Electromagnetic testing emt-mft chapter 9b

Electromagnetic testing emt-mft chapter 9b

Electromagnetic testing emt-mft chapter 9b

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

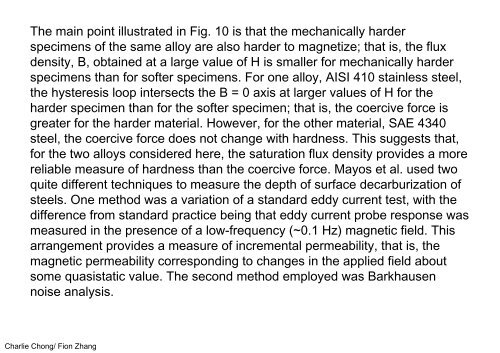

The main point illustrated in Fig. 10 is that the mechanically harder<br />

specimens of the same alloy are also harder to magnetize; that is, the flux<br />

density, B, obtained at a large value of H is smaller for mechanically harder<br />

specimens than for softer specimens. For one alloy, AISI 410 stainless steel,<br />

the hysteresis loop intersects the B = 0 axis at larger values of H for the<br />

harder specimen than for the softer specimen; that is, the coercive force is<br />

greater for the harder material. However, for the other material, SAE 4340<br />

steel, the coercive force does not change with hardness. This suggests that,<br />

for the two alloys considered here, the saturation flux density provides a more<br />

reliable measure of hardness than the coercive force. Mayos et al. used two<br />

quite different techniques to measure the depth of surface decarburization of<br />

steels. One method was a variation of a standard eddy current test, with the<br />

difference from standard practice being that eddy current probe response was<br />

measured in the presence of a low-frequency (~0.1 Hz) magnetic field. This<br />

arrangement provides a measure of incremental permeability, that is, the<br />

magnetic permeability corresponding to changes in the applied field about<br />

some quasistatic value. The second method employed was Barkhausen<br />

noise analysis.<br />

Charlie Chong/ Fion Zhang