cable ladder & tray

cable ladder & tray

cable ladder & tray

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

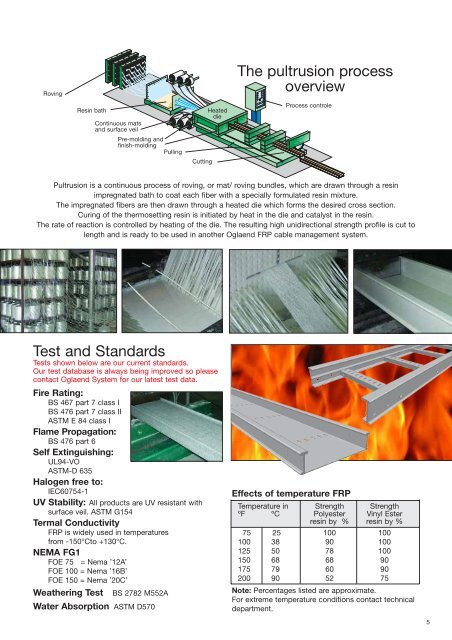

Roving<br />

The pultrusion process<br />

overview<br />

Resin bath<br />

Continuous mats<br />

and surface veil<br />

Pre-molding and<br />

finish-molding<br />

Pulling<br />

Cutting<br />

Heated<br />

die<br />

Process controle<br />

Pultrusion is a continuous process of roving, or mat/ roving bundles, which are drawn through a resin<br />

impregnated bath to coat each fiber with a specially formulated resin mixture.<br />

The impregnated fibers are then drawn through a heated die which forms the desired cross section.<br />

Curing of the thermosetting resin is initiated by heat in the die and catalyst in the resin.<br />

The rate of reaction is controlled by heating of the die. The resulting high unidirectional strength profile is cut to<br />

length and is ready to be used in another Oglaend FRP <strong>cable</strong> management system.<br />

Test and Standards<br />

Tests shown below are our current standards.<br />

Our test database is always being improved so please<br />

contact Oglaend System for our latest test data.<br />

Fire Rating:<br />

BS 467 part 7 class I<br />

BS 476 part 7 class II<br />

ASTM E 84 class I<br />

Flame Propagation:<br />

BS 476 part 6<br />

Self Extinguishing:<br />

UL94-VO<br />

ASTM-D 635<br />

Halogen free to:<br />

IEC60754-1<br />

UV Stability: All products are UV resistant with<br />

surface veil. ASTM G154<br />

Termal Conductivity<br />

FRP is widely used in temperatures<br />

from -150°Cto +130°C.<br />

NEMA FG1<br />

FOE 75 = Nema ’12A’<br />

FOE 100 = Nema ’16B’<br />

FOE 150 = Nema ’20C’<br />

Weathering Test BS 2782 M552A<br />

Water Absorption ASTM D570<br />

Effects of temperature FRP<br />

Temperature in Strength Strength<br />

ºF ºC Polyester Vinyl Ester<br />

resin by % resin by %<br />

75 25 100 100<br />

100 38 90 100<br />

125 50 78 100<br />

150 68 68 90<br />

175 79 60 90<br />

200 90 52 75<br />

Note: Percentages listed are approximate.<br />

For extreme temperature conditions contact technical<br />

department.<br />

5