Sullair Australia - QGC

Sullair Australia - QGC

Sullair Australia - QGC

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

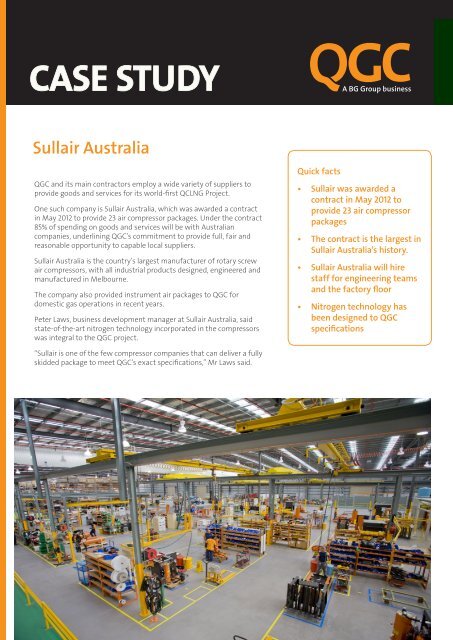

CASE STUDY<br />

AIPP REPORT May 2012<br />

<strong>Sullair</strong> <strong>Australia</strong><br />

<strong>QGC</strong> and its main contractors employ a wide variety of suppliers to<br />

provide goods and services for its world-first QCLNG Project.<br />

One such company is <strong>Sullair</strong> <strong>Australia</strong>, which was awarded a contract<br />

in May 2012 to provide 23 air compressor packages. Under the contract<br />

85% of spending on goods and services will be with <strong>Australia</strong>n<br />

companies, underlining <strong>QGC</strong>’s commitment to provide full, fair and<br />

reasonable opportunity to capable local suppliers.<br />

<strong>Sullair</strong> <strong>Australia</strong> is the country’s largest manufacturer of rotary screw<br />

air compressors, with all industrial products designed, engineered and<br />

manufactured in Melbourne.<br />

The company also provided instrument air packages to <strong>QGC</strong> for<br />

domestic gas operations in recent years.<br />

Peter Laws, business development manager at <strong>Sullair</strong> <strong>Australia</strong>, said<br />

state-of-the-art nitrogen technology incorporated in the compressors<br />

was integral to the <strong>QGC</strong> project.<br />

Quick facts<br />

• <strong>Sullair</strong> was awarded a<br />

contract in May 2012 to<br />

provide 23 air compressor<br />

packages<br />

• The contract is the largest in<br />

<strong>Sullair</strong> <strong>Australia</strong>’s history.<br />

• <strong>Sullair</strong> <strong>Australia</strong> will hire<br />

staff for engineering teams<br />

and the factory floor<br />

• Nitrogen technology has<br />

been designed to <strong>QGC</strong><br />

specifications<br />

“<strong>Sullair</strong> is one of the few compressor companies that can deliver a fully<br />

skidded package to meet <strong>QGC</strong>’s exact specifications,” Mr Laws said.

About <strong>QGC</strong><br />

<strong>QGC</strong> is a leading <strong>Australia</strong>n coal seam<br />

gas explorer and producer focused on<br />

developing world-class reserves for<br />

domestic and international supply.<br />

Almost 9000 staff and contractors<br />

work for us in central and southern<br />

Queensland.<br />

Our priority development is QCLNG<br />

– one of <strong>Australia</strong>’s biggest capital<br />

infrastructure projects and the world’s<br />

first liquefied natural gas project<br />

based on gas from coal seams.<br />

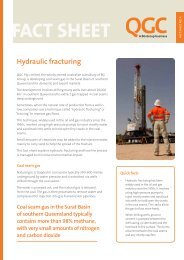

The contract is the largest in <strong>Sullair</strong> <strong>Australia</strong>’s<br />

history and will provide additional work for<br />

the factory over the coming 18 months.<br />

“The equipment scope is the most extensive I have seen for a single<br />

project in my 40 years in the industry.<br />

“We were able to offer the right technology and the solution we<br />

have engineered is tailored to <strong>QGC</strong>’s specific requirements to be<br />

able to operate in harsh conditions.”<br />

The contract is the largest in <strong>Sullair</strong> <strong>Australia</strong>’s history and will<br />

provide additional work for the factory during the coming 18<br />

months.<br />

“The contract with <strong>QGC</strong> will see <strong>Sullair</strong> <strong>Australia</strong> hire staff for our<br />

engineering teams and on the factory floor,” Mr Laws said.<br />

“We’ve been working with <strong>QGC</strong> on their domestic gas operations<br />

and we understand the needs of coal seam gas operators, including<br />

how to reliably supply parts and servicing.”<br />

Designing compressors in <strong>Australia</strong> has allowed <strong>Sullair</strong> to<br />

manufacture equipment to fit <strong>QGC</strong>’s specific needs. The company<br />

collaborates with customers to find efficiencies in energy usage,<br />

which leads to a decrease in operational costs.<br />

<strong>Sullair</strong>’s industrial compressors bear the <strong>Australia</strong>n Made symbol,<br />

which represents quality through longevity, reduced downtime and<br />

savings on servicing.<br />

QCLNG involves significantly<br />

expanding <strong>QGC</strong>’s operations in<br />

the Surat Basin and transporting<br />

the gas via a 540km underground<br />

pipeline network to Curtis Island, off<br />

Gladstone, where it will be cooled to a<br />

liquid for transport by ship.<br />

<strong>QGC</strong> also supplies about 20 per cent<br />

of Queensland’s gas demand through<br />

our existing domestic gas business.<br />

Our commitments<br />

We seek to minimise the effects of our<br />

operations on landholders and make a<br />

positive contribution to the protection<br />

of the environment.<br />

We run our business in accordance<br />

with government regulations, industry<br />

standards and the access rules that we<br />

agree with landholders.<br />

Our staff, contractors and consultants<br />

follow <strong>QGC</strong>’s Code of Conduct,<br />

outlined in our Information for<br />

Landholders booklet available via our<br />

website: www.qgc.com.au<br />

Contact details<br />

Please contact <strong>QGC</strong> for more information.<br />

1800 030 443 (toll-free)<br />

email: community@bg-group.com<br />

<strong>QGC</strong> Pty Limited<br />

275 George St<br />

Brisbane QLD 4000, <strong>Australia</strong>