Intelligence for All Wheel Drive - Haldex

Intelligence for All Wheel Drive - Haldex

Intelligence for All Wheel Drive - Haldex

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

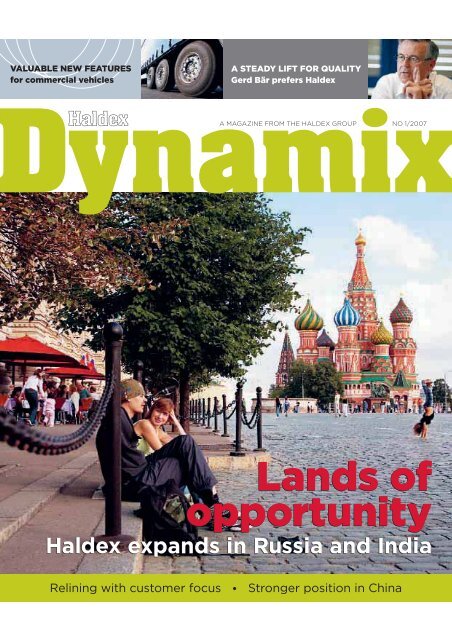

VALUABLE NEW FEATURES<br />

<strong>for</strong> commercial vehicles<br />

<strong>Haldex</strong><br />

A STEADY LIFT FOR QUALITY<br />

Gerd Bär prefers <strong>Haldex</strong><br />

A MAGAZINE FROM THE HALDEX GROUP NO 1/2007<br />

Lands of<br />

opportunity<br />

<strong>Haldex</strong> expands in Russia and India<br />

Relining with customer focus • Stronger position in China

�Content<br />

News<br />

IN SHORT. <strong>Haldex</strong> participates in a EU-supported<br />

project to improve traffic safety. 4<br />

STRONGER POSITION. The <strong>Haldex</strong> acquisition<br />

of Runguang Hydraulics provides the company<br />

access to the Chinese mobile hydraulics<br />

market. 22<br />

Customer first<br />

A TAIL OF SUCCESS. Gerd Bär GmbH dominates the<br />

field of mobile lifting systems. The company<br />

has chosen <strong>Haldex</strong> as sole supplier of<br />

crucial component. 6<br />

<strong>Haldex</strong> people<br />

WITNESS TO HISTORY. During his 33<br />

years in the company, Anders Loggert<br />

has seen — and been part of<br />

— <strong>Haldex</strong>’s rise into one of Sweden’s<br />

corporate success stories. 11<br />

<strong>Haldex</strong> Dynamix is a magazine published by the <strong>Haldex</strong> Group, Biblioteksgatan 11, Box 7200, SE-103 88 Stockholm, Sweden.<br />

Editor in chief: Lena Olofsdotter. Editorial services, design and prepress: Appelberg, Box 7344, SE-103 90 Stockholm Sweden, Tel + 46-8-406 54 00.<br />

Managing editor: Anne Hammarskjöld. Editorial commitee: Mats Kälvemark, Sherilyn Hensaw, Thomas Holm, Ulf Herlin, Mårten Lund, Diana Spieler, Steve Zarembski.<br />

Copy editing: Valerie Mindel. Graphic design: Lena Palmius. Print: Trydells Tryckeri, Laholm, Sweden. Cover photo: Ina Agency Press.<br />

Subscription: info@haldex.com or Fax + 1 (816) 891 9447. <strong>Haldex</strong> Dynamix is published twice a year, in Chinese, English, German and Swedish.<br />

2 <strong>Haldex</strong> Dynamix 1/2007<br />

11<br />

18<br />

Expertise<br />

JOINED FORCES. Dual brake discs, a fixed calliper<br />

brake and unbeatable maintenance are some of<br />

the features of SKF and <strong>Haldex</strong>’s new wheel <strong>for</strong><br />

commercial vehicles. 12<br />

THE HALDEX WAY. The Grand Rapids, Michigan,<br />

brake shoe relining plant in the United States puts<br />

listening to the customer at the center of its operations.<br />

24<br />

Features & Friends<br />

12<br />

NO BRAKES ON INDIA. In the wake of new<br />

safety regulations, India is facing a huge<br />

need <strong>for</strong> automatic brake adjusters. <strong>Haldex</strong><br />

India is ready to fill that need. 16<br />

ECONOMIC BOOM. Business is booming in<br />

both Russia and India, and <strong>Haldex</strong> is there to<br />

take advantage of the opportunities. 18<br />

DO IT LIKE TOYOTA. By eliminating waste, Japan’s<br />

Toyota has shown the world how to produce<br />

cars with maximum profitability. 23<br />

24<br />

www.haldex.com

6<br />

<strong>Haldex</strong> is preferred supplier of a key hydraulic component to Bär,<br />

Europes leading supplier of high quality mobile lifting systems.<br />

When the environment,<br />

safety and vehicle<br />

dynamics drive demand<br />

THE STRATEGIC SIGNIFICANCE OF HALDEX’ engagement in<br />

China, India and other so-called emerging markets is rapidly increasing.<br />

For example, the market in China <strong>for</strong> wheel-loaders is as large<br />

as that in the rest of the world. The acquisition of Runguan Hydraulics<br />

(see article on page 22) further rein<strong>for</strong>ces <strong>Haldex</strong> position as the<br />

leading supplier of hydraulics products to the Chinese construction<br />

equipment industry. <strong>Haldex</strong> Hydraulics (Qingzhou) Co. Ltd. will<br />

manufacture hydraulic pumps, valves and cylinders <strong>for</strong> different types<br />

of construction plant such as wheel loaders and excavators.<br />

Alongside the very positive developments in China, India is becoming<br />

an increasingly more important market <strong>for</strong> <strong>Haldex</strong>. In April 2007,<br />

new legislation was introduced here with regard to automatic brake<br />

adjustment systems <strong>for</strong> commercial vehicles. With 60 percent of the<br />

global market, <strong>Haldex</strong> is world leader in automatic brake adjusters<br />

and is at present starting up local production to ensure deliveries to<br />

commercial vehicle manufacturers in India. It is interesting to note<br />

that demand is being driven by legislation. Legislation is even being<br />

discussed in China and this could provide new opportunities <strong>for</strong> <strong>Haldex</strong><br />

and our partners in the commercial vehicle and construction equipment<br />

industries.<br />

In the usa, we can also see extensive and promising opportunities<br />

<strong>for</strong> <strong>Haldex</strong>. Environmental legislation is being tightened with regard<br />

to engine emission limits. This has meant an increase in demand <strong>for</strong><br />

Alfdex, the very successful crankcase gas cleaning system developed by<br />

<strong>Haldex</strong> in close cooperation with Alfa Laval. <strong>Haldex</strong>’ crankcase gases<br />

cleaning system has also been tested this spring on truck engines. The<br />

automotive industry has shown great interest in this technology that<br />

uses a variable pump, Varivent, which recirculates exhaust gases in diesel<br />

engines. egr, Exhaust Gas Recirculation, is in great demand in the<br />

usa but is also used by Scania and man, among others, in Europe.<br />

Also, <strong>Haldex</strong>’ Traction Systems Division is rising to meet large-scale<br />

challenges – deliveries of fourth generation 4wds are now being prepared.<br />

These will be used, among other things, in Volkswagen’s new<br />

Tiguan. We are also establishing a new factory in Mexico, with a delivery<br />

start to a new North American customer planned <strong>for</strong> 2008.<br />

<strong>Haldex</strong> mission values focus on safety, the environment and vehicle<br />

dynamics. Guided by these, we have built up a strong plat<strong>for</strong>m as a<br />

supplier to leading automotive manufacturers in Europe and the usa.<br />

It is both gratifying and exciting that similar quality concepts are now<br />

being demanded in the world’s fastest growing economies. <strong>Haldex</strong> is<br />

well prepared to meet these immense and stimulating<br />

challenges.<br />

Joakim Olsson<br />

Managing Director<br />

and Group ceo<br />

www.haldex.com 1/2007 <strong>Haldex</strong> Dynamix 3

�News<br />

Photo iStockphoto<br />

Tougher Japanese<br />

Fuel-Economy Limits<br />

The Japanese ministries of Industry<br />

and Transport, have agreed on<br />

new fuel efficiency standards. The<br />

ministries plan to revise regulations<br />

this summer. Cars, including diesel<br />

engine models, will be required to<br />

run 16.8 kilometres on one litre of<br />

fuel under a specific driving mode.<br />

The figure is 23.5% more than an<br />

average of 13.6 km/l in 2004. The<br />

2015 targets <strong>for</strong> small buses and<br />

trucks are set at 8.9 km/l and 15.2<br />

km/l, respectively, up 7.2 % and 12.6<br />

respectively from 2004 averages of<br />

8.3 km/l and 13.5 km/l.<br />

4 <strong>Haldex</strong> Dynamix 1/2007<br />

<strong>Haldex</strong> involved in EU<br />

traffic safety project<br />

THE 3-YEAR SPARC (Secure Propulsion using Advanced Redundant Control) project,<br />

a joint EU/industry-funded ef<strong>for</strong>t to improve traffic safety through advanced technology,<br />

was concluded this summer with a major presentation to the EU Commission<br />

on July 16 and to the vehicle industry on July 17, in Papenburg, Germany. About 400<br />

top managers and key figures from the vehicle industry attended the industry<br />

presentation. The project, which began in 2004, was coordinated by DaimlerChrysler<br />

and included 27 other representatives from the European vehicle industry. <strong>Haldex</strong><br />

has provided Electro Mechanical Brakes (EMB) <strong>for</strong> one of the trucks in the project as<br />

well as a complete control system, including EMB and Electronic Air Suspension, <strong>for</strong><br />

one of the project trailers. The purpose of SPARC was the creation of a predictive,<br />

rather than reactive, hazard detection system.<br />

For further in<strong>for</strong>mation on SPARC, visit: http://www.sparc-eu.net<br />

