Fiberglass Molded Products - Grating Pacific

Fiberglass Molded Products - Grating Pacific

Fiberglass Molded Products - Grating Pacific

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

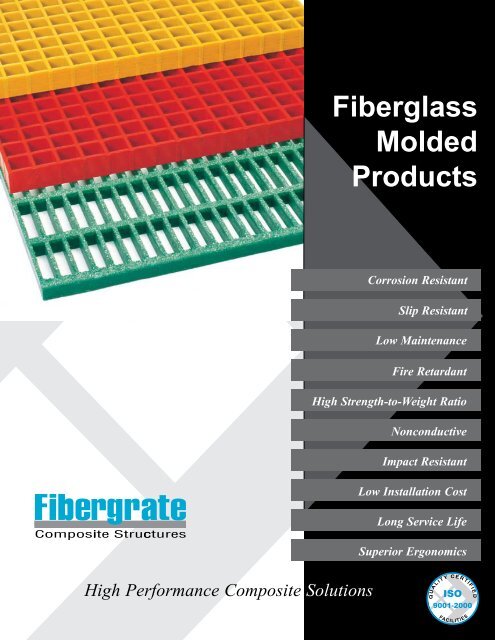

<strong>Fiberglass</strong><br />

<strong>Molded</strong><br />

<strong>Products</strong><br />

Corrosion Resistant<br />

Slip Resistant<br />

Low Maintenance<br />

Fire Retardant<br />

High Strength-to-Weight Ratio<br />

Nonconductive<br />

Impact Resistant<br />

Low Installation Cost<br />

Long Service Life<br />

Superior Ergonomics<br />

High Performance Composite Solutions<br />

Q U A L<br />

I T Y C E R T I F<br />

ISO<br />

I E D<br />

9001-2000<br />

FA C<br />

I L<br />

I T I E S

<strong>Fiberglass</strong> <strong>Molded</strong> <strong>Products</strong><br />

Combining unmatched corrosion resistance with strength,<br />

long life and safety, Fibergrate sets the standard for<br />

fiberglass reinforced plastic (FRP) molded products. With<br />

more than ten custom resins, Fibergrate products are proven to<br />

deliver years of reliable service, even in the most demanding corrosive<br />

conditions — conditions which cause conventional metallic and wood products<br />

to deteriorate rapidly.<br />

Fibergrate products are lightweight and easy to fabricate. Savings on labor<br />

and equipment often make the total installed cost of Fibergrate products<br />

comparable to that of steel. Combining these installation savings with low<br />

maintenance, long life and worker safety, Fibergrate products offer a life<br />

cycle cost that is significantly lower than that of metallic products.<br />

Fibergrate's molded grating lines include Fibergrate ® and<br />

Chemgrate ® molded grating for most applications, Fibergrate ®<br />

molded high load capacity grating for H-20 and forklift traffic,<br />

Micro-Mesh ® access flooring, AirMesh ® screening and<br />

Multigrid ® grating. For applications requiring a solid walkway,<br />

Fibergrate carries Fiberplate ® and Chemplate ® structural floor panels as<br />

well as Chemdeck ® and Fibergrate ® covered grating. Stair solutions include Fibertred ® and Chemtred ®<br />

stair treads panels for industrial and commercial use, covered stair treads for architectural applications and<br />

stair tread covers for existing stairways. Ergonomic work platform solutions include Safe-T-Stands ® which<br />

are available in varying heights and raised ergonomic workmats.<br />

Fibergrate's complete line of molded products and turnkey services offers a variety of solutions for most<br />

applications.<br />

• Architectural<br />

• Bridge & Highway<br />

• Chemical<br />

• Commercial<br />

• Food & Beverage<br />

• Manufacturing<br />

• Metals & Mining<br />

• Microelectronics<br />

• Oil & Gas<br />

Fibergrate Markets<br />

• Offshore<br />

• Pharmaceutical<br />

• Power<br />

• Pulp & Paper<br />

• Recreation<br />

• Telecommunications<br />

• Transportation<br />

• Water & Wastewater<br />

<br />

Fibergrate products<br />

are lightweight<br />

making them easy to<br />

handle and install<br />

Phone: 800-527-4043<br />

www.fibergrate.com

Fibergrate ® Benefits<br />

• Corrosion Resistance - the<br />

use of more than ten premium<br />

grade resin systems with a<br />

thoroughly wetted fiberglass<br />

process and a one-piece molded<br />

construction ensures solid<br />

structural integrity in tough<br />

environments<br />

• Slip Resistance - a meniscus<br />

or permanent grit surface<br />

provides a safe, slip-resistant<br />

walking surface<br />

• Low Maintenance - corrosion resistant and<br />

requires no scraping, sandblasting or painting<br />

• Fire Retardant - flame spread rating of 25<br />

or less, as tested in accordance with ASTM<br />

E-84; meets the self-extinguishing requirements<br />

of ASTM D-635<br />

• High Strength-to-Weight Ratio - less than<br />

one-half the weight of steel grating allowing<br />

easy removal for access below floor level and<br />

installation with no heavy equipment and less<br />

manpower<br />

• Electrically and Thermally Nonconductive<br />

- all-FRP construction provides additional worker<br />

safety<br />

• Impact Resistance - can withstand major impacts<br />

with little structural damage and no failure<br />

• Easily Fabricated - does not need heavy lifting<br />

equipment or expensive tools; can be easily carried<br />

by two workers; can be cut using standard circular<br />

or saber saws fitted with abrasive blades; has<br />

excellent utilization<br />

• Electronically Transparent - does not affect<br />

electromagnetic or radio wave frequencies<br />

FRP vs. Steel<br />

PRICE<br />

VALUE = SERVICE LIFE<br />

When comparing the price of Fibergrate fiberglass reinforced plastic (FRP) products to comparable metal or other<br />

conventional products, there are several factors to consider.<br />

One of the most important factors is the safety cost. Slips and falls are the second leading cause of industrial<br />

accidents and one of the leading causes of death. The slip-resistant surfaces of Fibergrate products can dramatically<br />

reduce accidental slips and falls. With each lost workday accident costing $50,000 to $100,000, Fibergrate could be the<br />

least expensive solution available.<br />

The initial, or first cost is usually figured on a square-foot basis. Fibergrate FRP material costs are typically higher than<br />

metal products. Too often the product with the lowest price is selected, particularly in new construction projects, because<br />

it seems to be the most economical. Unfortunately, the cheapest product often ends up costing more than Fibergrate FRP<br />

due to high maintenance and replacements costs of corroded building materials. The National Association of Corrosion<br />

Engineers estimates that the economic losses due to corrosion in the U.S. amount to $300 billion a year. Replacing<br />

corroded, unsafe flooring is one of Fibergrate's biggest markets. In most cases, if Fibergrate FRP had been installed<br />

initially, very few problems would have occurred.<br />

Another important factor is installed cost. Fibergrate FRP products are often less expensive than metallic products<br />

when installation costs are figured into the total price. Metal grating requires costly and time-consuming cutting and<br />

welding, and must be “end-banded.” Fibergrate FRP can easily be fabricated with hand tools. <strong>Molded</strong> grating construction<br />

requires no end-banding which saves time and money. Square mesh bearing bars run in both directions, maximizing<br />

utilization. Fibergrate FRP products weigh less than metal, making it easier to handle and less expensive to transport.<br />

The most important factor is total or life cycle cost. In highly corrosive applications, metal products will often<br />

deteriorate in a few years or less. In the same installation, Fibergrate FRP products will last many times longer. Combined<br />

with safety cost savings, this often makes Fibergrate the lowest cost product available. These are the reasons so many<br />

companies have switched from conventional metallic products to Fibergrate FRP products.<br />

Phone: 800-527-4043<br />

www.fibergrate.com

<strong>Molded</strong> <strong>Grating</strong> Selection and Details<br />

Fibergrate ® and Chemgrate ® <strong>Molded</strong> <strong>Grating</strong><br />

Brand Depth Mesh Standard Panel Sizes Wt. Per Open<br />

Sq. Ft. Area<br />

AirMesh ® 1/2" 1-1/2" x 1-1/2" square 4' x 8' (non-load carrying product) 0.8 lb 87%<br />

Multigrid ® 1/2" 2" x 2" square 4' x 12', 4' x 15' (must be fully supported) 1.0 lb 82%<br />

Chemgrate 5/8" 1" x 4" rectangular 12' x 4' 2.1 lb 58%<br />

Fibergrate 3/4" 1" x 4" rectangular 10' x 3', 8' x 4' 2.5 lb 69%<br />

Ecograte TM 3/4" 1" x 4" rectangular 8' x 4' 2.84 lb 46%<br />

Fibergrate 3/4" 1-1/2" x 1-1/2" square 3' x 10', 4' x 8', 4' x 12' 2.0 lb 70%<br />

Micro-Mesh ® 1" Top 3/4" sq, Btm 1-1/2" sq 4' x 12' 2.9 lb 44.4%<br />

Fibergrate 1" 1" x 1" square 3.28' (1M) x 6.56' (2M) 3.58 lb 58%<br />

Fibergrate 1" 1" x 4" rectangular 10' x 3', 8' x 4' 2.5 lb 69%<br />

Fibergrate 1" 1-1/2" x 1-1/2" square 3' x 10', 4' x 8', 4' x 12' 2.5 lb 70%<br />

Chemgrate 1" 1" x 4" rectangular standard 12' x 4', 12' x 3'-1/4" 2.7 lb 65%<br />

Chemgrate 1" 1" x 4" rectangular heavy duty 12' x 4' 3.4 lb 52%<br />

Chemgrate 1" 2" x 2" square 4' x 12' 1.7 lb 76%<br />

Micro-Mesh ® 1-1/8" Top 1.04" sq, 2.09" sq Btm 3.28' (1M) x 9.84' (3M) 3.58 lb 53%<br />

Fibergrate 1-1/4" 1-1/2" x 1-1/2" square 3' x 10', 4' x 8', 4' x 12', 5' x 10' 3.2 lb 70%<br />

