EIB Interface.QXD - Somfy

EIB Interface.QXD - Somfy

EIB Interface.QXD - Somfy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

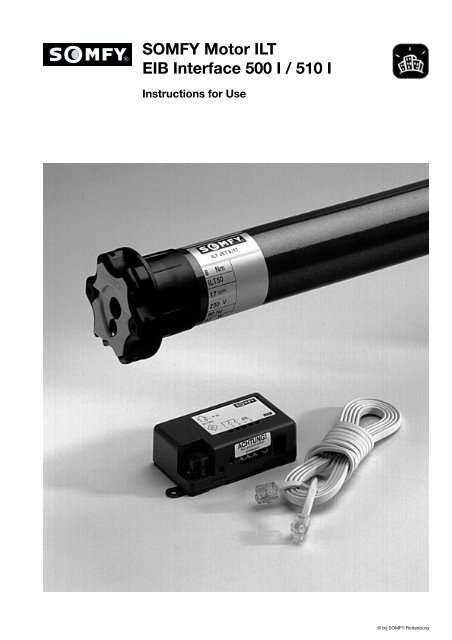

SOMFY Motor ILT<br />

<strong>EIB</strong> <strong>Interface</strong> 500 I / 510 I<br />

Instructions for Use<br />

© by SOMFY Rottenburg

SOMFY Motor ILT<br />

<strong>EIB</strong> <strong>Interface</strong> 500 I / 510 I<br />

Instructions for Use<br />

Dear Customer,<br />

Thank you for the trust you have vested in our products.<br />

With your purchase of this SOMFY Motor ILT you have<br />

acquired a product of highest quality made and equipped<br />

with state of the art technology.<br />

Before installing this product, please read these<br />

instructions thoroughly and observe all safety warnings<br />

that have been highlighted with the following symbols:<br />

Warning:<br />

High Voltage!<br />

Important Instructions<br />

Damage caused by non-observance of the safety and<br />

installation instructions in this manual or negligence are<br />

not covered by the warranty. SOMFY cannot and will not<br />

assume any liability for consequential damage or losses<br />

caused by negligence or non-observance of these<br />

installation instruction or local electrical and <strong>EIB</strong><br />

regulations and guidelines!<br />

Should you have any questions or problems with<br />

installing our product, call our technical support hotline:<br />

+49 180 52 52 131. Our support engineers will do their<br />

best to provide you with the support you need.<br />

Once again we would like to thank you for your trust in<br />

SOMFY products.<br />

SOMFY Feinmechanik und Elektrotechnik GmbH<br />

Felix-Wankel-Straße 50<br />

72108 Rottenburg/Neckar<br />

Table of Contents<br />

Advantages and Description of SOMFY Motor ILT ...................................................................................... 3<br />

1. Shaft Pre-Assembly .................................................................................................................................... 3<br />

1.1 Riveting the dog ................................................................................................................................ 4<br />

1.2 Drive types ........................................................................................................................................ 4<br />

2. Adjustment Instructions for SOMFY Motor ILT ........................................................................................ 4<br />

2.1 Final position adjustment with control box ...................................................................................... 4<br />

2.2 Upper final position adjustment ........................................................................................................ 4<br />

2.2.1 Change of direction .......................................................................................................................... 5<br />

2.3 Lower final position adjustment ........................................................................................................ 5<br />

2.4 User setting ...................................................................................................................................... 5<br />

2.4.1 Programming user setting with control box ...................................................................................... 5<br />

2.4.2 Initiating user setting ........................................................................................................................ 5<br />

3. Western Connector Pin Assignment and Attachment ............................................................................ 5<br />

3.1 Control line pin assignment (plan view) ............................................................................................ 5<br />

3.2 Attaching western connectors .......................................................................................................... 5<br />

4. Safety Systems ............................................................................................................................................ 6<br />

4.1 Trip-free dog .................................................................................................................................... 6<br />

4.2 Anti-intrusion system ........................................................................................................................ 7<br />

5. Technical Data ............................................................................................................................................ 8<br />