Photo INA Agencypress<br />

China plans <strong>for</strong><br />

Jatropha Biodiesel<br />

THE STATE FORESTRY ADMINISTRATION OF CHINA plans to plant 13 million<br />

hectares (an area the size of England) with Jatropha trees <strong>for</strong> biodiesel.<br />

Jatropha is currently grown on around 2 million hectares across the<br />

country. The <strong>for</strong>est, mostly spread over southern China, is expected eventually<br />

to produce nearly 6 million tons (6,8 billion litres) of biodiesel every<br />

year.<br />

www.haldex.com

Time <strong>for</strong> greener Formula 1<br />

The environmental requirements<br />

imposed on Formula 1 racing are<br />

being tightened and the end is<br />

drawing near <strong>for</strong> the considerable<br />

carbon dioxide emissions produced<br />

by Formula 1 cars. In 2011, new rules<br />

will be in effect <strong>for</strong> a greener racing<br />

environment.<br />

THE HEAD OF THE FIA car racing organization, Max<br />

Mosley suggests there will be new opportunities <strong>for</strong> racing<br />

teams and race car designers when the rules change<br />

in 2011. Bio fuels, energy recycling, limited fuel allocation<br />

and smaller cylinder volumes – perhaps even hybrid<br />

engines – will be used to decrease carbon dioxide emissions<br />

be<strong>for</strong>e Formula 1 falls into disrepute in the face of<br />

environmentally conscious public opinion.<br />

The designers are aware that the highest category <strong>for</strong>mula<br />

race cars are environmental bad guys and that the<br />

potential exists to reduce emissions. An 800 horse power<br />

Formula 1 car releases about 1,500 grams of carbon dioxide<br />

per kilometer on the track. In comparison, average<br />

emissions <strong>for</strong> cars today is 170 grams and the eu recently<br />

set a limit of 130 grams by 2012.<br />

Technology<br />

can save lives<br />

Safety oriented Intelligent Transport<br />

Systems, ITS, such as Adaptive<br />

Cruise Control and Intelligent Speed<br />

Assistance can save reduce casualties<br />

(fatalities and injured) by 40<br />

percent according to a report from<br />

the Dutch Institute <strong>for</strong> Road Safety<br />

Research. The report points out<br />

Intelligent Speed Assistance as the<br />

most promising new technology in<br />

terms of potential impact on safety.<br />

ALFDEX TAKES OFF<br />

ORDERS FOR THE ALFDEX OIL/MIST SEPARATOR have increased dramatically<br />

since last December. The main impetus <strong>for</strong> increased production is environmental<br />

legislation that is now taking effect. “In 2005, environmental laws took effect<br />

in Japan. In January<br />

2007, they took effect<br />

in the United States. In<br />

2008 and 2009, they<br />

will take effect in the<br />

EU,” says Mats Ekeroth,<br />

Alfdex president. Recent<br />

Photo iStockphoto<br />

‘‘<br />

In 2005, environmental laws took<br />

effect in Japan. In January 2007,<br />

they took effect in the United States.<br />

In 2008 and 2009, they will take<br />

effect in the eu.<br />

Mats Ekeroth, Alfdex president’’<br />

attention on greenhouse<br />

gases and global<br />

warming has not had an<br />

immediate impact on<br />

business, says Ekeroth.<br />

“Even without the ‘Al Gore effect,’ demand <strong>for</strong> our separator is up because of<br />

existing laws. Catalytic regulations, <strong>for</strong> example, are on the rise everywhere.”<br />

But as governments respond to new pressure, they may further tighten environmental<br />

legislation, which may result in additional demand <strong>for</strong> Alfdex, whose<br />

customers are large truck manufacturers.<br />

www.haldex.com 1/2007 <strong>Haldex</strong> Dynamix 5

A lift<br />

<strong>for</strong> quality and logistics<br />

<strong>for</strong> quality and logistics<br />

Gerd Bär is a man with his own way of doing<br />

things, a fact that has helped drive Gerd Bär<br />

GmbH to the top in the fi eld of a mobile lifting<br />

systems. The company has chosen <strong>Haldex</strong> as<br />

sole supplier of crucial components.<br />

Text Michael Lawton Photos Thomas Müller<br />

Entrepreneur Gerd Bär is a typical product of the<br />

Swabian region of Germany: He’s a bit stubborn, a<br />

bit conservative, very hardworking and driven. He<br />

started out running his father’s fl our mill. When<br />

he had turned it into a profi table business, he handed it<br />

over to his brother. Following his education, he went to<br />

work <strong>for</strong> a company that made lifts <strong>for</strong> the backs of trucks,<br />