Fibergrate 1-1/2" 1-1/2" x 1-1/2" square 3' x 10', 4' x 8', 4' x 12', 5' x 10' 3.7 lb 70%<br />

High Load 1-1/2" 1" x 2" rectangular 6' x 4' 6.2 lb 48%<br />

Micro-Mesh ® 1-1/2" Top 3/4" sq Btm 1-1/2" sq 2' x 2', 4' x 12' (see page 18 for grating details) 5.0 lb 44%<br />

Chemgrate 1-1/2" 1-1/2" x 1-1/2" square 4' x 12' 3.5 lb 69%<br />

Chemgrate 1-1/2" 1-1/2" x 6" rectangular 12' x 4' 3.4 lb 67%<br />

Fibergrate 2" 2" x 2" square 4' x 12' 4.0 lb 72%<br />

High Load 2" 1" x 2" rectangular 6' x 4' 8.4 lb 48%<br />

Chemgrate 2" 2" x 2" square 4' x 12' 4.1 lb 72%<br />

See page 8 for surface selection.<br />

<strong>Grating</strong> Details<br />

4.00<br />

0.75<br />

PLAN VIEW<br />

1.00 0.50 0.50<br />

ELEVATION VIEW<br />

SECTION PROPERTIES PER FT OF WIDTH<br />

A = 3.36 IN 2 I = 0.16 IN 4 S= 0.375 IN 3<br />

PLAN VIEW<br />

1.00 0.762 0.238<br />

1.00 0.762<br />

0.238<br />

0.816<br />

0.32<br />

1.00 0.50 0.50<br />

ELEVATION VIEW<br />

0.32<br />

4.00<br />

1.035<br />

0.184<br />

3/4" x 1" x 4"<br />

Ecograte TM<br />

Load Bars Run<br />

Width Direction<br />

# of Bars/Ft of Width<br />

12<br />

0.75<br />

Load Bar<br />

Width<br />

1/2"<br />

Load Bar<br />

Centers<br />

1"<br />

1" x 1" x 1"<br />

Square Mesh<br />

Open Area<br />

46%<br />

Approx.<br />

Weight<br />

2.85 psf<br />

Load Bars Run<br />

Width Direction<br />

# of Bars/Ft of Width<br />

12 Open Area<br />

Load Bar<br />

Width<br />

1/4"<br />

Load Bar<br />

Centers<br />

1"<br />

58%<br />

Approx.<br />

Weight<br />

3.58 psf<br />

Fibergrate<br />

SECTION PROPERTIES PER FT OF WIDTH<br />

SECTION PROPERTIES PER FT OF WIDTH<br />

A = 2.62 IN 2 I = 0.23 IN 4 S= 0.43 IN 3<br />

<br />

1.50<br />

1.50<br />

SECTION PROPERTIES<br />

A = 2.34 IN 2 PLAN VIEW<br />

0.75<br />

0.75<br />

ELEVATION<br />

PER<br />

I = 0.23 IN 4 0.30 0.24<br />

0.30 0.24<br />

VIEW<br />

FT OF WIDTH<br />

S= 0.37 IN 3 1" x 3/4" sq top<br />

Micro-Mesh ®<br />

Load Bars Run<br />

Width Direction<br />

# of Bars/Ft of Width<br />

8<br />

Load Bar<br />

Width 44.4%<br />

0.22 1/4"<br />

Load Bar<br />

1.063<br />

Centers<br />

1.50<br />

0.75<br />

Open Area<br />

Approx.<br />

Weight<br />

1.5" 2.9 psf<br />

1.5"<br />

PLAN<br />

1.5"<br />

ELEVATION<br />

A = 1.71 IN 2 VIEW<br />

0.25"±<br />

VIEW<br />

I = 0.14 IN 4 1.5"<br />

1"<br />

S= 0.29 IN 3 1" x 1-1/2"<br />

Square Mesh<br />

# of Bars/Ft of Width<br />

8<br />

Load Bar Open Area<br />

Width 70%<br />

1/4"<br />

Load Bar<br />

Approx.<br />

Centers<br />

Weight<br />

1-1/2" 2.5 psf<br />

Fibergrate<br />

Phone: 800-527-4043<br />

www.fibergrate.com

<strong>Molded</strong> <strong>Grating</strong> Details<br />

<strong>Grating</strong> Details<br />

1"<br />

1"<br />

PLAN VIEW<br />

0.25"±<br />

0.375"±<br />

ELEVATION VIEW<br />

SECTION PROPERTIES PER FT OF WIDTH<br />

4"<br />

1"<br />

1" x 1" x 4"<br />

Rectangular Mesh<br />

Load Bars Run<br />

Width Direction<br />

# of Bars/Ft of Width<br />

12<br />

Load Bar Open Area<br />

Width 69%<br />

1/4"<br />

Load Bar<br />

Approx.<br />

Centers<br />

Weight<br />

1" 2.5 psf<br />

Fibergrate<br />

PLAN VIEW<br />

2.085 [52.96] 1.0425 [26.48] 0.75 [19.05] 0.265 [6.73] 1-1/8" x 1" Sq Top<br />

Micro-Mesh ®<br />

2.085 [52.96]<br />

# of Bars/Ft of Width<br />

Open Area 6 Load Bar<br />

53%<br />

Width<br />

1.0425 [26.48]<br />

0.265"<br />

Approx.<br />

0.75 [19.05]<br />

Weight<br />

Load Bar<br />

2.64 psf<br />

Centers<br />

2.085 [52.96] 1.0425 [26.48] 0.75 [19.05] 0.265 [6.73]<br />

0.40 [10.16]<br />

1.034<br />

1.125 [28.58]<br />

ALL DIMENSIONS ARE IN INCHES [MM]<br />

ELEVATION VIEW<br />

SECTION PROPERTIES PER FT OF WIDTH<br />

A = 2.57 IN 2 I = 0.22 IN 4 S= 0.43 IN 3<br />

PLAN VIEW<br />

1.50<br />

1.50<br />

Load Bar<br />

1.50 1.25 0.25<br />

2"<br />

2"<br />

1.3125<br />

ELEVATION VIEW<br />

PLAN VIEW<br />

0.25"±<br />

ELEVATION VIEW<br />

SECTION PROPERTIES PER FT OF WIDTH<br />

A = 2.88 IN 2 I = 0.96 IN 4 S= 0.94 IN 3<br />

2"<br />

2"<br />

1.25<br />

0.1875<br />

SECTION PROPERTIES PER FT OF WIDTH<br />

A = 2.16 IN 2 I = 0.32 IN 4 S= 0.48 IN 3<br />

1-1/4" x 1-1/2"<br />

Square Mesh<br />

# of Bars/Ft of Width<br />

8<br />

Width<br />

1/4"<br />

Load Bar<br />

Centers<br />

1-1/2"<br />

Meniscus Not Available<br />

Open Area<br />

53%<br />

Approx<br />

Weight<br />

3.58 psf<br />

2" x 2"<br />

Square Mesh<br />

Fibergrate<br />

#of Bars/Ft of Width<br />

6<br />

Load Bar Open Area<br />

Width 72%<br />

1/4"<br />

Load Bar<br />

Approx.<br />

Centers<br />

Weight<br />

2" 4.0 psf<br />

Fibergrate<br />

SECTION PROPERTIES PER FT OF WIDTH<br />

A = 2.85 IN 2 I = 0.51 IN 4 S= 0.65 IN 3<br />

0.563"<br />

1.5"<br />

1.5"<br />

1"<br />

PLAN VIEW<br />

0.25"±<br />

ELEVATION VIEW<br />

1.5"<br />

1.5"<br />

1" 0.313"<br />

SECTION PROPERTIES PER FT OF WIDTH<br />

A = 2.11 IN 2 I = 0.07 IN 4 S= 0.22 IN 3<br />

4"<br />

1-1/2" x 1-1/2"<br />

Square Mesh<br />

#of Bars/Ft of Width<br />

8<br />

Load Bar Open Area<br />

Width 70%<br />

1/4"<br />

Load Bar<br />

Approx<br />

Centers<br />

Weight<br />

1-1/2" 3.75 psf<br />

Fibergrate<br />

5/8" x 1" x 4"<br />

Rectangular Mesh<br />

# of Bars/Ft of Width<br />

12<br />

Load Bar Open Area<br />

Width 58%<br />

5/16"<br />

Load Bar Approx.<br />

Centers Weight<br />

0.625" 1" 1.8 psf<br />

Chemgrate<br />

4"<br />

1"<br />

1"<br />

0.25"<br />

0.5"<br />

1"<br />

1" x 1" x 4"<br />

Standard<br />

# of Bars/Ft of Width<br />

12<br />

Load Bar Open Area<br />

Width 65%<br />

1/4"<br />

Load Bar Approx.<br />

Centers Weight<br />

1" 2.6 psf<br />

Chemgrate<br />

SECTION PROPERTIES PER FT OF WIDTH<br />

SECTION PROPERTIES PER FT OF WIDTH<br />

A = 2.62 IN 2 I = 0.22 IN 4 S= 0.43 IN 3 A = 4.13 IN 2 I = 0.34 IN 4 S= 0.69 IN 3<br />

4"<br />

1"<br />

1"<br />

0.375"<br />

1"<br />

0.625"<br />

1" x 1" x 4"<br />

Heavy Duty<br />

# of Bars/Ft of Width<br />

12<br />

Load Bar Open Area<br />

Width<br />

3/8"<br />

52%<br />

Load Bar Approx.<br />

Centers Weight<br />

1" 3.4 psf<br />

Chemgrate<br />

Phone: 800-527-4043<br />

www.fibergrate.com

<strong>Grating</strong> Details & Custom <strong>Products</strong><br />

<strong>Grating</strong> Details<br />

6"<br />

1.5"<br />

1.5"<br />

0.375"<br />

0.625"<br />

1.5"<br />

1-1/2" x 1-1/2" x 6"<br />

Rectangular Mesh<br />

# of Bars/Ft of Width<br />

8<br />

Load Bar Open Area<br />

Width 67%<br />

3/8"<br />

Load Bar Approx.<br />

Centers Weight<br />

1 1/2" 3.4 psf<br />

Chemgrate<br />

SECTION PROPERTIES PER FT OF WIDTH<br />

SECTION PROPERTIES PER FT OF WIDTH<br />

A = 3.60 IN 2 I = 0.67 IN 4 S= 0.89 IN 3 A = 1.27 IN 2 I = 0.11 IN 4 S= 0.21 IN 3<br />

2"<br />

2"<br />

2"<br />

0.25"<br />

1"<br />

0.25"<br />

1" x 2"<br />

Square Mesh<br />

# of Bars/Ft of Width<br />

6<br />

Load Bar Open Area<br />

Width 76%<br />

1/4"<br />

Load Bar Approx.<br />

Centers Weight<br />

2" 1.7 psf<br />

Chemgrate<br />

1.5"<br />

1.5"<br />

0.25"<br />

1-1/2" x 1-1/2"<br />

Square Mesh<br />

# of Bars/Ft of Width<br />

8<br />

Load Bar Open Area<br />

Width 69%<br />

1/4"<br />

2"<br />

2"<br />

0.313"<br />

2" x 2"<br />

Square Mesh<br />

# of Bars/Ft of Width<br />

6<br />

Load Bar Open Area<br />

Width<br />

5/16"<br />

72%<br />

0.25<br />

1.5"<br />

1.5"<br />

Load Bar Approx.<br />

Centers Weight<br />

1 1/2" 3.5 psf<br />

2"<br />

0.313"<br />

2"<br />

Load Bar Approx.<br />

Centers Weight<br />

2" 4.1 psf<br />

Chemgrate<br />

SECTION PROPERTIES PER FT OF WIDTH<br />

A = 2.85 IN 2 I = 0.51 IN 4 S= 0.65 IN 3 SECTION PROPERTIES PER FT OF WIDTH<br />

A = 2.88 IN 2 I = 0.96 IN 4 S= 0.94 IN 3<br />

Chemgrate<br />

Custom <strong>Molded</strong> <strong>Products</strong><br />

Fibergrate has the capability to offer molded grating configurations designed/manufactured to meet your<br />

unique application requirements. Fibergrate's custom services include special molded grating configurations<br />

as well as parts requiring high volume compression molding, RTM, and centrifugal castings processes. Using<br />

our hand-lay-up methods, Fibergrate is able to create architectural details for building facades using FRP<br />

materials.<br />

In addition to our custom sizes and shapes, Fibergrate also offers specialty resins custom designed to meet<br />

your specific needs. These special formulations are developed to address unique and demanding services and<br />