6. <strong>EIB</strong>-<strong>Interface</strong> 500 I/510 I ............................................................................................................................ 9<br />

6.1 Safety ................................................................................................................................................ 9<br />

6.2 Description ........................................................................................................................................ 9<br />

6.3 Installation ........................................................................................................................................ 9<br />

6.4 Connection ........................................................................................................................................ 9<br />

6.5 Commissioning ................................................................................................................................ 10<br />

6.6 Technical data / terminal connection plan ........................................................................................ 16<br />

2<br />

© by SOMFY Rottenburg

425<br />

SOMFY Motor ILT<br />

Instructions for Use<br />

Advantages of<br />

SOMFY Motor ILT:<br />

Final position adjustment<br />

The SOMFY Motor ILT is adjusted electronically through<br />

an extra-low voltage control line. It is not necessary to<br />

manually adjust the drive.<br />

==> Any necessary adjustments caused e. g. by a<br />

lengthening or shortening of the roller shutter can be<br />

made without opening the roller shutter box.<br />

Repeat accuracy of final positions<br />

==> SOMFY Motors are furnished with an exceptionally<br />

high degree of repeat accuracy (± 2 %).<br />

Final position recognition<br />

The electronic final position recognition does not<br />

mechanically stress the support material.<br />

==> Protects and prolongs the serviceable life of the roller<br />

shutter.<br />

Description of<br />

SOMFY Motor ILT<br />

SOMFY Motors are composed of single-phase capacitor<br />

motors, brakes, gears and an electromechanical final<br />

position shutoff system.<br />

Important information that requires your<br />

attention before installing the SOMFY Motor:<br />

CE conformity and interference suppression<br />

SOMFY Motors conform with the following European<br />

guidelines: 73/23/EEC and 89/336/EEC.<br />

SOMFY Motors in damp environments<br />

SOMFY drives are weather-proof protected in<br />

accordance with EN 60529. Observe VDE regulations, e.<br />

g. 0100, Sections 701, 702 and 737 as well as obligatory<br />

regulations and guidelines issued by local power<br />

suppliers and inspection authorities.<br />

Immobilisation detection<br />

SOMFY Motors are equipped with an integrated<br />

immobilization detection system that monitors the<br />

upwards movements of the roller shutters. The drive<br />

stops immediately.<br />

==> Protects the support material, e. g. when roller<br />

shutters are blocked by ice.<br />

1. Shaft Pre-Assembly<br />

Prefabricated spindles<br />

Slide the drive together with the suitable spindle adapter<br />

(1) and dog (2) into the spindle.<br />

Precision tubes<br />

Obstacle detection in conjunction with a trip-free dog<br />

(accessory)<br />

The obstacle detection system monitors the downward<br />

movement of the roller shutter and recognises a blocked<br />

shutter.<br />

==> The drive stops immediately and automatically<br />

provides clearance for the removal of the obstacle.<br />

1<br />

Unlatch the spindle on the drive end. Slide drive into the<br />

spindle so that the adapter cam fits into the jog.<br />

2<br />

Warning! Slide drive into the spindle. Never<br />

use a hammer or force of any kind!<br />

1.1 Riveting dog to precision tube<br />

3<br />

© by SOMFY Rottenburg

SOMFY Motor ILT<br />

Instructions for Use<br />

spindles<br />

● Adjust distance between dog and drive pursuant to L 2<br />

(see table under 1.2) and rivet or screw dog with 4<br />

