Daniil Itkis Lomonosov Moscow State University - elch.chem.msu.ru

Daniil Itkis Lomonosov Moscow State University - elch.chem.msu.ru

Daniil Itkis Lomonosov Moscow State University - elch.chem.msu.ru

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Model<br />

D = 2RT Development<br />

efft + − 1 f<br />

1 +<br />

F ln c Li 8<br />

Basic equations.— The mathematical Model description Development of Li-air bateries<br />

should include accurate models for the lithium-ion and oxygen<br />

iffusion absolute inside the temperature. cell, theInelectron our simulations, conductivity f / of ln cthe Li iscarbon<br />

approximated<br />

Li 2 to O 2 zero. formation and deposition at the cathode, the po-<br />

athode, the<br />

osity change inside the cathode, and rate equations for Reaction 1<br />

nd the Li-ion formation Li → Li + +e − . In this work, we used the<br />

heory<br />

ude.<br />

of concentrated solutions 10 to model the Li + and oxygen difusion<br />

and drift in the anode protective layer APL, separator, and<br />

Model Development<br />

athode electrolyte. 3.0 We also assumed a binary monovalent electroyte<br />

and no convection. The electrostatic potential of Li ions Li is<br />

2.8<br />

ssumed to satisfy the following drift-diffusion equation<br />

O2 c O2<br />

ref<br />

=2k<br />

r¯pc O2<br />

e 1−F/RT c − e −F/RT c if LC x<br />

where<br />

Basic<br />

R =<br />

equations.—<br />

8.314 J/mol KThe is themathematical universal gas constant<br />

description<br />

and T is theof Li-air bat-<br />

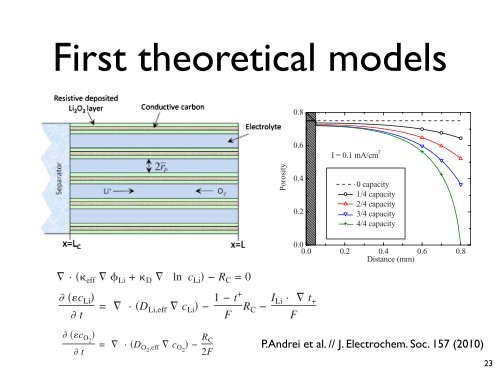

First theoretical models<br />

0 otherwise<br />

clude.<br />

C<br />

iffusion and reaction rate at the cathode. The formation of Li 2 O 2 at<br />

e cathode is modeled similarly to the one developed by Sandhu et<br />

. 6 In the second section, we present the numerical algorithm and<br />

mple simulation results. Then, we discuss about possible aproaches<br />

to improve the specific capacity SC of the cathode electeries<br />

should include accurate models for the lithium-ion and oxygen<br />

diffusion inside the cell, the electron conductivity of the carbon<br />

where = 0.5, k is a reaction rate constant, c<br />

ode and the energy density of Li-air batteries, after which we con-<br />

O2<br />

cathode, the Li 2 O 2 formation and deposition at the cathode, normalization the porosity<br />

change inside the cathode, Journal of and The Electro<strong>chem</strong>ical rate equations Society, for 157 12 Reaction IfA1287-A1295 we take1into 2010 consideration the electrical A1291 resistivity<br />

parameter, and c is the overpotential a<br />

which is assumed to deposit uniformly on the inner<br />

and the Li-ion formation Li → Li + +e − . In this work, we<br />

0.8 pores,<br />

usedthe theoverpotential can be written as<br />

theory of concentrated solutions 10 to model the Li<br />

Basic equations.— The mathematical description of Li-air + and oxygen diffusion<br />

and drift in the anode protective layer APL, separator, and<br />

2<br />

batries<br />

should include accurate models for the lithium-ion and oxygen<br />

c = Li − − U c − V Li2 O<br />

cathode electrolyte. <br />

0.6<br />

iffusion inside the 2.6 We also assumed a binary monovalent electro-<br />

· cell, the electron conductivity of the carbon = Li − − U c − R C eff Li + D ln c Li − R C =0 2<br />

Li2 O 2<br />

r¯p,0<br />

0<br />

ln<br />

I=0.1mA/cm 2<br />

lyte and no convection. The electrostatic potential of Li ions <br />

thode, the Li 2 O 2 formation and deposition at the cathode, the posity<br />

change inside the cathode, and rate equations for Reaction 1<br />

Li is<br />

here eff is the effective electric conductivity of the electrolyte, D<br />

lectrolyte d the Li-ion which formation is equal toLi the→concentration Li + +e − . of InLi this + , and work, R C iswe theused the<br />

eory xygenofconversion concentrated rate, solutions which is 10 equal to model to zerothe in Li the + APL and oxygen and difsion<br />

and<br />

eparator and<br />

drift<br />

is positive<br />

in the anode<br />

in the cathode.<br />

protective<br />

The<br />

layer<br />

concentration<br />

APL, separator,<br />

of Li +<br />

and<br />

atisfies<br />

thode 10<br />

electrolyte. We also assumed a binary monovalent electrote<br />

and no convection. The electrostatic potential of Li ions Li is<br />

sumed to satisfy the following drift-diffusion equation<br />

Voltage (V)<br />

2.4<br />

assumed to satisfy the following drift-diffusion (e) equation where V Li2 O 2<br />

