performance data - LMCurbs

performance data - LMCurbs

performance data - LMCurbs

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CONSTRUCTION FEATURES<br />

Model LQ ventilators are direct drive propeller roof fans designed to deliver large volumes of air. Nine sizes are<br />

available from 10" to 36" diameter. Capacities range from 135 to 14,100 CFM for exhaust ventilators and 465 to 13,500<br />

CFM for supply ventilators. LQ fans operate more quietly than conventional propeller roof ventilators and are<br />

recommended for applications requiring lower noise levels. LQ ventilators can be mounted in any position such as walls<br />

or sloping roofs.<br />

Birdscreen<br />

Constructed of .50” x 1.00”<br />

mesh heavy guage<br />

galvanized steel welded wire.<br />

Hood<br />

Heavy gauge aluminum<br />

hood with attractive low<br />

silhouette design. Hood is<br />

removable for accessibility<br />

to motor or propeller for<br />

servicing.<br />

Disconnect Switch<br />

Weather proof disconnect switch<br />

is factory mounted on ventilator<br />

base near motor terminal box,<br />

except for 3.00 HP units which<br />

use a rain-tight field mounted<br />

and wired disconnect switch.<br />

The switch is operated from<br />

outside of ventilator for<br />

maximum safety. Explosion<br />

proof disconnect switches are<br />

not mounted or wired and are<br />

not for outdoor use.<br />

Orifice<br />

Large streamlined<br />

orifice permits efficient,<br />

smooth air flow.<br />

Motor<br />

Motor is located in the full<br />

airstream which provides<br />

superior cooling, longer<br />

operation and reduces possible<br />

motor burn-outs from high<br />

ambient heat.<br />

All motors are totally enclosed<br />

type with lubricated shielded<br />

ball bearings.<br />

Steel Frame Construction<br />

Rugged structural steel frame<br />

transmits weight of the motor<br />

and propeller directly to<br />

curbcap. This eliminates any<br />

weight on hood, housing or<br />

curbcap base. Steel frame is<br />

finished with acrylic epoxy for<br />

resistance against most<br />

corrosive elements.<br />

Propeller<br />

Propellers feature an advanced<br />

tear-drop shape blade designed<br />

for exceptionally low noise level<br />

<strong>performance</strong>.<br />

The swept-back tear-drop blade<br />

shape with its aerodynamic<br />

leading edge propels the air<br />

through the streamlined orifice<br />

with a minimum of air turbulence.<br />

Aluminum blades are fastened to<br />

a formed steel hub with<br />

heavy-duty oversize rivets. The propeller is precision<br />

balanced for smooth vibrationless operation.<br />

Acme Engineering & Manufacturing Corp. certifies that the LQ Ventilators shown herein are licensed to bear the AMCA<br />

seal. The ratings shown are based on tests and procedures performed in accordance with AMCA Publication 211 and<br />

AMCA Publication 311 and comply with the requirements of the AMCA Certified Ratings Program.<br />

Page 2 <strong>LMCurbs</strong> Phone: 1-800-284-1412 Fax: 1-903-759-3598

Fan<br />

Size<br />

Fan<br />

Model<br />

RPM<br />

Tip<br />

Speed<br />

Ft./<br />

Min.<br />

HP<br />

Sones<br />

@<br />

.000"<br />

SP<br />

PERFORMANCE DATA<br />

LQ Exhaust Ventilators<br />

Approx<br />

Licensed CFM vs. Static Pressure<br />

Max. Ship Wt.<br />

BHP<br />

.000" .125" .250" .375" .500" .625" .750" .875" 1.000" 1.125" 1.250" 1.500" 1.750" 2.000" Lbs.<br />

10<br />

LQ108LO 1500 3925 .03 4.4 540 440 225 *111 19<br />

LQ108HI 1650 4320 .03 7.1 590 505 295 185 *111 19<br />

LQ12A6 1160 3590 .05 5.5 840 685 475 270 135 .054 38<br />

12<br />

LQ129LO 1350 4180 .11 6.7 975 845 695 500 335 210 .084 26<br />

LQ129HI 1550 4795 .11 9.7 1120 1005 885 740 565 415 310 200 .128 26<br />

LQ12D4 1760 5445 .17 11.3 1275 1180 1070 955 820 665 520 420 325 235 155 .187 40<br />

LQ14C6 1160 4150 .13 9.7 1310 1155 890 640 420 .105 49<br />

14 LQ14E4 1760 6295 .25 15.4 1655 1565 1465 1360 1205 1000 895 790 685 590 485 .242 49<br />

LQ14F4 1760 6295 .33 13.5 2000 1900 1790 1670 1510 1250 1080 950 800 670 540 .366 47<br />

LQ16D8-1 860 3560 .17 6.1 1360 1115 635 350 .071 55<br />

LQ16D8-2 860 3560 .17 5.1 1525 1245 820 480 .092 55<br />

LQ16C6 1160 4800 .13 11.1 1840 1670 1470 1050 770 570 370 .175 55<br />

16 LQ16D6 1160 4800 .17 8.8 2050 1870 1650 1290 980 730 530 .225 57<br />

LQ16F4 1760 7280 .33 21 2290 2200 2100 1980 1830 1580 1390 1270 1150 1030 910 710 .512 53<br />

LQ16G4 1760 7280 .50 18.4 2790 2680 2570 2470 2320 2140 1700 1540 1360 1180 1060 800 .610 63<br />

LQ16H4 1760 7280 .75 16.9 3160 3010 2870 2740 2600 2440 2130 1930 1750 1550 1350 1020 .783 67<br />

LQ18D8-1 860 4080 .17 6.3 1940 1620 1230 850 490 .106 67<br />

LQ18D8-2 860 4080 .17 7.0 2400 2080 1670 1110 640 .178 67<br />

LQ18E6 1160 5505 .25 11.2 2620 2390 2140 1880 1530 1270 1020 810 550 .259 65<br />

18 LQ18G6 1160 5505 .50 11.7 3240 3000 2760 2540 2000 1660 1310 920 700 .436 79<br />

LQ18H4 1760 8350 .75 18.3 3970 3810 3650 3500 3340 3200 3030 2840 2580 2390 2190 1840 1530 1250 .905 79<br />

LQ18J4 1760 8350 1.00 18.7 4340 4190 4030 3870 3720 3560 3380 3160 2870 2620 2420 2040 1670 1310 1.085 83<br />

LQ18K4 1760 8350 1.50 23 4920 4780 4620 4460 4300 4120 3960 3820 3680 3120 2820 2420 1940 1460 1.530 84<br />

