warning - Bishop Lifting Products, Inc.

warning - Bishop Lifting Products, Inc.

warning - Bishop Lifting Products, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Roundslings<br />

Identification, Inspection,<br />

Rigging Practices, Weight Table<br />

• Loads should not be rested on the sling<br />

• Slings should not be pulled from under the load when the load is resting in the sling<br />

• Twisting shall be avoided<br />

• During lifting, with or without load, personnel shall be alert for possible snagging<br />

• When using multiple basket or choker hitches, the load should be rigged to prevent the sling from slipping or sliding along the<br />

load<br />

• When using a basket hitch, the legs of the sling should contain or support the load from the sides, above the center of gravity, so<br />

that the load remains under control<br />

• Slings should not be dragged on the floor or over an abrasive surface<br />

• In a choker hitch, the choke point should only be on the sling body, not on a splice or fitting<br />

• In a choker hitch, an angle of choke less than 120 degrees should not be used without reducing the rated load<br />

• Slings should not be constricted, bunched, or pinched by the load, hook, or any fitting<br />

• The load applied to the hook should be centered in the base (bowl) of the hook to prevent point loading on the hook, unless the<br />

hook is designed for point loading<br />

• Slings shall not be shortened or lengthened by knotting or twisting<br />

Environmental Considerations<br />

Temperature<br />

• Polyester and nylon webbing slings shall not be used in contact with an object or at temperatures in excess of 194°F (90°C) or<br />

below (-40°C)<br />

• Some synthetic yarns do not retain their published breaking strength above 140°F (60°C). The roundsling manufacturer should<br />

be consulted for the temperature range of roundslings made from other synthetic materials<br />

Chemically Active Environments<br />

• The strength of synthetic web slings can be degraded by chemically active environments. This includes exposure to chemicals in<br />

the form of solids, liquids, gases, vapors, or fumes. The sling manufacturer or qualified person should be consulted before slings<br />

are used in chemically active environments<br />

Sources:<br />

ASME B30.9 “Slings” Standard<br />

WSTDA “Web Sling and Tie-Down Association<br />

OSHA 1910.184 “Slings”<br />

OSHA 1926.251 “Rigging Equipment for material handling”<br />

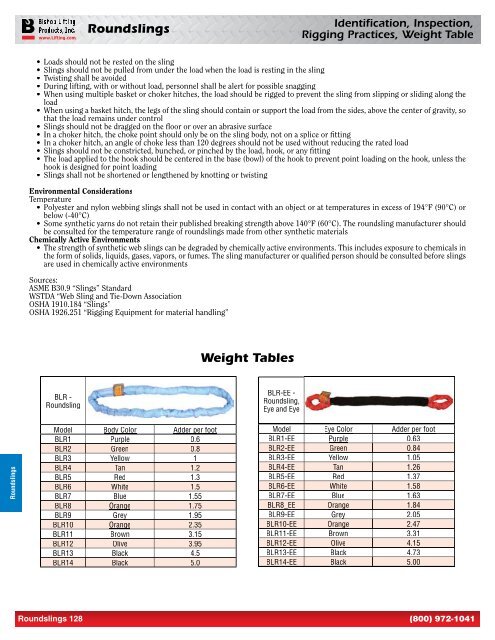

Weight Tables<br />

BLR -<br />

Roundsling<br />

BLR-EE -<br />

Roundsling,<br />

Eye and Eye<br />

Roundslings<br />

Model<br />

Body Color<br />

Adder per foot<br />

BLR1<br />

Purple 0.6<br />

BLR2 Green 0.8<br />

BLR3 Yellow 1<br />

BLR4 Tan 1.2<br />

BLR5 Red 1.3<br />

BLR6 White 1.5<br />

BLR7 Blue 1.55<br />

BLR8<br />

Orange 1.75<br />

BLR9<br />

Grey 1.95<br />

BLR10<br />

Orange 2.35<br />

BLR11 Brown 3.15<br />

BLR12 Olive 3.95<br />

BLR13 Black 4.5<br />

BLR14 Black 5.0<br />

Model<br />

Eye Color<br />

Adder per foot<br />

BLR1-EE<br />

Purple 0.63<br />

BLR2-EE Green 0.84<br />

BLR3-EE Yellow 1.05<br />

BLR4-EE Tan 1.26<br />

BLR5-EE Red 1.37<br />

BLR6-EE White 1.58<br />

BLR7-EE Blue 1.63<br />

BLR8_EE<br />

Orange 1.84<br />

BLR9-EE<br />

Grey 2.05<br />

BLR10-EE<br />

Orange 2.47<br />

BLR11-EE Brown 3.31<br />

BLR12-EE Olive 4.15<br />

BLR13-EE Black 4.73<br />

BLR14-EE Black 5.00<br />

Roundslings 128<br />

(800) 972-1041