and when the management wouldn’t let him get involved<br />

in policy making, he went off and founded his own company,<br />

Gerd Bär GmbH.<br />

Despite the fact that he has now retired from active<br />

involvement in Bär, Gerd Bär is still the spirit behind the<br />

company, which has just celebrated its 25th anniversary.<br />

Rolf Petermann-van den Berg, the company’s commercial<br />

director, says, “We are a very young leadership team, but<br />

we are all deeply infl uenced by [Gerd Bär].” The company<br />

makes the Bär Cargolift mobile lifting system and is the<br />

market leader in Germany, Poland, the Czech Republic and<br />

Russia. �<br />

6 <strong>Haldex</strong> Dynamix 1/2007 www.haldex.com

‘‘<br />

We also got rid of the need <strong>for</strong> welding<br />

– first because welders are rare and<br />

expensive<br />

’’<br />

and second because you then<br />

need to treat the joint with new rustproofing.<br />

Gerd Bär<br />

www.haldex.com 1/2007 <strong>Haldex</strong> Dynamix 7

Bär was the first mobile lifting system producer to offer<br />

aluminum plat<strong>for</strong>ms as standard. Bär was also the first<br />

company to offer a two-year guarantee on their steel<br />

parts, when six months was standard.<br />

Gerd Bär himself is known as an innovator in a fairly<br />

conservative environment: “I have made an impression on<br />

the industry,” he says, refl ecting on his career. “Others have<br />

followed me.”<br />

From the start, Bär was the fi rst company to offer aluminum<br />

plat<strong>for</strong>ms as standard. “We cost dm 500 [usd 350]<br />

more than the competition’s standard product as a result,”<br />

remembers Gerd Bär, “but we cost dm 1,000 [usd 750] less<br />

than the others with the aluminum plat<strong>for</strong>m option.”<br />

FIFTEEN YEARS AGO, Bär started treating its steel parts<br />

with a cathodic dip coating. That meant the company could<br />

offer a two-year guarantee instead of the six-months guarantee<br />

that had been usual until then. The fi rst German<br />

competitor caught up with Bär fi ve years ago, but competitors<br />

in the rest of Europe have just begun to use cathodic<br />

dip coating this year.<br />

8 <strong>Haldex</strong> Dynamix 1/2007<br />

“<strong>Haldex</strong> has been around<br />

longer and has better<br />

experience with the electrical<br />

side,” says Gerd Bär<br />

about his companys preferred<br />

supplier.<br />

The market is moving<br />

WHEN GERD BÄR, founder of Gerd Bär<br />

GmbH, says that others in the mobile lifting<br />

systems industry have been following his<br />

lead, he’s not just talking about Germany. He’s<br />

had a significant influence on the European<br />

industry as well and especially on European<br />

regulations.<br />

“European regulations have turned out<br />

to be very similar to those in Germany,” he<br />

says. “Other people have been skeptical, but I<br />

always said that we have to end up in Europe<br />

on the German side of center, when it comes<br />

to policy. And indeed, continental Europe is<br />

now much more German than it was.” The<br />

choice of words is significant: Only continental<br />

Europe seems to be moving in the same<br />

Rolf Petermann-van den Berg, Bär GmbH’s<br />

commercial director, notes an increasing<br />

demand <strong>for</strong> quality mobile lifting systems all<br />

through Europe.<br />

Bär’s latest innovation is the FreeAccess, a folded tailgate<br />

lift that only covers one of the double doors at the back of a<br />

transporter. The advantage is that it doesn’t have to be lowered<br />

when the driver only wants to get in and out of the van.<br />

But when something heavy or awkward has to be unloaded,<br />

the tailgate can be lowered, folded out to the full width of<br />

the vehicle and used as a full-size lift. Petermann explains<br />

that the Bär design allows the FreeAccess to be fi tted in just<br />

four hours. “You don’t have to cut any of the bodywork,”<br />

he says. “You don’t have to do any welding. You don’t even<br />

have to drill any holes because the holes we’ve used are<br />

already in the vehicle. You and I could do it between us<br />

right now.<br />

“This is going to be an important product <strong>for</strong> us in the<br />

future,” he continues. “We expect to sell 1,000 a year.”<br />

In addition, Bär introduced the idea of selling units that<br />

were already largely constructed. “In the old days you used<br />

direction. The United Kingdom, says Gerd Bär,<br />

has its own tradition, and that has made it<br />

difficult <strong>for</strong> Bär to get a solid foothold, even<br />

though it has one of its four subsidiaries there.<br />

But the development of European standards<br />

was only an extension of Gerd Bär’s<br />

work on the development of German standards.<br />

Some years back, he was the driving<br />

<strong>for</strong>ce behind the <strong>for</strong>mation of the Association<br />

of German Manufacturers of Lifting Equipment,<br />

which is now a Europe-wide organization.<br />

“We needed an organization like that,”<br />

says Gerd Bär now, “so that we could speak<br />

to the vehicle manufacturers on equal terms.”<br />

A major result of the group’s work was the<br />

development of a standard interface between<br />

trucks and lifts so that installing a lift didn’t<br />

mean having to rewire the truck. Now all<br />

that’s required is to fit a plug into a socket.<br />

But each European market has its own<br />

www.haldex.com

to get a kit of parts,” says Gerd Bär. “We also got rid of the<br />

need <strong>for</strong> welding – fi rst because welders are rare and expensive<br />

and second because you then need to treat the joint<br />

with new rust-proofi ng. <strong>All</strong> you have to do with our lifts is<br />

drill some holes and screw them on.”<br />

In addition to FreeAccess, Bär has the usual full-width<br />

tailgate lift and a series of lifts that retract underneath the<br />

chassis, so that they don’t interfere when trucks are driven<br />

up to a loading bay or when they are being unloaded by a<br />

<strong>for</strong>klift truck. Top of the line is the all-hydraulic Hydfalt, a<br />

double-folded lift in which the retracting, folding and lifting<br />

mechanisms are all hydraulically operated. Many of the<br />

products with up to 1.5 tons carrying capacity use Bär’s 2=4<br />

technology, where two cylinders (one <strong>for</strong> lifting and one <strong>for</strong><br />

tilting) replace the usual four, saving cost and weight.<br />

<strong>Haldex</strong> is the sole supplier of the hydraulic system <strong>for</strong><br />

Bär’s products. Gerd Bär says that <strong>Haldex</strong> is one of only two<br />

characteristics. Rolf Petermann-van den<br />

Berg Gerd, Bär GmbH’s commercial director,<br />

notes that Bär is market leader <strong>for</strong> lifts on<br />

secondhand trucks in Greece, even though<br />

until recently Bär didn’t have a dealer there.<br />

The trucks with the lifts were being sold from<br />

Germany.<br />

In the UK, column lifts seem to be standard,<br />

and operators are not inclined to fit Bär’s cantilevered<br />

lifts to their new trucks because of<br />

cost. But there is a good market in retrofits,<br />

where price seems not to be such an issue.<br />

In Poland, it is very often the vehicle dealers<br />

who have the main say in which lifts are to be<br />

fitted. Petermann says that causes problems,<br />

since Bär wants to be sure of the quality of<br />

the fitting. So the company has its own teams<br />

do the work, to avoid the risk that a dealer<br />

who is inexperienced will give Bär a bad name.<br />

In the German market, there are three typi-<br />

www.haldex.com<br />

cal scenarios: “The simplest situation <strong>for</strong> us is<br />

when the vehicle body builder has a couple<br />

of suppliers, and we’re No. 1,” says Petermann.<br />

“Then, when a customer comes, he will be<br />

advised to take our lift.”<br />

But that doesn’t always happen: “Sometimes<br />

the end user will insist on a particular<br />

product,” Petermann says. “That occurs<br />

mostly among the big food retailers or<br />

the vehicle hire companies. Many of<br />

the big companies buy their lifts<br />

directly from us. We deliver them to<br />

the bodywork manufacturer, but the<br />

invoice goes to the end user.”<br />

Increasingly now, however, vehicle<br />

makers are cutting out the vehicle<br />

body builders and offering complete<br />

solutions off the shelf. “That’s changing<br />

the market,” says Petermann.<br />

Bär’s main partners are still the vehicle body<br />

FreeAccess only covers one of the double doors at the<br />

back of a transporter, and doesn’t have to be lowered<br />

when the driver only wants to get in and out of the van.<br />

companies that produce the quality his company needs,<br />

and he adds, “<strong>Haldex</strong> has been around longer and has better<br />

experience with the electrical side.” Bär has designed its<br />

own compact unit that fi ts neatly into the main supporting<br />

beam, so that it is protected from the elements. <strong>Haldex</strong> will<br />

make 80 percent of the units, while Bär will make the other<br />

20 percent from <strong>Haldex</strong> components. “We have about 80<br />

versions of our hydraulic unit,” explains Gerd Bär, “but 20<br />

of them make up 80 percent of our output. So we will make<br />

the other 20 percent. That gives <strong>Haldex</strong> a good throughput,<br />

and we can do the small jobs.”<br />

BÄR HAS NEVER BEEN the cheapest lift manufacturer,<br />

but Rolf Petermann says you have to see the total picture.<br />

“Our lifts take less time to install, and they probably spend<br />

less time in the workshop afterwards,” he says. “If you’ve<br />

�<br />

taken that into account, the total cost is equivalent. In<br />

builders, however. Most of its lifts go to small<br />

firms that are best served by local suppliers,<br />

and that means that Bär is not dependent on<br />

any one customer. “If a big customer drops<br />

out, it would hurt,” says Petermann, “but it<br />

wouldn’t break us.” �<br />

Bär sends a specialized<br />

team to help vehicle<br />

dealers ensure the<br />

quality of the lift<br />

fittings.<br />

1/2007 <strong>Haldex</strong> Dynamix 9

Bär has designed its own compact unit that fits neatly<br />

into the main supporting beam. <strong>Haldex</strong> will make 80<br />

percent of the units, Bär makes the other 20 percent<br />

from <strong>Haldex</strong> components.<br />

addition, we offer features as standard that others offer as<br />

extras, such as the plug-and-play electrical interface.”<br />

But high quality is not always rewarded, and Gerd Bär<br />

admits that, in the past, the company tended to suffer from<br />

a problem typically found among medium-sized German<br />

engineering manufacturers: Products are made to please<br />

the engineers and not necessarily the customers. “I’m<br />

a technical man, and I tend sometimes to be a bit of an<br />

extremist, but I’d say you could see a change in ideology<br />

[within Bär] from around 1998, and a change in practice<br />

from around 2002,” he says. 1998 was when Gerd Bär’s<br />

son Tobias began to be involved in the strategy of the company.<br />

He became joint managing director in 2002. “Initially<br />

he was given certain areas of responsibility,” explains<br />

Gerd Bär. “He then extended his range until he took over<br />

everything last year.”<br />

Tobias Bär has helped the company produce products<br />

that are competitive throughout Europe, says his father. In<br />

the past, the company concentrated on the German-speaking<br />

world, but now its Web site is in seven languages. Subsidiaries<br />

in the Czech Republic and Poland have a been a<br />

big success, and the Russian market seems to be booming.<br />

It is planning to increase production from 11,900 units in<br />

10 <strong>Haldex</strong> Dynamix 1/2007<br />

The plug-and-play electrical interface is offered as<br />

standard.<br />

2006 to 13,800 this year. Petermann says that this is only<br />

partly due to the company’s growth: “We are dependent<br />

also on the level of the economy, and the current growth is<br />

helping us a lot,” he says.<br />

“We orient our work towards the standards of the vehicle<br />

manufacturers,” says Gerd Bär. “We have the same understanding<br />

of logistics and quality as they do. A lift is an integral<br />

part of a vehicle. It may represent a small proportion of<br />

the value, but if it fails, the vehicle can’t be used. We take<br />

that responsibility very seriously.” �<br />

www.haldex.com

AFTER COMPLETING HIS MBA at the University of<br />

Lund, Anders Loggert joined <strong>Haldex</strong> aged 29, as a fi nancial<br />