LQ21D8 860 4690 .17 8.4 2820 2510 1790 1480 1000 .190 149<br />

LQ21E8 860 4690 .25 8.1 3220 2760 2080 1550 1150 .252 151<br />

LQ21F8 860 4690 .33 9.0 3570 3120 2400 2050 1460 .331 161<br />

21<br />

LQ21G6-1 1160 6325 .50 12.8 3800 3520 3230 2780 2230 1950 1780 1490 1000 .468 161<br />

LQ21G6-2 1160 6325 .50 13.1 4350 4050 3720 3260 2650 2240 2020 1680 1110 .620 161<br />

LQ21H6 1160 6325 .75 13.5 4820 4540 4160 3700 3100 2800 2750 2140 1400 .818 165<br />

LQ21K4 1760 9595 1.50 26 5760 5580 5400 5210 5020 4830 4610 4300 3940 3460 3180 2880 2670 2250 1.635 166<br />

LQ21L4 1760 9595 2.00 25 6540 6370 6170 5960 5750 5540 5270 4830 4410 4100 3800 3280 3000 2590 2.160 165<br />

LQ24E8 860 5430 .25 7.6 3570 3175 2475 2010 1650 .285 172<br />

24 LQ24H6 1160 7325 .75 14.1 4700 4450 3980 3400 2980 2660 2380 2080 1670 1210 .700 186<br />

LQ24J6 1160 7325 1.00 16.9 5560 5280 4960 4600 4200 3740 3390 3130 2860 2530 2040 .997 208<br />

LQ30H8 860 6700 .75 19.1 7180 6780 6220 5400 4450 3970 3570 3060 2440 .837 292<br />

30<br />

LQ30J8 860 6700 1.00 14.5 9060 8520 8000 7400 6350 5300 4980 4500 3880 3120 2230 1.213 303<br />

LQ30L6 1160 9035 2.00 27 9450 9160 8820 8450 7970 7330 6400 5900 5580 5270 4950 4280 3500 2300 2.070 336<br />

LQ30M6 1160 9035 3.00 25 12000 11620 11230 10800 10400 9960 9510 8550 7620 7120 6790 6200 5510 4650 2.850 342<br />

36<br />

LQ36K8 860 8020 1.50 21 11150 10530 9870 8950 7430 6600 6300 5900 5300 1.860 409<br />

LQ36L8 860 8020 2.00 17.9 14100 13500 12800 12100 11000 9300 8600 8200 7700 7000 5900 2.420 415<br />

*Watts<br />

Performance shown is for installation Type A - Free inlet, Free outlet.<br />

Performance ratings include the effects of a birdscreen in the airstream.<br />

The sound level ratings shown are loudness values in fan sones at 5<br />

feet (1.524 m) in a hemispherical free field calculated per AMCA<br />

Standard 301. Values shown are for Installation Type A: Free Inlet fan<br />

sone levels.<br />

The brake horsepower capability of a fan motor is dependent of the<br />

degree of cooling the motor receives from the moving airstream over<br />

the motor. The above motor loadings do not overheat the motor and are<br />

within NEMA recommended limits. It is therefore not detrimental to the<br />

motor and is economically desirable.<br />

Page 3 <strong>LMCurbs</strong> Phone: 1-800-284-1412 Fax: 1-903-759-3598

Fan<br />

Size<br />

12<br />

14<br />

16<br />

18<br />

21<br />

24<br />

30<br />

36<br />

Fan<br />

Model<br />

RPM<br />

Tip<br />

Speed<br />

Ft./<br />

Min.<br />

HP<br />

Sones<br />

@<br />

.000"<br />

SP<br />

PERFORMANCE DATA<br />

LQ Supply Ventilators<br />

Approx<br />

Licensed CFM vs. Static Pressure<br />

Max. Ship Wt.<br />

BHP<br />

.000" .100" .125" .250" .375" .500" .625" .750" .875" 1.000" 1.125" 1.250" Lbs.<br />

LQ12A6-S 1160 3590 .05 5.8 920 550 465 .050 49<br />

LQ12D4-S 1760 5445 .17 11.9 1395 1240 1180 835 .176 51<br />

LQ14B6-S 1160 4150 .08 7.1 1075 840 740 .059 52<br />

LQ14E4-S 1760 6295 .25 14.5 1630 1500 1460 1235 875 .210 57<br />

LQ16C6-S 1160 4800 .13 9.4 1790 1440 1405 .135 68<br />

LQ16D6-S 1160 4800 .17 11.8 1965 1440 .178 70<br />

LQ16F4-S 1760 7280 .33 17.8 2310 2240 2210 1790 1510 1205 .402 66<br />

LQ16G4-S 1760 7280 .50 18.3 2720 2530 2475 2100 1595 .476 76<br />

LQ16H4-S 1760 7280 .75 21 2980 2690 2625 .705 76<br />

LQ18D8-S 860 4080 .17 9.1 2175 1725 1620 995 .206 139<br />

LQ18E6-S 1160 5505 .25 12.4 2655 2410 2350 2000 1605 .320 137<br />

LQ18J4-S 1760 8350 1.00 23 4030 3860 3820 3615 3390 3160 2915 2665 2415 2150 1885 1620 1.130 155<br />

LQ18K4-S 1760 8350 1.50 34 4450 4240 4180 3920 3640 3340 3010 2690 2490 2200 1.760 156<br />

LQ21D8-S 860 4690 .17 8.6 2585 2245 2155 1745 1335 .216 161<br />

LQ21F8-S 860 4690 .33 10.4 3140 2745 2625 2000 1190 .350 173<br />

LQ21G6-S 1160 6325 .50 14.1 3485 3240 3175 2850 2530 2250 1950 1580 1075 .530 173<br />

LQ21H6-S 1160 6325 .75 19.3 4235 3925 3850 3430 3000 2535 1990 1055 .850 177<br />

LQ21K4-S 1760 9595 1.50 32 5270 5145 5110 4945 4755 4520 4150 3580 3280 3090 2945 2800 1.675 178<br />

LQ24F8-S 860 5430 .33 11.5 3750 3420 3330 2840 2275 .384 183<br />

LQ24H6-S 1160 7325 .75 20 5030 4790 4720 4360 3950 3580 3210 2800 .897 187<br />

LQ24J6-S 1160 7325 1.00 21 5550 5240 5160 4760 4360 3970 3570 3140 1.173 209<br />

LQ30J8-S 860 6700 1.00 19.4 6870 6400 6280 5660 4980 4120 3170 1.070 301<br />

LQ30K8-S 860 6700 1.50 19.7 8040 7460 7320 6620 5800 4350 3470 2280 1.570 334<br />

