EUROROLL-BRAKE CONVEYOR ROLLERS dia. 80 ... - Euroroll.de

EUROROLL-BRAKE CONVEYOR ROLLERS dia. 80 ... - Euroroll.de

EUROROLL-BRAKE CONVEYOR ROLLERS dia. 80 ... - Euroroll.de

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>EUROROLL</strong>-Brake Rollers and <strong>EUROROLL</strong>-Brake<br />

Conveyor Rollers control the speed of the good to be<br />

conveyed on roller tracks while they keep the conveyed<br />

good at a constant run-off speed. This is<br />

achieved by means of planetary gearing, which at<br />

each revolution presses the centrifugal brake discs<br />

against the roller body, raising it with proportional<br />

brake force up to the brake momentum. The distance<br />

of the Brake Rollers and the correct brake<br />

roller type are influenced by several factors:<br />

1. Construction and capacity of the roller track<br />

2. Declination of the roller track<br />

3. Characteristics of the good to be conveyed<br />

(size, weight, sensitivity, barrel-shaped)<br />

4. Resistance of the Brake Roller<br />

5. Environmental conditions, e.g. wet, cold or<br />

warm conditions<br />

At least one Brake Roller or Brake Conveyor Roller<br />

has to be fitted per pallet place, as only then a<br />

controlled speed without acceleration and the appearance<br />

of great force can be achieved. The runoff<br />

speed should never be above 0.3 m/sec. The<br />

run-off speed is only 0.1 – 0.2 m/sec. when the<br />

Brake Rollers are correctly positioned. Important is<br />

the correct adjustment of the suspension of the<br />

Brake Rollers and Brake Conveyor Rollers. As only<br />

by means of the necessary pressing between the<br />

Brake Roller and the good to be conveyed (conveyor<br />

roller or pallet) a contact free from slipping<br />

occurs and a constant conveying speed is<br />

achieved.<br />

Braking Force Diagram<br />

Braking force <strong>dia</strong>grams are a great help to choose<br />

the correct type of Brake Rollers and Brake<br />

Conveyor Rollers. Forces (which mainly arise due<br />

to acceleration), which exceed the characteristic<br />

curve, can overload and <strong>de</strong>stroy the Brake Rollers.<br />

Therefore the Brake Rollers and Brake Conveyor<br />

Rollers always have to be fitted in pallet distance<br />

in roller tracks or even closer to each other. This<br />

means that the pallet in each position is always in<br />

contact with a Brake Roller (it’s a speed controller).<br />

34<br />

<strong>BRAKE</strong> <strong>ROLLERS</strong><br />

<strong>BRAKE</strong> <strong>CONVEYOR</strong> <strong>ROLLERS</strong><br />

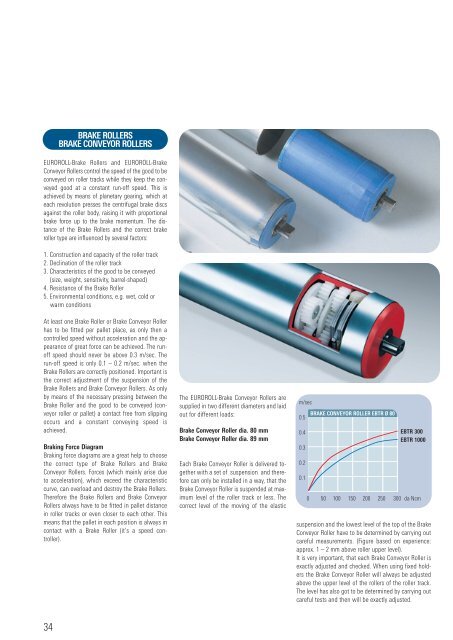

The <strong>EUROROLL</strong>-Brake Conveyor Rollers are<br />

supplied in two different <strong>dia</strong>meters and laid<br />

out for different loads:<br />

Brake Conveyor Roller <strong>dia</strong>. <strong>80</strong> mm<br />

Brake Conveyor Roller <strong>dia</strong>. 89 mm<br />

Each Brake Conveyor Roller is <strong>de</strong>livered together<br />

with a set of suspension and therefore<br />

can only be installed in a way, that the<br />

Brake Conveyor Roller is suspen<strong>de</strong>d at maximum<br />

level of the roller track or less. The<br />

correct level of the moving of the elastic<br />

m/sec<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

<strong>BRAKE</strong> <strong>CONVEYOR</strong> ROLLER EBTR Ø <strong>80</strong><br />