controller at sab Automotive and was there <strong>for</strong> four years<br />

be<strong>for</strong>e he switched to sales in 1978. “I got fed up with the<br />

balance sheet,” he smiles. “I wanted to do something else<br />

and I become sales manager <strong>for</strong> Scandinavia, Eastern<br />

Europe, Benelux and South America as well as handling<br />

inside sales in Landskrona.”<br />

In 1983, he moved to Blue Springs, Missouri, where he<br />

took up the position of general manager. “It was a kind<br />

of start-up position,” Loggert explains. “Production of the<br />

automatic brake adjuster had only just begun in the US<br />

when I moved there, and we were still in the red. The product<br />

hadn’t really been accepted yet so we had to do a real<br />

sales job,” he says. “But by not cutting corners and making<br />

sure the quality of the product was consistent with European<br />

standards, we won through, and other companies<br />

couldn’t compete.”<br />

In 1991, Loggert moved to Berching in Germany to<br />

run Schabmuller GmbH, an electrical dc motor plant<br />

acquired to compliment <strong>Haldex</strong>’s hydraulic applications.<br />

“This was probably my most challenging and diffi cult time<br />

with the company,” says Loggert. “The deal happened just<br />

months be<strong>for</strong>e the turnaround in the Communist bloc<br />

which instantly opened up new competition. We ran into<br />

problems and had to cut staff from 500 to 250”, says Loggert.<br />

“Those were very tough years and I learned a lot but it<br />

wasn’t much fun,” he says, ruefully.<br />

Working in so many different areas, including three<br />

out of <strong>Haldex</strong>’s four divisions has given Loggert a good<br />

overview of the entire group. But, he says, company operations<br />

were always consistent across the board. “That’s one<br />

of its great strengths,” Loggert opines. “And it means the<br />

quality of our products and our message to customers is<br />

always consistent,” he adds. “Of course, there are variations<br />

depending on local cultures, but we’ve always had good<br />

bosses who put people fi rst.”<br />

Loggert believes that having a strong core product was<br />

one of the drivers to the good relationships within the<br />

company. The automatic brake adjuster was introduced in<br />

1967 and didn’t show black fi gures until 10 years later. But,<br />

says Loggert, the owners had such patience and faith in the<br />

product and the workers that they took the necessary time<br />

to turn it into one of Sweden’s success stories.<br />

By early 1995, Loggert was back in Stockholm and<br />

engaged in Group Business Development, with the main<br />

task of setting up the Group in Asia. That was when the<br />

Korean and Chinese sales offi ces were set up and local<br />

potential customer penetration started. “That was one of<br />

the tasks I most enjoyed,” says Loggert. “I was one of our<br />

fi rst people in China and soon our operations there will<br />

rival Europe,” he adds proudly.<br />

In 1998, Loggert was offered the position of European<br />

sales manager <strong>for</strong> the Brake Systems division. He moved to<br />

his present position in 2005.<br />

“I’m very lucky to have been able to work all over the<br />

world,” Loggert refl ects. “It has taught me that even if you<br />

don’t speak the same language or if you have a different<br />

skin color, underneath it all, people fundamentally want<br />

the same out of life. And that applies to our customers<br />

too, which has shown me the importance of being consistent.”<br />

�<br />

�<strong>Haldex</strong><br />

People<br />

“The quality of our products<br />

is always consistent”<br />

Currently head of sales and marketing <strong>for</strong> Commercial Vehicle Systems (CVS) based in<br />

Strasbourg, Anders Loggert has had a long and varied career with <strong>Haldex</strong>. He looks back<br />

at the ups and downs of the past 33 years with the company.<br />

Text Anna MacQueen Photo Alastair Millar<br />

Name: Anders Loggert<br />

Age: 62 years old<br />

Lives: in Alsace, France.<br />

I’m married and we<br />

have one daughter and<br />

two grandchildren.<br />

Working <strong>for</strong> <strong>Haldex</strong> <strong>for</strong><br />

33 years and married<br />

<strong>for</strong> 36 – I’m kind of a<br />

boring guy!<br />

Education: I have an<br />

MBA from the University<br />

of Lund. I never really<br />

liked school. Some<br />

people say school was<br />

the best time of their<br />

life but I’ve enjoyed<br />

work more.<br />

Hobbies: I play a little<br />

golf and I like messing<br />

around with cars and<br />

BMWs in particular.<br />

Motto: Never give up!<br />

Historical figure you<br />

most admire: Mikhail<br />

Gorbachev.<br />

What is your one<br />

regret: Giving up my<br />

French lessons!<br />

www.haldex.com 1/2007 <strong>Haldex</strong> Dynamix 11

Double disc,<br />

double per<strong>for</strong>m<br />

<strong>Haldex</strong> and SKF from Sweden have jointly developed an advanced wheel end <strong>for</strong> commercial<br />

vehicles. Its typical features include a fixed caliper brake with two discs and the compact<br />

SKF hub unit. Text Michael Kern Photos <strong>Haldex</strong>, Gigant<br />

12 <strong>Haldex</strong> Dynamix 1/2007 www.haldex.com

ance<br />

www.haldex.com<br />

Closing the gap in stopping distance<br />

requires a better bite in truck brakes.<br />

DISC BRAKES have a fairly long history<br />

in cars. But in commercial vehicles,<br />

especially in heavy trucks, this<br />

type of brake has been used only <strong>for</strong> a<br />

relatively short period of time. That’s<br />

due to the fact that hydraulics are<br />

not really a practical power transmission<br />

medium <strong>for</strong> the brakes of such<br />

vehicles, which typically weigh about<br />

40 tonnes. And it was not until the<br />

mid 90s that purely pneumatic brakes<br />

reached the level of maturity required<br />

<strong>for</strong> fi eld operation. Manufacturers Scania<br />

and Mercedes were the pioneers, and it took<br />

about ten more years be<strong>for</strong>e the last European<br />

truck builder switched over to disc brakes.<br />

Today the standard both in trucks and trailers<br />

is sliding caliper brakes with one brake disc<br />

each. But there’s still plenty of room <strong>for</strong> technological<br />

advancement. After all, the wheel ends<br />

have to meet the same expectations as the truck<br />

as a whole. Today, more than ever, the trend is<br />

towards increased effi ciency with reduced weight<br />

and lower costs. <strong>Haldex</strong>’ Development Engineer<br />

Joakim Gripemark explains what this means<br />

with regard to brake clamping <strong>for</strong>ces – in other<br />

words, the “bite” of the brakes: “We expect that<br />

clamping <strong>for</strong>ces of up to 35 kNm will be required<br />

in future, compared to some 27 kNm today.”<br />

From a technical point of view, it would be no<br />

problem to make today’s sliding caliper brakes<br />

fi t <strong>for</strong> such fi erce <strong>for</strong>ces. But due to the required<br />

rein<strong>for</strong>cements, the result would be a roly-poly<br />

that would be diffi cult to incorporate in the available<br />

installation space – especially at the front<br />

axle where space is extremely restricted. So it<br />

was a logical step <strong>for</strong> <strong>Haldex</strong> to undertake the<br />