rivets or screws.<br />

Self-tapping screws: 4 screws (5 x 10 mm)<br />

Blind rivets: 4 steel rivets (ÿ 5 mm steel)<br />

1.2 Drive types<br />

L 1<br />

L 2<br />

L 3<br />

Drive type L 1 L 2 L 3<br />

ILT Jet 8/17 613 590 605<br />

ILT Ceres 10/17 613 590 605<br />

ILT Atlas 15/17 613 590 605<br />

ILT Meteor 20/17 663 640 655<br />

ILT Apollo 30/17 663 640 655<br />

ILT Mariner 40/17 753 730 745<br />

2.1 Final position adjustment with control box<br />

● Ensure that the drive is properly and duly connected to<br />

a 230 VAC mains supply.<br />

Important:<br />

1. The installation, testing and<br />

commissioning of 230 V installations must be<br />

carried out by qualified electricians or<br />

electrical technicians. Observe ISO<br />

standards, especially DIN-VDE standards,<br />

and ensure that the electrician/electrical<br />

technician has received the installation<br />

instructions for each drive.<br />

2. Before activating the 230 VAC power<br />

supply, plug in and screw down the connector<br />

to the drive.<br />

● Connect the western connector on one end of the<br />

Programming buttons<br />

B C D<br />

A<br />

2. Adjustment Instructions for<br />

SOMFY Motor ILT<br />

Use the control box to adjust the final positions of the<br />

motors. Manual adjustment is not necessary.<br />

Each motor comes equipped with two brought out lines: a<br />

3-conductor cable for supply voltage and a 4-conductor<br />

control line.<br />

RJ 9<br />

connector<br />

LED<br />

control line to the control box.<br />

When control line and control box are properly connected<br />

and the power supply has been activated the red LED on<br />

the control box flashes quickly.<br />

2.2 Upper final position adjustment<br />

● Each motor comes equipped with two brought out lines: a<br />

3-cond<br />

● Raise roller shutter with the UP button (B) to the<br />

desired position.<br />

● When upper final position is reached, release the<br />

UP button (B).<br />

conductor<br />

control line<br />

SELV = 5 V<br />

power supply ~230 V<br />

earth = gr/ye<br />

phase = br<br />

neutral = bl<br />

Important:<br />

Do not raise shutter to<br />

mechanical limit.<br />

2-3 cm clearance is<br />

required!<br />

4<br />

© by SOMFY Rottenburg

SOMFY Motor ILT<br />

Instructions for Use<br />

2.2.1 Change of direction<br />

Should the roller shutter not move in the desired<br />

direction, e. g. upwards after pressing the UP button,<br />

press and hold the STOP button for approximately 2<br />

seconds.<br />

2.3 Lower final position<br />

adjustment<br />

● Set slide switch (A) to the<br />

position for adjusting the lower<br />

final position.<br />

● Lower roller shutter with the<br />

DOWN button (D) to the desired<br />

position.<br />

● When lower final position is reached, release the<br />

DOWN button (D).<br />

Important:<br />

It is possible to correct final position settings<br />

by simply repeating the above procedures.<br />

2.4 User setting (intermediate position)<br />

The user setting has now been saved.<br />

2.4.2 Initiating user setting<br />

The user setting can be initiated when the roller shutter is<br />

stopped in any position by pressing the STOP button (C).<br />

3. Western Connector Pin<br />

UP (red)<br />

PE (blue)<br />

+5 V DC (white)<br />

DOWN (yellow)<br />

Assignment and Attachment<br />

3.1 Control line pin assignment (plan view)<br />

Depending on the cable type the conductors may also be<br />

colour-coded as follows: black, red, green, yellow.<br />

3.2 Attaching western connectors<br />

Use a pair of crimping pliers to strip and shorten a control<br />

The Motor allows you to program the roller shutter with a<br />

user setting. This means that in addition to the upper and<br />

lower final positions you have a user-programmable<br />

intermediate position where the roller shutter<br />

automatically stops when you press the STOP button and<br />

the drive is not running.<br />

2.4.1 Programming user setting with control box<br />

