About SEAT - Hewlett Packard

About SEAT - Hewlett Packard

About SEAT - Hewlett Packard

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

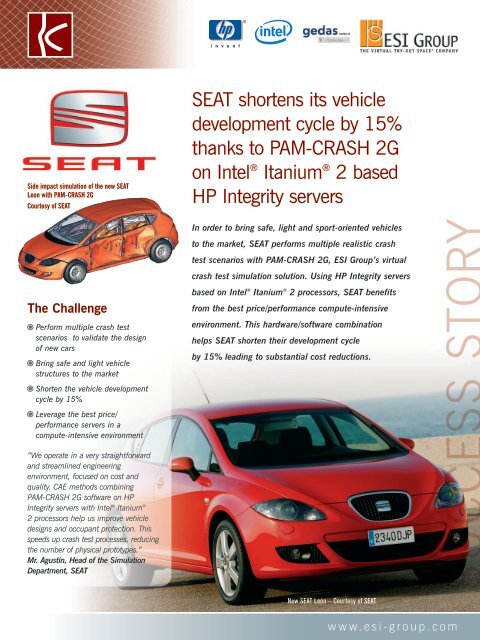

Side impact simulation of the new <strong>SEAT</strong><br />

Leon with PAM-CRASH 2G<br />

Courtesy of <strong>SEAT</strong><br />

The Challenge<br />

Perform multiple crash test<br />

scenarios to validate the design<br />

of new cars<br />

Bring safe and light vehicle<br />

structures to the market<br />

Shorten the vehicle development<br />

cycle by 15%<br />

Leverage the best price/<br />

performance servers in a<br />

compute-intensive environment<br />

“We operate in a very straightforward<br />

and streamlined engineering<br />

environment, focused on cost and<br />

quality. CAE methods combining<br />

PAM-CRASH 2G software on HP<br />

Integrity servers with Intel ® Itanium ®<br />

2 processors help us improve vehicle<br />

designs and occupant protection. This<br />

speeds up crash test processes, reducing<br />

the number of physical prototypes.”<br />

Mr. Agustín, Head of the Simulation<br />

Department, <strong>SEAT</strong><br />

<strong>SEAT</strong> shortens its vehicle<br />

development cycle by 15%<br />

thanks to PAM-CRASH 2G<br />

on Intel ® Itanium ® 2 based<br />

HP Integrity servers<br />

In order to bring safe, light and sport-oriented vehicles<br />

to the market, <strong>SEAT</strong> performs multiple realistic crash<br />

test scenarios with PAM-CRASH 2G, ESI Group’s virtual<br />

crash test simulation solution. Using HP Integrity servers<br />

based on Intel ® Itanium ® 2 processors, <strong>SEAT</strong> benefits<br />

from the best price/performance compute-intensive<br />

environment. This hardware/software combination<br />

helps <strong>SEAT</strong> shorten their development cycle<br />

by 15% leading to substantial cost reductions.<br />

New <strong>SEAT</strong> León – Courtesy of <strong>SEAT</strong><br />

w w w. e s i - g r o u p . c o m

Key Benefits<br />

Time optimization with overnight<br />

calculations<br />

Cost reductions<br />

Increase in the number of predictive<br />

physics-based virtual crash testing scenarios<br />

Better control of the different process<br />

parameters leading to safer cars and fewer<br />

prototype phases<br />

Pedestrian Protection<br />

performance of the<br />

latest <strong>SEAT</strong> Leon car<br />

model, simulated by<br />

PAM-CRASH 2G<br />

Courtesy of <strong>SEAT</strong><br />

“PAM-CRASH 2G and our new cluster help<br />

us to improve our product lifecycle on the<br />

latest car model Leon while saving time and<br />

money. Most of the development is done<br />

virtually using computer models, we can<br />

then crash virtually <strong>SEAT</strong> Leon several<br />

thousand times in different environments<br />

(speeds, size of occupants...).<br />

PAM-CRASH 2G contributes to bring on<br />

the market a safer, lighter and sportiveoriented<br />

product while enhancing the product<br />

design and manufacturing process.”<br />

Mr. Agustín, Head of the Simulation<br />

Department, <strong>SEAT</strong><br />

<strong>SEAT</strong> performs realistic crash<br />

simulation using PAM-CRASH 2G...<br />

In the highly competitive automotive industry, Computer Aided Engineering<br />

applications (CAE) leverage carmakers’ industrial know-how and help them<br />

speed-up time-to-market, increase the number of variants within tight<br />

development cycles and controlled budgets.<br />