design of a fi xed caliper with dual discs. Thanks<br />

to the fi xed caliper, the entire unit is no wider<br />

than the sliding caliper brakes used today. A support<br />

is not required.<br />

Development began in the year 2000 and<br />

immediately looked very promising. So the idea<br />

started to <strong>for</strong>m in the minds of the engineers<br />

to do it thoroughly and completely to be able to<br />

develop an entire wheel end. At this stage, skf<br />

became involved as an extremely experienced<br />

hub bearing unit manufacturer and contributed<br />

�Expertise<br />

The new fixed caliper dual disc brake reduces<br />

life cycle costs to a considerable extent.<br />

with a tailor-made integrated slim-line hub<br />

unit. Designed <strong>for</strong> one million kilometres of<br />

maintenance-free operation, it boasts a decisive<br />

advantage: When the discs are worn down, they<br />

can easily be drawn off the axles as soon as the<br />

wheel fl ange has been dismounted and the locking<br />

device opened.<br />

IT’S NOT WITHOUT REASON that skf was<br />

selected as a partner. The company took up<br />

series manufacture of compact truck hub units<br />

in 1990. Having produced more than fi ve million<br />

such units to date, skf is the most experienced<br />

manufacturer worldwide in this fi eld.<br />

But let’s take a detailed look at the so-called<br />

“ModulD” solution developed in cooperation<br />

with <strong>Haldex</strong>. The hub unit is of extremely slim<br />

design and offers precisely adjusted interplay<br />

between the bearing, grease and seals. It has<br />

been designed <strong>for</strong> a service life of one million<br />

kilometres. Conception of the unit was assisted<br />

by sophisticated calculation programs that made<br />

it possible to anticipate fi eld conditions at the<br />

laboratory stage. During fi eld tests, the impressive<br />

expected life of one million kilometers was<br />

�<br />

proven to be achievable.<br />

1/2007 <strong>Haldex</strong> Dynamix 13

�Expertise<br />

“ From a technical point of view, it would be no problem to make<br />

today’s sliding caliper brakes fit <strong>for</strong> such fierce <strong>for</strong>ces. But due to the<br />

required rein<strong>for</strong>cements, the result would be a roly-poly that would<br />

be difficult to incorporate in the available installation space.”<br />

� Five ingeniously positioned springs ensure<br />

that the disc virtually floats on the wheel end.<br />

The technicians used all their wiles when it<br />

came to the attachment of the brake: The disc<br />

is positioned on the toothwork of the integrated<br />

hub, interlocked. Here fi ve ingeniously designed<br />

springs permit lateral displacement, to ensure<br />

wear compensation and clearance. They also<br />

ensure that the contact between hub and disc<br />

does not become too close as to avoid excessive<br />

heat dissipation in the hub: The disc virtually<br />

fl oats on the hub and, as a consequence, noise<br />

development is exemplarily low. The fact that<br />

the thermal stress on the hub is kept as low as<br />

possible is vital <strong>for</strong> long hub life and at the same<br />

time means less strain on the tyres.<br />

ANOTHER ADVANTAGE of this ensemble is<br />

that the pads can be easily replaced from overhead<br />

without having to dismount the wheel<br />

fl ange or other components.<br />

Both the dual disc and the triple brake pads<br />

are being developed to last some 500,000 kilometres<br />

or more. So the replacement of pads and<br />

discs coincide and, the brake maintenance time<br />

<strong>for</strong> a trailer is now about six hours.<br />

Fitted with the new hub and offering today’s<br />

usual clamping <strong>for</strong>ce, “the skf-<strong>Haldex</strong> wheel end<br />

weighs about 15 percent less than current conventional<br />

solutions,” emphasizes Andreas Richter,<br />

Vice President Marketing of <strong>Haldex</strong> Brake<br />

14 <strong>Haldex</strong> Dynamix 1/2007 www.haldex.com

Products in Landskrona<br />

(Sweden), and adds.<br />

“After all, this is up to 25<br />

kilograms per axle.”<br />

But the new brake<br />

concept offers even<br />

more advantages.<br />

Thanks to its consistent<br />

modular design, the<br />

new wheel end is a model<br />

example of adaptability. This<br />

characteristic permits not only<br />

a wide range of different specifi -<br />

cations but also at the same time,<br />

retrofi t potential. “It is important<br />

that the customer can use the old axle<br />

and its journal,” Matthias J. Haupt, Vice<br />

President Marketing of skf’s Business<br />

Unit Trucks, explains the concept.<br />

The brake itself is extremely versatile too. For<br />

all 22,5” wheels, <strong>Haldex</strong> uses 21” brakes which<br />

saves more than 75 kilograms per triple-axle suspension.<br />

However, within the <strong>Haldex</strong> modular<br />

concept, a fi xed caliper brake, with the same pad<br />

and disc replacement intervals, could also be<br />

used <strong>for</strong> 19,5” wheels. This variant is attractive<br />

� Testing of the disc brake.<br />

� The SKF-<strong>Haldex</strong> wheel end, combining<br />

the two companies’ experience in disc brake<br />

design and compact truck hub units.<br />

www.haldex.com<br />

<strong>for</strong> all those who pay special attention to weight:<br />

“Compared to conventional 22.5-inch wheel<br />

ends, it reduces the weight per axle by as much<br />

as 35 kilograms,” Joakim Gripemark, product<br />

development, points out.<br />

But the <strong>Haldex</strong>-skf system is also suitable <strong>for</strong><br />

heavier clamping <strong>for</strong>ces. With more of a solid<br />

design (and thus a bit more weight) and fi tted<br />

with a 22-inch (430 mm) disc, the fi xed calliper<br />

dual disc brake is well prepared <strong>for</strong> clamping<br />

<strong>for</strong>ces of up to 35 kNm that will undoubtedly be<br />

required some time in the future. “The capacity<br />

of sliding caliper brakes is suffi cient <strong>for</strong> up to 30<br />

kNm,” Gripemark is convinced, “but if you need<br />

35 kNm, then there’s not enough space available<br />

<strong>for</strong> sliding caliper brakes.“<br />

FIELD TESTS WITH THE NEW WHEEL end<br />

are in full swing both in Europe and in the<br />

United States, not only in trailers but also in<br />

truck front axles. Here, in particular, such a<br />

space-saving slim design is likely to meet with<br />

high demand, at least when the independent<br />

wheel suspension <strong>for</strong> the steering axle becomes<br />

involved. “In 2006, we concluded the devel-<br />

The new SKF hub<br />

unit has been<br />

designed <strong>for</strong> a lifetime<br />

of one million<br />

maintenance-free<br />

kilometres.<br />

opment stage,” Andreas Richter outlines the<br />

history of the new fi xed caliper brake that is<br />

now ready <strong>for</strong> serial delivery. It is the German<br />

axle manufacturer Gigant who introduced the<br />

brake at the Solutrans trade fair in Lyon in April<br />

2007.�<br />

1/2007 <strong>Haldex</strong> Dynamix 15

�Features<br />

& Friends<br />

16 <strong>Haldex</strong> Dynamix 1/2007<br />

Text R.F. Mamoowala<br />

Photo R.F. Mamoowala and INA Agency Press<br />

Indian business<br />

in overdrive<br />

With India making the use of automatic<br />

brake adjusters mandatory <strong>for</strong><br />

commercial vehicles, <strong>Haldex</strong> India is<br />

pushing annual production towards<br />

1 million.<br />

THE MOOD IS UPBEAT at the Lounge of the Leela<br />

Kimpinski Hotel in Bombay, where the <strong>Haldex</strong> delegation<br />

awaits the arrival of Jay C. Longbottom, executive vice<br />

president of the <strong>Haldex</strong> Commercial Vehicle Systems (cvs).<br />

Longbottom has fl own in early that morning from the<br />

United States.<br />

The commercial vehicles segment of <strong>Haldex</strong> India is<br />

about to explode. It grew at 25 percent in 2006, and now,<br />

with India’s Mandatory Automatic Brake Adjusters legislation<br />

going into effect <strong>for</strong> all commercial vehicles starting<br />

April 1, 2007, the sky’s the limit.<br />

Explaining the importance of this landmark legislation in<br />

road safety, Ganesh R. Pai, coo of <strong>Haldex</strong> India (a joint venture<br />

of the Anand Group and <strong>Haldex</strong> <strong>for</strong>med in 1998), says<br />

the manual adjusters that were previously used required<br />

periodic adjustment of the gap between the brake liner and<br />

the drum and were vulnerable to human error. “Automatic<br />

brake adjusters [abas] take care of this problem,” he says,<br />

“making braking smoother and safer and reducing braking<br />

distance as well as maintenance time and cost.”<br />

<strong>Haldex</strong> India has already begun supplying self-setting<br />

abas to customers such as Tata Motors and Ashok Leyland.<br />

It started assembling s-abas in India in 2004 and has been<br />

producing from 1,000 to 2,000 pieces a month. With the<br />

new legislation, says Longbottom, who has just joined our<br />

little group <strong>for</strong> the interview, “We are pushing production<br />

towards a level of 1 million adjustors a year.<br />

“This is an exciting time in the commercial vehicle segment<br />

in India, with expansion in production, a strong economy<br />

and greater focus on safety in commercial vehicles,<br />

an area we are particularly concerned with,” Longbottom<br />

www.haldex.com

Jay Longbottom (left)<br />

and Ganesh Pai enjoy<br />

their close cooperation.<br />

says. He sees a great synergy between the Anand Group,<br />

(“a longstanding, successful group in the automotive and<br />

commercial vehicles segment, and our partner in India”)<br />

and <strong>Haldex</strong>, with its long tradition in vehicles and vehicle<br />

