carbidereamerSolid carbidereamerMonomax® Monomax® REAMAX® TS REAMAX® TSMonomax® REAMAX® REAMAX® TS REAMAX® TSDuomaxCutting ringDuomaxCutting ring2 IT 8Solid carbidereamerIT-Tolerance class see page 91Solid carbidereamerREAMAX® REAMAX® REAMAX® TSDuomaxCutting ring3Overview standard reamersAccording to the type of boreand material to be machined, youwill be guided to the appropriate/matching tool. The best cuttinggeometry (ASG) can be seen fromthe table "Tool recommendation"in each section.1DIHART REAMAX® TSTool RecommendationMaterial group1.02.0ToolREAMAX® TSStrength Rm (N/mm²)REAMAX®Monomax®expandable 500500-900Hardness HB 1,400 4,000 5,600 9,600 10,159 12,000 12,700 17,600 18,000 18,899 20,100 25,899 40,000 50,000 60,600 65,000 110,599 139,599 300,599Materialnon-alloy steelsnon-alloy /low alloy steelsMaterial examplematerial code/DINSt37-2 / 1.0037;9SMn28 / 1.0715;St44-2 / 1.0044St52-2 / 1.0050,C55 / 1.0525,16MnCr5 / 1.7131High-speed machiningTool attachementExampleCylindrical shankDAH®Cylindrical shankOrder No. Cutting Cutting Order No. Cutting Cuttinggeometry material/geometry material/(ASG) coating(ASG) Cylindrical coating shankMorse taper75J.93 ASG09 DST 75J.71 ASG09 TiN75J.93 ASG09 DST 75J.71 ASG09 TiNCylindrical shank456Example:Material:non-alloy steel St37Bore type: Through borePSSolid carbide < 500 reamerlead alloys9SMnPb28 / 1.0718 75J.93 ASG09 DST 75J.71 ASG09 TiN2.13.04.04.15.05.16.0> 90025042CrMo4 / 1.7225,CK60 / 1.1221 75J.93 ASG09 DST 75J.71 ASG3000 Cylindrical TiN shankRecommended cutting data: DAH®ABS®X6CrMo4 / 1.2341,X165CrMoV12 / 1.2601 75J.71Cutting ASG0106speed: TiN 75J.71 ASG0106 TiNInconel 718 / 2.4668,Nimonic 80A / 2.4631titanium,400 TiAl5Sn2 / 3.7114titanium alloys 600non alloy / low alloy steels:heat resistant structural,heat treated, nitride andtools steelsTool recommendation:DST Duomax cutting> 900 Cutting ring materialhigh alloy steelsOrder No.: 75J.93Cutting geometry: ASG09If you do not find aHSSstandard tool in this catalogue for your machining needs, we are happy to offer you a customer-specific tool.special alloys: Inconel,Hastelloy, Nimonic, stc.stainless steelsvc = 100 – 200 m/minFeed for x 18,000 mm:fz = 0,10 – 0,21 mm/toothX2CrNi189 / 1.4306,X5CrNiMo1810 / 1.4401 75J.47 ASG0106 DBF 75J.47 ASG0106 DBF78M6.1< 900stainless steelsX8CrNb17 / 1.4511,X10CrNiMoTi1810 / 1.4571 75J.47 ASG0106 DBF 75J.47 ASG0106 DBF7DIHART® Cutting Data7.0> 900stainless / fireproof steelsX10CrAl7 / 1.4713,X8CrS-38-18 / 1.4862 75J.47 ASG0106 DBF 75J.47 ASG0106 DBFExample DIHART® CuareasRecommended application areas8.0180 gray cast ironGG-25 / 0.6025,GG-35 / 0.6035 75J.37 ASG3000 DBG-N 75J.37 ASG3000 DBG-NRecommended applingaterialampleaterial code/N7-2 / 1.0037;n28 / 1.0715;4-2 / 1.00442-2 / 1.0050,/ 1.0525,nCr5 / 1.7131nPb28 / 1.071812HM250 alloy gray cast iron GG-NiCr202 / 0.6660 75J.37 ASG3000 DBG-N 75J.37 ASG3000 DBG-NFeedCutting speed vc (m/min)fz (mm/tooth)Guideline values for reamingCutting speed vc (m/min)(with face cut, feed reduced by 30%)(witspheroidal graphite cast 600 130 GGG-40 / 0.7040iron, ferritic75J.93 ASG3000 DST 75J.47 ASG3000 DBFstraight flutedstraight fluted straight fluted left hReamers short / 3×D Reamers long / 5×D Reamers short / 3×D GGG-50 Reamers / 0.7050 long / 5×DMaterialspheroidal graphite cast230GGG-55 ASG3000, / 0.7055 ASG0106, 75J.93 ASG03, ASG3000 ASG11, ASG1101 DST 75J.47 ASG09, ASG3000, ASG3000 ASG09B, ASG0106, DBF ASG1402 ASG03, ASG11, ASG110iron, ferritic / perliticexampleGTW-55 / 0.8055Materialmaterial code/spheroidal graphite castGGG-60 < / 0.7060 12 12 - 25 25 - 50 > 50 < 12 < 12 12- 25 1225 - 25 - 50 25 > - 50 > 50DIN> 600 250 iron, perliticGTS-65 / 0.8165 75J.93 ASG3000 DST 75J.47 ASG3000 DBFmalleable ironminmamamamamamamamamamamaxalloyed spheroidal graphite min-max min-max min-max min-max min-max min-max min-max min-max min-maxmin-min-min-min-min-min-min-min-min-min-min-min-minmamamamamamamaxmin-min-min-min-min-min-minmamaxmin-minmaxminmamamamaxmin-min-minmamax200 GGG-NiCr20-2 / 0.7661cast iron75J.37 ASG3000 DBG-N 75J.37 ASG3000 DBG-N60-100-6- 80- St37-2 60- / 1.0037; 80- 6- 100- 60-100-6- 80- 60-80- 500 non-alloy steels9SMn28 / 1.0715;0,05-0,10 0,07-0,15 0,09-0,20 0,10-0,25 0,07-0,14 0,05-0,10 0,10-0,21 0,07-0,15 0,12-0,24 0,09-0,20 0,13-0,30 0,10-0,214020010 160 St44-2 120 / 1.0044 160 10 200 14020010 GGV 160Ti < 120 0,2160300 vermicular cast ironGGV Ti > 0,2 75J.37 ASG3000 DBG-N 75J.37 ASG3000 DBG-N100- 60- 500- 100-6- 80- St52-2 60- / 1.0050,non-alloy /80- 6- 100- 60-100-6- 80- 60-80-C55 / 1.0525,copper alloy, brass,CuZn36Pb3 0,05-0,10 / 2.1182, 0,07-0,15 0,09-0,20 0,10-0,25200 140 900 200low alloy steels 10 160 16MnCr5 120 / 1.7131 160 10 200 140 90 lead-alloy 200 bronze, lead 10 160 120160G-CuPb15Sn / 2.1182 75J.93 ASG3000 DSTbronze: good cut0,07-0,1475J.710,05-0,10 0,10-0,21ASG30000,07-0,15 0,12-0,24TiN0,09-0,20 0,13-0,30 0,10-0,2100- 60-100-15- 80- 60-80- 15- 100- 60-copper 100-alloy, brass, bronze: 15- CuZn40Al1 80- 60- / 2.0550, 80-< 500 lead alloys9SMnPb28 / 1.0718100 average cutE-Cu57 0,05-0,10 / 2.0060 0,07-0,15 75J.71 0,09-0,20 ASG3000 0,10-0,25 TiN200 14020045 160 120160 45 200 14020045 160 1201600,07-0,14 75J.71 0,05-0,10 0,10-0,21 ASG3000 0,07-0,15 0,12-0,24 TiN 0,09-0,20 0,13-0,30 0,10-0,2DSTminmaxminmax6- 100-10 2006-1015-45Material TiN group6P1.02.02.13.0DBG-NStrengthRm (N/mm²)DBFHardness HBDJCDBCPCDHMDSTTiNDBG-NDBFDJC HMK8.19.09.110.0 DBC DST10.110.212.012.1rMo4 / 1.7225,60 / 1.1221 5-9 80- 60-> 900150 110non alloy / low alloy steels:80-heat resistant structural,5-9 80- 42CrMo4 60- / 1.7225, 80-150120 CK60 90 / 1.1221 5-9 80-heat treated, nitride and120 150N13.0PCD TiN60-110DBG-N60DBFDJCDBCPCDHMDSTTiNDBG-NDBFDJCDBCPCDAlMg1 / 3.3315,wrought 80- aluminium alloysAlMnCu / 3.0517 75J.17 ASG0706 DBC 75J.17 ASG0706 DBC5-9 80- 60-80-0,04-0,08 0,06-0,12 0,07-0,16 0,08-0,20 0,06-0,11 0,04-0,08 0,08-0,17 0,06-0,12 0,09-0,19 0,07-0,16 0,10-0,24 0,08-0,2150120 90120

DIHART® Tool SelectionIT-ToleranceTool recommendationx 1,40 – 5,59 mm x 5,60 – 11,99 mm x 12,00 – 17,99 mm x 18 – 40 mm x 40 – 65 mm x 65 – 110 mm1IT 5 – IT 6Solid carbidereamerMonomax® Monomax® Reamax® TS Reamax® TSDuomaxCutting ringIT 7Solid carbidereamerMonomax® Reamax® Reamax® TS Reamax® TSDuomaxCutting ring2M IT 8Solid carbidereamerIT-Tolerance class see page 91Solid carbidereamerReamax® Reamax® Reamax® TSDuomaxCutting ring3Overview standard reamersToolx 1,400x 4,000x 5,600x 9,600x 10,159x 12,000x 12,700x 17,600x 18,000x 18,899x 20,100x 25,899x 40,000x 50,000x 60,600x 65,000x 110,599x 139,599x 300,599Tool attachement4Cylindrical shankDAH®Reamax® TSCylindrical shank5Reamax®Monomax®expandableCylindrical shankMorse taper6Cylindrical shankSolid carbide reamerDuomax Cutting ringCylindrical shankDAH®ABS®7If you do not find a standard tool in this catalogue for your machining needs, we are happy to offer you a customer-specific tool.87

DIHART® Programme SummaryAdaptorsDAH® Compensating Holderwith HSK adaptor DIN 69893 AE 74HSK-A 40HSK-A 50HSK-A 63HSK-A 80HSK-A100DAH 63DAH 81DAH115DAH® Expanding chuckfor tools with cylindrical shankE 78DAH 63DAH 81x 12x 20x 3x 4x 5x 6x 8x 10x 12x 14x 16with ABS® adaptorE 74ABS 40ABS 50ABS 63DAH 81DAH115DAH® Adaptorfor tools with ABS® connectionE 78DAH 63DAH 81DAH115ABS 32ABS 40ABS 50ABS 63with taper shank DIN 69871 AD/BE 75SK 30SK 40SK 50DAH 63DAH 81DAH115with taper shank JIS B 6339 AD/BE 75SK 40SK 50DAH 63DAH 81DAH115DAH® 50 HS Compensating Holderwith HSK adaptor DIN 69893 AE 81HSK-A63x 20x 3x 4x 5x 6x 8x 10x 12x 14x 16DPS Floating Holderwith VDI connection DIN 69880E 82VDI 30VDI 40VDI 50x 3,01 – 20,00with taper shank DIN 69871 ADE 81SK 40x 20x 3x 4x 5x 6x 8x 10x 12x 14x 16with cylindrical shank similar to DIN 1835E 82x 25x 32x 25,4 (1")x 31,75 (1¼")x 3,01 – 20,00with taper shank JIS B 6339 ADE 81SK 40x 20x 3x 4x 5x 6x 8x 10x 12x 14x 168

DIHART® Programme Summary<strong>Reaming</strong> Toolsx 20x 25x 32Reamax® TS expandablex 18,000 – 65,000 mmHolder with cylindrical shank similar to DIN 1835PageE 161x 20x 25x 32x 18,000 – 41,999 mmDAH® Zero with cylindrical shank similar to DIN 1835x 35,000 – 65,000 mmABS 32 E 18Holder with ABS® connectionE 172DAH 81x 42,000 – 65,000 mmHolder with DAH® connectionE 19x 16x 20x 25x 32Reamax® solidx 12,000 – 40,000 mmHolder with cylindrical shank similar to DIN 1835E 273x 12x 16x 20Monomax® expandablex 5,600 – 25,899 mmwith cylindrical shank similar to DIN 1835E 344x 12x 16x 20x 5,600 – 25,899 mmwith cylindrical shank similar to DIN 1835E 36MK 2x 5,600 – 25,899 mmwith morse taper DIN 228 form AE 385x 3x 4x 6x 8x 10Solid Carbide Reamer solidx 1,400 – 12,700 mmwith cylindrical shank DIN 6535 HAE 44x 6x 8x 10x 4,800 – 12,700 mmwith cylindrical shank DIN 6535 HAE 456Duomax Cutting Ring expandablex 32x 40x 60,600 – 100,599 mmHolder with cylindrical shank similar to DIN 1835E 54DAH 81DAH115x 60,600 – 110,599 mmHolder with DAH® connectionE 557ABS 50ABS 63ABS 80x 60,600 – 110,599 mmHolder with ABS® connectionE 568cylindrical connection DAH® connection ABS® connection9