<strong>SEAT</strong>, the Spanish car company member of the Volkswagen Group, produces<br />

cars known for their excellence in design and their sporty positioning. By<br />

performing multiple virtual crash test scenarios with PAM-CRASH 2G on an<br />

Intel Itanium 2 based HP cluster, <strong>SEAT</strong> has developed a solid experience and<br />

knowledge in passive safety. PAM-CRASH 2G helped <strong>SEAT</strong> in the creation of<br />

safer, lighter and sport-oriented cars such as Altea, Leon, Toledo and Ibiza,<br />

while enhancing the product design and manufacturing process.<br />

Leveraging cutting edge engineering with simulation<br />

<strong>SEAT</strong>’s Research and Development center located in Martorell (Barcelona,<br />

Spain) is heavily focused on the use of outstanding technologies in order to face<br />

fierce competition. Engineers compute vehicle structures using PAM-CRASH 2G<br />

for frontal, side, rear and offset crash impacts. Process parameters range from<br />

material properties to links between the various structures’ components, rupture<br />

prediction and structure deformation during the crash. For a full car model of<br />

around 1 500 000 Finite Elements, PAM-CRASH 2G achieves significant time<br />

optimization with overnight calculations. PAM-CRASH 2G’s technology enables<br />

<strong>SEAT</strong> to obtain realistic and reliable results. The DMP parallel version based on<br />

the explicit solver for detailed crash simulation offers <strong>SEAT</strong> extremely accurate<br />

contact algorithm, detailed failure modeling, optimal computer hardware<br />

utilization, and reduced time computation.<br />

Outperforming pedestrian protection regulations<br />

The environmental pressure from regulations like FMVSS and Euro NCAP directly<br />

linked to pedestrian safety and airbag interaction with occupants has encouraged<br />

the development of advanced safety and crash features for which CAE is<br />

required. Consumer tests (Star ratings) have become a key sales driving force,<br />

contributing to company profitability. Therefore, this field of knowledge has been<br />

especially reinforced using the most recent technologies.<br />

<strong>SEAT</strong> engineers have made significant progress in the field of pedestrian<br />

protection, taking into account regulations and consumer tests. The objectives<br />

are to minimize lower and upper leg injuries as well as head impacts by<br />

identifying the most relevant parameters. Using PAM-CRASH 2G, <strong>SEAT</strong> has<br />

achieved a high level of performance to protect pedestrians.<br />

Regarding occupant safety, the use of PAM-CRASH 2G has allowed <strong>SEAT</strong><br />

engineers to optimize all restraint systems (front airbags, curtain airbags, side<br />

airbags and seat belts) and also the performance of all relevant interior parts<br />

in case of an impact (door panel, cockpit, etc...). Thanks to this simulation<br />

technology, front and side impact requirements were taken into account in the<br />

early phases of the project.<br />

Combined with HP servers based on Intel Itanium 2 processors,<br />

PAM-CRASH 2G has offered <strong>SEAT</strong> best-in-class performance, robustness<br />

and stability in real crash testing conditions. Using intensively other Virtual<br />

Development Technologies such as Virtual Reality, Digital Mock Up and Virtual<br />

factory, PAM-CRASH 2G delivers <strong>SEAT</strong> the best solution for car design and<br />

shortens their vehicle development cycle by 15%.