applications, as well as niche market needs. We can engineer resin systems to address temperature, flame,<br />

smoke and toxicity requirements. Our HSUV resin system was developed to address the intense UV affects<br />

found in offshore applications. Fibergrate’s custom formulations with low smoke/toxicity properties were<br />

engineered with the United States Navy for below-deck marine service.<br />

NSF Standard<br />

61-Certified<br />

Fibergrate Composite Structures is now the only FRP manufacturer offering NSF<br />

Standard 61-certified molded grating. Currently, this product is being offered in 2<br />

resins systems: Our traditional IFR resin system and a food-grade, fire-retardant<br />

vinyl ester resin. Standard color is light gray. Our NSF Std. 61-certified structural<br />

shapes, handrails, ladders and pultruded components can be combined to create<br />

valuable, long-lasting stair stiles, walkways and platforms.<br />

Phone: 800-527-4043<br />

www.fibergrate.com

<strong>Molded</strong> <strong>Grating</strong> Resins<br />

Resin Systems<br />

Corrosion in the workplace negatively impacts your bottom line. Each year, industrial plant executives eliminate<br />

expensive corrosion-related maintenance problems by switching to Fibergrate molded grating. Various applications<br />

present different requirements so Fibergrate has more than ten standard resin systems (the most in the industry) including<br />

the new FGI-AM (food grade isophthalic polyester antimicrobial) available in both Fibergrate and Chemgrate Resins.<br />

Fibergrate ® Resins<br />

• Vi-Corr ® - A superior vinyl ester resin developed for<br />

reliable performance in the toughest environments. It offers<br />

outstanding resistance to a wide range of highly corrosive<br />

situations, ranging from caustic to acidic. In fact, no other<br />

resin system can match Vi-Corr's performance in highly<br />

acidic environments. Color: orange or dark gray. Flame<br />

spread: ASTM E84 rating of 25 or less. Certifications: UL<br />

Classification available; DNV Type Approval No. F-16856;<br />

USCG Accepted; ABS Type Approval No. 01-HS34733-X).<br />

• IFR - This isophthalic polyester fire-retardant resin<br />

formulation is designed for industrial and chemical processing<br />

applications where corrosion resistance is important. Color:<br />

green or dark gray. Flame Spread: ASTM E84 rating of 25 or<br />

less. Certifications: UL Classification available.<br />

• FGI-AM* - This improved food-grade isophthalic polyester<br />

resin system offers antimicrobial properties to inhibit the<br />

growth of mold on the surface of the composite to protect the<br />

product itself along with the necessary corrosion resistance to<br />

meet the requirements of the food and beverage industry.<br />

Color: light gray. Flame Spread: ASTM E84 rating of 25 or<br />

less. Certifications: USDA accepted.<br />

• CORVEX ® - An economy polyester grating, Corvex<br />

outperforms a number of competitive fiberglass and metal<br />

products and meets the requirements for corrosion resistance<br />

found in light industrial and water/wastewater applications. Color:<br />

yellow, dark gray or dark green. Flame Spread: ASTM E84<br />

rating of 25 or less. Certifications: DNV Type Approval No. F-<br />

16856.<br />

• XFR - This extra fire-retardant vinyl ester resin is<br />

recommended for use where the fire potential is high.<br />

Color: dark gray. Flame Spread: ASTM E84 rating of 10 or<br />

less, a level exceeded by no other resin system. Certifications:<br />

DNV Type Approval No. F-16856.<br />

• ELS - This Extremely Low Smoke resin is an acrylic-modified<br />

polyester system that is ideal for tunnel, offshore, mass<br />

transit and other confined space applications. ELS exhibits low<br />

ignitability, low smoke generation and extremely low smoke<br />

toxicity. Color: light gray. Flame Spread: ASTM E84 rating<br />

of 25, a smoke density index of 100 and Fuel Contribution of<br />

0. Certifications: DNV Type Approval No. F-16856.<br />

<br />

• Super Vi-Corr ® - This family of resin systems consists<br />

of more than 30 custom formulas engineered to provide<br />

corrosion control solutions in applications that are too severe<br />

for conventional FRP and other building materials. Each<br />

Super Vi-Corr resin was engineered for the best possible<br />

performance in specific chemical and/or elevated temperature<br />

environments. These systems exist for aggressive chemical<br />

service in reagents like solvents, acidic oxidizers, chlorine<br />

dioxide, sodium hypochlorite and liquid desiccants. Certain<br />

formulas are also suited for elevated temperature applications<br />

up to 400° F. Super Vi-Corr gratings are typically used<br />

for packing hold-downs and support in environmental and<br />

process scrubber applications. Color: natural - tan to beige.<br />

Flame Spread: non fire retardant, unless specified.<br />

Chemgrate ® Resins<br />

• FS-25 - This food-grade polyester resin system is<br />

designed for applications where there is moderate exposure<br />

to corrosive elements. Color: light gray, yellow and<br />

green. Flame Spread: ASTM E84 rating of 25 or less.<br />

Certifications: USDA accepted.<br />

• FGI-AM* - This improved food-grade isophthalic polyester<br />

resin system offers antimicrobial properties to inhibit the<br />

growth of mold on the surface of the composite to protect the<br />

product itself along with the necessary corrosion resistance<br />

to meet the requirements of the food and beverage industry.<br />

Color: light gray. Flame Spread: ASTM E84 rating of 25 or<br />

less. Certifications: USDA accepted.<br />

• CP-84 - A chemical-grade premium polyester resin, CP-<br />

84 offers excellent corrosion resistance in highly acidic<br />

conditions. Color: green. Flame Spread: non fire retardant.<br />

Certifications: USDA accepted.<br />

• VE-25 - A premium vinyl ester resin system formulated<br />

to resist highly corrosive acids and caustics found in<br />

the harshest chemical environments. It is an economical<br />

alternative to exotic materials often specified for highly<br />

corrosive conditions. Color: orange or dark gray. Flame<br />

spread: ASTM E84 rating of 25 or less. VE-25 will maintain<br />

structural integrity at elevated temperatures of up to 180ºF.<br />

* This product is intended only for non-public health uses.<br />

Phone: 800-527-4043<br />

www.fibergrate.com

<strong>Molded</strong> <strong>Grating</strong> Surfaces<br />

Slip-resistant Surfaces<br />

Slips and falls are the second leading cause of industrial accidents. According to the National Safety Council, each<br />

injury related lost work day can cost $50,000 to $100,000. That is why Fibergrate developed three slip-resistant surfaces<br />

for flooring and stair solutions. These surfaces include meniscus and applied grit tops in the Fibergrate resins and<br />

integral grit in the Chemgrate resins.<br />

Meniscus Top<br />

The concave surface of Fibergrate's<br />

standard meniscus top provides<br />

superior slip-resistant footing in most<br />

environments including wet or oily<br />

conditions.<br />

Applied Grit Top<br />

Fibergrate's optional grit top grating<br />

has a quartz grit which is secondarily<br />

applied, cured and sealed onto the<br />

surface providing excellent slipresistant<br />

footing.<br />

Integral Grit Top<br />

Chemgrate's standard slip-resistant<br />

surface is a fully sealed integral quartz<br />

grit surface applied during the molding<br />

operation.<br />

Available Surfaces For <strong>Molded</strong> <strong>Grating</strong><br />

S = Standard O = Optional N/A= Not Available<br />

STANDARD RESIN SYSTEMS<br />

Surface CP-84 Corvex ® ELS FGI-AM ® FS-25 IFR VE-25 Vi-Corr ® Super<br />

Vi-Corr ®<br />

Meniscus N/A S S S O S O S S S<br />

Applied Grit O O O O O O O O O O<br />

Integral Grit S N/A N/A N/A S N/A S N/A N/A N/A<br />

FRP Conductive Surface<br />

Fibergrate can provide a secondarily applied conductive surface which drains off the buildup<br />

of unwanted, dangerous static electricity when properly grounded. This specialized surface<br />

produces an electrical resistance of less than 26 kilo-ohms per foot, while the grating retains<br />

all of the other desirable corrosion-resistant, fire-retardant, impact-resistant and lightweight<br />

characteristics of conventional fiberglass reinforced plastic (FRP) grating.<br />

