DeltaVision OMX brochure.indd

DeltaVision OMX brochure.indd

DeltaVision OMX brochure.indd

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

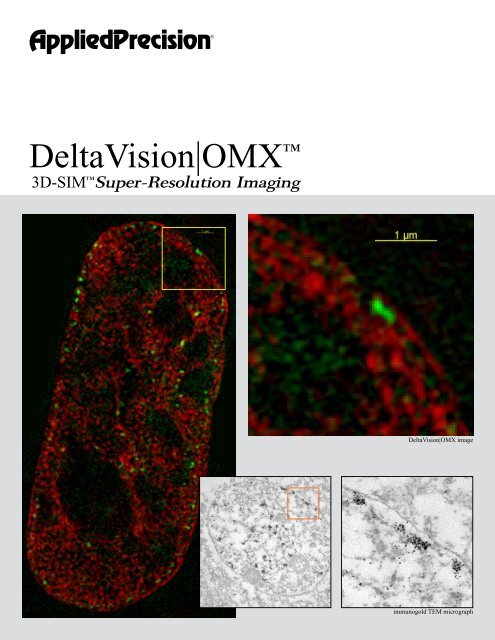

AppliedPrecision®<br />

<strong>DeltaVision</strong>|<strong>OMX</strong> <br />

<br />

3D-SIM Super-Resolution Imaging<br />

<strong>DeltaVision</strong>|<strong>OMX</strong> image<br />

immunogold TEM micrograph

What is super-resolution?<br />

In conventional microscope systems, image resolution<br />

is limited by the angle of light that can successfully<br />

traverse the light path and enter the objective lens.<br />

While objectives can be built with very high numerical<br />

apertures, a limit is reached when light can no longer<br />

cross the interfaces between different refractive indices.<br />

At this point, Brewster’s angle is achieved and additional<br />

light and information (resolution) do not make it into<br />

the objective lens. This angle ultimately limits the<br />

resolution of all microscope systems. Once this limit<br />

is reached, a system is said to be diffraction limited.<br />

Super-Resolution is loosely defined as the ability for an<br />

imaging system to exceed this limit driven by physics<br />

and the wavelength of light and provide resolutions<br />

that are significantly better than the diffraction limit<br />

described above.<br />

Applied Precision has led the way over the past fifteen<br />

years in empowering scientists to fully exploit this limit<br />

with image restoration (deconvolution) microscopy<br />

included in the <strong>DeltaVision</strong> Core and personalDV<br />

Microscopy Systems improving resolution by<br />

approximately 15-20% and contrast ten fold. In recent<br />

years, new methods have been developed to surpass<br />

the diffraction limit. These methods allow precise<br />

visualization and measurement of features that are less<br />

than one-half of the size of those seen with conventional<br />

microscopy. Improvement of resolution by a factor<br />

of 2 or more is how Applied Precision defines superresolution<br />

microscopy.<br />

How does <strong>DeltaVision</strong> <strong>OMX</strong> achieve<br />

super-resolution?<br />

<strong>DeltaVision</strong> <strong>OMX</strong> uses 3D-SIM super-resolution<br />

technology developed by the labs of Drs. Sedat,<br />

Gustafsson, and Agard at UCSF. <strong>DeltaVision</strong> <strong>OMX</strong> is<br />

a 3D structured illumination microscopy system that<br />

enables super resolution imaging. <strong>DeltaVision</strong> <strong>OMX</strong><br />

surpasses the 250nm resolution limit by a factor of two<br />

in x, y and z, and enables imaging beyond the surface<br />

of the coverslip with multiple probes. This technology<br />

will resolve features previously invisible to traditional<br />

microscopy and lets you image more of your biology,<br />

not just the biology that falls within a fraction of a<br />

micron of the basal surface of the cell.<br />

The <strong>DeltaVision</strong> <strong>OMX</strong> technology can image five,<br />

ten, fifteen, even twenty microns into cells and<br />

tissues. <strong>DeltaVision</strong> <strong>OMX</strong> works with conventional<br />

fluorochromes eliminating any need to genetically<br />

engineer novel or complex photoswitchable probes<br />

so that you can apply the preparation methods and<br />

fluorescent labeling reagents (antibodies and protein<br />

tags) currently used in the lab.