DIHART Reamax® TSTool RecommendationPage12 – 131<strong>Reaming</strong> HeadØ 18,000 – 65,000 mm 14 – 15HolderCylindrical shankDAH® ZeroABS® adaptorDAH® adaptorAssembly InstructionAssembly parts / Accessories1617181920 – 21212345Minimising setting timeThe radial clamping system allows thereaming tools to be changed withoutremoving the holder from the adaptor,reducing the setting time considerably.DIHART Reamax® TS provides maximumproduction reliability for the smallesttolerances.10 µUSL670 µxLSL-10 µ811

DIHART Reamax® TSTool Recommendation1Material groupStrength Rm (N/mm²)Hardness HBMaterialMaterial examplematerial code/DINOrder No.Cuttinggeometry(ASG)High-speed machiningCuttingmaterial/coatingOrder No.Cuttinggeometry(ASG)Cuttingmaterial/coating1.0m 500non-alloy steelsSt37-2 / 1.0037;9SMn28 / 1.0715;St44-2 / 1.004475J.93 ASG09 DST 75J.71 ASG09 TiN2.0500-900non-alloy /low alloy steelsSt52-2 / 1.0050,C55 / 1.0525,16MnCr5 / 1.713175J.93 ASG09 DST 75J.71 ASG09 TiN2.1< 500 lead alloys9SMnPb28 / 1.0718 75J.93 ASG09 DST 75J.71 ASG09 TiNP3.0> 900non alloy / low alloy steels:heat resistant structural,heat treated, nitride andtools steels42CrMo4 / 1.7225,CK60 / 1.1221 75J.93 ASG09 DST 75J.71 ASG3000 TiN4.0> 900high alloy steelsX6CrMo4 / 1.2341,X165CrMoV12 / 1.2601 75J.71 ASG0106 TiN 75J.71 ASG0106 TiN4.1HSS5.0250special alloys: Inconel,Hastelloy, Nimonic, stc.Inconel 718 / 2.4668,Nimonic 80A / 2.4631S5.1titanium,400 TiAl5Sn2 / 3.7114titanium alloys6.0m 600stainless steelsX2CrNi189 / 1.4306,X5CrNiMo1810 / 1.4401 75J.47 ASG0106 DBF 75J.47 ASG0106 DBFM6.1< 900stainless steelsX8CrNb17 / 1.4511,X10CrNiMoTi1810 / 1.4571 75J.47 ASG0106 DBF 75J.47 ASG0106 DBF7.0> 900stainless / fireproof steelsX10CrAl7 / 1.4713,X8CrS-38-18 / 1.4862 75J.47 ASG0106 DBF 75J.47 ASG0106 DBF8.0180gray cast ironGG-25 / 0.6025,GG-35 / 0.6035 75J.37 ASG3000 DBG-N 75J.37 ASG3000 DBG-N8.19.0250 alloy gray cast iron GG-NiCr202 / 0.6660 75J.37 ASG3000 DBG-N 75J.37 ASG3000 DBG-Nm 600 130spheroidal graphite castiron, ferriticGGG-40 / 0.7040 75J.93 ASG3000 DST 75J.47 ASG3000 DBFK9.110.0230> 600 250spheroidal graphite castiron, ferritic / perliticspheroidal graphite castiron, perliticmalleable ironGGG-50 / 0.7050GGG-55 / 0.7055GTW-55 / 0.805575J.93 ASG3000 DST 75J.47 ASG3000 DBFGGG-60 / 0.7060GTS-65 / 0.8165 75J.93 ASG3000 DST 75J.47 ASG3000 DBF10.1alloyed spheroidal graphite200 GGG-NiCr20-2 / 0.7661cast iron75J.37 ASG3000 DBG-N 75J.37 ASG3000 DBG-N10.2300vermicular cast ironGGV Ti < 0,2GGV Ti > 0,2 75J.37 ASG3000 DBG-N 75J.37 ASG3000 DBG-N12.090copper alloy, brass,lead-alloy bronze, leadbronze: good cutCuZn36Pb3 / 2.1182,G-CuPb15Sn / 2.1182 75J.93 ASG3000 DST 75J.71 ASG3000 TiN12.1100copper alloy, brass, bronze:average cutCuZn40Al1 / 2.0550,E-Cu57 / 2.0060 75J.71 ASG3000 TiN 75J.71 ASG3000 TiNN13.060wrought aluminium alloysAlMg1 / 3.3315,AlMnCu / 3.0517 75J.17 ASG0706 DBC 75J.17 ASG0706 DBC13.175cast aluminium alloy:Si-content 10%G-AlSi10Mg / 3.2381 75J.17 ASG0706 DBC 75J.17 ASG0706 DBC1400hardened steels< 45 HRC75J.37 ASG0106 DBG-N1800hardened steels> 45 HRC, m 55 HRC75J.37 ASG0106 DBG-NWe are happy to take inquiries concerning tools for materials without a recommendation.12Patented design

colophons, while two of them, numbered 26 and 173, do not (cat. 47, 48).A manuscript scribed by Ahmed Suhrawardi, one of Yaqut’s important agents,often referred to as the “Second Yaqut”, can also be found in the Museum ofTurkish and Islamic Art. The Qur’an that Müstakimzade mentioned in his book,“Tuhfe-i Hattatin” 44 , is today in the museum’s collection, recorded as number486. This work, dated 718/1318, was formerly preserved in the Haghia SophiaLibrary. The style and decoration of this Mushaf are strongly reminiscent of thetechnique of Yaqut (cat. 53).In the museum are two Mushafs scribed by Abdullah b. Mahmud al-Sayrafi,one of the followers of Yaqut. He learned calligraphy from one of Yaqut’s pupils,Seyyid Haydar Gundenuvis. However, he is numbered among the Ustâdân-ıSeb’a. 45 One of the works contains a colophon (inv. no. 178). The other is attributedto Abdullah Sayrafı, because of this sentence found at the end of the work: “Thismanuscript is believed to be the work of Abdullah Sayrafî Efendi, the teacher ofthe late Calligrapher Sheikh Hamdullah Efendi” (inv. no. 487, cat. 56).Another of the Seven Masters who followed in the footsteps of Yaqut wasErgun b. Abdullah al-Kamili, who learned Aqlam al-Sitta calligraphy from Yaquthimself. He died in the year AH.744/CE.1343. Two Mushafs scribed by Ergun b.Abdullah al-Kamili, complete with colophons, are recorded in the museum’sMushaf collection (inv. no. 202, 452, cat. 55).Very little is known about another of Yaqut’s followers, Yahya b. Nâsır al-Jamalial-Sufi. He is often confused with another calligrapher from Edirne named YahyaSufi, who lived during the time of Mehmed the Conqueror (inv. no. 430). 46Ali b. Malik al-Hafız al-Sebzvari was another of Yaqut’s important disciples. 47The fourth Mushaf that he wrote is found in the museum (inv. no. 490). 48An important Aqlam al-Sitta calligrapher of the Timurid Period, Shams al-Baysunghuri, was born in Herat. He wrote important works in the style of Yaqut.A magnificent Mushaf, a masterpiece of calligraphy and illumination, was scribedin the style of Yaqut, in naskh script (inv. no: 294, cat. 69). 4944 Tuhfe–i Hattatin: Calligraphers’ Paragon (Translator’s note)45 For more about his life see Ali Alparslan, “Abdullah–ı Sayrafî”, Türkiye Diyanet Vakfı İslamAnsiklopedisi, (DIA), Istanbul, Türkiye Diyanet Vakfı, 1988, v. I, p. 132.46 For more about this manuscript see Hat San’atı”, p. 189; Museum of Turkish and Islamic Art, p. 202– 203.47 For more about his life see Müstakimzade, p. 321– 322.48 Inv.no. 490. The Mushaf has 11 lines in naskh script to a page. There are no rosettes to mark thesections. The first page of the text is illuminated. The surah headings are scribed in gold leaf on a gildedbackground. There are a total of 386 folios. Page 385 (b) is the colophon which indicates this is the 4 thMushaf he scribed and that he hoped to scribe 100 more. The date on the Mushaf is 8 Dhu al–Qa‘dah,899/1494.49 Inv. no. 294 measures 26.4 x 35. 5 cm. and has 13 lines of naskh script per page. A total of 280 folios,the colophon indicates that it was scribed by the calligrapher, imitating of the style of Yaqut. It is dated22 Ramadan, 837/2 May 1434. According to inventory records, it was brought to the museum from the70

DIHART Reamax® TSDBCDBFDJFTiNHMDST<strong>Reaming</strong> Head – expandable12Holder with cylindrical shank similar to DIN 1835for X 18,000 – 65,000 mmA 16DAH® Zero Holder with cylindrical shank similar to DIN 1835for X 18,000 – 41,999 mmA 173Holder with ABS® connectionfor X 35,000 – 65,000 mmA 184Holder with DAH® connectionfor X 42,000 – 65,000 mmA 195DBF DBC DST DJFP M K N S H P M K N S H P M K N S H P M K N S H P M K N S H$ § § § $ 2) $ 3) § $ 2) $ 3) $$ $ § §Cutting geometry (ASG) Cutting geometry (ASG) Cutting geometry (ASG) Cutting geometry (ASG) Cutting geometry (ASG)for through holeASG 3000 ASG 0706 ASG 3000 machiningASG 09 ASG 30006Order No. Order No. Order No. Order No. Order No.75J.47.18H7N 75J.17.18H7G 75J.93.18H7N 75J.93.18H7L 75J.87.18H7N75J.47.20H7N 75J.17.20H7G 75J.93.20H7N 75J.93.20H7L 75J.87.20H7N75J.47.22H7N 75J.17.22H7G 75J.93.22H7N 75J.93.22H7L 75J.87.22H7N75J.47.24H7N 75J.17.24H7G 75J.93.24H7N 75J.93.24H7L 75J.87.24H7N75J.47.25H7N 75J.17.25H7G 75J.93.25H7N 75J.93.25H7L 75J.87.25H7N75J.47.28H7N 75J.17.28H7G 75J.93.28H7N 75J.93.28H7L 75J.87.28H7N75J.47.30H7N 75J.17.30H7G 75J.93.30H7N 75J.93.30H7L 75J.87.30H7N75J.47.32H7N 75J.17.32H7G 75J.93.32H7N 75J.93.32H7L 75J.87.32H7N75J.47.35H7N 75J.17.35H7G 75J.93.35H7N 75J.93.35H7L 75J.87.35H7N75J.47.40H7N 75J.17.40H7G 75J.93.40H7N 75J.93.40H7L 75J.87.40H7N75J.47.50H7N 75J.17.50H7G 75J.93.50H7N 75J.93.50H7L 75J.87.50H7N78Patented design15

DIHART Reamax® TSHolder with cylindrical shank similar to DIN 18351X 18,000 – 65,000 mmKwith internal coolant supplyPull studx Dx d h6bLcshort versionlong versionforforX D X D H7 Order No. L b c X d Order No. L b c X d18,000 – 19,999 18 H7 75A.40.13010 130 80 50 20 0,2 75A.40.15010 190 140 50 20 0,320,000 – 21,999 20 H7 75A.40.13020 130 80 50 20 0,2 75A.40.15020 190 140 50 20 0,322,000 – 26,99924 H7 75A.40.13030 130 80 50 20 0,3 75A.40.15030 210 160 50 20 0,422 H725 H727,000 – 34,99928 H7 75A.40.13040 176 120 56 25 0,5 75A.40.15040 236 180 56 25 0,730 H732 H735,000 – 41,99935 H7 75A.40.13050 176 120 56 25 0,6 75A.40.15050 256 200 56 25 1,040 H742,000 – 51,999 50 H7 75A.40.13060 180 120 60 32 0,9 75A.40.15060 280 220 60 32 1,552,000 – 65,000 75A.40.13070 180 120 60 32 1,0 75A.40.15070 280 220 60 32 1,0Supply includes:Reamax® TS holder with operating key, pull stud and open-end wrench (R page 21). Please order reaming head separately.16Patented design

DIHART Reamax® TSDAH® Zero Holder with cylindrical shank similar to DIN 1835X 18,000 – 41,999 mmwith internal coolant supply Kholder is pre-clamped and set to a concentricity of < 0.005 mm K1Pull studAdjustment screw2x Db (x 18,000 – 26,999)b (x 27,000 – 41,999)35 H735,000 – 41,99940 H7 75A.41.13050 176 120 56 25 0,5 75A.41.15050 256 200 56 25 1,05Lshort versionlong versionforforX D X D H7 Order No. L b c X d Order No. L b c X d18,000 – 19,999 18 H7 75A.41.13010 145 80 50 20 0,2 75A.41.15010 205 140 50 20 0,320,000 – 21,999 20 H7 75A.41.13020 145 80 50 20 0,3 75A.41.15020 205 140 50 20 0,422,000 – 26,99922 H724 H7 75A.41.13030 145 80 50 20 0,3 75A.41.15030 225 160 50 20 0,425 H727,000 – 34,99928 H730 H7 75A.41.13040 176 120 56 25 0,5 75A.41.15040 236 180 56 25 0,732 H7Supply includes:DAH® Zero holder with operating key, pull stud and open-end wrench (R page 21). Please order reaming head separately.cx d h634567817