Fibergrate HF <strong>Molded</strong> <strong>Grating</strong><br />

Fibergrate has combined a premium-grade vinyl ester resin and exotic reinforcements to manufacture the only molded<br />

grating system suitable for service in harsh hydrofluoric acid applications. HF <strong>Molded</strong> <strong>Grating</strong>, a non-fire retardant<br />

system, can see service in applications that would cause premature failure in most traditional molded grating systems.<br />

XFR<br />

Phone: 800-527-4043<br />

www.fibergrate.com

Load Tables - Fibergrate ® <strong>Molded</strong> <strong>Grating</strong>s<br />

Alternate thickness Fibergrate grating uniform load tables (3/4x1x4, 3/4x1-1/2x1-1/2, 1-1/4x1-1/2x1-1/2)<br />

can be found on our website - www.fibergrate.com - under <strong>Products</strong>, <strong>Molded</strong> <strong>Grating</strong>.<br />

<strong>Molded</strong> <strong>Grating</strong> Uniform Load Tables - Deflections in Inches Max Recom. LOAD (psf) Ultimate<br />

Clear Style Load (psf) Resin System Capacity<br />

Span Depth Mesh Corvex ® IFR Vi-Corr ® (psf)<br />

Super Vi-Corr ®<br />

(in) (in) (in x in) 50 65 100 150 200 300 500 1000 2000 ELS FGI XFR<br />

1 3/4x3/4

Load Tables - Fibergrate ® <strong>Molded</strong> <strong>Grating</strong>s<br />

Alternate thickness Fibergrate grating concentrated point load tables (1-1/4x1-1/2x1-1/2)<br />

can be found on our website - www.fibergrate.com - under <strong>Products</strong>, <strong>Molded</strong> <strong>Grating</strong>.<br />

<strong>Molded</strong> <strong>Grating</strong> concentrated Point Load Tables - Deflections in Inches<br />

Clear Style Load (lb)<br />

Span Depth Mesh<br />

(in) (in) (in x in) 50 100 200 300 500 1000 2000<br />

1 1 x 4

Load Tables - Fibergrate ® <strong>Molded</strong> <strong>Grating</strong>s<br />

Alternate thickness Fibergrate grating uniform load tables (3/4x1x4, 3/4x1-1/2x1-1/2, 1-1/4x1-1/2x1-1/2)<br />

can be found on our website - www.fibergrate.com - under <strong>Products</strong>, <strong>Molded</strong> <strong>Grating</strong>.<br />

<strong>Molded</strong> <strong>Grating</strong> concentrated line Load Tables - Deflections in Inches Max Recommended LOAD (lbs/ft) Ultimate<br />

Capacity<br />

Clear Style Load (lb/ft of width) Resin System<br />

Span Depth Mesh Corvex ® IFR Vi-Corr ® (lbs/ft)<br />

Super Vi-Corr ®<br />

(in) (in) (in x in) 50 100 200 300 500 1000 2000 ELS FGI XFR<br />

1 3/4x3/4

Load Tables - Chemgrate ® <strong>Molded</strong> <strong>Grating</strong>s<br />

MOLDED <strong>Grating</strong> UNIFORM Load Tables - Deflections in Inches<br />

MaxIMUM Ultimate<br />

Clear Style Load (psf) Recommended Capacity<br />

Span Depth Mesh<br />

LOAD<br />

(in) (in) (in x in) 50 65 100 150 200 300 500 1000 (psf)<br />

(psf)<br />

5/8<br />

1<br />

1x4<br />

2x2<br />

0.01<br />

Load Tables - Chemgrate ® <strong>Molded</strong> <strong>Grating</strong>s<br />

<strong>Molded</strong> <strong>Grating</strong> concentrated Point Load Tables - Deflections in Inches<br />

Clear Style Load (lb)<br />

Span Depth Mesh<br />

(in) (in) (in x in) 50 100 200 300 500 1000 2000<br />

5/8 1 x 4 0.01 0.02 0.04 0.06 0.10 0.20 0.41<br />

1 2 x 2

Load Tables - Chemgrate ® <strong>Molded</strong> <strong>Grating</strong>s<br />

<strong>Molded</strong> <strong>Grating</strong> concentrated line Load Tables - Deflections in Inches<br />

Max Ultimate<br />

Clear Style Load (lb/ft of width) Recommended Capacity<br />

Span Depth Mesh<br />

LOAD<br />

(lb/ft)<br />

(lb/ft)<br />

(in) (in) (in x in)<br />

12<br />

18<br />

24<br />

30<br />

36<br />

42<br />

48<br />

5/8<br />

1<br />

1<br />

1<br />

1-1/2<br />

1-1/2<br />

5/8<br />

1<br />

1<br />

1<br />

1-1/2<br />

1-1/2<br />

5/8<br />

1<br />

1<br />

1<br />

1-1/2<br />

1-1/2<br />

2<br />

5/8<br />

1<br />

1<br />

1<br />

1-1/2<br />

1-1/2<br />

2<br />

5/8<br />

1<br />

1<br />

1<br />

1-1/2<br />

1-1/2<br />

2<br />

1<br />

1<br />

1<br />

1-1/2<br />

1-1/2<br />

2<br />

1<br />

1<br />

1-1/2<br />

1-1/2<br />

2<br />

1 x 4<br />

2 x 2<br />

1 x 4 std.<br />

1 x 4 H.D.<br />

1-1/2 x 6<br />

1-1/2 x 1-1/2<br />

1 x 4<br />

2 x 2<br />

1 x 4 std.<br />

1 x 4 H.D.<br />

1-1/2 x 6<br />

1-1/2 x 1-1/2<br />

1 x 4<br />

2 x 2<br />

1 x 4 std.<br />

1 x 4 H.D.<br />

1-1/2 x 6<br />

1-1/2 x 1-1/2<br />

2 x 2<br />

1 x 4<br />

2 x 2<br />

1 x 4 std.<br />

1 x 4 H.D.<br />

1-1/2 x 6<br />

1-1/2 x 1-1/2<br />

2 x 2<br />

1 x 4<br />

2 x 2<br />

1 x 4 std.<br />

1 x 4 H.D.<br />

1-1/2 x 6<br />

1-1/2 x 1-1/2<br />

2 x 2<br />

2 x 2<br />

1 x 4 std.<br />

1 x 4 H.D.<br />

1-1/2 x 6<br />

1-1/2 x 1-1/2<br />

2 x 2<br />

1 x 4 std.<br />

1 x 4 H.D.<br />

1-1/2 x 6<br />

1-1/2 x 1-1/2<br />

2 x 2<br />

50<br />

0.02<br />

0.02<br />

High Load Capacity <strong>Grating</strong><br />

<strong>Molded</strong> High Load Capacity (HLC) grating is yet another<br />

product in the arsenal of engineered fiberglass<br />

reinforced plastic (FRP) solutions by Fibergrate. While<br />

capitalizing on most of the traditional benefits of<br />

molded grating products - high strength, corrosion<br />

resistance, fire retardancy, nonconductivity and low<br />

maintenance - this specially manufactured molded<br />

FRP product has been engineered to carry the<br />

forklift loads that traditional molded FRP grating<br />

products are unable to support.<br />

With a 48% open surface area, Fibergrate’s molded HLC grating is available in a 6’ x 4’ panel<br />

with depths of 1-1/2” and 2" and comes standard in a fire-retardant vinyl ester resin system, dark gray in<br />

color, with a smooth surface. Fibergrate’s molded HLC grating merits an ASTM E-84 flame spread rating<br />

of 25 or less and a Class 1 Fire Rating.<br />

Allowable Spans for Vehicular Loads<br />

Notes:<br />

1. Load is carried by the grating load bars immediate under wheel + four additional load bars adjacent to wheel.<br />

2. Allowable Span is based on a 0.25" maximum deflection and a Factor of Safety of 3.0. The other criteria may be required by certain construction codes. Check code requirements to determine<br />

design criteria.<br />

3. ALLOWABLE SPAN IS STRONGLY DEPENDENT ON WHEEL WIDTH AND VEHICLE WEIGHT/LOAD CAPACITY. If your application varies from the values given on this table, contact Fibergrate<br />

