MODERN THERMAL POWER PLANTS

MODERN THERMAL POWER PLANTS

MODERN THERMAL POWER PLANTS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

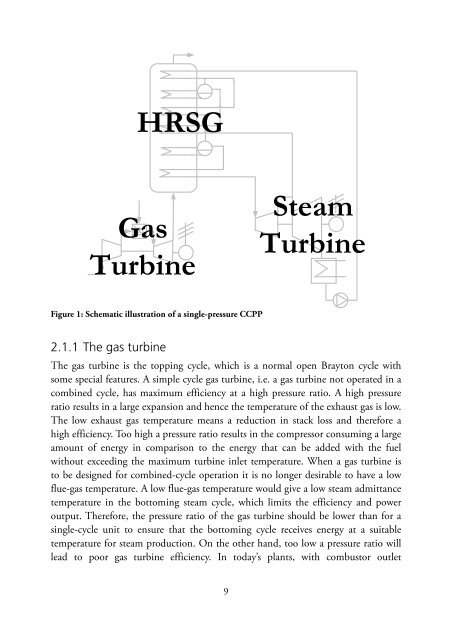

HRSG<br />

Gas<br />

Turbine<br />

Steam<br />

Turbine<br />

Figure 1: Schematic illustration of a single-pressure CCPP<br />

2.1.1 The gas turbine<br />

The gas turbine is the topping cycle, which is a normal open Brayton cycle with<br />

some special features. A simple cycle gas turbine, i.e. a gas turbine not operated in a<br />

combined cycle, has maximum efficiency at a high pressure ratio. A high pressure<br />

ratio results in a large expansion and hence the temperature of the exhaust gas is low.<br />

The low exhaust gas temperature means a reduction in stack loss and therefore a<br />

high efficiency. Too high a pressure ratio results in the compressor consuming a large<br />

amount of energy in comparison to the energy that can be added with the fuel<br />

without exceeding the maximum turbine inlet temperature. When a gas turbine is<br />

to be designed for combined-cycle operation it is no longer desirable to have a low<br />

flue-gas temperature. A low flue-gas temperature would give a low steam admittance<br />

temperature in the bottoming steam cycle, which limits the efficiency and power<br />

output. Therefore, the pressure ratio of the gas turbine should be lower than for a<br />

single-cycle unit to ensure that the bottoming cycle receives energy at a suitable<br />

temperature for steam production. On the other hand, too low a pressure ratio will<br />

lead to poor gas turbine efficiency. In today’s plants, with combustor outlet<br />

9