EBTR 300<br />

EBTR 1000<br />

0 50 100 150 200 250 300 da Ncm<br />

suspension and the lowest level of the top of the Brake<br />

Conveyor Roller have to be <strong>de</strong>termined by carrying out<br />

careful measurements. (Figure based on experience:<br />

approx. 1 – 2 mm above roller upper level).<br />

It is very important, that each Brake Conveyor Roller is<br />

exactly adjusted and checked. When using fixed hol<strong>de</strong>rs<br />

the Brake Conveyor Roller will always be adjusted<br />

above the upper level of the rollers of the roller track.<br />

The level has also got to be <strong>de</strong>termined by carrying out<br />

careful tests and then will be exactly adjusted.

0.4<br />

0.3<br />

0.2<br />

0.1<br />

©<br />

<strong>EUROROLL</strong>-<strong>BRAKE</strong> <strong>ROLLERS</strong><br />

<strong>BRAKE</strong> <strong>CONVEYOR</strong> <strong>ROLLERS</strong><br />

Areas of Application<br />

m/sec m/sec<br />

<strong>BRAKE</strong> <strong>BRAKE</strong> <strong>CONVEYOR</strong> <strong>CONVEYOR</strong> ROLLER ROLLER BTR Ø 89 BTR Ø 89<br />

0.5 0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

EBTR <strong>80</strong>0 EBTR <strong>80</strong>0<br />

EBTR 1200 EBTR 1200<br />

0 50 0 100 50 100 150 200 150 200 250 250 300 da 300 Ncmda<br />

Ncm<br />

m/sec m/sec<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

<strong>BRAKE</strong> <strong>BRAKE</strong> <strong>ROLLERS</strong> <strong>ROLLERS</strong> EBR EBR<br />

0 50 0 100 50 100 150 200 150 200 250 250 300 da 300 Ncmda<br />

Ncm<br />

Rubberised Brake Conveyor Roller<br />

<strong>EUROROLL</strong> supplies Brake Conveyor Rollers where the<br />

entire length of the roller has a shrinked-on rubber<br />

cover, which is used for steel pallets or plastic pallets.<br />

The result is to get a better friction between the Brake<br />

Conveyor Roller and the pallet.<br />

Depen<strong>de</strong>nt on the kind of installation EURO-<br />

ROLL-Brake Rollers can be supplied with short<br />

or long mountings. An extensive range of accessories<br />

to install the Brake Rollers and to ad-<br />

EBR - 300 EBR - 300 just them exactly supplements the product<br />

EBR - 500 EBR - 500 range.<br />

EBR - <strong>80</strong>0 EBR - <strong>80</strong>0<br />

EBR - 1000 EBR - 10002<br />

kinds of installation are possible:<br />

EBR - 1200 EBR - 1200Direct<br />

or indirect speed control of the pallet to<br />

be conveyed.<br />

35

Fixed installation, with flat spring suspension:<br />

EBTB<br />

Brake Conveyor Roller <strong>dia</strong>. <strong>80</strong> mm with flat spring<br />

suspension:<br />

Load up to 300 kg: EBTB 300<br />

Brake Conveyor Roller <strong>dia</strong>. <strong>80</strong> mm with flat spring<br />

suspension:<br />

Load up to 1000 kg: EBTB 1000<br />

The installation length EL (in mm)<br />

Design of the bracing tube:<br />

Tube bright steel - B<br />

Tube zinc-plated: - I<br />

Deep-freeze version: - TK<br />

Rubberised coating for steel<br />

and plastic pallets: - G<br />

Or<strong>de</strong>r example: EBTB 300 – 872 – I – G<br />

Brake Conveyor Roller with flat spring suspension<br />

for pallet weight up to 300 daN (kg), for installation<br />

length 872 mm, bracing tube zinc-plated,<br />

rubberised.<br />

Fixed installation, with stiff suspension: EBTS<br />

Brake Conveyor Roller <strong>dia</strong>. <strong>80</strong> mm with stiff suspension:<br />

Load up to 300 kg: EBTS 300<br />

Brake Conveyor Roller <strong>dia</strong>. <strong>80</strong> mm with stiff suspension:<br />