dynamics. “It’s exciting to work together to bring the best<br />

products to the Indian market,” he says.<br />

Pai is confi dent the new legislation will get maximum<br />

compliance. With Indian traffi c planners working to<br />

improve road safety, commuters demanding more com<strong>for</strong>t<br />

and safety and keen competition among auto manufacturers<br />

to deliver vehicles of superior quality, vehicle component<br />

manufacturers will have to gear up to keep the supply<br />

chain going and meet the market demand. “We are confi -<br />

dent of doing that,” he says.<br />

Pai comments that Anand is a “professionally run organisation<br />

that highly respects all its collaborators. <strong>Haldex</strong> is<br />

a globally known brand in the commercial segment, and it<br />

has brought the latest technology to the joint venture.”<br />

In addition to high-quality products, Longbottom says,<br />

“<strong>Haldex</strong> has a long history of safety that drives a very strong<br />

demand <strong>for</strong> our products. We see this legislation as a landmark<br />

and a strong development <strong>for</strong> our business. Apart<br />

from India, the Korean, Chinese and European markets<br />

are growing very quickly. This is one of the busiest periods<br />

we’ve had, and all our factories are running at full capacity.”<br />

Pai says the challenge will be maintaining the supply<br />

chain in the coming days. “We are growing at an exponentially<br />

high rate, changing from one product to another very<br />

rapidly,” he says. “But we have a very good cooperation<br />

[with the parent company] – one phone call and an entire<br />

team from Sweden and the us comes here, proving that<br />

India is an important market <strong>for</strong> them.”<br />

Investments in <strong>Haldex</strong>’s Indian production are expected<br />

to exceed 3 million us dollars, says Longbottom.<br />

“As the pace of infrastructure and technology development<br />

gathers steam, we’re stepping up production of abas,”<br />

he says. “We have other products too that will contribute<br />

tremendously to vehicle per<strong>for</strong>mance, vehicle dynamics<br />

and safety, and we look <strong>for</strong>ward to introducing those on the<br />

Indian market as well.” �<br />

‘‘ ’’<br />

Towards a safer, smoother ride<br />

It’s exciting to work together<br />

to bring the best products to the<br />

Indian market.<br />

The great mix of vehicles on Indian roads — bicycles, motorized two-wheelers,<br />

trucks, vans, buses, cars, hand-pulled carts and commercial three-wheelers<br />

— constantly challenges even the most skilled of drivers. On many busy roads,<br />

the cacophony of sound from racing engines, impatient honking and screeching<br />

brakes can give travelers a splitting headache.<br />

But robust economic development — upward of 9 percent in the first quarter<br />

of 2007 — and cheap bank loans have electrified the automobile industry and<br />

brought new vehicle purchases within the reach of the huge Indian middle class.<br />

Ef<strong>for</strong>ts are now focused on widening roads, constructing overpasses, smoothing<br />

traffic flow, controlling emissions and improving road safety. More and more<br />

billboards on road safety line the highways to educate road users on ways to<br />

reduce accidents.<br />

The Mandatory Automatic Brake Adjusters legislation, which makes compulsory<br />

the use of ABAs <strong>for</strong> commercial vehicles, is one such attempt to ensure<br />

smoother, more efficient and quicker braking. “A lot of things are happening,”<br />

says Magnus Bergström, senior vice president of <strong>Haldex</strong>’s Commercial Vehicle<br />

Systems Division in Sweden. “India is building a lot of roads, and now there is<br />

this legislation, which I think is very positive <strong>for</strong> road safety and better traffic<br />

management.”<br />

For Jay Longbottom, executive vice president of the <strong>Haldex</strong> Commercial<br />

Vehicle Systems (CVS) and a periodic visitor to India, the improvement in India’s<br />

road system is very visible. “The long struggle to upgrade the quality and safety<br />

of components in commercial vehicles is slowly bearing fruit,” he says.<br />

Longbottom also sees the beneficial effects of improved vehicle technology<br />

on the environment. “In our product line we concentrate on noise reduction and<br />

safety,” he says. “Within the <strong>Haldex</strong> group we have a number of products directly<br />

related to the environment. <strong>Haldex</strong> is very conscious of environmental and safety<br />

issues.”<br />

www.haldex.com 1/2007 <strong>Haldex</strong> Dynamix 17

Riding high<br />

on grow<br />

As the Russian and Indian economies<br />

surge <strong>for</strong>ward, they bring into play a new<br />

class of consumers, and global businesses<br />

sense huge opportunities.<br />

Text R.F. Mamoowala<br />

Illustration Ladislav Kosa<br />

Photo INA Agency<br />

18 <strong>Haldex</strong> Dynamix 1/2007<br />

Prudent macroeconomic management, a windfall<br />

from rising oil prices and strong economic<br />

growth over eight years – 7 percent in 2006 – have<br />

brought Russia back into business.<br />

At the World Economic Forum meeting in Davos, Switzerland,<br />

in January 2007, the Russian delegation reported<br />

that Russia’s gdp would soon overtake that of France.<br />

In the fi rst nine months of 2006, the volume of <strong>for</strong>eign<br />

investment in Russia increased by 55 percent, compared<br />

with the same period in 2005, according to the annual<br />

Global ceo Survey (of 1,100 ceos from 50 countries)<br />

released by global accountancy fi rm PricewaterhouseCoopers.<br />

“Russia remains the focus of great attention on<br />

the part of investors all over the world,” the survey states.<br />

It says also that <strong>for</strong> the fi rst time ever, in 2006 Russians<br />

bought more <strong>for</strong>eign than domestic cars.<br />

With highly valued natural resources, a strengthening<br />

ruble, an educated and skilled work<strong>for</strong>ce and rising wages,<br />

the Russian economic scenario has never looked better.<br />

Financial services, construction, retail and automotive sectors<br />

are all booming.<br />

“Top money spinners include groceries, beer and cars,”<br />

says a recent editorial in The Economist, commenting on<br />

Russia’s “demanding as well as aspirational” consumers.<br />

The editorial points to ikea, which has spent 2.4 billion u.s.<br />

dollars in Russia. It now has eight stores and runs eight<br />

mega-malls.<br />

“Russia has a potential <strong>for</strong> continued strong economic<br />

growth due to its national resources, especially oil and gas,”<br />

says Lennart Hammargren, <strong>Haldex</strong> sales manager <strong>for</strong> Eastern<br />

Europe. The overall gnp growth will boost the infrastructure<br />

sector, particularly road construction, generating<br />

a huge demand <strong>for</strong> construction vehicles, and increased<br />

trade with Western Europe will boost demand <strong>for</strong> long-haul<br />

transport trucks and trailers.<br />

As modernization of existing fl eets and improved maintenance<br />

come into play, Hammargren says, “high-quality<br />

products, safety issues and environmental concerns will<br />

have a favourable impact on superior suppliers of vehicles<br />

and components such as <strong>Haldex</strong>.”<br />

Hammargren explains that historically Russia had<br />

focused on domestic manufacture of all components, but,<br />

he says, “gradually the more modern and successful manufacturers<br />

are concentrating on their strong areas and opting<br />

<strong>for</strong> partners/suppliers in others.”<br />

IN 1915 GARPHYTTE BRUK – later <strong>Haldex</strong> – sensed the<br />

potential of the Russian market early, setting up a wire<br />

plant in Yekaterinburg in Central Russia in 1916. Two<br />

years later it was closed because of the Russian revolution,<br />

but Garphytte Bruk continued to serve the Russian market<br />

from various European plants. From the mid 1990s, says<br />

Hammargren, “sales have grown signifi cantly, and we’re<br />

approaching the 15 million euro mark.” In 2006 <strong>Haldex</strong><br />

opened a sales offi ce in Moscow.<br />

An important <strong>Haldex</strong> customer is Kamaz, the largest<br />

Russian heavy truck manufacture. Kamaz makes 50,000<br />

vehicles annually and plans to double this output in a<br />

few years. As the bus and trailer markets grow, there is<br />

www.haldex.com

th<br />

�<br />

www.haldex.com 1/2007 <strong>Haldex</strong> Dynamix 19

A modern shopping mall in St Petersburg.<br />

‘‘<br />

20 <strong>Haldex</strong> Dynamix 1/2007<br />

potential <strong>for</strong> more business <strong>for</strong> <strong>Haldex</strong>, “but, as in most<br />

developing markets, the balancing act between high-quality<br />

products and low prices has to be maintained,” Hammargren<br />

says.<br />

The health of the Indian economy, which in the past<br />

two quarters has seen a gdp growth above 9 percent, was<br />

recently demonstrated by the Forbes 2007 list of billionaires.<br />

This year, with 36 billionaires, India heads the Asian<br />

portion of the list, ending Japan’s reign as Asian country<br />

with the most billionaires.<br />

India’s healthy economy is further refl ected in its vibrant<br />

equity market, a <strong>for</strong>eign exchange reserve of usd 180 billion<br />

