Download a PDF - Stage Directions Magazine

Download a PDF - Stage Directions Magazine

Download a PDF - Stage Directions Magazine

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Answer Box<br />

|<br />

By Eric Gebhard<br />

A Delicate Staircase<br />

Engineering meets art for a freestanding staircase in the<br />

Guthrie’s production of A Delicate Balance<br />

Engineering<br />

for<br />

the stage<br />

always has its<br />

challenges and<br />

the staircase<br />

for A Delicate<br />

Balance is no<br />

exception. The<br />

task set before<br />

our technical<br />

team was<br />

to construct a<br />

helical staircase.<br />

To further<br />

complicate the<br />

challenge, we<br />

were required<br />

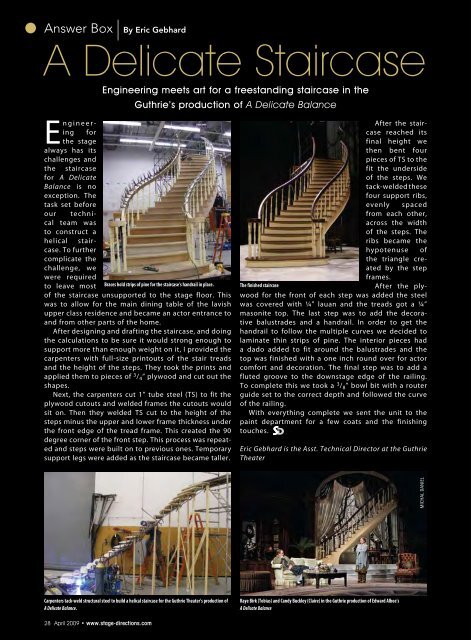

to leave most Braces hold strips of pine for the staircase’s handrail in place.<br />

of the staircase unsupported to the stage floor. This<br />

was to allow for the main dining table of the lavish<br />

upper class residence and became an actor entrance to<br />

and from other parts of the home.<br />

After designing and drafting the staircase, and doing<br />

the calculations to be sure it would strong enough to<br />

support more than enough weight on it, I provided the<br />

carpenters with full-size printouts of the stair treads<br />

and the height of the steps. They took the prints and<br />

applied them to pieces of 3 / 4 ” plywood and cut out the<br />

shapes.<br />

Next, the carpenters cut 1” tube steel (TS) to fit the<br />

plywood cutouts and welded frames the cutouts would<br />

sit on. Then they welded TS cut to the height of the<br />

steps minus the upper and lower frame thickness under<br />

the front edge of the tread frame. This created the 90<br />

degree corner of the front step. This process was repeated<br />

and steps were built on to previous ones. Temporary<br />

support legs were added as the staircase became taller.<br />

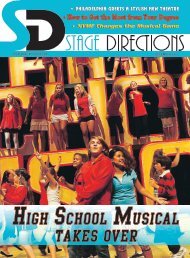

The finished staircase<br />

After the staircase<br />

reached its<br />

final height we<br />

then bent four<br />

pieces of TS to the<br />

fit the underside<br />

of the steps. We<br />

tack-welded these<br />

four support ribs,<br />

evenly spaced<br />

from each other,<br />

across the width<br />

of the steps. The<br />

ribs became the<br />

hypotenuse of<br />

the triangle created<br />

by the step<br />

frames.<br />

After the plywood<br />

for the front of each step was added the steel<br />

was covered with ¼” lauan and the treads got a ¼”<br />

masonite top. The last step was to add the decorative<br />

balustrades and a handrail. In order to get the<br />

handrail to follow the multiple curves we decided to<br />

laminate thin strips of pine. The interior pieces had<br />

a dado added to fit around the balustrades and the<br />

top was finished with a one inch round over for actor<br />

comfort and decoration. The final step was to add a<br />

fluted groove to the downstage edge of the railing.<br />

To complete this we took a 3 / 8 ” bowl bit with a router<br />

guide set to the correct depth and followed the curve<br />

of the railing.<br />

With everything complete we sent the unit to the<br />

paint department for a few coats and the finishing<br />

touches.<br />

Eric Gebhard is the Asst. Technical Director at the Guthrie<br />

Theater<br />

Michal Daniel<br />

Carpenters tack-weld structural steel to build a helical staircase for the Guthrie Theater’s production of<br />

A Delicate Balance.<br />

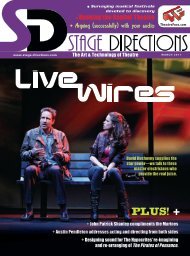

Raye Birk (Tobias) and Candy Buckley (Claire) in the Guthrie production of Edward Albee’s<br />

A Delicate Balance<br />

28 April 2009 • www.stage-directions.com