is the voltage drop across Li 2 O 2 , Li2<br />

0.4<br />

2.2<br />

(a)(b)<br />

(c) (d)<br />

trical resistivity 0capacity of Li 2 O 2 , and U c is the equilibrium<br />

2.9<br />

· 0.05 mA/cm 2<br />

Reaction 1 at the cathode.<br />

2.8 eff Li + <br />

(e) D ln c Li − R C =0 2 1/4 capacity<br />

2.0<br />

2.7<br />

(d) 0.1 mA/cm 2<br />

Equations 2-4, 2/4 capacity 9, 10, and 12 represent a system of<br />

(c)<br />

where eff is the effective 2.6 electric conductivity 0.2 mA/cm 2 of the electrolyte, 0.2 ential equations <br />

(b)<br />

D 3/4that capacity should be subject to boundary a<br />

2.5<br />

1.8<br />

(a)<br />

is the diffusional conductivity, c 0.5 mA/cm 2<br />

ditions and should 4/4 capacity be solved self-consistently to<br />

2.4<br />

0.0 0.1 0.2 0.3 0.4 0.5 Li is the concentration of the lithium<br />

lithium-ion and oxygen concentrations, the electrosta<br />

electrolyte<br />

Specific capacity (mAh/g C<br />

)<br />

1mA/cm<br />

c which is equal to the concentration 2<br />

of Li + Li <br />

, and<br />

1.6<br />

0.0 and<br />

R C the<br />

is the<br />

porosity at each location inside the electroche<br />

oxygen= conversion · D0 Li,eff 200 rate, c Li 400 which − 1 − 600 t+<br />

800 1000 1200<br />

0.0 function of 0.2 time. The 0.4 initial 0.6 conditions0.8<br />

t<br />

F<br />

is R C equal − I Li · t +<br />

to zero3<br />

F<br />

in the APL and<br />

as well as<br />

Distance (mm)<br />

separator Figure 2. Color and is online positive Modeling Specific inof capacity the oxygen cathode. (mAh/g diffusion C<br />

) The and concentration Li 2 O 2 formation<br />

in the porous carbon cathode.<br />

presented in the next two<br />

conditions of Li + for the one-dimensional cell simulated in<br />

subsections.<br />

s the diffusional conductivity, c Li is the concentration of the lithium<br />

Voltage (V)<br />

here is the porosity, D Li,eff is the effective electrolyte diffusion<br />

oefficient, t + is the transference number, F = 96,487 C/mol is<br />

satisfies 10 · eff Li + D ln c Li − R C =0 2<br />

Figure 4. Color online Cell voltage as a function of the SC for different<br />

discharge currents.<br />

here araday’s eff constant, is the c effective and Li I Li electric = − eff conductivity Li − D of the electrolyte, D<br />

the diffusional conductivity, = · D c Li Li,eff is the c Li − 1 ln − c t+ Li<br />

of lithium<br />

t<br />

F R is the<br />

C − I Li · t +<br />

lectrolyte density current. The oxygen concentration satisfies the 3<br />

ollowing<br />

ectrolytediffusion which<br />

equation<br />

is equal to the concentration of Li + F<br />

, and R C is the<br />

xygenwhere conversion is therate, porosity, whichDis Li,eff equal is the to effective zero in the electrolyte APL andiffusion<br />

parator coefficient, and is positive t + in the cathode. The concentration of Li +<br />

tisfies Faraday’s 10 constant, and I Li = − eff Li − D ln c Li is the<br />

maximum limit given by Eq. 27 because, for narrow cathodes, the one should either increase the diffusion coefficient of O 2 to make it<br />

oxygen can diffuse completely throughout the whole cathode volume.<br />

The02 cell Feb voltage 2011 decreases to 195.208.208.29. with decreasing Redistribution thickness of the subject side of to the ECS cathode license near the or copyright; separator to efficiently see http://www.ecsdl.org/t<br />

fill in the pores<br />

comparable to that of Li ions or increase the reaction rate at the left<br />

Downloaded c<br />

cathode O2 <br />

electrode. This is because in batteries with smaller cathode of the cathode with Li 2 O 2 .<br />

thickness, there<br />

= is is the less· surface<br />

Dtransference O2 ,eff areaavailable c O2 −and number, R C<br />

the overpotential F = atP.Andrei 4 96,487 The dependence et C/mol al. // of J. is the Electro<strong>chem</strong>. reaction rate as a function Soc. of 157 the position (2010)<br />

t<br />

2F<br />

the cathode as expressed by Eq. 14 becomes higher. The SC in Fig. inside the cell is represented in Fig. 7 for different states of discharge.<br />

While the battery discharges, the reaction rate decreases 23<br />

4 and 5 as well as in other figures in this section is expressed in<br />

mAh/g , where the mass includes only the mass of the carbon in the deep inside the cathode and increases at the surface of the cathode.<br />

here D O ,eff is the effective diffusion constant of the oxygen.<br />

Porosity<br />

Figure 6. Color online Local dependence of the porosity when the battery<br />

is fully charged 0 capacity, partly charged 1/4, 2/4, and 3/4 capacity, and<br />

nearly completely discharged 4/4 capacity.<br />

ref =