S U C C E S S S T O R Y<br />

… and benefits from the best price/performance<br />

in a compute-intensive environment<br />

Industry-leading HP Integrity servers, based on Intel Itanium 2 processors,<br />

deliver powerful throughput, flexible operation, and easy system management<br />

while supporting hundreds of CAE users running your complete suite of<br />

ESI-CAE applications. Running the HP-UX 11i version 2 Technical<br />

Computing Operating Environment (TCOE), HP Integrity servers support<br />

all ESI-CAE solver codes today, at the fastest possible performance.<br />

Powered by Intel Itanium 2 processors, HP Integrity servers outperform<br />

competing server architectures on the market, with lower memory latency,<br />

massive memory capacity, and a blazing I/O subsystem. They enable high<br />

data processing capacity in order to generate rapid and cost-effective results.<br />

Based on the EPIC Architecture with a 64-bit instruction set specifically<br />

developed to optimize parallels executions, the Intel Itanium 2 processor<br />

family makes it possible to replace expensive, proprietary RISC-based and<br />

mainframe platforms with more flexible and cost-effective HPC solutions.<br />

The result is a server family that uniquely balances a wide range of<br />

performance, security, scalability and cost requirements for high computing<br />

environment.<br />

“Being able to run the number of virtual crashes that every project<br />

requires to guaranty the strict passive safety requirements imposed<br />

by <strong>SEAT</strong>”<br />

Offset crash test, simulated with PAM-CRASH 2G, New <strong>SEAT</strong> Leon<br />

Courtesy of <strong>SEAT</strong><br />

This statement was the tough challenge faced by Mr Agustin’s team.<br />

Following benchmarks, it was clear that the system for running jobs had<br />

to be based on two-processors nodes. They opted for an HP cluster based<br />

on Integrity servers running with 36 Intel Itanium 2 processors at 1.6Ghz<br />

with the HP-UX OS.<br />

It only took his team a couple of weeks to install, configure and tune its<br />

cluster before the first crash tests. From the first crash tests made with<br />

PAM-CRASH 2G, it was clear that their new cluster was bringing various<br />

benefits such as:<br />

Quality Increase in crash test details,<br />

Reduced Costs,<br />

Improved Decision Making,<br />

Reduced time to market.<br />

“The HP Integrity Servers based<br />

on Intel Itanium 2 processors have<br />

provided an excellent price/performance<br />

ratio and great scalability combined<br />

along with PAM-CRASH 2G.”<br />

Mr. Agustín, Head of the<br />

Simulation Department, <strong>SEAT</strong><br />

Key Benefits<br />

Breakthrough Performance with massive<br />

execution resources (128 floating point,<br />

128 general registers, integrated larger<br />

L3 caches)<br />

Very efficient with PAM-CRASH Code<br />

and car models<br />

2-way to 2,048-way Scalability<br />

HP Integrity servers based<br />

on Intel ® Itanium ® 2 processors<br />

Courtesy of HP

S-SEALG-01 - Copyright ESI Group 2006 - Intel, Intel logo, Itanium and Itanium Inside are trademarks or registered trademarks of Intel Corporation or its subsidiaries in the United States and other countries.<br />

w w w . e s i - g r o u p . c o m<br />

i n f o @ e s i - g r o u p . c o m<br />

ESI GROUP HEADQUARTERS<br />

6 RUE HAMELIN<br />

BP 2008-16<br />

75761 PARIS CEDEX 16<br />

FRANCE<br />

Phone: +33 (0)1 53 65 14 14<br />

Fax: +33 (0)1 53 65 14 12<br />

ESI GROUP MARKETING<br />

PARC D AFFAIRES SILIC<br />

99 RUE DES SOLETS - BP 80112<br />

94513 RUNGIS CEDEX<br />

FRANCE<br />

Phone: +33 (0)1 41 73 58 00<br />

Fax: +33 (0)1 46 87 72 02<br />

<strong>About</strong> <strong>SEAT</strong><br />

ESI Group is a pioneer and world leading provider of digital simulation software for prototyping and manufacturing processes<br />