Set slide switch (A) on the control box to the middle<br />

position. Your control box now functions like a standard<br />

remote control.<br />

Press the DOWN button (D) and the roller shutter travels<br />

to the lower final position and automatically stops.<br />

red<br />

blue<br />

white<br />

yellow<br />

colour marking<br />

control line cable<br />

red<br />

blue<br />

white<br />

yellow<br />

Press the UP button (B) and the roller shutter travels to<br />

the upper final position and automatically stops.<br />

To stop the roller shutter simply press the STOP button<br />

(C).<br />

● Stop the roller shutter at the desired user setting<br />

position.<br />

● When the roller shutter has fully stopped at that<br />

position, press and hold the STOP button (C) for 5<br />

seconds.<br />

line cable and to attach a western connector.<br />

Important:<br />

Ensure that the western connectors are mounted<br />

inversely to each other. Otherwise the pin assignment<br />

of the connectors will no<br />

longer correspond properly (use colour marking on<br />

the control line for orientation).<br />

5<br />

© by SOMFY Rottenburg

SOMFY Motor ILT<br />

Instructions for Use<br />

4. Safety Systems<br />

„Right“ trip-free dog<br />

4.1 Trip-free dog<br />

The SOMFY Motor ILT together with the SOMFY trip-free<br />

dog is equipped with an obstacle recognition system. If<br />

the roller shutter run into an obstacle, the drive stops<br />

automatically and clearance is provided to remove the<br />

obstacle.<br />

Depending on the structure of the support material,<br />

observe that a „right“ or „left“ version of the trip-free dog<br />

is required.<br />

„Left“ trip-free dog<br />

Please note:<br />

Trip-free dogs and the anti-intrusion system can only be<br />

used together with an <strong>EIB</strong> <strong>Interface</strong> 510 I in a roller shutter<br />

system.<br />

LT 50 trip-free dog (reinforced) List No.<br />

Left trip-free dog 9706003<br />

Right trip-free gog 9706004<br />

6<br />

© by SOMFY Rottenburg

SOMFY Motor ILT<br />

Instructions for Use<br />

4.2 Anti-intrusion system<br />

The electromagnetic brake integrated in each SOMFY<br />

Motor ILT prevents the shutter spindle from rotating when<br />

an attempt is made to manually push up the roller shutter.<br />

The anti-intrusion system applies a downward force on<br />

the roller shutter. The shutter can no longer be moved<br />

and wound around the spindle by hand. The SOMFY<br />

Motor ILT and the SOMFY anti-intrusion system form an<br />

effective safety package.<br />

Bolt<br />

List No.<br />

Two-membered bolt; distance a: 80-130 mm<br />

Exemplary application:<br />

standard profiles in porch element 9700209<br />

Three-membered bolt; distance a: 120-170 mm<br />

Exemplary application:<br />

standard profiles in porch element<br />

and 24 and 30 slat prefabricated boxes. 9700210<br />

Four-membered bolt; distance a: 160-210 mm<br />

Exemplary application:<br />

stand.-profiles in 30 and 36 cm prefabricated boxes 9700211<br />

Two-membered for mini-profiles;<br />

distance a: 80-130 mm. Exemplary application:<br />

Mini-profile in porch element 9700212<br />

Three-membered for mini-profiles;<br />

Abstand a: 120-170 mm. Exemplary application:<br />

Mini-profile in porch element 9700213<br />

The choice of a suitable locking bolt is dependent upon<br />

the roller shutter system in use. The distance (a) between<br />

the spindle centre and the first shutter slat is decisive.<br />

The first shutter slat should still be in the runners when<br />

the roller shutter is in the lower final position.<br />

a<br />

Locking rings<br />

List No.<br />

for 60 wrench<br />

Exemplary application:<br />

octagonal spindle 9700215<br />

(Two locking rings required per locking bolt.)<br />

Please note:<br />

Trip-free dogs and the anti-intrusion system can only be<br />

used together with an <strong>EIB</strong> <strong>Interface</strong> 510 I in a roller shutter<br />