Engineering for application assistance.<br />

4. Load based on the AASHTO Standard Truck Load as defined in AASHTO LRFD Bridge Design Specifications, 2nd Ed. This does not imply that the allowable span meets the deflection requirements<br />

of this specification.<br />

15<br />

Phone: 800-527-4043<br />

www.fibergrate.com

HLC <strong>Grating</strong> Details<br />

1-1/2” <strong>Molded</strong> HLC <strong>Grating</strong><br />

2” <strong>Molded</strong> HLC <strong>Grating</strong><br />

1.0 0.33<br />

1.0 0.39<br />

Load Bars<br />

2.0<br />

1.0<br />

0.43<br />

1.5<br />

Load Bars<br />

2.0<br />

Plan View<br />

Plan View<br />

1.0<br />

0.48<br />

2.0<br />

Elevation<br />

1 1/2” Deep x 1” x 2” Rectangular Mesh<br />

# of Bars/Foot of Width = 12<br />

Load Bar Width = 0.43” Load Bar Centers = 1”<br />

Open Area = 48% Approx. Weight = 6.2 psf<br />

Panel Size 6’ x 4’ (span)<br />

Engineering Properties Per Ft of Width<br />

A= 7.45 in 2 I = 1.39 in 4 S = 1.80 in 3<br />

Average EI = 2,400,000 lb - in 2<br />

Elevation<br />

2” Deep x 1” x 2” Rectangular Mesh<br />

# of Bars/Foot of Width = 12<br />

Load Bar Width = 0.48” Load Bar Centers = 1”<br />

Open Area = 48% Approx. Weight = 8.4 psf<br />

Panel Size 6’ x 4’ (span)<br />

Engineering Properties Per Ft of Width<br />

A= 10.26 in 2 I = 3.40 in 4 S = 3.27 in 3<br />

Average EI = 6,000,000 lb - in 2<br />

6’ x4’ Finished Panel Size<br />

Note:<br />

Load carrying bars are oriented across the narrow (4’) dimension of the panel. Panels<br />

furnished with closed bars all sides.<br />

Phone: 800-527-4043 16<br />

www.fibergrate.com<br />

Microelectronics Facility

Load Tables - HLC <strong>Grating</strong><br />

<strong>Molded</strong> High Load Capacity <strong>Grating</strong><br />

Load/Deflection Information-<br />

Uniform Load Table - Deflection in Inches<br />

UNIFORM LOAD (psf)<br />

MAXIMUM<br />

STYLE<br />

RECOMMENDED ULTIMATE<br />

SPAN DEPTH MESH<br />

LOAD CAPACITY<br />

(in) (in) (in x in) 100 200 300 400 500 600 700 800 900 1000 (psf) (psf)<br />

12<br />

1-1/2 1 x 2

Micro-Mesh ® Access Flooring<br />

Micro-Mesh panels are the right choice to minimize vibration<br />

from rolling cart or wheelchair traffic. The ADA compliant 1/2"<br />

open area between bearing bars also prevents small tools and<br />

other objects from falling through the grating to the surface<br />

below. The “15 mm ball test” requirement, common in Europe<br />

and in offshore applications, is easily met by Micro-Mesh<br />

panels.<br />

Micro-Mesh ® fiberglass reinforced plastic (FRP) access<br />

flooring system is designed as a low cost alternative to<br />

aluminum, steel, stainless steel and other materials in<br />

applications where corrosion resistant under-floor access<br />

and unobstructed air flow is required. Lightweight, 2' x 2'<br />

Micro-Mesh panels are easily removed, providing ready<br />

access to electrical conduits, air supply plenums and service<br />

lines.<br />

Details<br />

#of Bars/Ft of Width<br />

16<br />

Load Bar Width<br />

1/4"<br />

Bottom Load Bar Centers<br />

1-1/2"<br />

Top Load Bar Centers<br />

3/4"<br />

Open Area<br />

44.4%<br />

Approx.Weight<br />

4.5 psf<br />

Adjustable quad-head grating pedestals allow for a fast, smooth<br />

installation and readily adjust to sub-floor contour to provide a level flooring surface. Micro-Mesh panels come<br />

standard with a smooth top and are also available with meniscus and applied grit tops.<br />

Fibergrate is now offering the 1-1/2" deep Micro-Mesh with 3/4" square top mesh in a 4' x 12' panel. In addition,<br />

the following new Micro-Mesh panels are also available: 1" deep with 3/4" square top mesh (4' x 12') and 1-1/8"<br />

deep with 1" square top mesh (1M x 3M) - see pages 4 and 5 for product details. Load table information for all<br />

new panels can be found on pages 9 and 11.<br />

Load and Deflection Data<br />

Load capacity and deflection data was developed using the<br />

Recommended Test Procedures for Access Floors by the<br />

Ceilings & Interior Systems Construction Association (CISCA).<br />

Setup requires that panels “...shall be supported on an understructure<br />

support identical to that utilized in an installed system”.<br />

ALL LOAD POINTS 1”<br />

CASE VI<br />

(Pedestal)<br />

CASE V<br />

(Weakest point)<br />

CASE I & CASE III<br />

(Centroid)<br />

CASE II & CASE IV<br />

(Midpoint edge)<br />

<strong>Grating</strong> Leg<br />

Supports<br />

(4 Corners)<br />

CONDITIONS:<br />

CASE I. Concentrated loading at the center of the panel (centroid)<br />

CASE II. Concentrated loading at the mid point of the edge (centerline edge)<br />

CASE III. Ultimate Capacity - Concentrated loading at the center of the panel<br />

(centroid)<br />

CASE IV. Ultimate Capacity - Concentrated loading at the midpoint of the<br />

edge (centerline edge)<br />

CASE V. Ultimate Capacity - Concentrated loading at the "weakest point" of<br />

the panel<br />

CASE VI. Ultimate Capacity - Pedestal<br />

LOADS TO PRODUCE<br />

0.08" DEFLECTION<br />

CASE I<br />

580 lb<br />

CASE II<br />

250 lb<br />

ULTIMATE CAPACITIES<br />

CASE III 4,700 lb<br />

CASE IV 1,200 lb<br />

CASE V 1,700 lb<br />

CASE VI 6,000 lb<br />

PANEL DEFLECTIONS<br />

LOAD CASE I CASE II<br />

(lb) (in) (in)<br />

100 0.006 0.032<br />

200 0.020 0.064<br />

300 0.037 0.096<br />

400 0.054 0.129<br />

500 0.069 0.161<br />

750 0.116 0.240<br />

1000 0.158 0.331<br />

For more information on Fibergrate's grating pedestal system, see page 26 or visit www.fibergrate.com for full brochure<br />

including layouts.<br />

18<br />

Phone: 800-527-4043<br />

www.fibergrate.com

New <strong>Products</strong><br />

Non-Magnetic Access Flooring<br />

New cable routing requirements implemented by some MRI vendors prohibit<br />

the use of metal access floor panels found in MRI magnet rooms. To meet<br />

the needs of this new requirement, Fibergrate developed a non-magnetic<br />

flooring system by customizing our standard Micro-Mesh panels and pedestal<br />

systems. A high pressure floor laminate is now adhered to the surface of the<br />

grating panel and non-magnetic pedestals are available. Fibergrate non-magnetic access flooring system should<br />

be the first choice for use in this market. For detailed literature and specification sheet, please visit the Fibergrate<br />

website - www.fibergrate.com - search <strong>Products</strong>, Non-Magnetic MRI Flooring System.<br />

EcoGrate <strong>Molded</strong> <strong>Grating</strong><br />

Fibergrate's Ecograte grating was developed for use in marine environments.<br />

This product exceeds the guidelines set forth by the Army Corp of Engineers<br />

who require a minimum of 43% open area, to protect seagrasses found below<br />

docks. Ecograte offers a 46% open area, is 3/4" deep with 1" by 4" rectangular<br />

mesh. In addition, this product meets the American with Disabilities Act<br />

(ADA) guidelines and its Aquagrit surface provides a barefoot-friendly, slip resistant surface to ensure a safe<br />

deck area. Ecograte can be used in various applications throughout the recreational market, such as amusement<br />

parks and waterways. For grating details, see page 4. More information is also available on our website<br />

- www.fibergrate.com - search <strong>Products</strong>, <strong>Molded</strong> <strong>Grating</strong>, Ecograte.<br />

Uniform Load Table - Deflection in Inches<br />

SPAN<br />

(in)<br />

UNIFORM LOAD (psf)<br />

50 65 100 150 200 300 500 1000 2000<br />

Maximum<br />

Recommended<br />

Load<br />

(psf)<br />

Ultimate<br />

Capacity<br />

(psf)<br />

12

AirMesh ® and Multigrid ® <strong>Grating</strong><br />

AirMesh ® Screening<br />

Originally designed to meet United States Navy specifications (ELS resin<br />

system) for air intake screens on ships, AirMesh ® molded FRP screening is<br />

now available for use in marine, commercial and general industrial applications.<br />

AirMesh is 1/2" deep, 1-1/2" square mesh screening with 1/8" thick bars available<br />

in 4' x 8' panels. To meet a wide range of requirements, AirMesh is available in<br />

all standard Fibergrate® molded resin systems. This advanced screen features<br />

Details (Non-load carrying)<br />

an 87% open area, allowing a<br />

1/2" x 1-1/2" generous airflow and a standard<br />

Square Mesh<br />

smooth surface for worker safety.<br />

#of Bars/Ft of Width<br />

8<br />

Load Bar Open Area<br />

Width 87%<br />

1/8"<br />

Load Bar<br />

Approx.<br />

Centers<br />

Weight<br />

1-1/2" 0.8 psf<br />

This open area also contributes to the light weight of AirMesh,<br />

making it easier to install. Corrosion resistant, anti-magnetic and<br />

nonconductive, AirMesh provides long, reliable life, even in the<br />

most demanding conditions.<br />

Multigrid ® <strong>Grating</strong><br />

Multigrid ® is a 1/2" deep multipurpose lightweight FRP grating originally designed to be used as safety<br />

screening. Multigrid is available in 4' x 12' and 4' x 15' panels. With its<br />

3/16" bars which are slightly thicker than AirMesh, Multigrid can also<br />

be used as a slip-resitant surface on floors and a protective walkway<br />

when installed on top of trickling filter media in wastewater applications.<br />

The 2" x 2" mesh size ensures continuous application of wastewater and<br />

suspended solids without plugging.<br />

Details (Must be fully supported)<br />

1/2" x 2"<br />

Square Mesh<br />

#of Bars/Ft of Width<br />

6<br />

Load Bar Open Area<br />

Width 82%<br />

3/16"<br />

Load Bar<br />

Approx.<br />

Centers<br />

Weight<br />

2" 0.96 psf<br />

This product can also be used for a wide range of industrial,<br />

commercial and institutional applications including<br />

machinery guards, fencing, space dividers in factories and<br />

warehouses and cages for tools, equipment and animals.<br />

Safety barriers or cages are another common use where<br />

di-electric or corrosive conditions require protection for<br />

working personnel.<br />

Phone: 800-527-4043 20<br />

www.fibergrate.com

Floor Plate<br />

Floor Plate<br />

Chemplate and Fiberplate are manufactured by building<br />

up multiple layers of fiberglass reinforcement and speciallyformulated<br />

resins. The result of this process is a solid composite<br />

panel offering both bidirectional strength and corrosion resistance.<br />

These specially designed products are nonporous and are easily cleaned by<br />

high pressure washer and can withstand cleaning solutions. Available in all<br />

molded grating resin systems (see page 7). Standard panel sizes are 3' x 10',<br />