LQ30L6-S 1160 9035 2.00 30 9380 9070 9000 8590 8130 7690 7140 6550 2.380 334<br />

LQ30M6-S 1160 9035 3.00 34 10700 10270 10180 9750 9420 9110 8480 7690 6750 5260 3.490 340<br />

LQ36L8-S 860 8020 2.00 21 10550 10000 9870 9190 8500 7800 7080 6340 5530 4690 2.170 409<br />

LQ36M8-S 860 8020 3.00 26 13500 12980 12850 12120 11380 10570 9740 8830 7900 6920 5830 4600 3.490 426<br />

Performance shown is for installation Type A - Free inlet, Free outlet.<br />

Performance ratings include the effects of a birdscreen in the airstream.<br />

The sound level ratings shown are loudness values in fan sones at 5<br />

feet (1.524 m) in a hemispherical free field calculated per AMCA<br />

Standard 301. Values shown are for Installation Type A: Free Outlet fan<br />

sone levels.<br />

The brake horsepower capability of a fan motor is dependent of the<br />

degree of cooling the motor receives from the moving airstream over the<br />

motor. The above motor loadings do not overheat the motor and are<br />

within NEMA recommended limits. It is therefore not detrimental to the<br />

motor and is economically desirable.<br />

Page 4 <strong>LMCurbs</strong> Phone: 1-800-284-1412 Fax: 1-903-759-3598

OPTIONAL ACCESSORIES<br />

Solid State Controller<br />

Solid state controllers are available for the<br />

ventilators equipped with 115 volt, single<br />

phase, shaded pole and the smaller size<br />

permanent split-capacitor motors. They<br />

provide a variable speed control and are<br />

easily installed in a standard wall box.<br />

They require only a simple 2 wire connection but are<br />

equipped with a third wire that maintains a constant voltage<br />

to the damper motor in the event a motorized backdraft<br />

damper is used with the ventilator.<br />

Backdraft Dampers<br />

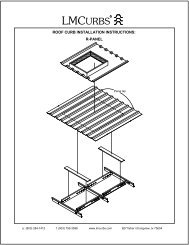

Prefabricated Curbs<br />

Heavy gauge galvanized steel or aluminum curbs for easy<br />

installation of exhauster over roof opening. Replaces<br />

conventional field constructed curbs for steel, concrete or<br />

wood roofs.<br />

Type RF - Roofed-over type features built-in cant strip to<br />

accommodate roofing materials for flashing up over top of<br />

curb. Wood nailer is standard except on Model CR curbs.<br />

Type SF - Self-flashing type features wide base flange for<br />

easy flashing to roof. This eliminates need for extending<br />

roofing material up over top of curb. ¼" polystyrene gasket<br />

is standard.<br />

Large oversized design provides for lower air velocity and<br />

quieter operation. All aluminum multi-blade construction.<br />

Precision balanced full opening blades with nylon bearings.<br />

The double tie rods reduce flutter. Exhaust dampers<br />

available as automatic or motorized; supply dampers<br />

available as motorized only.<br />

Damper Box<br />

A box type adapter for<br />

easy installation of<br />

damper. Fits inside the<br />

prefabricated or field<br />

constructed curb. Required<br />

for installation of damper in<br />

an Acme prefabricated<br />

curb.<br />

CURB DIMENSIONS<br />

DAMPER<br />

DAMPER<br />

BOX<br />

FAN<br />

SIZE<br />

MODEL J K N M H LQ LQ-S MODEL<br />

10 C20.5x20.5x8 28.50 20.50 17.50 14.50 8.00 AR14 ⎯ DB14LQ<br />

12 C22.5x22.5x8 30.50 22.50 19.50 16.50 8.00 AR16 WAGC16 DB16LQ<br />

14 C24.5x24.5x8 32.50 24.50 21.50 18.50 8.00 AR18 WAGC18 DB18LQ<br />

16 C26.5x26.5x8 34.50 26.50 23.50 20.50 8.00 AR20 WAGC20 DB20LQ<br />

18 C29.5x29.5x8 37.50 29.50 26.50 23.50 8.00 AR23 WAGC23 DB23LQ<br />

21 C32.5x32.5x8 40.50 32.50 29.50 26.50 8.00 AR26 WAGC26 DB26LQ<br />

24 C36.5x36.5x8 44.50 36.50 33.50 30.50 8.00 AR30 WAGC30 DB30LQ<br />

30 C44.5x44.5x8 52.50 44.50 41.00 38.50 8.00 AR38 WAGC38 DB38LQ<br />

36 C51x51x8 59.00 51.00 48.00 45.00 8.00 AR44 WAGC44 DB44LQ<br />

Dimensions shown in inches.<br />

Page 5 <strong>LMCurbs</strong> Phone: 1-800-284-1412 Fax: 1-903-759-3598

OPTIONAL COATINGS<br />

Coatings<br />

Aluminum and galvanized components remain unpainted as<br />

a standard finish, but when required, are processed through<br />

the finishing system to apply decorative or special coatings.<br />

A high turbulence oven is used to produce a baked on finish<br />

for most special coatings. Decorative coatings are not baked<br />

on.<br />

Decorative Coatings<br />

Acme offers 16 popular colors for decorative finishes utilizing<br />

an industrial grade enamel applied to the exterior of the fan.<br />

Special colors are available upon request. See your Acme<br />

Representative for complete color selections.<br />

Special Coatings<br />

Products receiving special coatings have components<br />

painted before assembly. Fasteners are not painted.<br />

• Acrylic Epoxy<br />

This product provides a more durable surface.<br />

• Carboline Sanitile<br />

(Eisenheiss)<br />

This air dry synthetic polyester forms a black coating that<br />

offers greater resistance to most organic and inorganic<br />

acids.<br />

• Heresite (air dry)<br />

A phenolic coating with greater resistance to most<br />

organic and inorganic acids.<br />

• Insulmastic<br />

A black asphalt based mastic that provides some<br />

condensation control, sound deadening and corrosion<br />

resistance.<br />

NOTE: For any coating selected the user assumes the responsibility for the corrosive agent, its concentration,<br />

temperature, moisture content and the ultimate effect on the coating and the equipment.<br />

DRAWING AND DIMENSIONAL DATA<br />

Typical drawings for dimensional purposes only. They are correct within limits suitable for normal installation requirements<br />

and do not necessarily show actual construction. Dimensions shown in inches.<br />