What is 3D-SIM?<br />

<strong>DeltaVision</strong> <strong>OMX</strong> extends the resolution limits of<br />

microscopy by superimposing a high-resolution<br />

sinusoidal illumination pattern onto the sample. This<br />

pattern generates moiré interference patterns with the<br />

high-resolution information contained within your<br />

sample. These moiré patterns occur at lower frequencies<br />

than the original high-resolution information in your<br />

sample. By translating and rotating this illumination<br />

pattern around the numerical aperture, twice the<br />

spatial information can be collected by the microscope<br />

effectively doubling the resolution of the microscope.<br />

standard widefield<br />

What about Temporal<br />

Resolution?<br />

Super-resolution is currently available for imaging fixed<br />

samples. However, <strong>DeltaVision</strong> <strong>OMX</strong> is also designed<br />

to deliver superior live cell performance.<br />

The unique optical path of the <strong>DeltaVision</strong> <strong>OMX</strong><br />

system enables true simultaneous imaging of up to<br />

four channels without compromising image quality. By<br />

combining this light path with novel timing control, all<br />

aspects of the imaging train from illumination shutter<br />

control to camera timing and position control systems<br />

are precisely timed to deliver the fastest possible<br />

performance.<br />

How fast? Up to 65 frames-per-second in each of up<br />

to four simultaneous channels; the equivalent of 260<br />

frames-per-second. These frame rates are not limited<br />

by 3D imaging; a stack of over 60 Z-sections can be<br />

acquired in four simultaneous channels in less than one<br />

second.<br />

Applied Precision has a well-earned reputation as<br />

the leader in engineered imaging solutions for high<br />

performance microscopy. <strong>DeltaVision</strong> <strong>OMX</strong> is a fully<br />

designed and integrated imaging solution that takes this<br />

performance to new levels.<br />

An established technology<br />

<strong>DeltaVision</strong> <strong>OMX</strong><br />

Two isoforms of beta-tubulin in a cultured neuron - Image courtesy of Stefanie<br />

Kaech Petrie and Aurelie Snyder, Advanced Light Microscopy Core at The<br />

Jungers Institute Oregon Health & Sciences University<br />

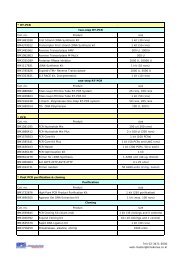

<strong>DeltaVision</strong> <strong>OMX</strong> systems have been in place<br />

around the world since 2008. As scientists make<br />

groundbreaking discoveries using 3D-SIM, the demand<br />

for the technology has grown. <strong>DeltaVision</strong> <strong>OMX</strong><br />

super-resolution systems are in use at the following<br />

institutions: The University of California, Davis, The<br />

Oxford University, The Samuel Lunenfeld Research<br />

Institute, The Georgia Institute of Technology, The<br />

University of Dundee and The University of Illinois. In<br />

2009, the number of research facilities using <strong>DeltaVision</strong><br />

<strong>OMX</strong> grew to include Cold Spring Harbor Laboratories,<br />

Ludwig Maximilian University of Munich, University<br />

of Technology Sydney, Massachusetts Institute of<br />

Technology and University of Cambridge.<br />

<strong>DeltaVision</strong>|<strong>OMX</strong>

<strong>DeltaVision</strong>|<strong>OMX</strong><br />

What does it take?<br />

This kind of spatial and temporal resolution can not<br />

be achieved without careful engineering and testing. It<br />

starts with meticulous system design. Each component<br />

is carefully chosen and selected to deliver the highest<br />

performance possible with today’s technology. Each<br />

component is scrutinized for maximum performance:<br />

• API certified highest quality PSF objective lens<br />

• Custom high-performance reverse light-path beam<br />

splitters<br />

• Custom detectors<br />

• Custom laser designs<br />

• Proprietary motion control<br />

• Proprietary timing control<br />

• Proprietary light scrambling methods<br />

• Proprietary light structure generation<br />

• Fully optimized microscopy chamber<br />

• Fully integrated laser table<br />

• Integrated electronics<br />

• Ergonomic workstation design<br />

The unique stage design of the <strong>DeltaVision</strong> <strong>OMX</strong> renders the best stability and<br />

repeatability available (lateral and axial stability images<br />

standard widefield<br />

<strong>DeltaVision</strong> <strong>OMX</strong><br />

Hippocampal neurons - Image courtesy of Eric Dent, University of Wisconsin Madison