4' x 8', 4' x 12' and 5' x 10'. (Custom sizes available.)<br />

Chemplate ® and Fiberplate ® Load and Deflection Data<br />

*Important: 1/8" Plate designed for use as covering only; not recommended for load bearing service.<br />

Depth (in)<br />

1/4<br />

3/8<br />

1/2<br />

3/4<br />

Span<br />

(in)<br />

Concentrated Load-Full Panel Uniform Load-Full Panel<br />

Concentrated Load<br />

Required to Produce<br />

Deflection Equal to<br />

1% of Span (lb)<br />

Maximum Load<br />

Load (lb)<br />

Maximum Load<br />

Load (psf)<br />

Norm 1 Firm 2 100 250 500 750 1000 Norm 1 Firm 2 25 50 75 100 150<br />

12 229 135 .047 .104 .199 .294 .392 336 208 .010 .014 .022 .029 .043 300 lb<br />

18 196 117 .079 .1.81 .351 -- -- 99 54 .056 .085 .115 .145 .204 256 lb<br />

24 181 116 .102 .268 -- -- -- 28 15 .177 .327 .476 -- -- 223 lb<br />

364 84 55 .350 -- -- -- -- -- -- -- -- -- -- -- 103 lb<br />

12 515 325 .018 .045 .093 .140 .190 480 300

Covered <strong>Grating</strong><br />

Covered grating is often used in loading and storage<br />

areas. Other applications include food processing<br />

facilities where covered grating walkways prohibit<br />

contamination to conveyor or work surfaces below;<br />

facilities where covered grating provides a walking<br />

surface and controls subsurface odors; walkways<br />

over tank tops and vats and solid flooring where<br />

narrow heels might present a tripping hazard with<br />

open mesh grating. Both Chemdeck and Fibergrate<br />

covered grating include a fiberglass gritted plate cover<br />

secondarily affixed to a molded grating panel. Covered grating offers a strong, level surface for foot or cart<br />

traffic and provides approximately 50% higher stiffness values than that of open mesh grating. Its standard<br />

grit-top cover assures secure footing.<br />

Chemdeck ® and Fibergrate ® Covered <strong>Grating</strong><br />

Chemdeck ® comes in standard panel sizes with either a 1/8" or<br />

1/4" deep plate applied to standard depths of grating. Chemdeck is<br />

available in all four Chemgrate resin systems — FS-25, FGI-AM,<br />

CP-84 and VE-25 — offering a variety of colors (dependant on resin<br />

selection - see page 6) that complement most walking surfaces.<br />

Fibergrate ® covered grating consists of a 1/8" or 1/4" deep plate<br />

applied to standard Fibergrate grating depths. Fibergrate covered grating is available in Corvex ® , IFR,<br />

Vi-Corr ® , ELS and XFR resin systems.<br />

Note: Type WLP Hold Down Clips are recommended to secure<br />

Chemdeck and Fibergrate covered grating panels to structural<br />

supports in order to eliminate potential damage to the covered<br />

grating. Fibergrate provides 8 WLP Hold Down clips per panel.<br />

22<br />

Phone: 800-527-4043<br />

www.fibergrate.com

Work Platform Solutions<br />

Work station platforms from Fibergrate are<br />

available in a variety of styles, heights and<br />

sizes to provide a slip- and corrosion-resistant<br />

and ergonomic solution for your facility.<br />

From portable one-piece workstands to fixed<br />

large-scale access platforms, Fibergrate will<br />

help you find the perfect fit for your working<br />

environment.<br />

Safe-T-Stand ®<br />

Safe-T-Stand<br />

platforms have<br />

a grit top which<br />

provides a safe,<br />

slip-resistant<br />

surface, while their resilient design<br />

eases the strain on feet, legs and back muscles.<br />

Stands are available in 2", 4", 6", 8" and 10" heights<br />

and have skid-resistant rubber feet for added safety.<br />

The proven strength, impact resistance and<br />

overall durability of FRP construction make<br />

Safe-T-Stand platforms equally usable in any<br />

process industry or manufacturing environment.<br />

Standard Safe-T-Stand platforms are manufactured<br />

using a specially-designed, USDA-accepted, foodgrade<br />

resin for food and beverage processing plants.<br />

The full line of Fibergrate resin systems is available<br />

for non-food applications.<br />

grating needed for drainage or waterflow and safe,<br />

ergonomic platforms. The feet raise the grating 1/2"<br />

above the ground and along with the open mesh,<br />

protect workers by allowing chips and fluids to fall<br />

below the standing surface eliminating slip and fall<br />

hazards.<br />

Fibergrate ® Custom Platform Solutions<br />

Fibergrate's turnkey approach to providing<br />

custom platform solutions include design and<br />

fabrication and installation services. From simple<br />

portable workstations to complex multifaceted<br />

platforms, the experienced personnel at Fibergrate<br />

can provide your facility with the perfect custom<br />

platform solution.<br />

Fibergrate ® Workmats<br />

Specially designed<br />

rubber feet are an<br />

economical way to<br />

create a raised, ergonomic<br />

grating workmat for use<br />

around machines, lathes and in<br />

wet areas. With the rubber feet,<br />

facilities have a cost-effective solution to elevate<br />

Phone: 800-527-4043 23<br />

www.fibergrate.com

Stair Solutions - Stair Treads<br />

Fibergrate provides several slip- and corrosion-resistant products for your<br />

stairway safety needs. Our complete stair solution line includes panels in a onepiece<br />

molded configuration for new or replacement step; covered stair treads to<br />

replace deteriorating concrete steps; or stair tread covers designed to add slip<br />

and corrosion resistance to existing metal, concrete or woods steps. Stair treads<br />

are available in a one-piece molded configuration engineered to exceed OSHA<br />

and other model building code standards<br />

for safety, strength, durability and corrosion<br />

resistance.<br />

Fibertred ® Panels<br />

Fibertred stair treads are available<br />

in the same high-performance resin<br />

formulations as Fibergrate grating. Unique<br />

cutting channels spaced at 6" intervals<br />

provide efficient utilization when custom<br />

fitting treads into stairways. These<br />

channels also ensure that all standard stair<br />

tread widths are terminated with closed ends. Up to five 24" wide stair<br />

treads can be cut from each side of a single panel. A 1-1/2" wide gritted<br />

strip is molded in on both sides of the panel for superior slip resistance.<br />

1-1/2" x 6"<br />

Fibergrate ® Covered Stair Treads<br />

Designed as an alternative to the high-maintenance concrete or<br />

slippery metal step, covered stair treads are designed for commercial<br />

and architectural applications where aesthetics and low maintenance are<br />

important considerations. Covered stair treads are available in FS-25 resin<br />

and has an integral grit top which comes in three slip-resistant textures —<br />

coarse, medium and fine which is suitable even for barefoot traffic. They<br />

can withstand many corrosive environments including salt, continuous<br />

moisture and constant cleaning.<br />

The lightweight tread weighs<br />

less than 20 percent that of a<br />

precast concrete step and can be<br />

easily fabricated and installed<br />

with simple wood working tools.<br />

24"<br />

10-1/2"<br />

24<br />

22-1/4"<br />

(depth) 1-1/2"<br />

Phone: 800-527-4043<br />

www.fibergrate.com

Stair Solutions - Stair Treads<br />

Approximate Weight 103 lb<br />

Normally for 42-1/2", 48-1/2",<br />

54-1/2" & 60-1/2" tread sizes<br />

21-1/2"<br />

27-3/8"<br />

10'-1/2"<br />

Chemtred ® Panels<br />

Chemtred is an open grating type<br />

stair tread with tapered bars that allow<br />

self-cleaning. Chemtred is molded with an<br />

integral solid contrasting nosing and integral<br />

slip-resistant grit top. There are two specially<br />

designed panel sizes and bars are on 1-1/2"<br />

and 6" centers. Panels are available in all<br />

Chemgrate resins.<br />

Load Table - Stair Treads<br />

9-3/8"<br />

12-3/8"<br />

10-7/8"<br />

12-3/8"<br />

13-7/8"<br />

(Depth 1-1/2")<br />

Approximate Weight 103 lb<br />

Normally for 42-1/2", 48-1/2", 54-<br />

1/2" & 60-1/2" tread sizes<br />

Tread Type Mesh Load Span (in) 18 24 30 36 42 48<br />

Tread (Depth x Width) Type (lb) Span/150 0.12 0.16 0.20 0.24 0.28 0.32<br />

12'-1/2"<br />

9-3/8"<br />

(Depth 1-1/2")<br />

7-7/8"<br />

9-3/8"<br />

10-7/8"<br />

Fibertred 1-1/2" x 6" Rectangular 250 0.03 0.05 0.09 0.16 0.25 0.41<br />

500 0.06 0.10 0.19 0.32 0.50 —<br />

Chemtred 1-1/2" x 6" Rectangular 250 0.03 0.05 0.09 0.14 0.25 0.41<br />

Notes:<br />

1. It is suggested that stair tread deflections be limited to Span/150. Deflections based on this ratio are at the top of the table.<br />

2. Deflections in the body of the table are for concentrated loads of both 250 and 500 lb A concentrated load is applied at the centerline of the<br />

tread, over a width of 4" and a depth of 6", starting at the nosing edge to simulate the landing of a foot.<br />

3. Stair treads with square mesh or for longer spans are available by custom order. Please contact Fibergrate for more information.<br />