LQ &LQ-S DIMENSIONS<br />

Fan<br />

LQ LQ-S LQ LQ-S LQ LQ-S LQ LQ-S Metal Gauges<br />

A<br />

Size<br />

B C E F Hood Base<br />

10 22.08 6.61 6.61 18.63 18.63 2.36 2.36 4.41 4.41 .050 .050<br />

12 24.08 6.74 7.24 21.00 24.00 2.49 2.50 7.88 7.88 .050 .050<br />

14 26.08 8.10 9.41 24.00 27.63 3.35 4.16 8.06 8.06 .050 .050<br />

16 28.08 9.83 10.31 27.63 31.60 4.58 4.56 9.00 9.00 .050 .050<br />

18 31.08 10.76 11.84 31.60 36.00 5.01 5.22 7.42 10.66 .050 .050<br />

21 34.10 12.09 13.48 36.72 41.38 5.47 4.98 9.00 13.45 .050 .063<br />

24 38.10 13.70 13.70 41.38 41.38 5.20 5.20 11.25 11.25 .050 .063<br />

30 46.10 15.89 15.89 52.13 52.13 6.89 6.89 13.06 13.06 .050 .063<br />

36 52.50 19.00 18.67 62.38 82.00 8.13 9.67 12.75 12.81 .080 .080<br />

Page 6 <strong>LMCurbs</strong> Phone: 1-800-284-1412 Fax: 1-903-759-3598

TYPICAL SPECIFICATIONS<br />

Low silhouette roof exhaust or supply fan shall be of a<br />

propeller, direct drive type.<br />

The precision balanced propeller shall have aluminum<br />

blades, die-formed with swept-back tear-drop shape and<br />

shall be attached to a heavy duty steel hub.<br />

The aluminum fan housing shall consist of a die-formed,<br />

double orifice for efficient airflow and a die-formed,<br />

aerodynamic shaped hood for less turbulent airflow.<br />

The acrylic epoxy finished structural steel frame shall<br />

transmit the weight of the motor and propeller directly to the<br />

curbcap/curb to prevent orifice distortion and shall allow for<br />

mounting in any position.<br />

Sealed ball bearing motors shall be adjustable on the motor<br />

base.<br />

Birdscreen shall be made from heavy duty galvanized wire.<br />

A disconnect device/switch shall be factory installed with a<br />

special weather resistant toggle cover for external operation.<br />

(Explosion proof not mounted or wired).<br />

All fans shall bear the AMCA Certified Ratings Seal for<br />

sound and air <strong>performance</strong>.<br />

Each fan shall have a permanently affixed manufacturer's<br />

nameplate containing the model number and serial number<br />

for future identification.<br />

Thermal overload protectors shall be available for single<br />

phase motors.<br />

Fans to be supplied with a two year limited warranty.<br />

Fans shall be Model LQ as manufactured by Acme<br />

Engineering and Manufacturing Corporation of Muskogee,<br />

Oklahoma.<br />

Most RoofMaster ® fans are listed by the<br />

Canadian Standards Association Testing<br />

Laboratory as approved.<br />

Most Acme RoofMaster ® fans bear the U.L.<br />

listing mark; consult the Acme representative<br />

for availability.<br />

Page 7 <strong>LMCurbs</strong> Phone: 1-800-284-1412 Fax: 1-903-759-3598

CENTRIFUGAL<br />

EXHAUSTERS<br />

CEILING AND CABINET<br />

EXHAUSTERS<br />

IN-LINE CENTRIFUGAL<br />

FANS<br />

IN-LINE AXIAL FANS<br />

PROPELLER<br />

ROOF FANS<br />

PROPELLER<br />

WALL FANS<br />

UTILITY BLOWERS<br />

SUPPLY AIR FANS<br />

ROOF VENTS<br />

PLENUM FANS<br />

BACKWARD<br />

INCLINED/AIRFOIL<br />

CENTRIFUGAL FANS<br />

CENTRIFUGAL<br />

INDUSTRIAL<br />

EXHAUSTERS<br />

LIMITED WARRANTY Acme Engineering<br />

and Manufacturing Corporation extends this<br />

limited warranty to the original buyer and warrants<br />

that products supplied by the Company<br />

shall be free from original defects in workmanship<br />

and materials for two years from<br />

date of shipment (except for Acme’s exclusive<br />

duplex split pillow block bearings and shaft 5<br />

years from shipment, belts one year from<br />

shipment, and polyethylene tubing at 90 days<br />

from shipping), provided same have been<br />

properly handled, stored, installed, serviced,<br />

maintained and operated. Refer to Form<br />

MS149 for complete limited warranty terms<br />

and conditions.<br />

WARNING Acme products are designed and<br />

manufactured to provide reliable <strong>performance</strong><br />

but they are not guaranteed to be<br />

100% free of defects. Even reliable products<br />

will experience occasional failures and this<br />

possibility should be recognized by the User.<br />

If these products are used in a life support<br />

ventilation system where failure could result in<br />

loss or injury, the User should provide adequate<br />

back-up ventilation, supplementary<br />

natural ventilation or failure alarm system, or<br />

acknowledge willingness to accept the risk of<br />

such loss or injury.<br />

WARNING DO NOT use in HAZARDOUS<br />

ENVIRONMENTS where fan’s electrical system<br />

could provide ignition to combustible or<br />

flammable materials unless unit is specifically<br />

built for hazardous environments.<br />

CAUTION Guards must be installed when fan<br />

is within reach of personnel or within seven (7)<br />

feet (2.134 m) of working level or when<br />

deemed advisable for safety.<br />