DIHART Reamax® TSHolder with ABS® connection1X 35,000 – 65,000 mmKwith internal coolant supplyPull studx DABSx dXsABS®forforX D X D H7 Order No.Xs ABSX d35,000 – 41,99935 H7 75A.60.13050 110 32 0,4240 H742,000 – 51,999 50 H7 75A.60.13060 115 32 0,5352,000 – 65,000 75A.60.13070 125 40 0,83Supply includes:Reamax® TS holder with operating key, pull stud and open-end wrench (R page 21). Please order reaming head separately.18Patented design

DIHART Reamax® TSHolder with DAH® ConnectionX 42,000 – 65,000 mmwith internal coolant supply K1Pull stud2x DDAH81b3L4short versionlong versionforforX D X D H7 Order No. L b DAH Order No. L b DAH542,000 – 51,999 50 H7 75A.30.13060 138 120 81 0,9 75A.30.15060 238 220 81 1,552,000 – 65,000 75A.30.13070 138 120 81 1,0 75A.30.15070 238 220 81 2,0Supply includes:Reamax® TS holder with operating key, pull stud and open-end wrench (R page 21). Please order reaming head separately.DAH® compensation holder see chapter 7.67819

1DIHART Reamax® TSAssembly instructions5Clean taper/face contact thoroughly (grease free).Screw pull stud 5 into reaming head and tighten withopen-end wrench 6.63Open clamping jaws 2 with key 3.Insert reaming head 1.211M23Close clamping jaws 2with key 3, notingrecommended torque.When inserting the reaminghead 1 this is drawn intoits final position by closingthe clamping jaws 2.Dia.rangeStartingtorque M18,000 – 19,999 1,5 Nm20,000 – 21,999 2,5 Nm22,000 – 26,999 4 Nm27,000 – 34,999 5 Nm35,000 – 41,999 6 Nm42,000 – 51,999 10 Nm52,000 – 65,000 13 Nm23When removing the reaming head 1 this is pressed out ofits position by the clamping jaws 2 which allows it to beeasily removed from the holder: open the clamping jaws 2with the key 3, remove the reaming head 1.1Adjusting to compensate for wearThe smallest bore tolerances of up to IT4 can be achievedby readjusting with the hexagonal key 4.420Patented design

DIHART Reamax® TSOperating Instruction DAH® Zero12Adjusting:• Set the μm dial by adjusting the bezel position.• Determine the highest setting on the dial by turning thetool.• Turn the adjustment screw clockwise using an Allen key1, correcting the concentricity.Over tension by approx. 5 µm.• Engage the opposite adjustment screws 2 and driveback the tool by the specified overtension value.• Engage the two other adjustment screws.• Align all 4 adjustment screws until concentricity is < 2 µm.Please note:• Only unscrew the adjustment screws by a max of ½ to 1rotation.• Never use the holder without the reamer head clampedand then only when the adjustment screws aretightened.12343 4 5 6Operating keyLHexagonalkey*Assembly parts / AccessoriesPull studsOpen-end wrenchfor pull studsforforX D X D H7 Size Order No. L Starting Width across Order No. Width across Order No.torque M flatsflats18,000 – 19,999 18 H7 8IP L05 01240 1,5 Nm SW 4 15E.30.10010 SW 5 18589 1000520,000 – 21,999 20 H7 SW 2,5 18050 10025 100 2,5 Nm SW 5 15E.30.10020 SW 5 18589 100055622,000 – 26,99922 H7 SW 3 18050 10030 100 4 Nm SW 5 15E.30.10030 SW 6 18589 1000624 H725 H727,000 – 34,99935,000 – 41,99928 H7 SW 3 18050 10030 100 5 Nm SW 8 15E.30.10040 SW 8 18589 1000830 H732 H735 H7 SW 3 18050 10030 100 6 Nm SW 6 15E.30.10050 SW 10 18589 1001040 H742,000 – 51,999 50 H7 SW 4 18050 10040 100 10 Nm SW 8 15E.30.10050 SW 10 18589 1001052,000 – 65,000 SW 5 18050 10050 13 Nm SW 10 15E.30.10070 SW 13 18589 10013* not included in supply7821

BENEFITS for you:Precision ground for guaranteedqualityModular tool systemMaximum stability through tensilestress for the most demandingmachining tasksExtremely high repeatability througha tapered flat bearing faceExtremely high machiningperformance for the greatestefficiencyMinimum quantity lubrication (MQL)optimised for environmentallyfriendly useDIHART Reamax®Tool RecommendationReplaceable InsertØ 12,000 – 40,000 mmHolderCylindrical shankAssembly InstructionsAssembly parts / AccessoriesPage24 – 2526272829123Simple possible replacementThe DIHART Reamax® replaceable insertis fixed on to the tool holder with a tie-rodand a clamping nut. There is no need for timeand cost intensive setting to the final sizeas the inserts are manufactured specificallyfor each application to the exact diameterand tolerance. With DIHART Reamax®replacement time is no idle time.456Application:- All current materials- Through holes and blind bores- 3 × D and 5 × D- High speed – up to 300 m/min- Feed – up to 2.4 mm/rev7823

DIHART Reamax®Tool Recommendation1Material groupStrength Rm (N/mm²)Hardness HBMaterialMaterial examplematerial code/DINOrder No.Cuttinggeometry(ASG)High-speed machiningCuttingmaterial/coatingOrder No.Cuttinggeometry(ASG)Cuttingmaterial/coating21.02.0m 500500-900non-alloy steelsnon-alloy /low alloy steelsSt37-2 / 1.0037;9SMn28 / 1.0715;St44-2 / 1.0044St52-2 / 1.0050,C55 / 1.0525,16MnCr5 / 1.7131640.92 ASG05 DST 640.70 ASG05 TiN640.92 ASG05 DST 640.70 ASG05 TiN2.1< 500 lead alloys9SMnPb28 / 1.0718 640.92 ASG05 DST 640.70 ASG05 TiNP3.0> 900non alloy / low alloy steels:heat resistant structural,heat treated, nitride andtools steels42CrMo4 / 1.7225,CK60 / 1.1221 640.92 ASG05 DST 640.71 ASG3000 TiN4.0> 900high alloy steelsX6CrMo4 / 1.2341,X165CrMoV12 / 1.2601 640.70 ASG0106 TiN 640.71 ASG0106 TiN4.1HSS5.0250special alloys: Inconel,Hastelloy, Nimonic, stc.Inconel 718 / 2.4668,Nimonic 80A / 2.4631S5.1titanium,400 TiAl5Sn2 / 3.7114titanium alloys6.0m 600stainless steelsX2CrNi189 / 1.4306,X5CrNiMo1810 / 1.4401 640.49 ASG0106 DBF 640.49 ASG0106 DBFM6.1< 900stainless steelsX8CrNb17 / 1.4511,X10CrNiMoTi1810 / 1.4571 640.49 ASG0106 DBF 640.49 ASG0106 DBF7.0> 900stainless / fireproof steelsX10CrAl7 / 1.4713,X8CrS-38-18 / 1.4862 640.49 ASG0106 DBF 640.49 ASG0106 DBF8.0180gray cast ironGG-25 / 0.6025,GG-35 / 0.6035 640.37 ASG3000 DBG-N 640.37 ASG3000 DBG-N8.19.0250 alloy gray cast iron GG-NiCr202 / 0.6660 640.37 ASG3000 DBG-N 640.37 ASG3000 DBG-Nm 600 130spheroidal graphite castiron, ferriticGGG-40 / 0.7040 640.93 ASG3000 DST 640.37 ASG3000 DBG-NK9.110.0230> 600 250spheroidal graphite castiron, ferritic / perliticspheroidal graphite castiron, perliticmalleable ironGGG-50 / 0.7050GGG-55 / 0.7055GTW-55 / 0.8055640.93 ASG3000 DST 640.37 ASG3000 DBG-NGGG-60 / 0.7060GTS-65 / 0.8165 640.93 ASG3000 DST 640.37 ASG3000 DBG-N10.1alloyed spheroidal graphite200 GGG-NiCr20-2 / 0.7661cast iron640.37 ASG3000 DBG-N 640.37 ASG3000 DBG-N10.2300vermicular cast ironGGV Ti < 0,2GGV Ti > 0,2 640.37 ASG3000 DBG-N 640.37 ASG3000 DBG-N12.090copper alloy, brass,lead-alloy bronze, leadbronze: good cutCuZn36Pb3 / 2.1182,G-CuPb15Sn / 2.1182 640.93 ASG3000 DST 640.71 ASG3000 TiN12.1100copper alloy, brass, bronze:average cutCuZn40Al1 / 2.0550,E-Cu57 / 2.0060 640.71 ASG3000 TiN 640.71 ASG3000 TiNN13.060wrought aluminium alloysAlMg1 / 3.3315,AlMnCu / 3.0517 640.27 ASG0706 DBC 640.27 ASG0706 DBC13.175cast aluminium alloy:Si-content 10%G-AlSi10Mg / 3.2381 640.27 ASG0706 DBC 640.27 ASG0706 DBC1400hardened steels< 45 HRC640.37 ASG0106 DBG-N1800hardened steels> 45 HRC, m 55 HRC640.37 ASG0106 DBG-NWe are happy to take inquiries concerning tools for materials without a recommendation.24Patent applied for inside and outside Germany

High-speed machiningDIHART Reamax®Tool RecommendationConventional machining with carbide1Order No.Cuttinggeometry(ASG)Cuttingmaterial/coatingOrder No.Cuttinggeometry(ASG)Cuttingmaterial/coatingOrder No.Cuttinggeometry(ASG)CuttingmaterialOrder No.Cuttinggeometry(ASG)Cuttingmaterial640.93 ASG3000 DST 640.71 ASG3000 TiN 640.21 ASG3000 HM 640.21 ASG3000 HM640.93 ASG3000 DST 640.71 ASG3000 TiN 640.21 ASG02 HM 640.21 ASG02 HM2640.93 ASG3000 DST 640.71 ASG3000 TiN 640.21 ASG3000 HM 640.21 ASG3000 HM640.93 ASG3000 DST 640.71 ASG3000 TiN 640.21 ASG3000 HM 640.21 ASG3000 HM640.71 ASG0106 TiN 640.71 ASG0106 TiN 640.21 ASG0106 HM 640.21 ASG0106 HM3640.21 ASG03 HM 640.21 ASG03 HM640.49 ASG0106 DBF 640.49 ASG0106 DBF 640.21 ASG0106 HM 640.21 ASG0106 HM4640.49 ASG0106 DBF 640.49 ASG0106 DBF 640.21 ASG0106 HM 640.21 ASG0106 HM640.49 ASG0106 DBF 640.49 ASG0106 DBF 640.21 ASG0106 HM 640.21 ASG0106 HM640.37 ASG3000 DBG-N 640.37 ASG3000 DBG-N 640.21 ASG3000 HM 640.21 ASG3000 HM640.37 ASG3000 DBG-N 640.37 ASG3000 DBG-N 640.21 ASG3000 HM 640.21 ASG3000 HM640.93 ASG3000 DST 640.37 ASG3000 DBG-N 640.21 ASG02 HM 640.21 ASG02 HM5640.93 ASG3000 DST 640.37 ASG3000 DBG-N 640.21 ASG3000 HM 640.21 ASG3000 HM640.93 ASG3000 DST 640.37 ASG3000 DBG-N 640.21 ASG3000 HM 640.21 ASG3000 HM640.37 ASG3000 DBG-N 640.37 ASG3000 DBG-N 640.21 ASG3000 HM 640.21 ASG3000 HM640.37 ASG3000 DBG-N 640.37 ASG3000 DBG-N 640.21 ASG3000 HM 640.21 ASG3000 HM6640.93 ASG3000 DST 640.71 ASG3000 TiN 640.21 ASG0106 HM 640.21 ASG0106 HM640.71 ASG3000 TiN 640.71 ASG3000 TiN 640.21 ASG0106 HM 640.21 ASG0106 HM640.27 ASG0706 DBC 640.27 ASG0706 DBC 640.21 ASG02 HM 640.21 ASG02 HM640.27 ASG0706 DBC 640.27 ASG0706 DBC 640.21 ASG3000 HM 640.21 ASG3000 HM7640.27 ASG0706 DBC 640.27 ASG0706 DBC 640.21 ASG3000 HM 640.21 ASG3000 HM640.37 ASG0106 DBG-N640.37 ASG0106 DBG-NCutting speed and feed see pages 94 - 95.8Important: See chapter 8 for more application details and safety notes !25