Load Table - Covered Stair Treads<br />

Tread Type Load Span (in) 30 36 42 48 54 60<br />

(Depth x Width) (lb) L/D=150 0.2 0.24 0.28 0.32 0.36 0.4<br />

1-5/8" x 10-5/8" 250 0.08 0.15 0.23 0.35 — —<br />

500 0.17 0.29 0.47 — — —<br />

1-5/8" x 12-1/4" 250 0.07 0.11 0.18 0.27 0.37 —<br />

500 0.13 0.23 0.36 — — —<br />

2-1/8" x 10-1/4" 250 0.04 0.06 0.09 0.14 0.20 0.27<br />

500 0.07 0.13 0.19 0.28 0.39 —<br />

2-1/8" x 12-1/4" 250 0.03 0.05 0.08 0.12 0.17 0.23<br />

500 0.05 0.10 0.17 0.24 0.33 0.46<br />

<strong>Grating</strong> tolerances ± 1/8"<br />

Phone: 800-527-4043 25<br />

www.fibergrate.com

Stair Solutions - Stair Tread Covers<br />

Fiberplate ® stair<br />

tread covers are a<br />

convenient way to<br />

provide solid<br />

slip-resistant footing for<br />

existing stairs. Stair<br />

tread covers may be installed over wood, concrete or metal steps.<br />

Standard color is dark gray with a highly visible safety yellow<br />

nosing and light gray for architectural applications.<br />

An integral aluminum oxide grit-top surface provides secure<br />

footing for maximum safety and a highly durable tread.<br />

Reinforced with a woven glass mat for durability and impact<br />

resistance, these tread covers come in 8", 9" 10", 11" and 12" depths. The standard thickness is 1/8" with<br />

1/4" thick covers available for heavy duty applications. Standard 12' panels are easily cut to size during<br />

installation, or are available precut to custom lengths.<br />

Phosphorescent Nosing<br />

Fiberplate stair tread covers can be ordered with a special<br />

phosphorescent coating for the nosing area, causing it to glow<br />

even after the primary light source has been removed. The<br />

special nosing is perfect in stairways which serve as emergency<br />

exits during power outages, outdoor accessways where lighting<br />

is periodically dimmed as in arenas and concert halls or as a<br />

safety measure for nighttime operation in outdoor applications<br />

such as on passenger ships. This special nosing has been<br />

tested in accordance with ISO/TC 8/SC 1 N. Ships and Marine<br />

Technology — Low Location Lighting on Passenger Ships.<br />

Installation Details<br />

1-1/2"<br />

Depth<br />

Low Profile<br />

Head Fastener<br />

Field Drill Holes<br />

(Seal All Holes)<br />

Contrasting<br />

Nosing<br />

Add Fastener in<br />

Rear if Required<br />

Wood or Concrete<br />

Stair Tread<br />

26<br />

1/4" x 2" Truss<br />

Head Bolt 316SS<br />

Field Drill Holes<br />

(Seal All Holes)<br />

Contrasting Nosing<br />

Retaining Clip 316SS<br />

1/4" Lockwasher 316SS<br />

1/4" Nut 316SS<br />

Add Fastener in Rear if Required<br />

Steel or FRP<br />

Stair Tread<br />

Phone: 800-527-4043<br />

www.fibergrate.com

Accessories<br />

Clip Assemblies For <strong>Molded</strong> <strong>Products</strong><br />

Fibergrate offers specially designed attachments and clips, both to fasten panels together and to secure<br />

them to support structures. All types are made of Type 316 Stainless Steel and are available in 1", 1-1/2"<br />

and 2" sizes. Install clips a maximum of every 48" and use at least four clips per piece of grating (at least<br />

eight clips per 4' x 12' panel).<br />

TYPE M HOLD DOWN<br />

CLIPS: secure panels to<br />

a support in the same<br />

manner as Type J Clips,<br />

but designed to use two<br />

adjacent grating bars for<br />

a more secure fit. Similar<br />

in design to metal<br />

grating saddle clips.<br />

TYPE WLP<br />

STRUCTURAL<br />

CLIPS: secure<br />

covered grating or<br />

plate to a structure.<br />

(Also available in<br />

304 SS)<br />

TYPE J HOLD<br />

DOWN CLIPS:<br />

secure grating<br />

panels to support<br />

frames.<br />

TYPE H<br />

(TRUSS HEAD)<br />

STRUCTURAL<br />

CLIPS: secure<br />

plate to a<br />

structure.<br />

TYPE F END PANEL<br />

CLIPS: provide a<br />

simplified method for<br />

joining factory edges<br />

of adjacent abutting<br />

panels. (Not for use<br />

with Chemgrate resins.)<br />

TYPE G HOLD<br />

DOWN CLIPS:<br />

attach grating<br />

to any structural<br />

member flange,<br />

3/4" or smaller in<br />

thickness, with no<br />

drilling required.<br />

Field cutting<br />

of one bar required<br />

TYPE EI HOLD<br />

DOWN CLIP:<br />

secure panels<br />

to a support.<br />

EZ Angle® Embedment Angle<br />

EZ Angle® embedment angle is precision-designed for<br />

solid seating of 1", 1-1/2", and 2" deep gratings. EZ Angle<br />

embedment angle is stocked in 20' lengths for immediate<br />

shipment. For animated installation instructions, visit our<br />

resource center at www.fibergrate.com.<br />

Sealing and Bonding Kits<br />

To maintain corrosion resistance and structural integrity, Fibergrate<br />

offers standard resin sealing in 1/2 pint and gallon kits for<br />

protecting the exposed ends of cut panels and other components.<br />

One 1/2 pint kit coats approximately 20-40 lineal feet. Sealing and<br />

bonding kits come in a natural, unpigmented color.<br />

Phone: 800-527-4043 27<br />

www.fibergrate.com

<strong>Grating</strong> Pedestals<br />

Made with the same adherence to quality as all Fibergrate products,<br />

specially designed pedestals for square mesh molded grating are<br />

manufactured to provide safe support for elevated flooring. Pedestal<br />

supported floors are versatile; they can be modified or moved from place to<br />

place as necessary and pedestals are generally much less expensive than<br />

beam support systems. Adjustable pedestals are available in heights from<br />

3-1/4" to 72" (with additional bracing). Pedestals are available with 1-1/2" or<br />

2" single heads or quad heads to fit Fibergrate<br />

or Chemgrate grating (diagrams show single head).<br />

Mini Pedestal Elevation Standard Pedestal Elevation Extended Pedestal Elevation<br />

Pedestal<br />

Configuration<br />

Mini<br />

Standard<br />

Extended<br />

‘A’ Range<br />

Head<br />

Total<br />

Single Head<br />

Quad Head<br />

Adjustment<br />

Min. Max. 1-1/2” 2” Fibergrate ® Chemgrate ®<br />

3-1/4” 4-3/4” 1-1/2” 561103 562103 563103 564103<br />

4” 5-1/2” 1-1/2” 561104 562104 563104 564104<br />

4-3/4” 6-1/4” 1-1/2” 561105 562105 563105 564105<br />

5” 7-3/4” 2-3/4” 561205 562205 563205 564205<br />

6-3/4” 9-1/2” 2-3/4” 561207 562207 563207 564207<br />

8-3/4” 11-1/2” 2-3/4” 561209 562209 563209 564209<br />

9-1/2” 14” 4-1/2” 561310 562310 563310 564310<br />

12” 18” 6” 561312 562312 563312 564312<br />

15” 21” 6” 561315 562315 563315 564315<br />

18” 24” 6” 561318 562318 563318 564318<br />

21” 27” 6” 561321 562321 563321 564321<br />

24” 30” 6” 561324 562324 563324 564324<br />

27” 33” 6” 561327 562327 563327 564327<br />

30" 36" 6" 561330 562330 563330 564330<br />

33" 39" 6" 561333 562333 563333 564333<br />

36” 42” 6” 561336 562336 563336 564336<br />

Notes: Available to 72” - contact Fibergrate for more information on extended lengths and bracing. For a more detailed<br />

brochure on pedestals, go to www.fibergrate.com or contact Fibergrate.<br />

28 Phone: 800-527-4043<br />

www.fibergrate.com

Engineering Notes<br />

The strength and corrosion resistance of FRP<br />

grating are related to the glass content, resin<br />

content, resin type and method of construction.<br />

Fibergrate molded products provide an outstanding<br />

balance of corrosion resistance, slip resistance and<br />

strength.<br />

There are three frequently used methods of<br />

support for molded fiberglass grating:<br />

1) two continuous edge supports with bearing<br />

bars perpendicular to the supports;<br />

2) continuous support around all sides; and<br />

3) four-corner support, or point support. (For<br />

example, pedestals are provided to support the<br />

grating a few inches above the existing floor<br />

when large volumes of liquids are flowing<br />

onto the floor and where a slip-resistant<br />

drainable floor surface is required because of<br />

operating requirements.)<br />

Panels are normally supported around the perimeter<br />

to assure panel-to-panel alignment.<br />

In using Fibergrate’s grating, the principles are<br />

similar to metal grating usage, but you must keep<br />

in mind that the flexural modulus of elasticity of<br />

reinforced fiberglass bars is lower than that of steel.<br />

As a result, the allowable deflection is often the<br />

limiting consideration.<br />

Engineering Notes<br />

Optimum floor installation costs are achieved<br />

by minimizing the combined cost of the support<br />

structure and grating. As the span is decreased, load<br />

capacity requirements of the grating are reduced.<br />

Estimating two or three span options will establish<br />

the optimum system.<br />

Mesh Selection: The following notes can<br />

be helpful in selecting the optimum mesh<br />

configuration.<br />

(1) <strong>Grating</strong> with heavier bars should be selected<br />

for floors subjected to more abusive services.<br />

In these type applications the 3/8" wide<br />

bearing bars and 5/8" crossbars of the 1"<br />

(1" x 4") Heavy Duty and the 1-1/2"<br />

(1-1/2" x 6") would be more suitable than<br />

the 1/4" wide bars on other mesh sizes.<br />

(2) Rectangular mesh pattern grating provides the<br />

highest load-carrying capacity based upon<br />

cost per square foot.<br />

(3) Square pattern mesh configurations have<br />

nearly equal strength in both directions. Spans<br />

larger than four feet, multiple floor cutouts,<br />

high load/four-sided support layouts or<br />

pedestal supported floors are conditions<br />

frequently well-served by square mesh<br />

configurations. High utilization per standard<br />

panel and bidirectional aesthetics are<br />

beneficial features of square mesh patterns.<br />

Simple Beam Support: All data in our tables are<br />

based on simple beam support. Load and deflection<br />

for other types of beams, i.e., cantilever, fixed end<br />

support, continuous support, etc. can be estimated<br />

by using standard beam formulas.<br />

Load vs. Deflection: Load vs. Deflection is<br />

approximately proportional for a given span (i.e. if a<br />

concentrated 400 lb load deflects a 30" span 1/4", an<br />

800 lb load would deflect the same span 1/2").<br />

Other Spans: Consult Fibergrate's Engineering<br />

Department.<br />

Phone: 800-527-4043 29<br />

www.fibergrate.com

Load Information/<strong>Grating</strong> Selection<br />

Load/Deflection Tables Information<br />

Fibergrate load and deflection tables are designed to be user friendly by separating uniform load information<br />

from concentrated load information and concentrated point load data. These layouts allow designers to quickly<br />

and accurately denote the grating best suited for the intended purpose. Fibergrate employs state-of-the-art<br />