How does 3D-SIM work?<br />

The resolution of the microscope is limited by the amount<br />

of spatial information that can pass sucessfully through<br />

the optics. This is represented by the fine grid pattern<br />

in panel 1. If we mix that high-resolution information<br />

with a known signal that we can resolve (panel 2), we<br />

generate a new pattern, the moiré pattern seen in panel<br />

3. Here the pattern that we see is the difference between<br />

the two patterns and can easily be represented without<br />

high-resolution methods.<br />

Likewise, in 3D-SIM, a three-dimensional illumination<br />

pattern is superimposed on the sample. This pattern<br />

generates a new pattern (a moiré pattern) that contains<br />

both the illumination and sample data. By carefully<br />

reconstructing the sample data from the moiré pattern, it<br />

is possible to create a super-resolution three-dimensional<br />

image of the original sample.<br />

Because the illumination pattern is three-dimensional,<br />

the image that is created contains both the lateral<br />

(2D) and the axial (3D) data. This is limited only by<br />

how deep into the sample the illumination pattern can<br />

be maintained before light scattering attenuates the<br />

illumination pattern (usually tens of microns into the<br />

sample). This illumination pattern can be efficiently<br />

generated with multiple excitation wavelengths allowing<br />

multiple fluorochromes can be used in the same sample.<br />

3D-SIM is the only super resolution method that can use<br />

multiple probes in the same sample (currently up to 4)<br />

and that can image well beyond the sample substrate.<br />

panel 1<br />

panel 2<br />

panel 3<br />

conventional<br />

<strong>DeltaVision</strong> <strong>OMX</strong><br />

P53 Binding Protein 1 (P53BP1) at a double-stranded DNA break. Courtesy Gang Bao (Georgia Inst. Technology) and David Spector and Ileng Kurmaran (CSHL).