DIHART Reamax®X 12,000 – 40,000 mm1Replaceable InsertK for through hole and blind hole machiningPlease note: don't use x 12,000 - 12,500 for blind hole machiningaa2x Dx Dx xfor through hole machiningCustom reaming head – selection options!fSelection: Cutting material, material, coolant supplyCutting material/ coatingSelection example: material St37, cutting material DST, central coolant supply,bore without interruption = Order No. 640.93Diameter H7 – available from stock!Selection: DimensionsX Dmin.diameterNo.for materialfor materialfor faceofmachiningteethOrder No. Order No. P M K N S H P M K N S HX x~a~f~640.66 640.67 DJC $ 2) 32,001-40,000 xD – 4,0 9,0 0,5 8640.20 640.21 HM § 1) § 1) § 1) § 1) § 1) § 1) § 1) § 1) § 1) § 1)12,000-15,999 xD – 2,5 9,0 0,5 6640.70 640.71 TiN $ $ § 4) $ § $ § 5) $640.36 640.37 DBG-N § $ $ § $16,000-21,999 xD – 3,0 9,0 0,5 6640.48 640.49 DBF $ § $ $ §22,000-25,999 xD – 3,0 9,0 0,5 8640.26 640.27 DBC § §640.92 640.93 DST § $ 3)26,000-32,000 xD – 4,0 9,0 0,5 8Selection example:Bore diameter 21 mmOrder example: Order No. 640.93 · Bore diameter 21 mm · Bore tolerance H6 · Material St37 or ASG3000 (Cutting geometry page 24-25)§ main area of application $ suitable in some casesCutting material / coatingfor materialwithout interruptionwith interruptionDBG-NDSTP M K N S H P M K N S H P M K N S H§ $ § $ 3) § $ 3)$ § $Cutting geometry (ASG) Cutting geometry (ASG) Cutting geometry (ASG)for through holeASG 3000 ASG 3000 machiningASG 09X D X x a f No. ofOrder No. Order No. Order No.~ ~ ~ teeth15 H7 12,5 9 0,5 6 640.37.15H7N 640.93.15H7N 640.93.15H7L16 H7 13 9 0,5 6 640.37.16H7N 640.93.16H7N 640.93.16H7L18 H7 15 9 0,5 6 640.37.18H7N 640.93.18H7N 640.93.18H7L20 H7 17 9 0,5 6 640.37.20H7N 640.93.20H7N 640.93.20H7L22 H7 19 9 0,5 6 640.37.22H7N 640.93.22H7N 640.93.22H7L24 H7 21 9 0,5 6 640.37.24H7N 640.93.24H7N 640.93.24H7L25 H7 22 9 0,5 8 640.37.25H7N 640.93.25H7N 640.93.25H7L28 H7 24 9 0,5 8 640.37.28H7N 640.93.28H7N 640.93.28H7L30 H7 26 9 0,5 8 640.37.30H7N 640.93.30H7N 640.93.30H7L261) conventional machining · 2) GJS (spheroidal graphite cast iron) · 3) material group 12.0 · 4) material group 12.1 · 5) material group 12.0&12.1

DIHART Reamax®Holder with cylindrical shank similar to DIN 1835X 12 – 40 mmwith internal coolant supply Ksuitable for minimum quantity lubrication (MQL) Knot suitable for shrinking K12x Dx d h6bLc34short versionlong versionforforX D X D H7 Order No. L b c X d Order No. L b c X d512,000 – 15,999 15 H7 640.01.001 107 3×D 48 16 0,11 640.81.001 137 5×D 48 16 0,1316,000 – 21,99922,000 – 25,99918 H7 640.01.002 119 3×D 50 20 0,18 640.81.002 169 5×D 50 20 0,2316 H720 H724 H7 640.01.003 140 3×D 56 25 0,34 640.81.003 196 5×D 56 25 0,4422 H725 H7626,000 – 32,00028 H7 640.01.005 160 3×D 56 25 0,46 640.81.005 226 5×D 56 25 0,6530 H732,001 – 40,000 640.01.006 199 3×D 60 32 0,86 640.81.006 270 5×D 60 32 1,13Supply includes: Reamax® holder with assembly parts / accessories (page 29). Please order replaceable insert separately.78Patent applied for inside and outside Germany27

DIHART Reamax®Assembly instructions15Clean taper/face contact thoroughly (grease free).Apply light grease on tie bar thread 5.2Locate tie bar 5 on insert and holder.Important note: for nominal size 3, 4 and 5, fit withmarking on tie bar and insert aligned.5M3Draw in tie bar with the clamping nut. Before tightening,turn insert and tie bar clockwise until it stops.Tighten the clamping nut as far as possible using thetorque key to the specified starting torque M.Dia.rangeStartingtorque M12,000 – 15,999 4-5 Nm16,000 – 21,999 6-7 Nm22,000 – 25,999 10-12 Nm26,000 – 32,000 18-20 Nm32,001 – 40,000 26-28 Nm3Removing the replaceable insert:Loosen the clamping screw.Pull tie bar from holder and insert.Locate operating key 3 in insert and loosen insert byturning.328Patent applied for inside and outside Germany

DIHART Reamax®Assembly parts / Accessories125 Replaceable insertHolder6 7 833 4Operating keyOpen-end wrenchLX D X D H7for forWidth Short version Long version Starting Width across Order No.across flats Order No. L Order No. L torque M flats12,000 – 15,999 15 H7 SW 4 18050 10040 100 18050 20040 200 4-5 Nm SW 12 18589 00012416,000 – 21,99922,000 – 25,99916 H7 SW 5 18050 10050 100 18050 35050 350 6-7 Nm SW 14 18589 0001418 H720 H722 H7 SW 7 18050 10070 100 18050 35070 350 10-12 Nm SW 19 18589 0001924 H725 H7526,000 – 32,00028 H7 SW 8 18050 10080 100 18050 35080 350 18-20 Nm SW 22 18589 0002230 H732,001 – 40,000 SW 10 18050 20100 200 18050 35100 350 26-28 Nm SW 27 18589 00027forX DforX D H75 6 7 8Tie bar Seeger ring Clamping nut Clamping nutDIN472short versionlong versionOrder No. Order No. Order No. Order No.612,000 – 15,999 15 H7 640.03.001 55232 01010 640.04.001 640.84.00116,000 – 21,99922,000 – 25,99916 H7 640.03.002 55232 01210 640.04.002 640.84.00218 H720 H722 H7 640.03.003 55232 01610 640.04.003 640.84.00324 H725 H7726,000 – 32,00028 H7 640.03.004 55232 01610 640.04.005 640.84.00530 H732,001 – 40,000 640.03.005 55232 02210 640.04.006 640.84.006Supply includes Reamax® holder: Operating key, open-end wrench, tie-rod, Seeger ring and clamping nut.829

DIHART Monomax®123DIHART Monomax®One-piece tools – known as monoblock tools – are one ofDIHART’s specialities. The demands which have been madeover decades are reflected in an enormous number of typesand variations. This successful tool programme has beencompletely revised and standardised by efficient manufacturing.BENEFITS for you:Designed for small hole diametersCan be adjusted for extremely small hole tolerancesExtremely high process reliability through monoconstructionPrecision ground to sizeApplication:- Non-alloy and low alloy steels- Stainless, heat resistant and high alloy steels- Grey cast iron and spheroidal graphite cast iron- Copper alloys, brass and bronze- Aluminium- Titanium, titanium alloys, CGI and plastic on requestVersions:- Short and long versions- Lateral and central coolant outlet for best possible use- Cutting materials, uncoated and coated carbide or DST- Diameter 5,600 – 25,899 mm30

DIHART Monomax®Tool RecommendationPage32 – 331Monomax®x 5,600 – 25,899 mmshort version with cylindrical shanklong version with cylindrical shanklong version with morse taper34 – 3536 – 3738234567831

DIHART Monomax®Tool Recommendation1Material groupStrength Rm (N/mm²)Hardness HBMaterialMaterial examplematerial code/DINOrder No.shortlongCuttinggeometry(ASG)High-speed machiningCuttingmaterial/coatingOrder No.shortlongCuttinggeometry(ASG)Cuttingmaterial/coating21.03P2.0m 500500-900non-alloy steelsnon-alloy /low alloy steelsSt37-2 / 1.0037;9SMn28 / 1.0715;St44-2 / 1.0044St52-2 / 1.0050,C55 / 1.0525,16MnCr5 / 1.713156J.9356R.9356J.9356R.93ASG09ASG09DSTDST56J.7156R.7156J.7156R.71ASG09ASG09TiNTiN2.1< 500 lead alloys9SMnPb28 / 1.071856J.9356R.93ASG09DST56J.7156R.71ASG09TiN4.0 3.0> 900> 900non alloy / low alloy steels:heat resistant structural,heat treated, nitride andtools steelshigh alloy steels42CrMo4 / 1.7225,CK60 / 1.1221X6CrMo4 / 1.2341,X165CrMoV12 / 1.260156J.9356R.9356J.7156R.71ASG09ASG0106DSTTiN56J.7156R.7156J.7156R.71ASG3000ASG0106TiNTiN4.1HSS5.0250special alloys: Inconel,Hastelloy, Nimonic, stc.Inconel 718 / 2.4668,Nimonic 80A / 2.4631S6.0 5.1M9.0 8.1 8.0 7.0 6.1K12.1 12.0 10.2 10.1 10.0 9.1HN16.0 15.0 14.0 13.1 13.0titanium,400 TiAl5Sn2 / 3.7114titanium alloysm 600< 900> 900180X2CrNi189 / 1.4306,X5CrNiMo1810 / 1.4401X8CrNb17 / 1.4511,X10CrNiMoTi1810 / 1.4571X10CrAl7 / 1.4713,X8CrS-38-18 / 1.4862GG-25 / 0.6025,GG-35 / 0.6035250 alloy gray cast iron GG-NiCr202 / 0.6660spheroidal graphite castm 600 130 GGG-40 / 0.7040iron, ferritic230> 600 25014001800GGG-50 / 0.7050GGG-55 / 0.7055GTW-55 / 0.8055GGG-60 / 0.7060GTS-65 / 0.8165alloyed spheroidal graphite200 GGG-NiCr20-2 / 0.7661cast iron300901006075stainless steelsstainless steelsstainless / fireproof steelsgray cast ironspheroidal graphite castiron, ferritic / perliticspheroidal graphite castiron, perliticmalleable ironvermicular cast ironcopper alloy, brass,lead-alloy bronze, leadbronze: good cutcopper alloy, brass, bronze:average cutwrought aluminium alloyscast aluminium alloy:Si-content 0,2CuZn36Pb3 / 2.1182,G-CuPb15Sn / 2.1182CuZn40Al1 / 2.0550,E-Cu57 / 2.0060AlMg1 / 3.3315,AlMnCu / 3.0517G-AlMg5 / 3.3561,G-AlSi9Mg / 3.2373cast aluminium alloy:100 G-AlSi10Mg / 3.2381Si-content > 10%hardened steels< 45 HRChardened steels> 45 HRC, m 55 HRC56J.4756R.4756J.4756R.4756J.4756R.4756J.3756R.3756J.3756R.3756J.9356R.9356J.9356R.9356J.9356R.9356J.3756R.3756J.3756R.3756J.9356R.9356J.7156R.7156J.1756R.1756J.1756R.1756J.1756R.1756J.3756R.3756J.3756R.37ASG0106ASG0106ASG0106ASG3000ASG3000ASG3000ASG3000ASG3000ASG3000ASG3000ASG3000ASG3000ASG0706ASG0706ASG0706ASG0106ASG0106DBFDBFDBFDBG-NDBG-NDSTDSTDSTDBG-NDBG-NDSTTiNDBCDBCDBCDBG-NDBG-N56J.4756R.4756J.4756R.4756J.4756R.4756J.3756R.3756J.3756R.3756J.3756R.3756J.3756R.3756J.3756R.3756J.3756R.3756J.3756R.3756J.7156R.7156J.7156R.7156J.1756R.1756J.1756R.1756J.1756R.17ASG0106ASG0106ASG0106ASG3000ASG3000ASG3000ASG3000ASG3000ASG3000ASG3000ASG3000ASG3000ASG0706ASG0706ASG0706DBFDBFDBFDBG-NDBG-NDBG-NDBG-NDBG-NDBG-NDBG-NWe are happy to take inquiries concerning tools for materials without a recommendation.TiNTiNDBCDBCDBC32