and booming manufacturing and services sectors.<br />

Young Indian professionals with hefty disposable incomes<br />

sport fl ashy cars, snazzy mobile phones and expensive<br />

designer wear.<br />

Indian policymakers maintain that an annual growth<br />

rate of 8.4 percent is sustainable until 2020, and they say<br />

a double-digit growth rate is just around the corner. A key<br />

projection is that India’s gdp will surpass that of the United<br />

States be<strong>for</strong>e 2050.<br />

Manufacturing, driven by increased effi ciency of privatesector<br />

fi rms, is partly responsible <strong>for</strong> this robust growth.<br />

“Restructuring has made India’s private sector leaner, fi tter,<br />

and more productive,” says a Goldman Sachs report,<br />

India’s Rising Growth Potential (Jan. 22, 2007).<br />

As manufacturing gathers pace, the construction and<br />

automotive industries will benefi t. More investment in<br />

highways will, according to the report, “reduce travel times<br />

by half, lower fuel costs and freight delivery times and<br />

enable fi rms to leverage economies of scale, help ease congestion<br />

in cities and attract activity. Most importantly, the<br />

highways will open up … the closed worlds of India’s villages,”<br />

further boosting the economy.<br />

IN ITS ECONOMIC SURVEY 2006–07, the Indian government<br />

calls the auto sector, which has grown at 16 percent<br />

since 2001, a key sector in the economy. “Automobile<br />

exports crossed the usd 1 billion mark in 2003–04 and<br />

increased to usd 2.28 billion in 2005–06,” the paper says,<br />

and urges the auto sector to “keep innovating and upgrading”<br />

to remain globally competitive.<br />

For <strong>Haldex</strong> India, the environment couldn’t be better,<br />

says coo Ganesh R. Pai. “As the infrastructure sector develops,<br />

the auto industry is registering a good growth rate,”<br />

he says. “The commercial vehicle sector is growing at more<br />

An important <strong>Haldex</strong> customer is Kamaz, the largest Russian heavy truck manufacture.<br />

Kamaz makes 50,000 vehicles annually and plans to double this output in a few years.<br />

www.haldex.com<br />

‘

‘<br />

This year, with 36 billionaires,<br />

India heads the Asian portion<br />

’’<br />

of the<br />

list, ending Japan’s reign as Asian<br />

country with the most billionaires.<br />

than 20 percent and will continue to remain buoyant.”<br />

<strong>Haldex</strong> India produces manual brake adjusters <strong>for</strong><br />

both the domestic and export markets. As of April<br />

2007 an Indian law makes it mandatory <strong>for</strong> all<br />

commercial vehicles with air brakes to change from<br />

manual to automatic brake adjusters (abas). “Internationally<br />

<strong>Haldex</strong> is a major player in supplying<br />

abas,” says Pai. “In India, too, we supply abas<br />

to both Ashok Leyland and Tata Motors. This<br />

product, which we make in India, is technically<br />

sound and requires less maintenance. The new<br />

law will expand the market, and we are gearing<br />

up <strong>for</strong> much higher numbers with a big expansion<br />

plan.”<br />

<strong>Haldex</strong> India also makes ConSep (condensercum-separator)<br />

<strong>for</strong> the domestic auto market, with<br />

buy-back arrangements with <strong>Haldex</strong>.<br />

According to a recent study done by MasterCard<br />

International, the size of the mass affl uent market<br />

(household income of usd 7,500–50,000) in India<br />

was 5.2 million households in 2005. MasterCard<br />

International’s chief economic adviser, Yuwa Hedrick-Wong,<br />

estimates that this number will double<br />

to 10.5 million households by 2015, with an average<br />

income of usd 11,912. Indians will become avid consumers,<br />

spending a total of 51.3 billion on everything<br />

from shopping to dining and entertainment, travel<br />

and leisure, private health and luxury medicine<br />

and automobiles, pcs, mobile phones and the like.<br />

“Global businesses will ignore the Indian market<br />

only at their peril,” he says. �<br />

5,2 million Indian households can af<strong>for</strong>d a beautifully decorated home.<br />

Risk … and reward<br />

Businesses can win in new markets if they keep one eye<br />

on potential risks, and the other on the unique opportunities<br />

and advantages on offer, says <strong>Haldex</strong>’s Eastern<br />

Europe Sales Manager Lennart Hammargren. As in any<br />

new markets, there is political risk in Russia, he says,<br />

but as Russia improves its relations with the rest of the<br />

world, this is diminishing. “Also,” he says, “to be successful,<br />

a company’s presence must be established. A large<br />

territory like Russia, with many time zones, requires a<br />

local presence.”<br />

Another challenge is to find the right employees in a<br />

market with high attrition rates. “<strong>Haldex</strong> typically likes to<br />

develop and educate its employees over a long period,”<br />

he says.<br />

<strong>Haldex</strong> India’s Ganesh Pai says that while India’s stable<br />

political environment is a huge plus, businesses must<br />

be sensitive to cultural issues. In India, he says, “people<br />

management” is most important. “Trained manpower<br />

availability is excellent,” Pai says, “and India is becoming<br />

the resource country <strong>for</strong> everybody. Those who can<br />

manage this skilled resource well will be the winners.”<br />

But income inequality and growing rural-urban and<br />

educated-uneducated divides may well cause problems.<br />

Failure to provide a more inclusive growth may result in<br />

social tension and political pressure to slow down the<br />

re<strong>for</strong>m process. “If managed badly, this has the potential<br />

to kill the golden goose of growht,” is the sober warning<br />

in Goldman Sachs’ “India’s Rising Growth Potential’ (Jan.<br />

22, 2007).<br />

www.haldex.com 1/2007 <strong>Haldex</strong> Dynamix 21

�News<br />

A stronger presence<br />

Improves service <strong>for</strong> customers in China<br />

<strong>Haldex</strong> has acquired Runguang Hydraulics, one of the leading suppliers<br />

of hydraulics products to the Chinese construction machinery industry.<br />

A NEWLY FORMED COMPANY,<br />

<strong>Haldex</strong> Hydraulics (Qingzhou) Co.<br />

Ltd, has taken over the employees<br />

and most of the assets of<br />

Runguang Hydraulics. <strong>Haldex</strong><br />

Hydraulics (Qingzhou) will<br />

produce hydraulic pumps,<br />

valves and cylinders, mainly<br />

<strong>for</strong> use in different types<br />

of construction machinery<br />

such as wheel loaders and<br />

excavators. The company will<br />

have 1,200 employees, with largely vertically<br />

integrated production. The prospects <strong>for</strong> future<br />

growth are considered to be favorable.<br />

The transaction will enable the <strong>Haldex</strong><br />

Group’s hydraulics division to benefi t from Runguang’s<br />

40 years of experience in the Chinese<br />

mobile hydraulics market, and to become one of<br />

the leading suppliers of hydraulic pumps, valves<br />

and cylinders to Chinese construction machinery<br />

manufacturers. The acquisition will also<br />

give <strong>Haldex</strong> access to the products that are currently<br />

being used in China. As market demand<br />

<strong>for</strong> improved technical solutions grows, <strong>Haldex</strong><br />

will be able to phase in its own technology and<br />

expand in terms of both product line and applications.<br />

The <strong>Haldex</strong> Hydraulics (Qingzhou) operations<br />

is sited at new plant facilities in Qingzhou, in<br />

the Shandong province. Sales and the recently<br />

launched production of hydraulic power systems<br />

at one of the two new <strong>Haldex</strong>-owned plants in<br />

Suzhou has been coordinated with the new coowned<br />

company.<br />

“This cooperation with Runguang Hydraulics<br />

will enable <strong>Haldex</strong> to benefi t from their<br />

stable relations with Chinese customers and<br />

strengthen <strong>Haldex</strong>’s market position in China.<br />

Because the production base is already in place,<br />

we will also quickly be able to serve our international<br />

customers in the Chinese market,”says<br />

<strong>Haldex</strong> President and Group ceo Joakim<br />

Olsson. �<br />

22 <strong>Haldex</strong> Dynamix 1/2007 www.haldex.com<br />

Photo Victor Brott

Just in time<br />

– the Toyota way<br />

�Features<br />

& Friends<br />

Japan’s Toyota created a revolutionary production system based on the elimination of waste. It<br />

changed the face of auto manufacturing — and manufacturing in general, writes Christer Karlsson,<br />