<strong>About</strong> ESI Group that take into account the physics of materials. ESI Group has developed an entire suite of coherent, industry-oriented<br />

applications to realistically simulate a product's behavior during testing, to fine tune the manufacturing processes in synergy with the desired product performance, and<br />

to evaluate the environment’s impact on product usage. ESI Group’s product portfolio, which has been industrially validated and combined in multi-trade value chains,<br />

represents a unique collaborative, virtual engineering solution, known as the Virtual Try-Out Space (VTOS), enabling a continuous improvement on the virtual prototype.<br />

By drastically reducing costs and development lead times, VTOS solutions offer major competitive advantages by progressively eliminating the need for physical prototypes.<br />

FRANCE<br />

ESI FRANCE<br />

PARC D AFFAIRES SILIC<br />

99 RUE DES SOLETS - BP 80112<br />

94513 RUNGIS CEDEX<br />

FRANCE<br />

Phone: +33 (0)1 49 78 28 00<br />

Fax: +33 (0)1 46 87 72 02<br />

USA<br />

ESI North America<br />

Commercial Headquarters<br />

36800 Woodward Avenue<br />

Suite 200<br />

Bloomfield Hills, MI 48304<br />

USA<br />

Phone: +1 (248) 203 0642<br />

Fax: +1 (248) 203 0696<br />

GERMANY<br />

ESI GmbH<br />

Mergenthalerallee 15-21<br />

65760 Eschborn<br />

Germany<br />

Phone: +49(0)6196 9583-0<br />

Fax: +49 (0)6196 9583-111<br />

USA<br />

ESI CFD<br />

215 Wynn Drive<br />

Huntsville, AL 35805<br />

USA<br />

Phone: +1 (256) 726-4800<br />

Fax: +1 (256) 726-4836<br />

BENELUX AND SCANDINAVIA<br />

ESI B.V.<br />

Gebouw Kortland<br />

Nieuwe Tiendweg 11<br />

2922 EN Krimpen aan den IJssel<br />

The Netherlands<br />

Phone: +31 180 514860<br />

Fax: +31 180 518533<br />

SOUTH AMERICA<br />

ESI Group South America<br />

Technical Support Office<br />

Rua Artur de Azevedo,<br />

1857 cj. 45<br />

São Paulo - SP 05404-015<br />

Brazil<br />

Phone/Fax: +55 11 3062-3698<br />

CZECH REPUBLIC & EASTERN<br />

EUROPEAN COUNTRIES<br />

MECAS ESI s.r.o.<br />

Úslavská 10<br />

326 00 Plzen<br />

Czech Republic<br />

Phone: +420 377 432 931<br />

Fax: +420 377 432 930<br />

JAPAN<br />

NIHON ESI K.K.<br />

Headquarters and Sales Division<br />

Yoyogi-Uehara West Building,<br />

45-18 Oyama-Cho - Shibuya-ku<br />

Tokyo 151-0065<br />

Japan<br />

Phone: +81 3 6407 2347<br />

Fax: +81 3 6407 2395<br />

E U R O P E<br />

SPAIN<br />

The Virtual Try-Out Space S.L.<br />

Edificio IKEA, Oficina 311<br />

C/ Estartetxe, 5<br />

48940 Leioa (Bizkaia)<br />

Spain<br />

Phone: +34 94 480 47 60<br />

Fax: +34 94 480 51 99<br />

KOREA<br />

Hankook ESI<br />

157-033, 5F KOMEGA bldg.,<br />

660-6,<br />

Deungchon-3Dong, Gangseo-ku,<br />

Seoul<br />

South Korea<br />

Phone: +82 2 3664 0073<br />

Fax/ +82 2 3662 0084<br />

SWITZERLAND<br />

Calcom ESI SA<br />

Parc Scientifique EPFL<br />

CH-1015 Lausanne<br />

Switzerland<br />

Phone: +41 21 693 2918<br />

Fax: +41 21 693 4740<br />

A M E R I C A S A S I A<br />

S U C C E S S S T O R Y<br />

<strong>SEAT</strong> is a Spanish company owned by the German Volkswagen Group. Since 2002, together with Lamborghini<br />

