The Micronic Mydata LDI 5s Series

The Micronic Mydata LDI 5s Series

The Micronic Mydata LDI 5s Series

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

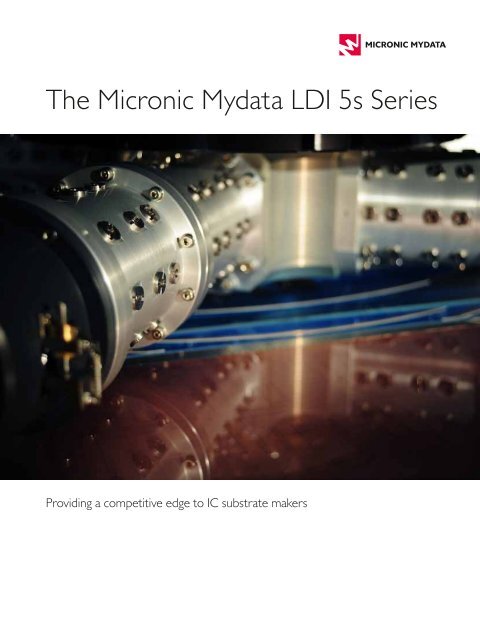

<strong>The</strong> <strong>Micronic</strong> <strong>Mydata</strong> <strong>LDI</strong> <strong>5s</strong> <strong>Series</strong><br />

Providing a competitive edge to IC substrate makers

Laser direct imaging with the<br />

highest precision and productivity<br />

in the industry<br />

<strong>The</strong> <strong>Micronic</strong> <strong>Mydata</strong> <strong>LDI</strong> <strong>5s</strong> <strong>Series</strong> builds on the<br />

company’s core competencies including large area<br />

patterning, gray scale SLM technology, UV lasers,<br />

high-speed data handling and precision mechanics.<br />

<strong>The</strong>se are combined with an innovative scanning<br />

system and twin tables, resulting in a system that<br />

delivers high resolution and pattern placement<br />

accuracy without compromising productivity<br />

Sub-10μm resolution<br />

<strong>The</strong> optical system projects sharp sub-10μm images<br />

in dry film resist, yielding vertical profiles for<br />

accurate copper plating. A proprietary linear gray<br />

scale spatial light modulator (SLM) generates a fine<br />

writing grid for precise positioning of pattern features.<br />

L/S=7/7µm (Pitch 14µm),<br />

7µm lines 19µm and spaces thick dry in 19μm film resist dry film (DFR) resist (DFR)<br />

Unmatched productivity and precision<br />

<strong>The</strong> revolutionary optical projection system provides<br />

smooth and efficient rotor-based scanning.<br />

Four writing arms scan the panel in turn, minimizing<br />

overhead time. <strong>The</strong> <strong>Micronic</strong> <strong>Mydata</strong> <strong>LDI</strong> <strong>5s</strong> <strong>Series</strong><br />

can be integrated into packaging production lines<br />

using industry standard mechanical and electrical<br />

interfaces. It features a high-speed material handler<br />

that supports unmatched productivity and precision.

Autofocus system<br />

Actively follows the substrate topography<br />

for optimal focus performance<br />

Sub-10μm alignment<br />

Accurate alignment and pattern overlay are achieved<br />

by mapping the pattern data to match any distortions<br />

and irregularities of the individual panels. This<br />

is done in real time for each panel by measuring the<br />

alignment mark positions with the three widefield<br />

alignment cameras. A high-speed graphics processor-based<br />

datapath adapts the pattern to each panel<br />

without sacrificing productivity.<br />

Load panel<br />

Measure<br />

alignment<br />

Procedure to test alignment overlay<br />

Load panel<br />

Expose layer 1 Expose layer 2<br />

Unload panel<br />

Measure<br />

alignment<br />

Unload panel<br />

Develop panel<br />

Measure<br />

panel<br />

High throughput<br />

A high-power, 355nm diode-pumped solid state<br />

laser allows for the use of conventional dry film<br />

resists, on panel sizes of up to 510 x 515mm 2 .<br />

<strong>The</strong> high productivity provided by the <strong>Micronic</strong><br />