123456783356H.9356Q.93ASG3000DST56H.7156Q.71ASG3000TiN56J.2156R.21ASG3000HM56H.2156Q.21ASG3000HM56H.9356Q.93ASG3000DST56H.7156Q.71ASG3000TiN56J.2156R.21ASG02HM56H.2156Q.21ASG02HM56H.9356Q.93ASG3000DST56H.7156Q.71ASG3000TiN56J.2156R.21ASG3000HM56H.2156Q.21ASG3000HM56H.9356Q.93ASG3000DST56H.7156Q.71ASG3000TiN56J.2156R.21ASG3000HM56H.2156Q.21ASG3000HM56H.7156Q.71ASG0106TiN56H.7156Q.71ASG0106TiN56J.2156R.21ASG0106HM56H.2156Q.21ASG0106HM56J.2156R.21ASG03HM56H.2156Q.21ASG03HM56H.4756Q.47ASG0106DBF56H.4756Q.47ASG0106DBF56J.2156R.21ASG0106HM56H.2156Q.21ASG0106HM56H.4756Q.47ASG0106DBF56H.4756Q.47ASG0106DBF56J.2156R.21ASG0106HM56H.2156Q.21ASG0106HM56H.4756Q.47ASG0106DBF56H.4756Q.47ASG0106DBF56J.2156R.21ASG0106HM56H.2156Q.21ASG0106HM56H.3756Q.37ASG3000DBG-N56H.3756Q.37ASG3000DBG-N56J.2156R.21ASG3000HM56H.2156Q.21ASG3000HM56H.3756Q.37ASG3000DBG-N56H.3756Q.37ASG3000DBG-N56J.2156R.21ASG3000HM56H.2156Q.21ASG3000HM56H.9356Q.93ASG3000DST56H.3756Q.37ASG3000DBG-N56J.2156R.21ASG02HM56H.2156Q.21ASG02HM56H.9356Q.93ASG3000DST56H.3756Q.37ASG3000DBG-N56J.2156R.21ASG3000HM56H.2156Q.21ASG3000HM56H.9356Q.93ASG3000DST56H.3756Q.37ASG3000DBG-N56J.2156R.21ASG3000HM56H.2156Q.21ASG3000HM56H.3756Q.37ASG3000DBG-N56H.3756Q.37ASG3000DBG-N56J.2156R.21ASG3000HM56H.2156Q.21ASG3000HM56H.3756Q.37ASG3000DBG-N56H.3756Q.37ASG3000DBG-N56J.2156R.21ASG3000HM56H.2156Q.21ASG3000HM56H.9356Q.93ASG3000DST56H.7156Q.71ASG3000TiN56J.2156R.21ASG0106HM56H.2156Q.21ASG0106HM56H.7156Q.71ASG3000TiN56H.7156Q.71ASG3000TiN56J.2156R.21ASG0106HM56H.2156Q.21ASG0106HM56H.1756Q.17ASG0706DBC56H.1756Q.17ASG0706DBC56J.2156R.21ASG02HM56H.2156Q.21ASG02HM56H.1756Q.17ASG0706DBC56H.1756Q.17ASG0706DBC56J.2156R.21ASG3000HM56H.2156Q.21ASG3000HM56H.1756Q.17ASG0706DBC56H.1756Q.17ASG0706DBC56J.2156R.21ASG3000HM56H.2156Q.21ASG3000HM56H.3756Q.37ASG0106DBG-N56H.3756Q.37ASG0106DBG-NDIHART Monomax®Tool RecommendationHigh-speed machiningOrder No.shortlongCuttinggeometry(ASG)Cuttingmaterial/coatingOrder No.shortlongCuttinggeometry(ASG)Cuttingmaterial/coatingConventional machining with carbideOrder No.shortlongCuttinggeometry(ASG)CuttingmaterialOrder No.shortlongCuttinggeometry(ASG)CuttingmaterialImportant: See chapter 8 for more application details and safety notes !Cutting speed and feed see pages 94 - 95.

DIHART Monomax®X 5,600– 25,899 mmShort version with cylindrical shank similar to DIN 18351K with internal coolant supply2ax Dx d h63fbLcDiameter H7 – available from stock!Cutting material / coatingfor materialwithout interruptionwith interruptionTiNP M K N S H P M K N S H$ $ $ 4) $ $ $ $ 4) $§ $ $ 5) $ § $ $ 5) $Cutting geometry (ASG) Cutting geometry (ASG)for through holeASG 3000 machiningASG 09X D X d × c L b f a No. ofOrder No.Order No.~ ~ teeth6 H7 12 × 45 85 40 0,1 9,5 4 56J.71.06H7N 56J.71.06H7L8 H7 12 × 45 85 40 0,1 9,5 4 56J.71.08H7N 56J.71.08H7L10 H7 12 × 45 95 50 0,1 9,5 6 56J.71.10H7N 56J.71.10H7L12 H7 12 × 45 95 50 0,1 9,5 6 56J.71.12H7N 56J.71.12H7L14 H7 12 × 45 95 50 0,1 9,5 6 56J.71.14H7N 56J.71.14H7L15 H7 12 × 45 95 50 0,1 9,5 6 56J.71.15H7N 56J.71.15H7L16 H7 16 × 50 100 50 0,1 9,5 6 56J.71.16H7N 56J.71.16H7L18 H7 16 × 50 100 50 0,1 9,5 6 56J.71.18H7N 56J.71.18H7L20 H7 20 × 60 120 60 0,1 9,5 6 56J.71.20H7N 56J.71.20H7L1) conventional machining · 2) GJS (spheroidal graphite cast iron) · 3) material group 12.0 · 4) material group 12.1 · 5) material group 12.0&12.134

DIHART Monomax®Short version with cylindrical shank similar to DIN 18351Custom reaming tool – selection options!Selection: Cutting material, material, coolant supplySelection: Dimensions2Cutting material/ coatingfor materialfor materialOrder No. Order No. P M K N S H P M K N S H X D Xd×c L b f a~ ~56J.21 56H.21 HM § 1) § 1) § 1) § 1) § 1) § 1) § 1) § 1) § 1) § 1)5,600-8,899 12×45 85 40 0,1 9,5 456J.71 56H.71 TiN $ $ $ 4) $ § $ $ 5) $8,900-15,899 12×45 95 50 0,1 9,5 656J.37 56H.37 DBG-N $ $ $ $ $56J.47 56H.47 DBF $ § $ $ §15,900-18,899 16×50 100 50 0,1 9,5 656J.17 56H.17 DBC § §18,900-25,899 20×60 120 60 0,1 9,5 656J.93 56H.93 DST § § 3)56J.67 56H.67 DJC $ 2) 18,900-25,899 20×60 200 140 0,1 9,5 6Selection example: material St37, cutting material DST, central coolant supply,bore without interruption = Order No. 56H.93CylindricalshankSelection example:Bore diameter 24 mmOrder example: Order No. 56H.93 · Bore diameter 24 mm · Bore tolerance H6 · Material St37 or ASG09 (Cutting geometry page 32-33)§ main area of application $ suitable in some casesNo.ofteeth34DBG-N DBF DSTP M K N S H P M K N S H P M K N S H P M K N S H$ $ $ § § § 3) § § 3)5$ $ $ $ $ §Cutting geometry (ASG) Cutting geometry (ASG) Cutting geometry (ASG) Cutting geometry (ASG)for through holeASG 3000 ASG 3000 ASG 3000 machiningASG 09Order No. Order No. Order No. Order No.56J.37.06H7N 56J.47.06H7N 56J.93.06H7N 56J.93.06H7L56J.37.08H7N 56J.47.08H7N 56J.93.08H7N 56J.93.08H7L56J.37.10H7N 56J.47.10H7N 56J.93.10H7N 56J.93.10H7L56J.37.12H7N 56J.47.12H7N 56J.93.12H7N 56J.93.12H7L56J.37.14H7N 56J.47.14H7N 56J.93.14H7N 56J.93.14H7L56J.37.15H7N 56J.47.15H7N 56J.93.15H7N 56J.93.15H7L56J.37.16H7N 56J.47.16H7N 56J.93.16H7N 56J.93.16H7L56J.37.18H7N 56J.47.18H7N 56J.93.18H7N 56J.93.18H7L56J.37.20H7N 56J.47.20H7N 56J.93.20H7N 56J.93.20H7L67835

DIHART Monomax®X 5,600– 25,899 mmLong version with cylindrical shank similar to DIN 18351Kwith internal coolant supply2ax Dx d h63fbLcDiameter H7 – available from stock!Cutting material / coatingfor materialwithout interruptionwith interruptionTiNP M K N S H P M K N S H$ $ $ 4) $ $ $ $ 4) $§ $ $ 5) $ § $ $ 5) $Cutting geometry (ASG) Cutting geometry (ASG)for through holeASG 3000 machiningASG 09X D X d × c L b f a No. ofOrder No.Order No.~ ~ teeth6 H7 12 × 45 130 85 0,1 9,5 4 56R.71.06H7N 56R.71.06H7L8 H7 12 × 45 130 85 0,1 9,5 4 56R.71.08H7N 56R.71.08H7L10 H7 12 × 45 160 115 0,1 9,5 6 56R.71.10H7N 56R.71.10H7L12 H7 12 × 45 160 115 0,1 9,5 6 56R.71.12H7N 56R.71.12H7L14 H7 12 × 45 160 115 0,1 9,5 6 56R.71.14H7N 56R.71.14H7L15 H7 12 × 45 160 115 0,1 9,5 6 56R.71.15H7N 56R.71.15H7L16 H7 16 × 50 180 130 0,1 9,5 6 56R.71.16H7N 56R.71.16H7L18 H7 16 × 50 180 130 0,1 9,5 6 56R.71.18H7N 56R.71.18H7L20 H7 20 × 60 200 140 0,1 9,5 6 56R.71.20H7N 56R.71.20H7L1) conventional machining · 2) GJS (spheroidal graphite cast iron) · 3) material group 12.0 · 4) material group 12.1 · 5) material group 12.0&12.136

DIHART Monomax®Long version with cylindrical shank similar to DIN 18351Custom reaming tool – selection options!Selection: Cutting material, material, coolant supplySelection: Dimensions2Cutting material/ coatingfor materialfor materialOrder No. Order No. P M K N S H P M K N S H X D Xd×c L b f a~ ~56R.21 56Q.21 HM § 1) § 1) § 1) § 1) § 1) § 1) § 1) § 1) § 1) § 1)5,600-8,899 12×45 130 85 0,1 9,5 456R.71 56Q.71 TiN $ $ $ 4) $ § $ $ 5) $8,900-9,899 12×45 130 85 0,1 9,5 656R.37 56Q.37 DBG-N $ $ $ $ $56R.47 56Q.47 DBF $ § $ $ §9,900-15,899 12×45 160 115 0,1 9,5 656R.17 56Q.17 DBC § §15,900-18,899 16×50 180 130 0,1 9,5 656R.93 56Q.93 DST § § 3)56R.67 56Q.67 DJC $ 2) 18,900-25,899 20×60 200 140 0,1 9,5 6Selection example: material St37, cutting material DST, central coolant supply,bore without interruption = Order No. 56Q.93CylindricalshankSelection example:Bore diameter 24 mmOrder example: Order No. 56Q.93 · Bore diameter 24 mm · Bore tolerance H6 · Material St37 or ASG09 (Cutting geometry page 32-33)§ main area of application $ suitable in some casesNo.ofteeth34DBG-N DBF DSTP M K N S H P M K N S H P M K N S H P M K N S H5$ $ $ § § § 3) § § 3)$ $ $ $ $ §Cutting geometry (ASG) Cutting geometry (ASG) Cutting geometry (ASG) Cutting geometry (ASG)for through holeASG 3000 ASG 3000 ASG 3000 machiningASG 09Order No. Order No. Order No. Order No.56R.37.06H7N 56R.47.06H7N 56R.93.06H7N 56R.93.06H7L56R.37.08H7N 56R.47.08H7N 56R.93.08H7N 56R.93.08H7L56R.37.10H7N 56R.47.10H7N 56R.93.10H7N 56R.93.10H7L56R.37.12H7N 56R.47.12H7N 56R.93.12H7N 56R.93.12H7L56R.37.14H7N 56R.47.14H7N 56R.93.14H7N 56R.93.14H7L56R.37.15H7N 56R.47.15H7N 56R.93.15H7N 56R.93.15H7L56R.37.16H7N 56R.47.16H7N 56R.93.16H7N 56R.93.16H7L56R.37.18H7N 56R.47.18H7N 56R.93.18H7N 56R.93.18H7L56R.37.20H7N 56R.47.20H7N 56R.93.20H7N 56R.93.20H7L67837

DIHART Monomax®X 5,600 – 25,899 mmLong version with morse taper DIN 228 form A1K without internal coolant supply2ax D3fbLTangOrder No.099.03.002Custom reaming tool – selection options!Selection: Cutting material, materialSelection: DimensionsP M K N S H P M K N S H X D MK L b a f56X.21 HM § 1) § 1) § 1) § 1) § 1) § 1) § 1) § 1) § 1) § 1)Order No. Order No.Cutting material/ coatingfor materialSelection example: material GG25, cutting material HM,bore without interruption = Order No. 56X.21for material~ ~5,600-8,899 2 90 85 9,5 0,1 48,900-9,899 2 90 85 9,5 0,1 69,900-15,899 2 120 115 9,5 0,1 615,900-18,899 2 135 130 9,5 0,1 618,900-25,899 2 145 140 9,5 0,1 6Selection example:Bore diameter 24 mmOrder example: Order No. 56X.21 · Bore diameter 24 mm · Bore tolerance H6 · Material GG25 or ASG3000 (Cutting geometry page 32-33)§ main area of application $ suitable in some casesMorsetaperNo.ofteeth1) conventional machining · 2) GJS (spheroidal graphite cast iron) · 3) material group 12.0 · 4) material group 12.1 · 5) material group 12.0&12.1Supply includes: Monomax® complete with tang.38

DIHART Monomax®Design your own tool!Is there no solution in the standard range? Are the dimensions not what you require?Easy Special makes it possible for you create your own combination of standard modules in the widest variety of dimensions.Select the basic type, define the effective length and choose the desired adapter for the tool.12Examples:Extra long Monomax® reamerwith cylindrical shank34Monomax® reamerwith DAH® / HSK adaptor567839

DIHART® Solid Carbide Reamers1234Hightech for smaller diametersThe DIHART® solid carbide range of multiple blade reamersin diameters from 1,400 to 12,700 mm is the complementto the Reamax® -product range (diameters 12,000 -40,000 mm). With this, DIHART® offers you a solid carbiderange for high-performance machining up to a diameter of40.0 mm. The solid carbide reamers are delivered from thefactory with the required dimensions.BENEFITS for you:For very small hole diametersExtremely high stiffness for optimum machiningprocessesExtremely high cutting performance throughDIHART® cutting edge geometryInternal coolant supply for long tool lifeLeft-hand spiraled for defined chip flow40

DIHART® Solid Carbide ReamersTool RecommendationPage42 – 431for blind hole machiningx 1,400 – 12,700 mmfor through hole machiningx 4,800 – 12,700 mm4445234567841