and Audi itself, <strong>SEAT</strong> is a member of the Audi Brand Group. The company is currently in the process of<br />

undertaking a profound restructuring designed to transform it into the “nueva <strong>SEAT</strong>”, a remodelled company<br />

resting on the twin pillars of efficient processes and customer orientation, both supported by a change in<br />

organizational culture. The company provides employment for 12,700 persons, and offers a modern range of<br />

products comprising six models: the Alhambra, Altea, Córdoba, Ibiza, León and Toledo, all of which are imbued<br />

with the unique identifying features of design and sports-oriented character.<br />

www.seat.com<br />

<strong>About</strong> gedas<br />

gedas provides consulting on the development, system integration<br />

and operation of IT solutions to companies in the automotive and<br />

manufacturing industries. gedas’s technological expertise in its core market,<br />

along with its knowledge of business processes specific to the automotive<br />

industry, also serves to benefit numerous customers from other industries<br />

Gedas contact<br />

Christian Pomar<br />

Alliance and Sales manager<br />

christian.pomar@gedas.es<br />

and the public administration sector. The IT service provider has developed its own comprehensive philosophy, called<br />

“Intelligent Transformation,” which is based on three core concepts: technological benefits, an integrated approach<br />

and a useful interface between people and technology. gedas, a member of T-Systems, is headquartered in Barcelona.<br />

In 2005, the company and its approximately 1.100 employees generated sales of 145 million.<br />

www.gedas.com<br />

<strong>About</strong> HP<br />

HP is a technology solutions provider to consumers, businesses and<br />

HP contact<br />

Lee Fisher<br />

institutions globally. The company’s offerings span IT infrastructure,<br />

CAE Worldwide Business & Alliances<br />

global services, business and home computing, and imaging and<br />

<strong>Hewlett</strong>-<strong>Packard</strong><br />

printing. For the four fiscal quarters ended Jan. 31, 2006, HP<br />

lee.fisher@hp.com<br />

revenue totaled $87.9 billion.<br />

More information about HP (NYSE, Nasdaq: HPQ) is available at www.hp.com<br />

<strong>About</strong> Intel<br />

Founded in 1968 to build semiconductor memory products, Intel<br />

introduced the world’s first microprocessor in, 1971. Today Intel the<br />

world’s largest chip maker is also a leading manufacturer of computer,<br />

networking, and communications products.<br />

Learn more at www.intel.com/intel/index.htm<br />

Intel contact<br />

Stephan Hilby<br />

Strategic Relations Manager<br />

stephan.hilby@intel.com<br />

SOUTH-EAST ASIA<br />

ESI Group South East Asia<br />

Technical Office<br />

96-1, Jalan PJU 1/3B<br />

SunwayMas Commercial Center<br />

47301 Petaling Jaya, Selangor<br />

Malaysia<br />

Phone: +60 3 - 78049973<br />

Fax: +60 12 - 2739978<br />

UNITED KINGDOM<br />

ESI-UK Ltd.<br />

John Eccles House,<br />

Robert Robinson Avenue,<br />

The Oxford Science Park, Oxford<br />

OX4 4GP - United Kingdom<br />

Phone: +44 (0) 1865 338007<br />

Fax: +44 (0) 1865 338100<br />

CHINA<br />

ZHONG GUO ESI CO., LTD<br />

Unit 608A, Guangdong Soft-Park<br />

No.11 Caipin Road, Complex Bldg.<br />

Guangzhou Science City (GSC)<br />

Guangzhou City 510663<br />

China<br />

Phone: +86 (020) 3206 8272<br />

Fax: +86 (020) 3206 8107<br />

PAM-SYSTEM and all PAM-product names are trademarks of ESI Group - All other trademarks are the property of their respective owners - Specifications are subject to change without notice.<br />

INDIA<br />

ESI Software Pvt. Ltd<br />

No. 24-25, 27th Cross<br />

Banasankari 2nd Stage<br />

Bangalore 560 070<br />

India<br />

Phone: +91 80 2671 9006<br />

Fax: +91 80 2671 9025