Hong Kong Guide to Good Manufacturing Practice for the Secondary ...

Hong Kong Guide to Good Manufacturing Practice for the Secondary ...

Hong Kong Guide to Good Manufacturing Practice for the Secondary ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

7. DOCUMENTATION<br />

General Requirements<br />

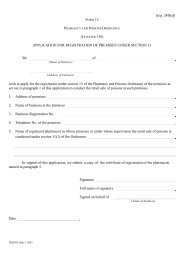

7.1 Documents should be designed, prepared, reviewed and distributed with care. They<br />

should comply with <strong>the</strong> relevant statu<strong>to</strong>ry requirements <strong>for</strong> licensed manufacturers and<br />

holders of <strong>the</strong> Certificate of Drug/Product Registration.<br />

7.2 Documents should be approved, signed and dated by appropriate and authorised<br />

persons.<br />

7.3 Documents should have unambiguous contents; title, nature and <strong>the</strong> purpose should be<br />

clearly stated. They should be laid out in an orderly fashion and be easy <strong>to</strong> check.<br />

Reproduced documents should be clear and legible. The reproduction of working<br />

documents from master documents must not allow any error <strong>to</strong> be introduced through<br />

<strong>the</strong> reproduction process.<br />

7.4 Documents should be regularly reviewed and kept up-<strong>to</strong>-date. When a document has<br />

been revised, systems should be operated <strong>to</strong> prevent inadvertent use of superseded<br />

documents.<br />

7.5 Documents should not be hand-written; although, where documents require <strong>the</strong> entry of<br />

data, <strong>the</strong>se entries may be made in clear, legible, indelible handwriting. Sufficient space<br />

should be provided <strong>for</strong> such entries.<br />

7.6 Any alteration made <strong>to</strong> <strong>the</strong> entry on a document should be signed and dated; <strong>the</strong><br />

alteration should permit <strong>the</strong> reading of <strong>the</strong> original in<strong>for</strong>mation. Where appropriate, <strong>the</strong><br />

reason <strong>for</strong> <strong>the</strong> alteration should be recorded.<br />

7.7 The records should be made or completed at <strong>the</strong> time each action is taken and in such a<br />

way that all significant activities concerning <strong>the</strong> packaging of pharmaceutical products<br />

are traceable.<br />

7.8 Batch documentation must be kept <strong>for</strong> one year after <strong>the</strong> expiry of <strong>the</strong> batch <strong>to</strong> which it<br />

relates or at least five years after certification of <strong>the</strong> batch by <strong>the</strong> Quality Assurance<br />

Officer, whichever is <strong>the</strong> longer.<br />

7.9 Data may be recorded by electronic data processing systems, pho<strong>to</strong>graphic or o<strong>the</strong>r<br />

reliable means, but detailed procedures relating <strong>to</strong> <strong>the</strong> system in use should be available<br />

and <strong>the</strong> accuracy of <strong>the</strong> records should be checked. If documentation is handled by<br />

electronic data processing methods, only authorised persons should be able <strong>to</strong> enter or<br />

modify data in <strong>the</strong> computer and <strong>the</strong>re should be a record of changes and deletions;<br />

access should be restricted by passwords or o<strong>the</strong>r means and <strong>the</strong> result of entry of<br />

critical data should be independently checked. Batch records electronically s<strong>to</strong>red should<br />

be protected by back-up transfer on magnetic tape, microfilm, paper or o<strong>the</strong>r means. It<br />

is particularly important that <strong>the</strong> data are readily available throughout <strong>the</strong> period of<br />

retention.<br />

<strong>Secondary</strong> Packaging Documents<br />

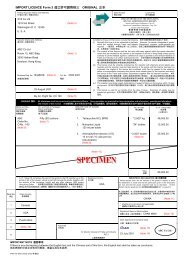

7.10 All packaging materials used in secondary packaging operations should have approved<br />

specifications which serve as <strong>the</strong> basis <strong>for</strong> quality evaluation by <strong>the</strong> Quality Assurance<br />

Officer upon <strong>the</strong>ir receipt.<br />

7.11 Written receipt, release and rejection procedures should be available <strong>for</strong> materials and<br />

products, and in particular <strong>for</strong> <strong>the</strong> release <strong>for</strong> sale or supply of <strong>the</strong> finished product by<br />

<strong>the</strong> Quality Assurance Officer. Records of receipt, release and rejection should be<br />

maintained <strong>for</strong> materials and products.<br />

<strong>Hong</strong> <strong>Kong</strong> <strong>Guide</strong> <strong>to</strong> <strong>Good</strong> <strong>Manufacturing</strong> <strong>Practice</strong> <strong>for</strong> <strong>the</strong> <strong>Secondary</strong> Packaging of Pharmaceutical Products Page 10