DIHART® Solid Carbide ReamersTool Recommendation1Material groupStrength Rm (N/mm²)Hardness HBMaterialMaterial examplematerial code/DINOrder No.Cuttinggeometry(ASG)High-speed machiningCuttingmaterial/coatingOrder No.Cuttinggeometry(ASG)Cuttingmaterial/coating21.02.0m 500500-900non-alloy steelsnon-alloy /low alloy steelsSt37-2 / 1.0037;9SMn28 / 1.0715;St44-2 / 1.0044St52-2 / 1.0050,C55 / 1.0525,16MnCr5 / 1.7131526.39 ASG0501 TiN 526.39 ASG0501 TiN526.39 ASG0501 TiN 526.39 ASG0501 TiN2.1< 500 lead alloys9SMnPb28 / 1.0718 526.39 ASG0501 TiN 526.39 ASG0501 TiN3P3.04.0> 900> 900non alloy / low alloy steels:heat resistant structural,heat treated, nitride andtools steelshigh alloy steels42CrMo4 / 1.7225,CK60 / 1.1221 526.39 ASG0501 TiN 526.39 ASG0501 TiNX6CrMo4 / 1.2341,X165CrMoV12 / 1.2601 526.39 ASG0501 TiN 526.39 ASG0501 TiN4.1HSS5.0250special alloys: Inconel,Hastelloy, Nimonic, stc.Inconel 718 / 2.4668,Nimonic 80A / 2.46314S5.16.0titanium,400 TiAl5Sn2 / 3.7114titanium alloysm 600stainless steelsX2CrNi189 / 1.4306,X5CrNiMo1810 / 1.4401 526.36 ASG0501 DBF 526.36 ASG0501 DBFM6.1< 900stainless steelsX8CrNb17 / 1.4511,X10CrNiMoTi1810 / 1.4571 526.36 ASG0501 DBF 526.36 ASG0501 DBF7.0> 900stainless / fireproof steelsX10CrAl7 / 1.4713,X8CrS-38-18 / 1.4862 526.36 ASG0501 DBF 526.36 ASG0501 DBF8.0180gray cast ironGG-25 / 0.6025,GG-35 / 0.6035 526.37 ASG0501 DBG-N 526.37 ASG0501 DBG-N8.19.0250 alloy gray cast iron GG-NiCr202 / 0.6660 526.37 ASG0501 DBG-N 526.37 ASG0501 DBG-Nm 600 130spheroidal graphite castiron, ferriticGGG-40 / 0.7040 526.37 ASG0501 DBG-N 526.37 ASG0501 DBG-NK9.110.0230> 600 250spheroidal graphite castiron, ferritic / perliticspheroidal graphite castiron, perliticmalleable ironGGG-50 / 0.7050GGG-55 / 0.7055GTW-55 / 0.8055526.37 ASG0501 DBG-N 526.37 ASG0501 DBG-NGGG-60 / 0.7060GTS-65 / 0.8165 526.37 ASG0501 DBG-N 526.37 ASG0501 DBG-N10.1alloyed spheroidal graphite200 GGG-NiCr20-2 / 0.7661cast iron526.37 ASG0501 DBG-N 526.37 ASG0501 DBG-N10.2300vermicular cast ironGGV Ti < 0,2GGV Ti > 0,2 526.37 ASG0501 DBG-N 526.37 ASG0501 DBG-N12.090copper alloy, brass,lead-alloy bronze, leadbronze: good cutCuZn36Pb3 / 2.1182,G-CuPb15Sn / 2.1182 526.39 ASG0501 TiN 526.39 ASG0501 TiN12.1100copper alloy, brass, bronze:average cutCuZn40Al1 / 2.0550,E-Cu57 / 2.0060 526.39 ASG0501 TiN 526.39 ASG0501 TiNN13.060wrought aluminium alloysAlMg1 / 3.3315,AlMnCu / 3.0517 526.38 ASG0501 DBC 526.38 ASG0501 DBC13.175cast aluminium alloy:Si-content 10%G-AlSi10Mg / 3.2381 526.38 ASG0501 DBC 526.38 ASG0501 DBC1400hardened steels< 45 HRC526.37 ASG0501 DBG-N1800hardened steels> 45 HRC, m 55 HRC526.37 ASG0501 DBG-NWe are happy to take inquiries concerning tools for materials without a recommendation.42

High-speed machiningDIHART® Solid Carbide ReamersTool RecommendationConventional machining with carbide1Order No.Cuttinggeometry(ASG)Cuttingmaterial/coatingOrder No.Cuttinggeometry(ASG)Cuttingmaterial/coatingOrder No.Cuttinggeometry(ASG)CuttingmaterialOrder No.Cuttinggeometry(ASG)Cuttingmaterial526.19 ASG07 TiN 526.19 ASG07 TiN 526.35 ASG0501 HM 526.15 ASG07 HM526.19 ASG07 TiN 526.19 ASG07 TiN 526.35 ASG0501 HM 526.15 ASG02 HM2526.19 ASG07 TiN 526.19 ASG07 TiN 526.35 ASG0501 HM 526.15 ASG07 HM526.19 ASG07 TiN 526.19 ASG07 TiN 526.35 ASG0501 HM 526.15 ASG07 HM526.19 ASG0106 TiN 526.19 ASG0106 TiN 526.35 ASG0501 HM 526.15 ASG0106 HM3526.15 ASG0106 HM526.16 ASG0106 DBF 526.16 ASG0106 DBF 526.35 ASG0501 HM 526.15 ASG0106 HM4526.16 ASG0106 DBF 526.16 ASG0106 DBF 526.35 ASG0501 HM 526.15 ASG0106 HM526.16 ASG0106 DBF 526.16 ASG0106 DBF 526.35 ASG0501 HM 526.15 ASG0106 HM526.17 ASG07 DBG-N 526.17 ASG07 DBG-N 526.35 ASG0501 HM 526.15 ASG07 HM526.17 ASG07 DBG-N 526.17 ASG07 DBG-N 526.35 ASG0501 HM 526.15 ASG07 HM5526.17 ASG07 DBG-N 526.17 ASG07 DBG-N 526.35 ASG0501 HM 526.15 ASG07 HM526.17 ASG07 DBG-N 526.17 ASG07 DBG-N 526.35 ASG0501 HM 526.15 ASG07 HM526.17 ASG07 DBG-N 526.17 ASG07 DBG-N 526.35 ASG0501 HM 526.15 ASG07 HM526.17 ASG07 DBG-N 526.17 ASG07 DBG-N 526.35 ASG0501 HM 526.15 ASG07 HM526.17 ASG07 DBG-N 526.17 ASG07 DBG-N 526.35 ASG0501 HM 526.15 ASG07 HM6526.19 ASG07 TiN 526.19 ASG07 TiN 526.35 ASG0501 HM 526.15 ASG0106 HM526.19 ASG07 TiN 526.19 ASG07 TiN 526.35 ASG0501 HM 526.15 ASG0106 HM526.18 ASG0706 DBC 526.18 ASG0706 DBC 526.35 ASG0501 HM 526.15 ASG07 HM526.18 ASG0706 DBC 526.18 ASG0706 DBC 526.35 ASG0501 HM 526.15 ASG07 HM7526.18 ASG0706 DBC 526.18 ASG0706 DBC 526.35 ASG0501 HM 526.15 ASG07 HM526.17 ASG0106 DBG-N526.17 ASG0106 DBG-NCutting speed and feed see pages 94 - 95.8Important: See chapter 8 for more application details and safety notes !43

DIHART® Solid Carbide ReamersX 1,400 – 12,700 mmwith cylindrical shank DIN 6535 HA1K with and without internal coolant supply2for blind hole machiningax Dx d h63bLc4Custom reaming tool – selection options!Selection: Cutting material, material, coolant supplySelection: DimensionsX 1,400 – 4,159 ≥ X 4,160Order No.Cutting material/ coatingP M K N S H526.15 HM § 1) § 1) § 1) § 1) § 1)526.19 TiN § $ $ 2) $526.17 DBG-N $ §526.16 DBF $ §for material526.18 DBC §Selection example: material GGG40, cutting material DBF, central coolant supply,bore without interruption = Order No. 526.16CylindricalshankNo.ofteethX D X d×c L b a~1,400-2,759 3×28 48 20 6 42,760-3,159 3×28 48 20 8 43,160-4,159 4×28 54 26 8 44,160-4,799 6×36 74 38 8 44,800-6,159 6×36 74 38 12 46,160-6,799 8×36 91 55 12 46,800-7,159 8×36 91 55 16 47,160-8,159 8×36 91 55 16 68,160-8,699 10×40 103 63 16 68,700-10,159 10×40 103 63 20 610,160-10,599 12×45 118 73 20 610,600-12,159 12×45 118 73 24 612,160-12,700 14×45 132 87 28 6Selection example:Bore diameter 5 mmOrder example: Order No. 526.16 · Bore diameter 5 mm · Bore tolerance H8 · Material GGG40 or ASG0501 (Cutting geometry page 42-43)§ main area of application $ suitable in some cases44

X 4,800 – 12,700 mmDIHART® Solid Carbide Reamerswith cylindrical shank DIN 6535 HAwith internal coolant supply K1for through hole machininga2x Dx d h6bLc34Custom reaming tool – selection options!Selection: Cutting material, material, coolant supplyOrder No.Cutting material/ coatingP M K N S H526.35 HM § 1) § 1) § 1) § 1) § 1)526.39 TiN § $ $ 2) $526.37 DBG-N $ §526.36 DBF $ §for material526.38 DBC §Selection example: material GGG40, cutting material DBF, central coolant supply,bore without interruption = Order No. 526.36X D X d×c L b a~4,800-6,159 6×36 74 38 12 46,160-6,799 8×36 91 55 12 46,800-7,159 8×36 91 55 16 47,160-8,159 8×36 91 55 16 68,160-8,699 10×40 103 63 16 68,700-10,159 10×40 103 63 20 610,160-10,599 12×45 118 73 20 610,600-12,159 12×45 118 73 24 612,160-12,700 14×45 132 87 28 6Selection example:Bore diameter 5 mmOrder example: Order No. 526.36 · Bore diameter 5 mm · Bore tolerance H8 · Material GGG40 or ASG0501 (Cutting geometry page 42-43)§ main area of application $ suitable in some casesSelection: DimensionsCylindricalshankNo.ofteeth5671) conventional machining · 2) GJS (spheroidal graphite cast iron) · 3) material group 12.0 · 4) material group 12.1 · 5) material group 12.0&12.1845

DIHART® Duomax Cutting Ring12345We have put our entire wealth ofexperience into the generation ofDIHART® Cutting Ring, called Duomax.The DIHART® Cutting Ring for reaming basic andthrough holes is established and often copied due to itscost-effectiveness. This is one of the modular multi-bladetooling systems that features the easily replaceable DI-HART® Cutting Ring on the holder. The user gets a finishgroundtool which does not require any time-consumingsetting and adjustment work to the individual cutters.The indexable inserts for reaming have two fully utilisablecutting edges. Each set of indexable inserts saves you aretipping cycle and thereby reduces tool costs and time aswell as effort spent on logistics. When retipping is requiredafter delivering double the tool life, this is also much easierto do in comparison with the soldered DIHART® CuttingRing, because the number of machining steps in theprocess has been reduced. In connection with this, the toollife of the basic body is also longer, because it is no longersubjected to thermal stress. In addition, the precisionand stability of the basic body has been further improvedthrough optimisation of the basic shape.A variety of cutting tool materials and coatings enable theindividual adaptation of reamers to machining assignmentsand perfect processing of a wide variety of materials. Inthe future, a variety of coatings for this will be conceivablethat cannot be used on soldered tools. Overall theflexibility with regard to selecting the cutting material andcoating for reaming processes will significantly increaseproductivity. Moreover, tolerance and geometry changescan be accomplished quickly and with little effort.BENEFITS for you:Retipping for extremely high cost efficiencyFor large hole diametersModular multi-blade tooling systemCompensation for wear through simplereadjustmentA variety of cutting materials and coatingsExtremely high flexibilityThe cutting ring system is one of the modular tool rangesfrom DIHART®. The ring has support zones for non-deformationalaccommodation of the cutting forces. Expansionzones permit an elastic expansion of the ring for compensatingfor wear on the cutters.Through repeated regrinding, the service life of the ringcan be increased many times over. Cutting edge wear iscompensated – all functional surfaces are fully reground.Reground tools have the same functionality as new ones.BENEFITS for you:For large hole diametersMultiple bladeModularCompensation for wear through simplereadjustmentA variety of cutting materials and coatingsCan be reground and refitted with cutters forextremely high cost efficiency46

DIHART® Cutting RingTool RecommendationPage48 – 511Duomax 52Ø 62 – 110 mmCutting RingØ 60,60 – 110,59 mm532HolderCylindrical shankDAH® adaptorABS® adaptorAssembly parts / Accessories545556573Assembly InstructionsVariant:- 10 diameter from 62 -110 mm- Hole tolerances of M IT5- Use with cast metal, solutions for steel,stainless steels, aluminium and othermaterials to followDuomax 58 – 59Cutting Ring60 – 614567847