<strong>DeltaVision</strong> <strong>OMX</strong> Specifications<br />

General Information<br />

• Three-dimensional Imaging and Analysis System<br />

• High spatial resolution beyond the diffraction limit<br />

- ~100 nm lateral (depending on wavelength and optics)<br />

- ~200 nm axial (depending on wavelengths and optics)<br />

• Fast temporal resolution truly simultaneous live-cell<br />

imaging<br />

• Up to four-channels per data set<br />

• Super resolution beyond the cover slip using 3D-SIM<br />

Structured Illumination Microscopy (per technology<br />

inventors Sedat, Agard and Gustafsson at UCSF)<br />

• High speed imaging at up to 65 frames/second in each of<br />

four channels<br />

• Applied Precision certified optics<br />

• Includes personalDV widefield deconvolution system for<br />

integrated target ID and standard widefield imaging<br />

• Custom Applied Precision transilluminator with ultrawhite<br />

LED<br />

• Choice of large field-of-view or high-speed camera options<br />

• Laser fluorescence illumination<br />

• Conventional and Structured Illumination light paths<br />

• Image acquisition software<br />

• Full suite of image processing and analysis tools<br />

• Stage mapping between personalDV and<br />

<strong>DeltaVision</strong> <strong>OMX</strong> systems<br />

• Proprietary image restructuring software<br />

• Time-lapse<br />

• 3-D Modeling and analysis<br />

• Includes toolkit, calibration slides, alignment optics, and<br />

immersion oil kits.<br />

Imaging Components<br />

• Custom optics assembly with novel optical light path<br />

• API certified highest quality PSF objective lens<br />

• High precision, repeatable X, Y, Z stage<br />

- Absolute accuracy: +/- 0.02%<br />

- Repeatability: +/- 10 nm (Z), +/- 150 nm (X, Y)<br />

- Step resolution: 5 nm (Z), 10 nm (X, Y)<br />

- Maximum travel: 25 mm (X, Y, and Z)<br />

• Novel Z-axis closed-loop piezo crystal drive<br />

• Closed loop diffraction grating motion and rotary stage<br />

• Fixed optics light path<br />

• Integrated proprietary FPGA timing architecture<br />

• Integrated motion control system<br />

• Integrated camera control architecture<br />

• Fixed-cell filter set with custom lasers<br />

• Optional Live-cell filter set<br />

• Includes 405 nm and 488 nm high power lasers<br />

• Optional Lasers<br />

- 514 nm<br />

- 592.5 nm<br />

- 642 nm<br />

• High-speed excitation shutter for each laser (2 ms)<br />

• Neutral Density filter wheel for each laser<br />

• Novel widefield scrambling technology<br />

• Olympus Plan-Apo 60X, 1.42 NA PSF “A” quality<br />

objective lens (Standard)<br />

- API certified for optimal 3D imaging performance<br />

- UIS-2 extended color correction<br />

• Optional U-Apo 60X, 1.30 NA Silicone Oil Lens<br />

optimized for live-cell imaging<br />

- API certified for optimal 3D imaging performance<br />

- UIS-2 extended color correction<br />

• High-performance custom 20 MHz cooled interline CCD<br />

camera for maximum field-of-view<br />

• Optional high-sensitivity custom EMCCD frame-transfer<br />

camera for maximum sensitivity and frame speed<br />

• <strong>OMX</strong> Master control computer<br />

• Separate computers for each camera<br />

• High-performance image processing and analysis<br />

workstation<br />

• High-performance dedicated gigabit Ethernet switch<br />

Filter Sets<br />

• Standard fixed-cell filter set (DAPI, Alexa488, Alexa594,<br />

Alexa642)<br />

• Optional live-cell filter set (CFP, YFP, EGFP, mCherry,<br />

DIC)<br />

• Optional filter drawers available<br />

CCD Cameras<br />

• Custom monochrome 20 MHz camera with Sony ICX285<br />

ER progressive scan CCD<br />

• Custom monochrome 10 MHz camera with E2V backthinned,<br />

frame-transfer, CCD camera. ~92% QE with<br />

electron multiplication (Optional)<br />

R. parkeri infected Cos7 cells - Image courtesy of Matt<br />

Welch, University of California at Berkeley<br />

Streptococcus cells - Image courtesy of Cynthia<br />

Whitchurch, University of Technology, Sydney, Australia<br />

Image courtesy of Renato Mortara, Universidade Federal<br />

de São Paulo (UNIFESP), Sao Paulo, Brazil

personalDV System Specifications<br />

Workstations<br />

• <strong>OMX</strong> Master Controller<br />

- Dual-processor, dual-core 64-bit Xeon workstation<br />

- 4 GB DDR RAM<br />

- 500 GB hard disk<br />

- Dual gigabit Ethernet adapters<br />

- Windows XP-64 Professional<br />

- 24” widescreen (1920 x 1600) flat panel monitor<br />

• <strong>OMX</strong> Image Processing Workstation<br />

- Dual-processor, quad-core 64-bit Intel Xeon workstation<br />

- 4 GB DDR RAM<br />

- 320 GB System hard disk<br />

- 3 X 500 GB RAID 5 hard disk (1 TB total)<br />

- Dual gigabit Ethernet adapters<br />

- CentOS EL 4.0 Linux®<br />

- 24” widescreen (1920 x 1600) flat panel monitor<br />

• <strong>OMX</strong> Camera Workstations<br />

- Dedicated to each camera<br />

- Gigabit Ethernet<br />

• <strong>OMX</strong> Instrument Control<br />

- Proprietary Nanomotion-3 motion control interface<br />

- Proprietary Applied Precision Field Programmable Gate<br />

Array (FPGA) timing controller<br />

softWoRx Image Processing and Analysis Software<br />

• 5-D Image Window (X, Y, Z, Time, Channel)<br />

• Multi-processor enabled software tools<br />

• Multi-threaded image processing<br />

- Deconvolution<br />

- Volume rendering<br />

• System-level processing queueing<br />

- Deconvolution<br />

- Volume rendering<br />

- Quick projections<br />

- TIFF file conversion<br />

- Movie conversion (AVI and Quicktime®)<br />

• Task Builder<br />

• Orthogonal Viewer<br />

• Arbitrary line profiles<br />

• On-the-fly color blending<br />

• Co-localization measurements (2 methods)<br />

• File chooser with interactive thumbnails<br />

• Time projections<br />

• Data extraction tools<br />

• Interactive volume rendering<br />

• FRET analysis tool<br />

• Drag-and-drop deconvolution queueing<br />

• Support for file sizes over 2 GB<br />

• Fully network compatible<br />

• Image deconvolution methods:<br />

- Constrained Iterative Algorithms (four methods)<br />

- Nearest Neighbor<br />

• Image import formats supported:<br />

- Tagged Image File Format (TIFF®)<br />

- UIC MetaMorph® STK<br />

- BioRad® MRC-600 Pic<br />

- Inovision ISee<br />

System Configuration<br />

• API Solid-state Transmitted White Light Illuminator<br />

• InsightSSI 4 channel solid state illumination unit<br />

• Fast shutter<br />

• 10-position ND filter wheel<br />

• 10-position EX filter wheel<br />

• 6-position EM filter wheel<br />

• Optical fiber<br />

• Fiber Optic Module (FOM)<br />

• IX-71 microscope base<br />

• Custom <strong>DeltaVision</strong> Quad filter set<br />

• 60x objective/1.42NA<br />

• Stackable IC/MIC<br />

• Dual processor tower computer, 400GB<br />

• 25 mm stage<br />

• CoolSnap ES2 Camera (PCI)<br />

• Benchtop microscopy isolation platform<br />

• 19” monitor<br />

• Backlit keyboard, laser mouse<br />

Stage Specifications<br />

• Z axis<br />

- Travel: 1 mm<br />

- Resolution: 40 nm<br />

- Linearity error:

<strong>DeltaVision</strong> <strong>OMX</strong> Specifications (continued)<br />

• Image output formats:<br />

- MPEG movie file export format supported<br />

- Tagged Image File Format (TIFF)<br />

- Quicktime ® movie file<br />

- Photoshop ® (.psd) multi-layer file export format<br />

• 3D modeling from 2D image data volume<br />

• Per channel image analysis:<br />

- Image stitch<br />

- Image rotation on X, Y or Z axis<br />

- Volume View<br />

- 2D and 3D measurements<br />

- Histogram review and non-destructive min/max intensity<br />

adjustments<br />

- Numerical data inspection from region of interest with<br />

ASCII export<br />

- 3D data graph from region of interest<br />

• Complete Optical Transfer Function (OTF) Library for<br />

common microscope objectives<br />

• Archive data via network connection or on-board<br />

DVD-RW<br />

softWoRx Licenses<br />

- Includes softWoRx DMS license<br />

- Includes softWoRx Suite license<br />

Ergonomic Design<br />

• Optics Module<br />

- Laser safety interlocks<br />

- Light tight enclosure<br />

- Vibration isolation (mechanical and acoustic)<br />

- Class 100 HEPA filtering with positive pressure<br />

- Vibration isolation table<br />

- Integrated lighting<br />

- 3 ft x 4 ft x 6ft (90 cm x 120 cm x 180 cm)<br />

• Laser Module<br />

- Laser safety interlocks<br />

- Rigid optical design<br />

- Multiple light paths<br />

- 2.5 ft x 4 ft x 4 ft (105 cm x 120 cm x 120 cm)<br />

- Integrated electronics rack<br />

• Ergonomically designed workstation desk<br />

- 3 ft x 4ft x 2.5 ft (90 cm x 120 cm x 105 cm)<br />

• Maximum system weight = 1500 lbs (680 kg)<br />

Electrical/Environmental Specifications<br />

The <strong>DeltaVision</strong> <strong>OMX</strong> requires a laboratory roughly 8’x 16’<br />

(2.5m x 5m) to provide adequate space for all the components<br />

and to accommodate the work flow. The following are the<br />

room requirements:<br />

• Minimum Size: 8 ft x 16 ft x 8 ft high<br />

• Dry, clean air or nitrogen lines:<br />

- 100 psi regulated for clean gun, de-ionized<br />

- 100 psi regulated for <strong>OMX</strong> table<br />

• Room temperature maintained at 72° F (+/- 2° F over 4<br />

hour period). System heat load ~ 5 kW.<br />

• Power<br />

- System power: 200-240 V ± 10%, 50 Hz ± 5%, 20<br />

Amperes, single outlet located within 6 feet of laser/<br />

electronics cabinet<br />

- Additional power: 120 V± 10%, 60 Hz ± 5% or 200-240<br />

V ± 10%, 50 Hz ± 5%<br />

- Installation category 2 (office power)<br />

- Total power ~3-5 kW<br />

- An Uninterruptible Power Source or power conditioner<br />

supplied by user is recommended<br />

Cover Image - PCNA localization in CHO cell nuclei. Used with<br />

permission from Andrew Belmont, University of Illinois, Urbana-<br />

Champaign.<br />

personalDV Workstation Table<br />

Optics Module Cabinet Laser Module Cabinet Workstation Table<br />

Applied Precision, Inc<br />

1040 12th Ave NW<br />

Issaquah, WA 98027<br />

Tel: 425.557.1000<br />

www.appliedprecision.com<br />

© 2009 Applied Precision, Inc. All Rights Reserved.<br />

Rev B 122209<br />

Applied Precision, <strong>DeltaVision</strong>, softWoRx and NanoMotion<br />

are registered trademarks and <strong>DeltaVision</strong>|<strong>OMX</strong> and 3D-SIM<br />

are trademarks of Applied Precision, Inc. All other trade<br />

marks are property of their respective owners.