You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

awakes<br />

Woods is no stranger to <strong>Hitachi</strong> mining shovels.<br />

Prior to Hycroft, he was general manager of Nome<br />

Operations for NovaGold Resources—Alaska Gold.<br />

He has over 30 years of mining experience, with<br />

nearly 20 of those managing large-scale, open-pit<br />

mines and projects in North America including the<br />

Fort Knox mine in Alaska. Over the years, he’s been<br />

in a position to witness <strong>Hitachi</strong> productivity and<br />

quality for himself, and he knew he wanted it for<br />

Hycroft Mine.<br />

“Unfortunately, our frst 5500-6 shovel was literally<br />

on the dock in Japan ready to be shipped when<br />

the 2011 tsunami hit,” recalls Woods. “Although<br />

there cannot be enough said to describe the hardship<br />

the Japanese people went through as a result of that<br />

disaster, it had repercussions around the world. And,<br />

it certainly placed a real hardship on us. There was a<br />

lot of gnashing and grinding of teeth on our end as<br />

we tried to fgure what to do in the interim, because<br />

obviously our entire order and production plan had<br />

to be altered.<br />

“But we felt strongly enough about the product,<br />

and (our dealer) Arnold Machinery’s support of the<br />

product, that we decided to stick it out. We really<br />

like the <strong>Hitachi</strong> 5500s. They’re dependable and very<br />

productive. And now that they’re here, I’m glad we<br />

waited. In the interim, Arnold Machinery helped fnd<br />

and refurbish a couple of used EX3500s. We plan<br />

to keep them, and ultimately move them to another<br />

mine we’re just getting ready to open up.<br />

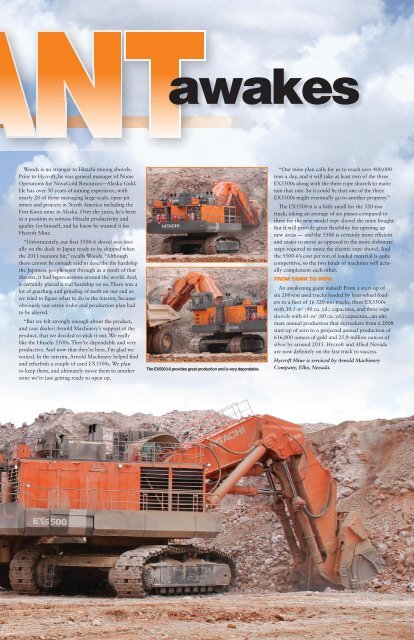

The EX5500-6 provides great production and is very dependable.<br />

“Our mine plan calls for us to reach over 400,000<br />

tons a day, and it will take at least two of the three<br />

EX5500s along with the three rope shovels to maintain<br />

that rate. So it could be that one of the three<br />

EX5500s might eventually go to another property.”<br />

The EX5500-6 is a little small for the 320-ton<br />

truck, taking an average of six passes compared to<br />

three for the new model rope shovel the mine bought.<br />

But it will provide great fexibility for opening up<br />

new areas — and the 5500 is certainly more effcient<br />

and easier to move as opposed to the more elaborate<br />

steps required to move the electric rope shovel. And<br />

the 5500-6’s cost per ton of loaded material is quite<br />

competitive, so the two kinds of machines will actually<br />

complement each other.<br />

From yAwN To wow<br />

An awakening giant indeed! From a start-up of<br />

six 200-ton used trucks loaded by four-wheel loaders<br />

to a feet of 16 320-ton trucks, three EX5500s<br />

with 30.5-m 3 (40 cu. yd.) capacities, and three rope<br />

shovels with 61-m 3 (80 cu. yd.) capacities...an ultimate<br />

annual production that skyrockets from a 2008<br />

start-up of zero to a projected annual production of<br />

616,800 ounces of gold and 25.9-million ounces of<br />

silver by around 2015. Hycroft and Allied Nevada<br />

are now defnitely on the fast track to success.<br />

Hycroft Mine is serviced by Arnold Machinery<br />

Company, Elko, Nevada.