DIHART® DuomaxTool Recommendation1Material groupStrength Rm (N/mm²)Hardness HBMaterialMaterial examplematerial code/DINOrder No.Cuttinggeometry(ASG)High-speed machiningCuttingmaterial/coatingOrder No.Cuttinggeometry(ASG)Cuttingmaterial/coating21.02.0m 500500-900non-alloy steelsnon-alloy /low alloy steelsSt37-2 / 1.0037;9SMn28 / 1.0715;St44-2 / 1.0044St52-2 / 1.0050,C55 / 1.0525,16MnCr5 / 1.713133G.93 ASG09 DST 33G.71 ASG09 TiN33G.93 ASG09 DST 33G.71 ASG09 TiN2.1< 500 lead alloys9SMnPb28 / 1.0718 33G.93 ASG09 DST 33G.71 ASG09 TiN3P3.04.0> 900> 900non alloy / low alloy steels:heat resistant structural,heat treated, nitride andtools steelshigh alloy steels42CrMo4 / 1.7225,CK60 / 1.1221 33G.93 ASG09 DST 33G.71 ASG3000 TiNX6CrMo4 / 1.2341,X165CrMoV12 / 1.2601 33G.71 ASG0106 TiN 33G.71 ASG0106 TiN4.1HSS5.0250special alloys: Inconel,Hastelloy, Nimonic, stc.Inconel 718 / 2.4668,Nimonic 80A / 2.46314S5.16.0titanium,400 TiAl5Sn2 / 3.7114titanium alloysm 600stainless steelsX2CrNi189 / 1.4306,X5CrNiMo1810 / 1.4401 33G.47 ASG0106 DBF 33G.47 ASG0106 DBFM6.1< 900stainless steelsX8CrNb17 / 1.4511,X10CrNiMoTi1810 / 1.4571 33G.47 ASG0106 DBF 33G.47 ASG0106 DBF7.0> 900stainless / fireproof steelsX10CrAl7 / 1.4713,X8CrS-38-18 / 1.4862 33G.47 ASG0106 DBF 33G.47 ASG0106 DBF58.08.19.0180gray cast ironGG-25 / 0.6025,GG-35 / 0.6035 33G.37 ASG3000 DBG-N 33G.37 ASG3000 DBG-N250 alloy gray cast iron GG-NiCr202 / 0.6660 33G.37 ASG3000 DBG-N 33G.37 ASG3000 DBG-Nspheroidal graphite castm 600 130 GGG-40 / 0.7040iron, ferritic33G.93 ASG3000 DST 33G.47 ASG3000 DBFK9.110.0230> 600 250spheroidal graphite castiron, ferritic / perliticspheroidal graphite castiron, perliticmalleable ironGGG-50 / 0.7050GGG-55 / 0.7055GTW-55 / 0.805533G.93 ASG3000 DST 33G.47 ASG3000 DBFGGG-60 / 0.7060GTS-65 / 0.8165 33G.93 ASG3000 DST 33G.47 ASG3000 DBF10.1alloyed spheroidal graphite200 GGG-NiCr20-2 / 0.7661cast iron33G.37 ASG3000 DBG-N 33G.37 ASG3000 DBG-N10.2300vermicular cast ironGGV Ti < 0,2GGV Ti > 0,2 33G.37 ASG3000 DBG-N 33G.37 ASG3000 DBG-N12.090copper alloy, brass,lead-alloy bronze, leadbronze: good cutCuZn36Pb3 / 2.1182,G-CuPb15Sn / 2.1182 33G.93 ASG3000 DST 33G.71 ASG3000 TiN12.1100copper alloy, brass,bronze:average cutCuZn40Al1 / 2.0550,E-Cu57 / 2.0060 33G.71 ASG3000 TiN 33G.71 ASG3000 TiNN13.060wrought aluminium alloysAlMg1 / 3.3315,AlMnCu / 3.0517 33G.17 ASG0706 DBC 33G.17 ASG0706 DBC13.175cast aluminium alloy:Si-content 10%33G.17 ASG0706 DBC 33G.17 ASG0706 DBChardened steels< 45 HRChardened steels> 45 HRC, m 55 HRC48We are happy to take inquiries concerning tools for materials without a recommendation.

High-speed machiningDIHART® DuomaxTool RecommendationConventional machining with carbide1Order No.Cuttinggeometry(ASG)Cuttingmaterial/coatingOrder No.Cuttinggeometry(ASG)Cuttingmaterial/coatingOrder No.Cuttinggeometry(ASG)CuttingmaterialOrder No.Cuttinggeometry(ASG)Cuttingmaterial33G.93 ASG3000 DST 33G.71 ASG3000 TiN 33G.21 ASG3000 HM 33G.21 ASG3000 HM33G.93 ASG3000 DST 33G.71 ASG3000 TiN 33G.21 ASG02 HM 33G.21 ASG02 HM233G.93 ASG3000 DST 33G.71 ASG3000 TiN 33G.21 ASG3000 HM 33G.21 ASG3000 HM33G.93 ASG3000 DST 33G.71 ASG3000 TiN 33G.21 ASG3000 HM 33G.21 ASG3000 HM33G.71 ASG0106 TiN 33G.71 ASG0106 TiN 33G.21 ASG0106 HM 33G.21 ASG0106 HM333G.21 ASG03 HM 33G.21 ASG03 HM33G.47 ASG0106 DBF 33G.47 ASG0106 DBF 33G.21 ASG0106 HM 33G.21 ASG0106 HM433G.47 ASG0106 DBF 33G.47 ASG0106 DBF 33G.21 ASG0106 HM 33G.21 ASG0106 HM33G.47 ASG0106 DBF 33G.47 ASG0106 DBF 33G.21 ASG0106 HM 33G.21 ASG0106 HM33G.37 ASG3000 DBG-N 33G.37 ASG3000 DBG-N 33G.21 ASG3000 HM 33G.21 ASG3000 HM33G.37 ASG3000 DBG-N 33G.37 ASG3000 DBG-N 33G.21 ASG3000 HM 33G.21 ASG3000 HM533G.93 ASG3000 DST 33G.47 ASG3000 DBF 33G.21 ASG02 HM 33G.21 ASG02 HM33G.93 ASG3000 DST 33G.47 ASG3000 DBF 33G.21 ASG3000 HM 33G.21 ASG3000 HM33G.93 ASG3000 DST 33G.47 ASG3000 DBF 33G.21 ASG3000 HM 33G.21 ASG3000 HM33G.37 ASG3000 DBG-N 33G.37 ASG3000 DBG-N 33G.21 ASG3000 HM 33G.21 ASG3000 HM33G.37 ASG3000 DBG-N 33G.37 ASG3000 DBG-N 33G.21 ASG3000 HM 33G.21 ASG3000 HM633G.93 ASG3000 DST 33G.71 ASG3000 TiN 33G.21 ASG0106 HM 33G.21 ASG0106 HM33G.71 ASG3000 TiN 33G.71 ASG3000 TiN 33G.21 ASG0106 HM 33G.21 ASG0106 HM33G.17 ASG0706 DBC 33G.17 ASG0706 DBC 33G.21 ASG02 HM 33G.21 ASG02 HM33G.17 ASG0706 DBC 33G.17 ASG0706 DBC 33G.21 ASG3000 HM 33G.21 ASG3000 HM733G.17 ASG0706 DBC 33G.17 ASG0706 DBC 33G.21 ASG3000 HM 33G.21 ASG3000 HMCutting speed and feed see pages 94 - 95.8Important: See chapter 8 for more application details and safety notes !49

DIHART® Cutting RingTool Recommendation1Material groupStrength Rm (N/mm²)Hardness HBMaterialMaterial examplematerial code/DINOrder No.Cuttinggeometry(ASG)High-speed machiningCuttingmaterial/coatingOrder No.Cuttinggeometry(ASG)Cuttingmaterial/coating21.02.0m 500500-900non-alloy steelsnon-alloy /low alloy steelsSt37-2 / 1.0037;9SMn28 / 1.0715;St44-2 / 1.0044St52-2 / 1.0050,C55 / 1.0525,16MnCr5 / 1.7131300.45 ASG09 DST 300.05 ASG09 TiN300.45 ASG09 DST 300.05 ASG09 TiN2.1< 500 lead alloys9SMnPb28 / 1.0718 300.45 ASG09 DST 300.05 ASG09 TiN3P3.04.0> 900> 900non alloy / low alloy steels:heat resistant structural,heat treated, nitride andtools steelshigh alloy steels42CrMo4 / 1.7225,CK60 / 1.1221 300.45 ASG09 DST 300.05 ASG3000 TiNX6CrMo4 / 1.2341,X165CrMoV12 / 1.2601 300.05 ASG0106 TiN 300.05 ASG0106 TiN4.1HSS5.0250special alloys: Inconel,Hastelloy, Nimonic, stc.Inconel 718 / 2.4668,Nimonic 80A / 2.46314S5.16.0titanium,400 TiAl5Sn2 / 3.7114titanium alloysm 600stainless steelsX2CrNi189 / 1.4306,X5CrNiMo1810 / 1.4401 300.05 ASG0106 TiN 300.05 ASG0106 TiNM6.1< 900stainless steelsX8CrNb17 / 1.4511,X10CrNiMoTi1810 / 1.4571 300.05 ASG0106 TiN 300.05 ASG0106 TiN7.0> 900stainless / fireproof steelsX10CrAl7 / 1.4713,X8CrS-38-18 / 1.4862 300.05 ASG0106 TiN 300.05 ASG0106 TiN58.08.19.0180gray cast ironGG-25 / 0.6025,GG-35 / 0.6035 300.07 ASG3000 DBG-N 300.07 ASG3000 DBG-N250 alloy gray cast iron GG-NiCr202 / 0.6660 300.07 ASG3000 DBG-N 300.07 ASG3000 DBG-Nspheroidal graphite castm 600 130 GGG-40 / 0.7040iron, ferritic300.45 ASG3000 DST 300.07 ASG3000 DBG-NK9.110.0230> 600 250spheroidal graphite castiron, ferritic / perliticspheroidal graphite castiron, perliticmalleable ironGGG-50 / 0.7050GGG-55 / 0.7055GTW-55 / 0.8055300.45 ASG3000 DST 300.07 ASG3000 DBG-NGGG-60 / 0.7060GTS-65 / 0.8165 300.45 ASG3000 DST 300.07 ASG3000 DBG-N10.1alloyed spheroidal graphite200 GGG-NiCr20-2 / 0.7661cast iron300.07 ASG3000 DBG-N 300.07 ASG3000 DBG-N10.2300vermicular cast ironGGV Ti < 0,2GGV Ti > 0,2 300.07 ASG3000 DBG-N 300.07 ASG3000 DBG-N12.090copper alloy, brass,lead-alloy bronze, leadbronze: good cutCuZn36Pb3 / 2.1182,G-CuPb15Sn / 2.1182 300.45 ASG3000 DST 300.05 ASG3000 TiN12.1100copper alloy, brass, bronze:average cutCuZn40Al1 / 2.0550,E-Cu57 / 2.0060 300.05 ASG3000 TiN 300.05 ASG3000 TiNN13.060wrought aluminium alloysAlMg1 / 3.3315,AlMnCu / 3.0517 300.17 ASG0706 DBC 300.17 ASG0706 DBC13.175cast aluminium alloy:Si-content 10%300.17 ASG0706 DBC 300.17 ASG0706 DBChardened steels< 45 HRChardened steels> 45 HRC, m 55 HRC50We are happy to take inquiries concerning tools for materials without a recommendation.

High-speed machiningDIHART® Cutting RingTool RecommendationConventional machining with carbide1Order No.Cuttinggeometry(ASG)Cuttingmaterial/coatingOrder No.Cuttinggeometry(ASG)Cuttingmaterial/coatingOrder No.Cuttinggeometry(ASG)CuttingmaterialOrder No.Cuttinggeometry(ASG)Cuttingmaterial300.45 ASG3000 DST 300.05 ASG3000 TiN 300.25 ASG3000 HM 300.25 ASG3000 HM300.45 ASG3000 DST 300.05 ASG3000 TiN 300.25 ASG02 HM 300.25 ASG02 HM2300.45 ASG3000 DST 300.05 ASG3000 TiN 300.25 ASG3000 HM 300.25 ASG3000 HM300.45 ASG3000 DST 300.05 ASG3000 TiN 300.25 ASG3000 HM 300.25 ASG3000 HM300.05 ASG0106 TiN 300.05 ASG0106 TiN 300.25 ASG0106 HM 300.25 ASG0106 HM3300.25 ASG03 HM 300.25 ASG03 HM300.05 ASG0106 TiN 300.05 ASG0106 TiN 300.25 ASG0106 HM 300.25 ASG0106 HM4300.05 ASG0106 TiN 300.05 ASG0106 TiN 300.25 ASG0106 HM 300.25 ASG0106 HM300.05 ASG0106 TiN 300.05 ASG0106 TiN 300.25 ASG0106 HM 300.25 ASG0106 HM300.07 ASG3000 DBG-N 300.07 ASG3000 DBG-N 300.25 ASG3000 HM 300.25 ASG3000 HM300.07 ASG3000 DBG-N 300.07 ASG3000 DBG-N 300.25 ASG3000 HM 300.25 ASG3000 HM5300.45 ASG3000 DST 300.07 ASG3000 DBG-N 300.25 ASG02 HM 300.25 ASG02 HM300.45 ASG3000 DST 300.07 ASG3000 DBG-N 300.25 ASG3000 HM 300.25 ASG3000 HM300.45 ASG3000 DST 300.07 ASG3000 DBG-N 300.25 ASG3000 HM 300.25 ASG3000 HM300.07 ASG3000 DBG-N 300.07 ASG3000 DBG-N 300.25 ASG3000 HM 300.25 ASG3000 HM300.07 ASG3000 DBG-N 300.07 ASG3000 DBG-N 300.25 ASG3000 HM 300.25 ASG3000 HM6300.45 ASG3000 DST 300.05 ASG3000 TiN 300.25 ASG0106 HM 300.25 ASG0106 HM300.05 ASG3000 TiN 300.05 ASG3000 TiN 300.25 ASG0106 HM 300.25 ASG0106 HM300.17 ASG0706 DBC 300.17 ASG0706 DBC 300.25 ASG02 HM 300.25 ASG02 HM300.17 ASG0706 DBC 300.17 ASG0706 DBC 300.25 ASG3000 HM 300.25 ASG3000 HM7300.17 ASG0706 DBC 300.17 ASG0706 DBC 300.25 ASG3000 HM 300.25 ASG3000 HMCutting speed and feed see pages 94 - 95.8Important: See chapter 8 for more application details and safety notes !51

