The BEECK Product Range

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

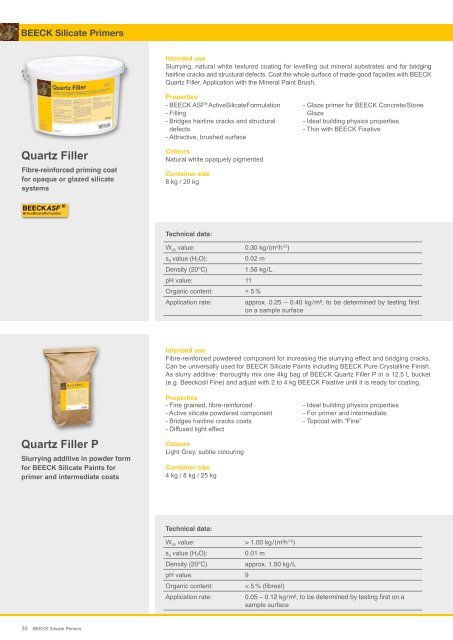

<strong>BEECK</strong> Silicate Primers<br />

Quartz Filler<br />

Fibre-reinforced priming coat<br />

for opaque or glazed silicate<br />

systems<br />

<strong>BEECK</strong>ASF ®<br />

ActiveSilicateFormulation<br />

Quartz Filler P<br />

Slurrying additive in powder form<br />

for <strong>BEECK</strong> Silicate Paints for<br />

primer and intermediate coats<br />

Intended use<br />

Slurrying, natural white textured coating for levelling out mineral substrates and for bridging<br />

hairline cracks and structural defects. Coat the whole surface of made-good façades with <strong>BEECK</strong><br />

Quartz Filler. Application with the Mineral Paint Brush.<br />

Properties<br />

- <strong>BEECK</strong> ASF ® ActiveSilicateFormulation<br />

- Filling<br />

- Bridges hairline cracks and structural<br />

defects<br />

- Attractive, brushed surface<br />

Colours<br />

Natural white opaquely pigmented<br />

Container size<br />

8 kg / 20 kg<br />

Technical data:<br />

- Glaze primer for <strong>BEECK</strong> Concrete/Stone<br />

Glaze<br />

- Ideal building physics properties<br />

- Thin with <strong>BEECK</strong> Fixative<br />

W 24 value: 0.30 kg /(m 2 h 1/2 )<br />

s d value (H 2O):<br />

0.02 m<br />

Density (20°C)<br />

1.56 kg / L<br />

pH value: 11<br />

Organic content: < 5 %<br />

Application rate:<br />

approx. 0.25 – 0.40 kg / m², to be determined by testing first<br />

on a sample surface<br />

Intended use<br />

Fibre-reinforced powdered component for increasing the slurrying effect and bridging cracks.<br />

Can be universally used for <strong>BEECK</strong> Silicate Paints including <strong>BEECK</strong> Pure Crystalline Finish.<br />

As slurry additive: thoroughly mix one 4kg bag of <strong>BEECK</strong> Quartz Filler P in a 12.5 L bucket<br />

(e.g. Beeckosil Fine) and adjust with 2 to 4 kg <strong>BEECK</strong> Fixative until it is ready for coating.<br />

Properties<br />

- Fine grained, fibre-reinforced<br />

- Active silicate powdered component<br />

- Bridges hairline cracks coats<br />

- Diffused light effect<br />

Colours<br />

Light Grey, subtle colouring<br />

Container size<br />

4 kg / 8 kg / 25 kg<br />

- Ideal building physics properties<br />

- For primer and intermediate<br />

- Topcoat with “Fine”<br />

“Gründerzeithaus”<br />

Leopoldstraße 153 in<br />

Munich<br />

Task:<br />

<strong>The</strong> aim was to completely redesign the colour<br />

finish of the façade of this “Gründerzeit” building.<br />

Examination of the old coating showed that multiple<br />

layers of organically bonded, film-forming<br />

coatings had been applied to the mineral façade<br />

render and had resulted in building physics<br />

limitations. <strong>The</strong> surfaces were highly soiled due<br />

to thermoplastic effects and contained extensive<br />

fine hairline cracks.<br />

<strong>The</strong> following criteria were used to define the objective<br />

of the new colour finish:<br />

- <strong>The</strong> old multi-layered organic coating was to be<br />

removed completely from the façade through<br />

paint stripping.<br />

- A coating system with high weathering resistance<br />

and long lives, extreme water vapour<br />

permeability, and an unmistakeable matt, mineral<br />

character.<br />

- By creating sample areas, a suitable paint system<br />

and colour were to be found, which removed<br />

the hairline crack phenomena with suitable<br />

products.<br />

- <strong>The</strong> new coating system should only be applied<br />

using mineral paint techniques, very thinly with<br />

a brush.<br />

Project stages:<br />

Due to the existing condition of the surfaces<br />

found on site the old coating was removed completely.<br />

Sample areas were created using the<br />

defined technology. After making good existing<br />

render and applying new render the planned<br />

coating technology was applied. After the individual<br />

work steps were completed the responsible<br />

<strong>BEECK</strong> consultant examined the results and released<br />

the finished areas for further work.<br />

<strong>The</strong> work on site was checked and documented<br />

continuously with regard to the specified products<br />

and technology.<br />

Result:<br />

<strong>The</strong> standards worded in the objectives were<br />

achieved. <strong>The</strong> coating system and colour defined<br />

on the basis of old sample areas produced<br />

a true-to-style matt appearance and lends the<br />

façade surface a unique mineral profile.<br />

Technical data:<br />

W 24 value: > 1.00 kg /(m 2 h 1/2 )<br />

s d value (H 2O):<br />

0.01 m<br />

Density (20°C)<br />

approx. 1.50 kg / L<br />

pH value: 9<br />

Organic content: < 5 % (fibres!)<br />

Application rate:<br />

0.05 – 0.12 kg / m², to be determined by testing first on a<br />

sample surface<br />

<strong>Product</strong> use:<br />

- Render neutralisation with <strong>BEECK</strong> Etching Fluid<br />

- Priming coat with <strong>BEECK</strong> Fixative<br />

- Priming coat with <strong>BEECK</strong> Quartz Filler<br />

- Intermediate and top coat with Beeckosil Fine<br />

30 <strong>BEECK</strong> Silicate Primers<br />

<strong>BEECK</strong> Silicate Primers 31