MANmagazine Power 1/2015

With the MANmagazine by MAN Diesel & Turbo, we invite you to explore our universe of versatile technology. Join us on a world tour to Ecuador, Saudi Arabia, China and Switzerland to discover the fascinating and awe-inspiring details of cutting-edge power, marine and turbo applications.

With the MANmagazine by MAN Diesel & Turbo, we invite you to explore our universe of versatile technology. Join us on a world tour to Ecuador, Saudi Arabia, China and Switzerland to discover the fascinating and awe-inspiring details of cutting-edge power, marine and turbo applications.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

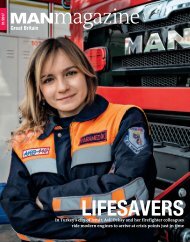

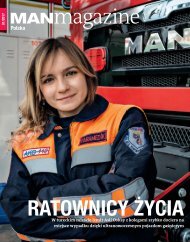

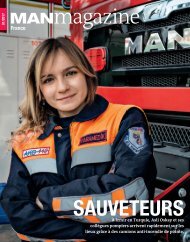

man magazine<br />

1/<strong>2015</strong><br />

Teamwork and trust is essential<br />

for a project of this magnitude.<br />

The rising cost of raw materials<br />

exerts pressure on<br />

manufacturing margins. By<br />

increasing production efficiency,<br />

MAN Diesel & Turbo<br />

production trains facilitate<br />

even expanding competitiveness<br />

for a leading PTA<br />

manufacturer in China.<br />

Protecting<br />

profitability<br />

The PTA plant operated by the Hengli<br />

Group is located in Dalian, in the<br />

south of China’s Liaoning Province.<br />

Foto: Photos: Eric Gregory Powell<br />

“With this<br />

partner, we<br />

have entered<br />

the league of<br />

mega PTA<br />

plants.”<br />

Dr. Lothar Wallscheid, VP Basic Industry<br />

segment, MAN Diesel & Turbo<br />

This radial gear stage compressor<br />

RG160 reflects the rapid turbine<br />

development of recent years.<br />

B<br />

ased in Dalian, China, the Hengli<br />

Group is one of the world’s major<br />

manufacturers of terephthalic<br />

acid (PTA), one of the key chemicals used in<br />

making plastics and textiles. Recently, the rising<br />

costs of raw materials have squeezed margins<br />

to the point that some of the company’s<br />

competitors have struggled to stay profitable.<br />

The Hengli Group, however, has managed to<br />

buck that trend. One of the key reasons for this<br />

business resilience is its decision to use MAN<br />

Diesel & Turbo production trains to upgrade<br />

the efficiency of its manufacturing facilities in<br />

Dalian. “With the Hengli Group as one of our<br />

major partners, we’ve entered the league of<br />

mega PTA plants,” says Dr. Lothar Wallscheid,<br />

VP Basic Industry segment at MAN Diesel &<br />

Turbo. “For the Dalian facility, we initially developed<br />

four machinery trains that became<br />

operational in 2013. As requirements grew,<br />

Hengli ordered another two identical trains –<br />

so far the world’s largest of their kind.”<br />

“Our trains are the beating heart of PTA<br />

production for Hengli,” adds Marc Groß from<br />

MAN Diesel & Turbo’s onsite team. “The train<br />

consists of a compressor that powers the production<br />

reactor, an axial expander used to recover<br />

energy from the production process, as<br />

well as a steam turbine and engine generator<br />

to produce electricity powering the plant.”<br />

Hengli’s PTA production facilities are of<br />

particular strategic importance to the company,<br />

because around 50% of the manufactured<br />

26 27