Load up to 1000 kg: EBTS 1000<br />

Installation length EL (in mm)<br />

Design of the bracing tube:<br />

Tube bright steel: - B<br />

Tube zinc-plated: - I<br />

Deep-freeze version: - TK<br />

Rubberised coating for steel<br />

and plastic pallets: - G<br />

Or<strong>de</strong>r example: EBTS 1000 – 872 – B<br />

Brake Conveyor Roller with stiff suspension for<br />

pallet weight up to 1000 daN (kg), for installation<br />

length 872 mm, bracing tube bright<br />

38<br />

TYPES OF INSTALLATIONS<br />

Ø 10.1<br />

for Ø <strong>80</strong><br />

for Ø 60<br />

13.6<br />

2.5<br />

Ø 10.1<br />

51<br />

124<br />

51<br />

10 14<br />

50<br />

10<br />

100 - 104<br />

EL<br />

RL<br />

96 - 104<br />

132<br />

EL<br />

RL<br />

50<br />

18<br />

15<br />

30<br />

55<br />

for Ø <strong>80</strong><br />

for Ø 60<br />

13.6<br />

2.5<br />

min. 75 min. 75<br />

Ø <strong>80</strong><br />

min. 96<br />

Ø <strong>80</strong><br />

15<br />

3<br />

100 - 104<br />

45<br />

11<br />

96 - 104<br />

2<br />

1.5<br />

18<br />

min. 96<br />

40<br />

51<br />

14<br />

50<br />

Ø 10.1<br />

124<br />

51<br />

20<br />

100 - 104<br />

96 - 104<br />

132<br />

30 15<br />

moving direction<br />

Ø 60<br />

Ø 60<br />

50<br />

moving direction<br />

Ø 10.1<br />

15<br />

3<br />

55<br />

Ø 10.1<br />

45<br />

11

©<br />

<strong>EUROROLL</strong>-<strong>BRAKE</strong> <strong>CONVEYOR</strong><br />

<strong>ROLLERS</strong> <strong>dia</strong>. <strong>80</strong> mm<br />

Dimensions, Technical Data<br />

Ø 10.2<br />

130<br />

<strong>BRAKE</strong> <strong>CONVEYOR</strong> <strong>ROLLERS</strong> <strong>dia</strong>. <strong>80</strong><br />

Roller Type Allowed Deliverable<br />

Pallet Weight Suspension Types<br />

EBT - 300 100 - 500 kg EBTS, EBTB, EBTR<br />

EBT - 1000 300 - 1000 kg EBTS, EBTB, EBTR<br />

52<br />

max. 120 (104) 104<br />

Ø <strong>80</strong><br />

2<br />

50 - 54<br />

130<br />

Ø 10.2<br />

40<br />

EL<br />

RL<br />

40<br />

LAYOUT<br />

Ø 10.2<br />

moving direction<br />

Ø 60<br />

Rollers Rollers Deep-freeze Contact<br />

zinc-plated bright Version Coating<br />

I B TK KB<br />

I B TK KB<br />

Installation with adjustable, spring suspension:<br />

EBTR<br />

Brake Conveyor Roller <strong>dia</strong>. <strong>80</strong> mm with<br />

adjustable, spring suspension:<br />

Load up to 300 kg: EBTR 300<br />

Brake Conveyor Roller <strong>dia</strong>. <strong>80</strong> mm with<br />

adjustable, spring suspension:<br />

Load up to 1000 kg: EBTR 1000<br />

Installation length EL (in mm)<br />

Design of the bracing tube:<br />

Tube bright steel: - B<br />

Tube zinc-plated: - I<br />

Deep-freeze version: - TK<br />

Rubberised coating for steel<br />

and plastic pallet: - G<br />

Or<strong>de</strong>r example: EBTR 1000– 872 – I<br />

Brake Conveyor Roller with adjustable spring<br />

suspension for pallet weight up to 1000 daN<br />

(kg), for fitting length 872 mm, bracing tube<br />

zinc-plated.<br />

ACCESSORIES/SPARE PARTS<br />

Brake Conveyor Roller <strong>dia</strong>. <strong>80</strong> mm, without<br />

suspension set.<br />

Load up to 300 kg: EBTR 300 – 0<br />

Brake Conveyor Roller <strong>dia</strong>. <strong>80</strong> mm, without<br />

suspension set.<br />

Load up to 1000 kg: EBTR 1000 – 0<br />

Or<strong>de</strong>r example: EBTR 1000 – 0 – 872 – I<br />

Brake Conveyor Roller without flat spring suspension<br />

set for pallet weight up to 1000 daN<br />

(kg), for fitting length 872 mm, bracing tube<br />

zinc-plated.<br />

Flat spring suspension (set): EBTB – BFH<br />

Fixing suspension (set): EBTS – STH<br />

Spring suspension, adjustable: AHBTR<br />

39