DISCLAIMER The Company has made a diligent<br />

effort to illustrate and describe the products<br />

in this literature accurately; however, such<br />

illustrations and descriptions are for the sole<br />

purpose of identification, and do not express or<br />

imply a warranty that the products are merchantable,<br />

or fit for a particular purpose, or that<br />

the products will necessarily conform to the illustrations<br />

or descriptions or dimension.<br />

Member Air Movement and Control Association<br />

<strong>LMCurbs</strong><br />

P.O. Box 5299,Longview, Texas 75604<br />

Telephone: 800-284-1412 Fax: 903-759-0879<br />

www.. .lmcurbs.com email: lmcurbs@lmcurbs.com November 2002 Form C5U

Read and Save These Instructions<br />

FORM 613090<br />

INSTALLATION & MAINTENANCE INSTRUCTIONS<br />

Models EC, ECH, LQ, USC, USCH, and USQ<br />

RECEIVING AND INSPECTION<br />

Immediately upon receipt of a shipment, carefully inspect for<br />

damage and shortage. Turn propeller by hand to see that it turns<br />

freely and does not bind. If any damage and/or shortage is<br />

detected or suspected the carrier must be asked to conduct an<br />

inspection. The consignee’s representative should not accept<br />

shipment without a notation on the delivery receipt indicating<br />

items not delivered or apparent extent of damage.<br />

When a shipment is opened and damage is found which was not<br />

evident externally (concealed damage), it is mandatory that the<br />

consignee request an immediate inspection by the carrier. Report<br />

damage to the carrier within 15 days. Failure to report damage<br />

within the above time limit will cause rejection of a claim.<br />

HANDLING<br />

When handling fans and their accessories, always use equipment<br />

and methods that will not cause damage. Fans should be lifted<br />

using slings and padding or spreaders to avoid damage.<br />

CAUTION! Always make sure that all lifting and handling<br />

equipment and techniques conform to current safety standards.<br />

Avoid lifting fans in a way that will bend or distort fan parts. Never<br />

pass slings or timbers through the orifices of fan.<br />

CAUTION! Do not lift by the fan hood. Fans with special coatings<br />

or paints must be protected in handling to prevent damage.<br />

STORAGE<br />

Fans are protected against damage during shipment. If they<br />

cannot be installed and put into operation immediately upon<br />

receipt certain precautions are necessary to prevent deterioration<br />

during storage. Responsibility for integrity of fans and<br />

accessories during storage must be assumed by the user. The<br />

manufacturer will not be responsible for damage during storage.<br />

These suggestions are provided solely as a convenience to the<br />

user, who shall make his own decision as to whether to use any or<br />

all of them.<br />

INDOOR: The ideal storage environment for fans and<br />

accessories is indoors, above grade, in a low humidity<br />

atmosphere which is sealed to prevent the entry of blowing dust,<br />

rain, or snow. Temperatures should be evenly maintained at<br />

between 70°F and 105°F (wide temperature swings may cause<br />

condensation and "sweating" of metal parts). Windows should be<br />

covered to prevent temperature variations caused by sunlight.<br />

Provide thermometers and humidity indicators at several points<br />

and maintain the atmosphere at 40% relative humidity, or lower.<br />

It may be necessary to use trays of renewable desiccant or<br />

portable dehumidifier to remove moisture from the air in the<br />

storage enclosure.<br />

Thermostatically controlled portable heaters (vented to outdoors)<br />

may be required to maintain even temperatures inside the<br />

enclosure.<br />

CAUTION! Provide fire extinguishers, or fire alarms, or<br />

emergency response communication to protect building and<br />

equipment against fire damage. Be sure that building and storage<br />

practices meet all local, state and federal fire and safety codes.<br />

The following fans or accessories must be stored indoors, in a<br />

clean dry atmosphere:<br />

a. Propeller wall fans not in wall housings.<br />

b. Any fan protected by a cardboard carton.<br />

c. Motors dismounted from fans.<br />

d. Spare wheels or propellers.<br />

e. Belts, sheaves, bushings and other parts when not<br />

mounted on fan.<br />

f. Boxes, bags or cartons of hardware.<br />

g. Curbs<br />

h. Dampers<br />

Remove any accumulations of dirt, water, ice or snow and wipe<br />

dry before moving indoor storage. Allow cold parts to reach room<br />

temperature to avoid “sweating” of metal parts. Open boxes or<br />

cartons. Remove any accumulated moisture; if necessary use<br />

portable electric heaters to dry parts and packages. Leave<br />

coverings loose to permit air circulation and to permit periodic<br />

inspection.