DIHART® DuomaxX 62 – 110 mmCutting ring for tolerance S8 - E812x D3al245Custom cutting ring – selection options!Order No.Selection: Cutting material, materialCutting material/ coatingP M K N S H P M K N S H33G.21 HM $ 1) $ 1) $ 1) $ 1) $ 1) $ 1) $ 1) $ 1) $ 1) $ 1)33G.71 TiN $ $ $ 4) $ § $ $ 5) $33G.37 DBG-N $ § $ $ §33G.47 DBF $ § $ $ §33G.17 DBC § §33G.93 DST § $ $ 3)33G.67 DJC $ 2)for material33G.87 DJF $Selection example:Material St37, cutting material DST, = Order No. 33G.93for materialPreferredNo. ofrangeteethX D X D a l2~ ~62 10,3 19,6 660,600 -79,59979,600 -100,599Selection: Dimensions65 10,3 19,6 670 10,3 19,6 672 10,3 19,6 675 10,3 19,6 680 10,3 19,6 890 10,3 19,6 892 10,3 19,6 8100 10,3 19,6 8100,600 -110,599110 10,3 19,6 10Selection example:Bore diameter 62 mmOrder example: Order No. 33G.93 · Bore diameter 62 mm · Bore tolerance H7 · Material St37 or ASG3000 (Cutting geometry page 50-51).§ main area of application $ suitable in some casesAssembly parts, AccessoriesTorque keyClampingscrewReplaceablebladeSupply includes: Cutting ring Duomax mounted with inserts andclamping screws.Please order torque key and replaceable blade separately.Order No. Order No. Order No.ArticleArticleN00 57710S3090-9IPL05 033112,25 NmL05 007409IP52Patented design

X 60,600 – 110,599 mmDIHART® Cutting Ring1x Dx x2al23Custom cutting ring – selection options!Order No.Selection: Cutting material, materialCutting material/ coatingfor materialP M K N S H P M K N S H300.25 HM $ 1) $ 1) $ 1) $ 1) $ 1) $ 1) $ 1) $ 1) $ 1) $ 1)300.05 TiN $ $ $ 4) $ § $ $ 5) $300.07 DBG-N $ § $ $ §300.47 DBF $ § $ $ §300.17 DBC § §300.45 DST § $ $ 3)300.08 DJC $ 2)Selection example:Material St37, cutting material DST, = Order No. 300.45HMTiNDBG-NDBF DBCDSTDJCmachiningX D X x a l2 l2~ ~ ~ ~60,600 -79,59979,600 -100,599100,600 -110,599xD – 8,4 16,0 18,5 17,5 6xD – 8,4 16,0 18,5 17,5 8xD – 8,4 16,0 18,5 17,5 10Order example: Order No. 300.45 · Bore diameter 70 mm · Bore tolerance H6 · Material St37 or ASG09 (Cutting geometry page 50-51).§ main area of application $ suitable in some casesfor materialSelection: Dimensionsmin.diameterfor faceSelection example:Bore diameter 70 mmNo. ofteeth456Cutting ring from dia. 17,60 to 60,59 mm and x 110,60 to 300,59 mm on request.781) conventional machining · 2) GJS (spheroidal graphite cast iron) · 3) material group 12.0 · 4) material group 12.1 · 5) material group 12.0&12.153

DIHART® Duomax Cutting RingHolder with cylindrical shank similar to DIN 18351X 60,600 – 100,599 mmK with internal coolant supplyK cylindrical shank with flat available on requestfor through hole machining2x Dx ex d h63Cutting ringDuomaxfbLcfor blind hole machining4x Dx ex d h6DuomaxfbcCutting ringL5for through hole machining short version long versionfor for CylindricalCutting Ring Duomax shankX D X D X d × c X e f Order No. L b Order No. L b~60,600 – 70,599 62, 65, 70 32 × 60 40,0 24,5 503.76.008 189,5 105 1,81 504.76.009 321,5 237 3,4670,600 – 79,599 72, 75 32 × 60 40,0 24,5 503.76.009 189,5 105 2,00 504.76.010 321,5 237 3,8779,600 – 90,599 80, 90 40 × 70 56,2 28,5 503.76.010 203,5 105 3,40 504.76.011 338,5 240 6,1490,600 – 100,599 92, 100 40 × 70 56,2 28,5 503.76.011 203,5 105 6,14 504.76.012 338,5 240for blind hole machining short version long versionfor for CylindricalCutting Ring Duomax shankX D X D X d × c X e f Order No. Order No. L b Order No. Order No. L b~60,600 – 70,599 62, 65, 70 32 × 60 37,0 1,5 513.76.008 513.81.008 166,5 105 1,78 514.76.008 514.81.008 298,5 237 2,9070,600 – 79,599 72, 75 32 × 60 37,0 1,5 513.76.009 513.81.009 166,5 105 1,76 514.76.009 514.81.009 298,5 237 3,0179,600 – 90,599 80, 90 40 × 70 53,2 1,5 513.76.010 513.81.010 176,5 105 3,13 514.76.010 514.81.010 311,5 240 4,9090,600 – 100,599 92, 100 40 × 70 53,2 1,5 513.76.011 513.81.011 176,5 105 514.76.011 514.81.011 311,5 240 5,55Supply includes: Holder complete (assembly parts see page 57). Please order cutting ring separately.54

DIHART® Duomax Cutting RingHolder with DAH® ConnectionX 60,600 – 110,599 mmwith internal coolant supply Kfurther holders on request K1for through hole machining2x Dx eDAHCutting ringDuomaxfbL3for blind hole machiningx Dx eDAH4DuomaxfbCutting ringL5for through hole machiningforforCutting Ring DuomaxX D X D Order No. DAH L b X e f Order No. Order No. DAH L b X e f~ ~60,600 – 70,599 62, 65, 70 507.02.043 81 117 99 40,0 24,5 1,7070,600 – 79,599 72, 75 507.02.044 81 117 99 40,0 24,5 1,9060,600 – 70,599 62, 65, 70 507.02.008 115 121,5 96 40,0 24,5 2,50 517.76.008 517.81.008 115 145,5 120 37,0 1,5 2,5270,600 – 79,599 72, 75 507.02.009 115 121,5 96 40,0 24,5 2,79 517.76.009 517.81.009 115 145,5 120 37,0 1,5 2,5279,600 – 90,599 80, 90 507.02.010 115 121,5 96 56,2 28,5 3,80 517.76.010 517.81.010 115 155,5 130 53,2 1,5 3,9590,600 – 100,599 92, 100 507.02.011 115 121,5 96 56,2 28,5 4,22 517.76.011 517.81.011 115 155,5 130 53,2 1,5 4,33100,600 – 110,599 110 507.02.012 115 122,5 97 73,4 35,5 5,50Supply includes:DAH® holder complete (assembly parts see page 57). Please order cutting ring separately.DAH® adaptors see chapter 7.for blind hole machining67855

DIHART® Duomax Cutting RingHolder with ABS® Connection1X 60,600 – 100,599 mmK with internal coolant supplyK further holders on requestfor through hole machining2x Dx eABS3Cutting ringDuomaxfbLfor blind hole machining4x Dx eABSCutting ringDuomaxfbL5for through hole machiningfor blind hole machiningforforCutting Ring DuomaxX D X D Order No. ABS L b X e f Order No. Order No. ABS L b X e f~ ~60,600 – 65,599 62 508.53.020 50 119 105 40,0 24,5 1,95 518.78.013 518.82.013 50 119 105 37,0 1,5 1,7565,600 – 70,599 65, 70 508.53.021 63 125 105 40,0 24,5 2,33 518.78.014 518.82.014 63 125 105 37,0 1,5 2,1570,600 – 79,599 72, 75 508.53.009 63 125 105 40,0 24,5 2,50 518.78.009 518.82.009 63 125 105 37,0 1,5 2,2379,600 – 90,599 80, 90 508.53.010 63 125 105 56,2 28,5 3,55 518.78.010 518.82.010 63 125 105 53,2 1,5 3,2990,600 – 100,599 92, 100 508.53.011 63 125 105 56,2 28,5 3,93 518.78.011 518.82.011 63 125 105 53,2 1,5 3,60100,600 – 110,599 110 508.53.022 80 131,5106,5 73,4 35,5 6,21Supply includes:ABS® holder complete (assembly parts see page 57). Please order cutting ring separately.ABS® adaptors see catalogue "<strong>KomPass</strong> – Bore machining, chapter 5".56Patented design

DIHART® Cutting RingAssembly parts / AccessoriesHolder for through hole machining11 2 Duomax 3Cutting ringHolder21 2 3Nut Conical ring Positioning pinforCutting RingX DforDuomaxX DOrder No. Order No. Order No.360,600 – 79,599 62, 65, 70, 72, 75 099.00.090 301.80.006 300.30.00779,600 – 100,599 80, 90, 92, 100 099.00.092 301.80.007 300.30.008100,600 – 110,599 110 099.00.095 306.20.001 300.30.008Holder for blind hole machining453 45 Duomax 1 2Cutting ringHolder1 2 3 4 5Bush Nut Pin Conical screw Conical screw6x ex eforDuomaxX D X D Order No. Order No. Order No. Order No. X e Order No. X e60,600 – 70,599 62, 65, 70 510.15.008 350.23.002 350.14.002 510.45.007 37,0 510.55.007 37,070,600 – 79,599 72, 75 510.15.009 350.23.002 350.14.002 510.45.007 37,0 510.55.007 37,079,600 – 90,599 80, 90 510.15.010 350.23.003 350.14.003 510.45.008 53,2 510.55.008 53,290,600 – 100,599 92, 100 510.15.011 350.23.003 350.14.003 510.45.008 53,2 510.55.008 53,27857

DIHART® DuomaxAssembly instructions on holder for through hole machining1Arrow markings:light greaseFace surfaces on holder and Duomax are greasefree2Positioning of the drive pins to the right of letter A (themeasuring tooth is located at letter A and is also markedon the holder with a spot).Before tightening and adjusting turn the Duomax againstthe direction of machining until hitting the drive pins.Measuring tooth A3Please observe the marking on holder and Duomax ,check alignment of the coolant bores.4+Adjust the diameter to the middle of the tolerance(counter-clockwise thread).5MeasuringtoothAThe diameter can only be measured at the marked cuttingedges (measuring tooth A) due to unequal angularposition!If the diameter was set too large, the conical ring mustbe loosened and the Duomax readjusted.Assembly instructions insertsCleaning:Make sure that the insert seats 3 and inserts are absolutelyclean/grease-free. If necessary, remove tiny dust particleswith compressed air!21534Montage:• All inserts and insert seats are marked with letters 1.This ensures correct assignment to the insert seat.• The number markings 2 ensure that all inserts are positionedcorrectly.• Tighten the screw 4 (order no. N00 57710) to 2.25 Nm.Torque wrench order no. L05 0331158

DIHART® DuomaxAssembly instructions on holder for blind hole machiningArrow markings:light greaseFace surfaces on holder and Duomax are greasefree1Positioning of the drive pins to the right of letter A (the measuringtooth is located at letter A and is also marked on the holder with aspot). Before tightening and adjusting turn the Duomax against thedirection of machining until hitting the drive pins.2Measuring tooth AMDia.rangeStartingtorque M61 – 79 120 – 140 Nm80 – 100 180 – 220 NmScrew the nut onto the holder with the smooth face against the bush.Mount the Duomax with the conical screw. After fastening the conicalscrew check that there is space between bush and Duomax. Fastenconical screw according to index table.3Please observe the marking on holder and Duomax, check alignment ofthe coolant bores. Adjust the diameter to the middle of the tolerance.4+The diameter can only be measured at the marked cutting edges(measuring tooth A) due to unequal angular position!5If the diameter was set too large, the nut must be loosened and theDuomax readjusted.Measuring tooth A6Measuring the diameter:The measuring tooth is located at letter A and is also marked on the holder with a spot 5.Caution!• Uneven angle division !• There are 2 cutters 180° opposite = measuring tooth A.• Measure the diameter at the front of the cutter (due to tapering,see illustration).• Avoid damaging the cutters• When turning the insert, the diameter must be readjusted.• Delivery status: Duomax with mounted inserts.A7859