Acoustic Emission Testing. Fibergrate's load tables provide a maximum load below which corrosion resistance<br />

damage does not occur.<br />

Acoustic Emission<br />

Acoustic Emission testing has long been an accepted industry practice for the non-destructive proof testing of<br />

fiber-reinforced tanks, pipes, pressure vessels and utility truck booms. Acoustic Emission detects the earliest<br />

evidence of failure in an FRP composite under load by detecting the inaudible sounds which occur as a result of:<br />

1) cracking of the resin matrix, 2) delamination between the composite plies, 3) fracture of the reinforcing fiber,<br />

or 4) interface failure between the matrix and reinforcement. Such failures represent the earliest opportunity for<br />

intrusion of the corrosion elements. By utilizing Acoustic Emission technology, Fibergrate is able to establish<br />

the Maximum Recommended Load rating for each grating product at which maximum corrosion resistance will<br />

be offered.<br />

Ultimate Capacity<br />

Fibergrate has tested its molded grating product line to its ultimate capacity. ULTIMATE CAPACITY represents<br />

a complete and total failure of the grating and is presented to illustrate the reserve strength of the grating at a<br />

given span. Because there is some variation in ultimate load capacity from resin to resin, Fibergrate has chosen<br />

to list the lowest or most conservative ultimate capacity value. Ultimate capacities are not to be used for design:<br />

functionality of the grating is limited to Maximum Recommended Load.<br />

Manufacturing Control Limits<br />

The load/deflection values given in this brochure are average values developed through Fibergrate's Quality<br />

Assurance Program. The manufacturing control limit on stiffness for all panels is plus or minus 7.5% of these<br />

average values. This represents the tightest control on performance variation in the industry based on<br />

published data.<br />

1" Rectangular 1", 1-1/2" & 2"<br />

MOLDED GRATING PULTRUDED Safe-T-Span<br />

Application Needs<br />

Mesh Square Mesh<br />

® MOLTRUDED Rigidex ® II ®<br />

1" Rectangular 1", 1-1/2" & 2" GRATING<br />

Corrosion Resistance HR HR R R<br />

Mesh<br />

MOLDED PULTRUDED MOLTRUDED ®<br />

Square Mesh<br />

RIGIDEX I ® RIGIDEX II ®<br />

Strength/Stiffness (longest span) R R HR HR<br />

Impact Resistance R HR A R<br />

Open Area (for drainage, aeration, light penetration) HR HR A HR<br />

Single Direction Span R A HR HR<br />

Bidirectional Span N HR N N<br />

Ease of Layout and Installation A HR A A<br />

Lightweight in Comparison to Metals HR HR HR HR<br />

Custom Panel Sizes Available A R R N<br />

HR = Highly Recommended R = Recommended A = Acceptable N = Not Recommended<br />

30<br />

Phone: 800-527-4043<br />

www.fibergrate.com

Chemical Resistance Guide<br />

Chemical Environment<br />

%<br />

Concentration<br />

Temp<br />

˚F<br />

Phone: 800-527-4043 31<br />

www.fibergrate.com<br />

<strong>Molded</strong><br />

Pultruded<br />

Fibergrate ® Chemgrate ® Safe-T-Span ®<br />

Vi-Corr ® Super Vi-Corr ® IFR/Rigidex II FGI Corvex ® XFR FS-25 CP-84 VE-25 VEFR ISOFR<br />

Acetic Acid 50 MAX C C C C C I C C C C C<br />

Acetone 100 75 S S I I T I I I S I N<br />

Alcohols 100 120 C C I I I S I I C I I<br />

Alum ALL MAX C C C C C C C C C C C<br />

Aluminum Chloride ALL MAX C C C C C C C C C C C<br />

Aluminum Fluoride 20 75 C C I I I I I I C I I<br />

Ammonium Hydroxide 30 75 C C N N N N N I C I N<br />

Ammonium Salts-Neutral ALL 120 C C C C S S I I S C S<br />

Ammonium Salts-Aggressive ALL 75 S C I I T I I I S T N<br />

Aromatic Solvents ALL 75 T T N N N N N N T N N<br />

Barium Salts ALL MAX C C C C C C C C C C C<br />

Benzene 100 140 I S I I N I I I I I N<br />

Black Liquor (Pulp Mill) ALL MAX C C I I N I I I C I N<br />

Bleach Liquor (Pulp Mill) ALL MAX C C I I N N I I C I N<br />

Calcium Hydroxide 25 MAX C C S S I I S S C S I<br />

Calcium Hypochlorite ALL MAX C C I I N I I I C I N<br />

Calcium Salts ALL MAX C C C C C C C C C C C<br />

Carbon Tetrachloride 100 75 C C I I N S N I C S N<br />

Chlorinated Hydrocarbons 100 75 T T T T T N N N T T T<br />

Chlorine Dioxide SAT 140 C C N N N N N T C S N<br />

Chlorine Water SAT 120 C C I I T I I I C I N<br />

Chlorine, Wet SAT MAX C C N N N N N N C N N<br />

Chlorobenzene 100 75 S S N N N N N N S N N<br />

Chlorobenzene ALL Up to 100 C C N N N N N N C N N<br />

Chloroform 100 75 N N N N N N N N N N N<br />

Chromic Acid 50 140 S S S S N N I S S I N<br />

Citric Acid ALL MAX C C C C C C I C C C C<br />

Copper Cyanide Plating ALL 125 C C S S I N S S C S I<br />

Copper Salts ALL MAX C C C C C C C C C C C<br />

Crude Oil (Sweet or Sour) ALL MAX C C C C C C C C C C C<br />

Dichlorobenzene 100 75 T S N N N N N N T N N<br />

Ethers 75 T T N N N N N N T N N<br />

Ferric Chloride 100 MAX C C C C C C I C C C C<br />

Ferric Salts ALL MAX C C C C C C C C C C C<br />

Fluoride Salts+HCI ALL 75 C C S S N I S S C I N<br />

Fluosilicic Acid 10 75 C C S S S S S S C S I<br />

Formaldehyde 37 150 C C I I I I I I C S I<br />

Formic Acid 25 100 C C S S I I I S C S I<br />

Fuel (Diesel, Jet, Gasoline) ALL 100 C C C C C C C C C C C<br />

Glycerine 100 MAX C C C C C C C C C C C<br />

Green Liquor (Pulp Mill) ALL MAX C C N N N N N I C I N<br />

Hydrobromic Acid 48 MAX S S S S I I I S S I N<br />

Hydrochloric Acid 10 MAX C C S S S C S S C S S<br />

Hydrochloric Acid 30 MAX C C S S I I S S C I I<br />

Hydrochloric Acid (concentrated) ALL Up to 180 I C N N N N N N I N N<br />

Hydrocyanic Acid ALL MAX C C I I I I I I C S I<br />

Hydrofluoric Acid 20 75 S C N N N N N N S N N<br />

Hydrogen Peroxide 30 75 C C N N N I N N C S N<br />

Lactic Acid 100 MAX C C C C C C C C C C C<br />

Lime Slurry SAT MAX C C C C C C C C C C C<br />

Lithium Chloride SAT MAX N C N N N N N N N N N<br />

Lithium Salts ALL MAX C C C C C C C C C T T<br />

Magnesium Salts ALL MAX C C C C C C C C C C C<br />

Maleic Acid 100 MAX C C S S I C I S C S I<br />

Mercury Chloride 100 MAX C C C C C C S C C C C<br />

Nickel Salts ALL MAX C C C C C C C C C C C<br />

Nitric Acid 20 120 C C S S I I S S C I I<br />

Nitric Acid 35 100 C C N N N I N I C I N<br />

Nitric Acid 40 Ambient I C N N N N N N I N N<br />

Nitric, Hydrofluoric 20:2 75 I C N N N N N N I N N<br />

Nitrous Acid 10 75 C C C C C C I C C C C<br />

Ozone for Sewage Treatment 100 C C C C C C C C C C C<br />

Perchloroethylene 100 75 S C N N N I N N S I N<br />

Phenol 10 75 C C N N N N N N C I N<br />

Phenol 88 Ambient S C N N N N N N S N N<br />

Phosphoric Acid 85 MAX C C C C S C I C C C S<br />

Phosphoric Acid, Super 115 MAX C C I I T S N I C S N<br />

Potassium Hydroxide 10 120 C C I I N N I I C S N<br />

Potassium Salts ALL MAX C C C C C C C C C C C<br />

Silver Nitrate 100 MAX C C C C C C I C C C C<br />

Sodium Cyanide ALL 75 C C I I I I I I C S I<br />