Rotate wheels or propellers by hand to distribute bearing grease<br />

over the entire bearing surfaces.<br />

Store at least 3 ½” off the floor on wooden blocks covered with<br />

moisture proof paper or polyethylene sheathing. Provide aisles<br />

between parts and along all walls, to permit air circulation and<br />

space for inspection.<br />

OUTDOOR: Fans designed for outdoor use may be stored<br />

outdoors, if absolutely necessary. The storage area should be<br />

reasonably level and drained or ditched to prevent<br />

accumulation of water. Fencing and lighting for security are<br />

desirable. Roads or aisles for portable cranes and hauling<br />

equipment are needed. Consider the use of drift fencing to<br />

minimize accumulation of blowing snow or dirt.<br />

The following fans may be stored outdoors, if dry indoor storage<br />

space is not available:<br />

a. Fans intended for outdoor use that are crated in wood.<br />

b. Wall fans installed in wall housings.<br />

All fans must be supported on wooden blocks or timbers above<br />

water or normal snow levels. Provide enough blocking to<br />

prevent settling into soft ground. Fans should be set in place<br />

using the directional arrow markings on the crate as a guide.<br />

Locate pieces far enough apart to permit air circulation, sunlight,<br />

and space for periodic inspection. Place all parts on their<br />

supports so that rain water will run off, or to minimize water<br />

accumulation. Do not cover parts with plastic film or<br />

tarps-these cause condensation of moisture from the air<br />

passing through heating and cooling cycles.<br />

Fan wheels and propellers should be blocked to prevent<br />

spinning caused by strong winds.<br />

INSPECTION AND MAINTENANCE DURING STORAGE<br />

Inspect fans and accessories at least once per month, while in<br />

storage. Log results of inspection and maintenance performed.<br />

A typical log entry should include the following:<br />

a. Date<br />

b. Inspector’s Name<br />

c. Name of Fan<br />

d. Location<br />

e. Condition of Paint or Coating<br />

f. Is moisture present<br />

If moisture or dirt accumulations are found on parts, the source<br />

should be located and eliminated. Fans should be rotated at<br />

each inspection by hand ten to fifteen revolutions to redistribute<br />

the motor and bearing lubricant.<br />

If paint deterioration begins, consideration should be given to<br />

touch-up or repainting. Fans with special coatings may require<br />

special techniques for touch-up or repair.<br />

Machined parts coated with rust preventive should be restored<br />

to good condition promptly if signs of rust occur. The most<br />

critical items are pulleys, shafts and bearing locking collars. At<br />

the first sign of rusting on any of the above parts, remove the<br />

original rust preventive coating with petroleum solvent and<br />

clean lint-free cloths. Polish any remaining rust from surfaces<br />

with crocus cloth or fine emery paper and oil. Do not destroy the<br />

continuity of the surfaces. Wipe clean with lint-free cloths and<br />

recoat surfaces evenly and thoroughly with Tectly 506 (Ashland<br />

Oil Company) or equal. For hard to reach internal surfaces or<br />

for occasional use, consider using Tectly 511M Rust Preventive<br />

or WD40 or equal.<br />

REMOVING FROM STORAGE<br />

As fans are removed from storage to be installed in their final<br />

location, they should be protected and maintained in similar<br />

fashion, until the fan equipment goes into operation.<br />

INSTALLATION<br />

1. CAUTION! This unit has rotating parts and safety<br />

precautions should be exercised during installation,<br />

operation and maintenance.<br />

2. WARNING! Do not use in hazardous environments where<br />

the fan’s electrical system could provide ignition to<br />

combustible or flammable materials, unless unit is<br />

specifically built for hazardous environments.<br />

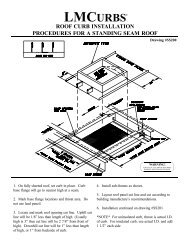

3. If the fan manufacturer prefab curb is used, a flange is<br />

provided for mounting the damper. Damper should be<br />

installed before setting the exhauster.<br />

4. If a damper box is being used, assemble the box and mount<br />

in the curb before setting the ventilator. The damper may<br />

be installed at this time if desired. The damper should be<br />

fastened to the bottom of the damper box, curb flanges or<br />

nailing strips in the curb.<br />

5. WARNING! The belt driven hood, when opened for<br />

maintenance, may present a hazard in winds of moderate<br />

to high velocity. It is therefore recommended that:<br />

a. Maintenance work requiring the hoods to be opened<br />

be performed in periods when winds are light or calm,<br />

if possible.<br />

g. Is dirt accumulated<br />

h. Corrective steps taken<br />

b. If the hood must be opened in wind, it should be<br />

hinged with the hood top facing away from the<br />

prevailing wind direction, if possible.<br />

Page 2 <strong>LMCurbs</strong> Phone: 1-800-284-1412 Fax: 1-903-759-3598

c. A prop support, such as a 2” x 4” of appropriate<br />

length, should be placed between the opened hood<br />

and the fan body to prevent accidental closing.<br />

6. Larger units are shipped with hoods in two halves because<br />

of their size. See the assembly instructions (Form 613104)<br />

attached to the hood.<br />

7. Before starting, check all fasteners for tightness;<br />

particularly in the propeller hub. Turn the propeller by hand<br />

to make sure it is in alignment with the orifice and the fan<br />

blades do not strike.<br />

8. CAUTION! Before proceeding, make sure electrical<br />

service to fan is locked in the “OFF” position.<br />

9. All wiring should be in accordance with local ordinances<br />

and the National Electric code.<br />

10. WARNING! Check voltage at the fan to see if it<br />

corresponds with the motor nameplate. High or low voltage<br />

can seriously damage the motor. Extra care should be<br />

taken when wiring two speed motors since improper<br />

connections will damage motor and void motor warranty.<br />

On belt driven ventilators, leave enough slack in wiring to<br />

allow for motor movement when adjusting belt tension.<br />

11. Apply power momentarily and compare the rotation of the<br />

impeller with the directional arrow on fan. In the case of<br />

three phase motors, the direction can be changed by<br />

interchanging any two of the three motor leads. In the case<br />

of single phase motors, the reversing instructions will<br />

appear on the wiring diagram on the motor wiring<br />

compartment cover, or on the side of the motor.<br />

12. Using a minimum of eight (8) lag bolts, two (2) on each side<br />

near corners, securely fasten exhauster to curb, replace<br />

small hood and fasten all bolts securely. The fan should<br />

rest on the curb as level as possible.<br />

13. After all installation and wiring has been completed, a final<br />

check should be made to determine that the hood fasteners<br />

are tightly secured.<br />

14. CAUTION! Guards must be installed when fan is within<br />

reach of personnel or within seven (7) feet (2.134 m) of<br />

working level or when deemed advisable for safety.<br />

MAINTENANCE<br />

1. Under normal usage, no spare parts are recommended for<br />

one year of operation. Recommended spare parts are<br />

shown on page 4 and 5.<br />

2. CAUTION! Before proceeding make sure electrical service<br />

to fan is locked in the “OFF” position.<br />

WINDMILLING: Even when the power supply is locked<br />

out, fans may cause injury or damage if the impeller is<br />

subject to “windmilling” which is the turning of the impeller<br />

and drive components due to a draft in the system. To<br />

guard against this hazard, the impeller should be secured<br />

to physically restrict rotational movement.<br />

3. Motor bearings are prelubricated. Consult information<br />

printed on the motor for lubrication instructions.<br />

4. Impeller shaft bearings on belt driven units are<br />

prelubricated and do not require relubrication. Units with<br />

pillow block bearings have grease fittings and, under<br />

normal operating conditions, will need no required for 3 to 5<br />

years. If relubrication is required, use a grease conforming<br />

to NLGI No. 2. CAUTION! Lubricating bearings with a high<br />

pressure gun can blow bearing seals and overfill the<br />