<strong>Mydata</strong> <strong>LDI</strong> <strong>5s</strong> <strong>Series</strong> is largely enabled by an<br />

innovative twin-stage design. As a panel is being<br />

printed on one of the stages, the next panel is<br />

loaded onto the other stage where alignment and<br />

focus mapping are performed. Thus writing and<br />

alignment are done in parallel so that throughput is<br />

not sacrificed. <strong>The</strong> stages then swap positions and<br />

continue to alternate without interruption, meaning<br />

that the tool effectively writes continuously.<br />

Twin table stage system<br />

Allows concurrent writing and<br />

substrate align/load/unload<br />

Alignment overlay data<br />

distribution showing 4<br />

performance of 2.5µm<br />

Deviation from first layer:<br />

Mean = 1.1µm, 4σ = 2.5µm, Max = 3.6µm<br />

Alignment overlay test grid<br />

Scale = 10µm per grid point<br />

(465 x 465 mm array)<br />

Position deviation from first layer<br />

scale=10µm/grid, area 465*465 mm<br />

X-deviation Y-deviation from first layer layer [µm][μm]<br />

10 µm<br />

5 µm<br />

Y-deviation X-deviation from first layer [µm] [μm]

Pushing the limits<br />

<strong>Micronic</strong> <strong>Mydata</strong> worldwide<br />

HEADQUARTERS<br />

<strong>Micronic</strong> <strong>Mydata</strong> AB<br />

PO Box 3141<br />

SE-183 03 Täby<br />

Sweden<br />

Tel: +46 8 638 52 00<br />

Fax: +46 8 638 52 90<br />

Visit: Nytorpsvägen 9, Täby<br />

info@micronic-mydata.com<br />

CHINA<br />

<strong>Micronic</strong> <strong>Mydata</strong> (Shanghai) Co., Ltd.<br />

Unit 101, K Block<br />

Lane 168, Da Duhe Road.<br />

Putuo District, 200062<br />

Shanghai P.R. China<br />

Tel: +86 21 3252 3785/86<br />

Fax: +86 21 3252 3780<br />

JAPAN<br />

<strong>Micronic</strong> <strong>Mydata</strong> Japan K.K.<br />

Mitsugi-Kotobukicho Bldg.<br />

1-1-3 Kotobuki-cho<br />

Fuchu-shi<br />

Tokyo 183-0056<br />

Tel: +81 42-354-1320<br />

Fax:+81 42-354-1321<br />

SOUTH KOREA<br />

<strong>Micronic</strong> Laser Systems Korea Co Ltd<br />

3rd Floor Jung-San<br />

Bldg. 1026-8<br />

Sanbon-Dong, Gunpo-Si<br />

Gyeonggi-Do, 435-040<br />

Tel: +82-31-387-5111<br />

Fax: +82-31-388-0087<br />

TAIWAN<br />

<strong>Micronic</strong> Laser Systems/ Hermes-Epitek Corp<br />

Second Floor<br />

#18 Pu-Ding Road<br />

Der-An building<br />

Hsin-Chu, 300<br />

Tel: +886-3-564-6656<br />

Fax: +886-3-564-6664<br />

USA<br />

<strong>Micronic</strong> Laser Systems Inc.<br />

1922 Zanker Road<br />

San Jose<br />

CA 95112<br />

Tel: +1 (408) 392 2260<br />

Fax:+1 (408) 392 2261<br />

<strong>Micronic</strong> <strong>Mydata</strong> patents:<br />

US 7 710 634, US 7 715 641, US 7 787 174, US 7 800 815, US 7 842 926, US 2010/0225974 A1, US 2010/0208329 A1, US 2010/0142838 A1, US 2010/0229146 A1, US 2010/0225943, A1, US 2010/0225236 A1, US 2010/0141966 A1,<br />

US 2010/0142757 A1, US 2010/0225992 A1, US 2010/0225979 A1, WO 2010/100270 A1, WO 2010/100273 A2, WO 2010/063830, A1, WO 2010/063826 A1, WO 2010/063827 A1, WO 2010/100272 A1, WO 2010/100268 A2,<br />

WO 2010/092188 A1, WO 2010/092189 A1, WO 2010/100269 A1, WO 2010/092128 A1, other patents pending.<br />

<strong>Micronic</strong> <strong>Mydata</strong> AB (publ.), Nytorpsvägen 9, Box 3141, 183 03 Täby, Sweden. Tel +46 8 638 52 00. Fax +46 8 638 52 90 www.micronic-mydata.com<br />

AB16791 Oct 2011