Professor Innovation and Operations Management at Copenhagen Business School.<br />

IN THE AFTERMATH OF WORLD WAR II, Toyoda Eiji, a<br />

nephew of Toyota founder Toyoda Sakichi, traveled to the<br />

United States to study car production at gm, Ford and amc<br />

(American Motor Corporation). In a letter back to his uncle,<br />

he wrote:<br />

“The production system here is incredibly impressive,<br />

but un<strong>for</strong>tunately impossible <strong>for</strong> us to do, since we lack<br />

both the raw material and the energy needed <strong>for</strong> this production<br />

method.”<br />

In response, Taiichi Ohno, a production engineer at<br />

Toyota, developed a system, called the “Toyota Production<br />

System” or simply “Lean Production,” in which the central<br />

idea was that everything being produced had to add value<br />

to the product or to the customer. A process called “waste<br />

elimination” was introduced, where eight different types of<br />

“waste” – muda in Japanese – were identifi ed (see sidebar)<br />

and eliminated.<br />

The strategy was very simple. To begin with, workers<br />

were educated in the production process <strong>for</strong> nine to 10<br />

weeks (at the Ford factory in the u.s., in contrast, workers<br />

In 1994 Christer Karls-<br />

received one week of training). When the workers had sufson<br />

was appointed<br />

fi cient knowledge of the production process, Ohno asked<br />

Professor in the field of<br />

them to participate in an experiment: If they found them-<br />

Innovation and Operaselves<br />

not adding value to the production, they were to raise<br />

‘‘<br />

tions Management at<br />

their hand. He then focused on eliminating the muda in the<br />

the Stockholm School<br />

area with the largest number of raised hands. Sometime<br />

of Economics. Since<br />

later, the test was per<strong>for</strong>med again, and new bottlenecks<br />

2004 he is Dean CBS<br />

were found and eliminated. The process was repeated a<br />

Executive and Profes-<br />

number of times and eventually a phenomenon appeared,<br />

sor Innovation, Copen-<br />

later referred to as “Continuous Improvement,” where<br />

The production system here<br />

hagen Business School.<br />

everyone involved in production began eliminating mudas<br />

as they appeared.<br />

is incredibly impressive, but un<strong>for</strong>tu-<br />

The eight types of<br />

One muda to be eliminated was storage and buffers in<br />

muda, sources of<br />

nately impossible <strong>for</strong> us to do, since<br />

all areas of production. Having reduced these to a minimal<br />

waste, in the produc- level, the concept of “just in time” was created, whereby any we lack<br />

’’<br />

both the raw material and the<br />

tion process:<br />

item at any point in the production process arrived just in<br />

1. Overproduction time – neither too early nor too late.<br />

energy needed <strong>for</strong> this production<br />

2. Waiting<br />

While the Toyota production system uses a slightly<br />

3. Transportation<br />

method.<br />

larger work<strong>for</strong>ce and more machinery than the traditional<br />

4. Labor<br />

Western model, the emphasis is on throughput: moving<br />

5. Inventory<br />

products through the production chain without mistakes<br />

6. Motion<br />

or defects as quickly as possible. Although the cost <strong>for</strong> this<br />

7. Defective parts is slightly higher, the overall effect is that the cost <strong>for</strong> assets<br />

8. System<br />

is kept to a minimum, resulting in a signifi cantly higher<br />

return on capital. �<br />

www.haldex.com 1/2007 <strong>Haldex</strong> Dynamix 23

On the cutting<br />

“ Our ef<strong>for</strong>ts at the Service Centers are focused on the<br />

core principles of the <strong>Haldex</strong> way: Customer First,<br />

Respect <strong>for</strong> the Individual and Elimination of Waste.”<br />

24 <strong>Haldex</strong> Dynamix 1/2007 www.haldex.com

edge of relining<br />

Relining brakes has become a high-tech science at <strong>Haldex</strong>’s<br />

brake shoe relining plant in Grand Rapids, Michigan. The operation<br />

is geared to and driven by what the customer is ordering.<br />

WALK IN THE MAIN ENTRANCE of the <strong>Haldex</strong><br />

brake shoe relining plant in Grand Rapids,<br />

Michigan, turn right past the time clock, walk 50<br />

feet, and you’ll step into the future of the dynamic<br />

brake relining industry. Behind you is the older<br />

portion of the plant, with dim lights, a stained<br />

concrete fl oor and a look that is less than modern.<br />

Ahead is the year-old 6,000-square-foot addition.<br />

Bright and clean, with freshly painted walls, it<br />

has a modern, almost cheery, scrubbed look that<br />

belies the gritty nature of the work done here.<br />

This plant, in the heart of America’s Midwest,<br />

is the model <strong>for</strong> all 12 of the <strong>Haldex</strong> Commercial<br />

Vehicle Systems’ Service Centers in North<br />

America. Worn and damaged brake shoes from<br />

big trucks and other heavy-duty vehicles come<br />

into the Service Center, where, using increasingly<br />

sophisticated equipment, employees<br />

refurbish and reline the brake shoe cores, sending<br />

them back out into service. And just as the<br />

brakes are being remanufactured, the <strong>Haldex</strong><br />

plants themselves are being reconditioned into<br />

modern, advanced facilities.<br />

Roger See examines each core as he removes them from the paint<br />

line.<br />

www.haldex.com<br />

Text and photos Dwight Cendrowski<br />

“It’s a dynamic industry, and you’ve got to be<br />

nimble,” says Brian Cordle, <strong>Haldex</strong> sales and<br />

marketing manager. More and more competitors<br />

are springing up worldwide, from Asia to Mexico<br />

to South America. “We’re making sure we do a<br />

good job communicating with our customers,”<br />

he says.<br />

That’s what’s happening at the Grand Rapids<br />

shop. Service manager Chuck Zimmer points<br />

with obvious pride to the bright, new relining<br />

space as he ticks off the reasons <strong>Haldex</strong> is a<br />

tough competitor: unmatched service and quick<br />

response to customer orders, the most reliable<br />

brake linings (made by <strong>Haldex</strong> in Prattville, Alabama)<br />

and an unfl agging devotion to quality in<br />

every step of the manufacturing process. As an<br />

example, Zimmer points a basin where newly<br />

processed brake shoe cores are dipped in a paint<br />

and rust inhibitor. To keep the active ingredients<br />

evenly suspended, he says, “the paint is stirred<br />

seven days a week, 24 hours a day, and new paint<br />

is stirred <strong>for</strong> eight hours be<strong>for</strong>e it’s added.”<br />

<strong>Haldex</strong> has the relining process down to a<br />

�Expertise<br />

science, and newer facilities, streamlined workfl<br />

ow and advanced technologies are kicking the<br />

process into the higher gear demanded by the<br />

increasingly worldwide competition. Helmut<br />

Derra is <strong>Haldex</strong>’s director of friction remanufacturing<br />

in North America. “Globalization of<br />

the supply chain has made the market much<br />

more competitive in the past couple years,” says<br />

Derra. “Our ef<strong>for</strong>ts at the Service Centers are<br />

focused on the core principles of the <strong>Haldex</strong> way:<br />

Customer First, Respect <strong>for</strong> the Individual and<br />

Elimination of Waste.” The Grand Rapids plant<br />

showcases that determination.<br />

THE EXTRA OPEN SPACE HERE provides<br />

<strong>for</strong> the ebb and fl ow of customer orders. When<br />

spring comes to the Midwest and orders spike,<br />

the extra space and capability is there to absorb<br />

the work without a hiccup. “It allows us to run a<br />

smooth fl ow and do the quality checks needed to<br />

ensure that we have top-quality parts going out,”<br />

says Zimmer.<br />

“Quality” is a word that surfaces again and<br />

again. From the beginning to the end of the process,<br />

quality checks are stressed. The operation<br />

is geared to and driven by what the customer is<br />

ordering. On average, more than 10 percent of<br />

brake shoe cores that come in don’t pass muster<br />

and are discarded.<br />

One examples of cutting-edge technology<br />

A special paint with rust inhibitor assures uni<strong>for</strong>m coverage and corrosion<br />

resistance.<br />

1/2007 <strong>Haldex</strong> Dynamix 25

�Expertise<br />

“ The paint is<br />

stirred seven days<br />

a week, 24 hours a<br />

day, and new paint<br />

is stirred <strong>for</strong> eight<br />

hours be<strong>for</strong>e it’s<br />

added.”<br />

Chuck Zimmer<br />

used by <strong>Haldex</strong> is the deliner. The computercontrolled<br />

machine uses laser technology to automatically<br />

remove the rivets and old linings in far<br />

less time than older mechanical methods, thereby<br />

increasing effi ciency. And when the brake shoe<br />