bearing with grease. This condition can result in excessive<br />

churning and overheating. For normal operating conditions<br />

it is standard practice to fill only 30% of the bearing void<br />

with grease. Do not over lubricate.<br />

5. On belt driven units, check belt tension after the first 48<br />

hours of operation and there after annually. Belt should<br />

depress its width when pressed firmly inward at midway<br />

point between the pulleys. Too much tension will damage<br />

the bearings. Belt should be tight enough to prevent<br />

slippage. When replacing worn belt, replace motor pulley if<br />

“shoulder” is worn in groove. WARNING! Do not operate<br />

at speeds higher than that cataloged for this equipment. Do<br />

not replace motor pulley with a larger diameter pulley. Do<br />

not replace the fan pulley with one smaller in diameter. The<br />

pulley ratios are set so that the motor will not be<br />

overloaded.<br />

6. WARNING! When changing bearings, secure propeller<br />

with ropes or equivalent before loosening bearing set<br />

screws on fan shaft.<br />

7. If impeller shaft bearings need replacement, replace with<br />

bearings comparable to original equipment. If duplex split<br />

pillow block bearings are used, install new bearings into<br />

neoprene rings, check correct position of propeller with<br />

orifice, position bearings in die-formed recess and tighten<br />

screws. Replace die-formed bearing cap and tighten four<br />

bolts.<br />

NOTE: If locking collar type bearing is used, collar must first<br />

be positioned against inner race on bearing nearest the<br />

impeller and turned in direction of impeller rotation with drift<br />

pin and hammer until it locks. Locking collars must be on<br />

inboard (facing) sides of bearings. Secure bearing to shaft<br />

with set screw. Lock and secure other bearing to shaft in<br />

same manner.<br />

NOTE: If pillow block type bearings are used, slide<br />

bearings onto the shaft to desired location and bolt bearing<br />

Page 3 <strong>LMCurbs</strong> Phone: 1-800-284-1412 Fax: 1-903-759-3598

lock securely to support base. Slide shaft back and forth<br />

in secured bearing (do not drive with hammer) and rotate<br />

to make certain it turns freely. Check correct position of<br />

propeller with inlet orifice. Then secure bearings to shaft by<br />

tightening set screws.<br />

SET SCREW TIGHTENING SCHEDULE<br />

1. Before initial operation of the fan, tighten set screws<br />

according to the procedure outlined below.<br />

2. After 500 operating hours or three months, whichever<br />

comes first, tighten set screws to the full recommended<br />

torque.<br />

3. At least once a year, tighten set screws to the full<br />

recommended torque.<br />

PROCEDURE FOR TIGHTENING SET SCREWS IN<br />

BEARINGS AND HUBS<br />

VARIABLE FREQUENCY<br />

DRIVES AND MOTORS<br />

There are occasions when a Variable Frequency Drive (VFD)<br />

will cause poor motor <strong>performance</strong> and possible damage. To<br />

avoid these problems, the Company recommends the following:<br />

1. Select compatible motor and VFD converter; if possible,<br />

the motor and the converter should be from the same<br />

manufacturer or at least the converter selected should be<br />

recommended by the motor manufacturer.<br />

2. A motor shaft grounding system should be used to prevent<br />

motor bearing damage from eddy currents.<br />

NOTE: The Company will not honor motor warranty claims<br />

if the customer fails to follow these recommendations.<br />

One Set Screw Application<br />

Using a torque wrench, tighten the set screw to the torque<br />

recommended in Table 1.<br />

Two Set Screw Application<br />

1. Using a torque wrench, tighten one set screw to half of the<br />

torque recommended in Table 1.<br />

2. Tighten the second set screw to the full recommended<br />

torque.<br />

3. Tighten the first set screw to the full recommended torque.<br />

Table 1. Recommended Tightening Torque<br />

for Set Screws<br />

Set Screw Diameter Torque (in-lbs)<br />

#10 35<br />

1/4 80<br />

5/16 126<br />

3/8 240<br />

7/16 384<br />

1/2 744<br />

9/16 1080<br />

5/8 1500<br />

3/4 2580<br />

7/8 3600<br />

1 5400<br />

Page 4 <strong>LMCurbs</strong> Phone: 1-800-284-1412 Fax: 1-903-759-3598

Belt Drive<br />

Models EC, ECH, USC, USCH<br />

Parts List Legend<br />

No. Description Qty.<br />

1 Hood Corner Piece 4<br />

2 Hood Top and Slide 2<br />

3 Hood Center 1**<br />

4 Support Beam 2<br />

5 Support Post 4<br />

6 Hood Ends 2<br />

7 Birdscreen 1<br />

8 Belt* 1<br />

9 Fan Pulley* 1<br />

10 Motor Pulley* 1<br />

11 Motor* 1<br />

12 Bearing Cap 1<br />

13 Frame Assembly 1<br />

14 (HD) Propeller 1***<br />

15 Propeller 1<br />

16 Channel Corners 4<br />

17 End Channels 2<br />

18 Hinge Bracket 4<br />

19 Curbcap Sides 2<br />

20 Curbcap Ends 2<br />

21 Inner Curbcap 4<br />

*Recommended spare parts<br />

** Sizes 48 through 72 require quantity of 2<br />

***Heavy Duty Propeller<br />

Page 5 <strong>LMCurbs</strong> Phone: 1-800-284-1412 Fax: 1-903-759-3598

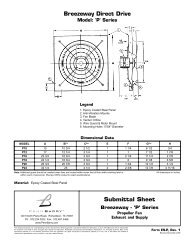

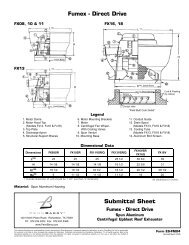

Direct Drive<br />

Models LQ & USQ<br />

Parts List Legend<br />

No. Description Qty<br />

1 Hood 1<br />

2 Propeller 1<br />

3 Birdscreen 1<br />

4 Reinforcing Piece 4<br />

5 Gasket 4<br />

6 Housing Assembly 1<br />

7 Frame Assembly 1<br />

8 Motor* 1<br />

9 Disconnect Switch 1<br />

*Recommended spare parts<br />

Page 6 <strong>LMCurbs</strong> Phone: 1-800-284-1412 Fax: 1-903-759-3598

TYPICAL EXHAUST & SUPPLY VENTILATORS<br />

EXHAUST<br />

SUPPLY<br />

PREFABRICATED CURBS<br />

EXHAUST<br />

SUPPLY<br />

Page 7 <strong>LMCurbs</strong> Phone: 1-800-284-1412 Fax: 1-903-759-3598

DESIGN CHANGES Acme reserves the right to<br />

make changes in design, improvements and<br />

additions in and to its products any time without<br />

imposing any liability or obligations to itself to<br />

apply or install the same in any product manufactured<br />

by it.<br />

TERMS AND CONDITIONS<br />

TITLE The title and right of possession of the<br />

equipment sold herein shall remain with the<br />

Company and such equipment shall remain<br />

personal property until all payments herein (including<br />

deferred payments whether evidenced<br />

by notes or otherwise) shall have been made in<br />

full in cash and the Purchaser agrees to do all<br />

acts necessary to perfect and maintain such<br />

right and title in the Company.<br />

SAFETY ACCESSORIES The Company manufactures<br />

equipment designed to serve multiple<br />

applications and offers a wide range of safety<br />

equipment, including guards and other devices,<br />

as may be required to meet customer specifications.<br />

Without exception, the Company recommends<br />

that all orders include applicable safety<br />

devices. Equipment ordered without applicable<br />

safety devices is clearly the responsibility of the<br />

Purchaser. Further, the Purchaser warrants<br />

that he has determined and acquired any and<br />

all safety devices required for equipment sold<br />

by the Company. Weather covers and guards<br />

for motor and V-belt drives, couplings, shafts<br />

and bearings, along with inlet and outlet<br />

screens, are optional accessories noted in the<br />

price list.<br />

These instructions cover the usual installation, operation and maintenance methods for which the product(s) was designed. They do not purport to<br />

cover all details or variations in the product(s) nor to provide for every possible contingency that might be met in connection with the installation, operation<br />

and maintenance. For any departures from these instructions, or should particular problems arise which are not covered sufficiently for the purchaser’s<br />

purpose, the matter should be referred to the Company.<br />

WARNING Acme products are designed and manufactured to provide reliable <strong>performance</strong> but they are not guaranteed to be 100% free of defects.<br />

Even reliable products will experience occasional failures and this possibility should be recognized by the User. If these products are used in a life support<br />

ventilation system where failure could result in loss or injury, the User should provide adequate back-up ventilation, supplementary natural ventilation<br />

or failure alarm system, or acknowledge willingness to accept the risk of such loss or injury.<br />

WARNING DO NOT use in HAZARDOUS ENVIRONMENTS where fan’s electrical system could provide ignition to combustible or flammable materials<br />

unless unit is specifically built for hazardous environments. Comply with all local and national safety codes including the National Electrical Code (NEC)<br />

and National Fire Protection Act (NFPA).<br />

CAUTION Guards must be installed when fan is within reach of personnel or within seven (7) feet (2.134 m) of working level or when deemed advisable<br />

for safety.<br />

DISCLAIMER The Company has made a diligent effort to illustrate and describe the products in this literature accurately; however, such illustrations<br />

and descriptions are for the sole purpose of identification, and do not express or imply a warranty that the products are merchantable, or fit for a particular<br />

purpose, or that the products will necessarily conform to the illustrations or descriptions or dimension.<br />

LIMITED WARRANTY<br />

WARRANTY AND DISCLAIMER: Acme Engineering<br />

and Manufacturing Corporation extends<br />

this limited warranty to the original buyer and<br />

warrants that products supplied by the Company,<br />

shall be free from original defects in<br />

workmanship and materials for two years from<br />

date of shipment (except for the warranty periods<br />

noted for products listed below), provided<br />

same have been properly handled, stored, installed,<br />

serviced, maintained and operated.<br />

This warranty shall not apply to products which<br />

have been altered or repaired without the Company’s<br />

express authorization, or altered or repaired<br />

in any way so as, in the Company’s<br />

judgment, to affect its <strong>performance</strong> or reliability,<br />

nor which have been improperly installed or<br />

subjected to misuse, negligence, or accident, or<br />

incorrectly used in combination with other substances.<br />

The Buyer assumes all risks and liability<br />

for results of use of all products.<br />

Evaporative cooling pads are warranted to be<br />

free of defects in materials and workmanship<br />

for a period of two years from date of shipment<br />

provided same have been properly handled,<br />

stored, installed, serviced, maintained and operated;<br />

and further, not subjected to excessive<br />

heat, corrosive agents or chemicals, or mechanical<br />

abuse that may cause tearing, crushing<br />

or undue deterioration, nor used on a system<br />

or in a manner other than that for which it<br />

was designed as explained in the product literature.<br />

The following products are warranted to be free<br />

of defects in materials and workmanship for the<br />

periods shown from date of shipment: Acme’s<br />

exclusive duplex split pillow block bearings and<br />

shaft five years, belts one year, Polyethylene<br />

tubing 90 days, AIR40 Heater warranty one<br />

year, AIR40 Emitter warranty three years and<br />

<strong>LMCurbs</strong><br />

P.O. Box 5299<br />

Longview, Texas 75604<br />

Telephone 800-284-1412<br />

Fax 903-759-0879<br />

DDP fan lifetime warranty on its propeller, cone,<br />

and housing.<br />

LIMITATION OF REMEDY AND DAMAGES:<br />

All claims under this warranty must be made in<br />

writing and delivered to P. O. Box 978, Muskogee,<br />

Oklahoma, 74402, within 15 days after discovery<br />

of the defect and prior to the expiration<br />

of two years from the date of shipment by the<br />

Company of the product claimed defective, and<br />

Buyer shall be barred from any remedy if Buyer<br />

fails to make such claim within such period.<br />

Within 30 days after receipt of a timely claim,<br />

the Company shall have the option either to inspect<br />

the product while in Buyer’s possession<br />

or to request Buyer to return the product to the<br />

Company at Buyer’s expense for inspection by<br />

the Company. The Company shall replace, or<br />

at its option repair, free of charge, any product<br />

it determines to be defective, and it shall ship<br />

the repaired or replacement product to Buyer<br />

F.O.B. point of shipment; provided, however, if<br />

circumstances are such as in the Company’s<br />

judgment to prohibit repair or replacement to<br />

remedy the warranted defects, the Buyer’s sole<br />

and exclusive remedy shall be a refund to the<br />

Buyer of any part of the invoice price, paid to<br />

the Company, for the defective product or part.<br />

The Company is not responsible for the cost of<br />

removal of the defective product or part, damages<br />

due to removal, or any expenses incurred<br />

in shipping the product or part to or from the<br />

Company’s plant, or the installation of the repaired<br />

or replaced product or part.<br />

Implied warranties, when applicable, shall commence<br />

upon the same date as the express warranty<br />

provided above, and shall, except for warranties<br />

of title, extend only for the duration of<br />

the express warranty. Some states do not allow<br />

limitations on how long an implied<br />

warranty lasts, so the above limitation<br />

may not apply to you. The only remedy<br />

provided to you under an applicable<br />

implied warranty and the express<br />

warranty shall be the remedy provided<br />

under the express warranty,<br />

subject to the terms and conditions<br />

contained therein. The Company shall not be<br />

liable for incidental and consequential losses<br />

and damages under the express warranty, any<br />

applicable implied warranty, or claims for negligence,<br />

except to the extent that this limitation is<br />

found to be unenforceable under applicable<br />

state law. Some states do not allow the exclusion<br />

or limitation of incidental or consequential<br />

damages, so the above limitation or exclusion<br />

may not apply to you. This warranty gives you<br />

specific legal rights, and you may also have<br />

other rights which vary from state to state.<br />

No employee, agent, dealer, or other person is<br />

authorized to give any warranties on behalf of<br />

the Company or to assume for the Company<br />

any other liability in connection with any of its<br />

products except in writing and signed by an officer<br />

of the Company.<br />

REPLACEMENT PARTS If replacement parts<br />

are ordered, buyer warrants that the original<br />

components in which these replacement parts<br />

will be placed are in satisfactory working condition,<br />

and when said replacement parts are installed,<br />

the resultant installation will operate in a<br />

safe manner, at speeds and temperatures for<br />

which the original equipment was purchased.<br />

TECHNICAL ADVICE AND RECOMMENDA-<br />

TIONS, DISCLAIMER: Notwithstanding any<br />

past practice or dealings or any custom of the<br />

trade, sales shall not include the furnishing of<br />

technical advice or assistance or system design.<br />

Any such assistance shall be at the Company’s<br />

sole option and may be subject to additional<br />

charge.<br />

The Company assumes no obligation or liability<br />

on account of any recommendations, opinions<br />

or advice as to the choice, installation or use of<br />

products. Any such recommendations, opinions<br />

or advice are given and shall be accepted at<br />

your own risk and shall not constitute any warranty<br />

or guarantee of such products or their<br />

<strong>performance</strong>.<br />

GENERAL In no event shall any claim for consequential<br />

damages be made by either party.<br />

The Company will comply with all applicable<br />

Federal, State, and local laws.<br />

<strong>LMCurbs</strong> Phone: 1-800-284-1412 Fax: 1-903-759-3598 December 2003 Form 613090