system. By integrating the anti-intrusion system to an<br />

existing roller shutter unit the slat roll diameter increases.<br />

7<br />

© by SOMFY Rottenburg

SOMFY Motor ILT<br />

Instructions for Use<br />

5. Technical Data<br />

ILT Jet<br />

8/17<br />

ILT Ceres<br />

10/17<br />

ILT Atlas<br />

15/17<br />

ILT Meteor<br />

20/17<br />

ILT Apollo<br />

30/17<br />

ILT Mariner<br />

40/17<br />

Safety class<br />

IP protection classification<br />

Rated torque<br />

Rated rotational speed<br />

Rated voltage<br />

Rated output<br />

Current consumption<br />

Frequency<br />

Rated consumption<br />

Pick-up time<br />

Ultimate interruption<br />

capacity<br />

Base adapter<br />

for 50 mm spindle<br />

Duty type as per VDE 0530<br />

Product standard<br />

Conformity<br />

II<br />

IP 44<br />

8 Nm 10 Nm 15 Nm 20 Nm 30 Nm 40 Nm<br />

17 rpm<br />

~230 VAC (207 V – 244 V)<br />

90 W 120 W 140 W 160 W 240 W 270 W<br />

0,45 A 0,5 A 0,65 A 0,75 A 1,1 A 1,2 A<br />

50 Hz<br />

90 W 120 W 140 W 160 W 240 W 270 W<br />

4 min.<br />

300 rotations<br />

50 x 1.5 mm<br />

intermittent operation tr = 40% / make-up time tB = 4 min.<br />

VDE 0700 Section 238<br />

CE pursuant to EN 50081-1 und EN 50082-1<br />

Control line<br />

Control line type AWG26 (4 x 0.12 mm 2 )<br />

Connector type western connector Typ RJ9 4/4<br />

Length between drive<br />

and control box<br />

10 m max.<br />

8<br />

© by SOMFY Rottenburg

<strong>EIB</strong>-<strong>Interface</strong> 500 I/510 I<br />

Instructions for Use<br />

6. <strong>EIB</strong>-<strong>Interface</strong> 500 I/510 I<br />

6.1 Safety<br />

The installation, testing and commissioning of<br />

<strong>EIB</strong>s and <strong>EIB</strong> bus devices must be carried out<br />

by qualified electricians or electrical<br />

technicians. Observe ISO standards,<br />

especially DIN-VDE standards, as well as the<br />

installation instructions in the ZVEI/ZVEH*<br />

<strong>EIB</strong>-Manual when laying and connecting<br />

leads and cables for bus and peripheral<br />

devices.<br />

6.3 Installation<br />

Before installing the <strong>EIB</strong> interface and the<br />

Motor, ensure that the drive’s 230 VAC mains<br />

connection cable is disconnected from the <strong>EIB</strong><br />

interface terminals.<br />

The <strong>EIB</strong> interface can be surface or flush-mounted.<br />

Flush-mounting<br />

We recommend the use of a flush mounting box 107 x<br />

107 x 57 mm (e. g. Kaiser). Remove the mounting eyelets<br />

(1) and insert the <strong>EIB</strong> interface into the flush-mounting<br />

box.<br />

6.2 Description<br />

IP 20<br />

5V / 29V<br />

1 2 3 4 5<br />

6.4 Connection<br />

1 mounting eyelet 4 programming LED<br />

2 <strong>EIB</strong> bus terminal 5 programming button<br />

3a terminals 1-5, 6 terminal for control line<br />

connection-side<br />

Motor<br />

3b terminals 1-5,<br />

(western socket)<br />

screw-clamp-side<br />

Set terminals 1-5 (3) only potential-free!<br />

Pin assignment:<br />

• bus terminal (2): bus cable conductors<br />

• terminals (3) 1-3: conventional switch (page 7)<br />

• terminals (3) 4+5: window contact<br />

• western socket (6): Motor control line<br />

9<br />

© by SOMFY Rottenburg

<strong>EIB</strong>-<strong>Interface</strong> 500 I/510 I<br />

Instructions for Use<br />

6.5 Commissioning<br />

Operate <strong>EIB</strong> interface in accordance<br />

with the specific technical data!<br />

To program the physical address, press the programming<br />

button (5). Programming LED (4) illuminates.<br />

Recommendation: Use a screwdriver (see illustration) to<br />

access the programming button (5).<br />

Prior to commissioning your <strong>EIB</strong> interface, program the<br />

physical address, group address, parameters and user<br />

application in the ETS. You will find the necessary <strong>EIB</strong><br />

actuator product data in the product data base in the<br />

product family directory „roller shutters“ and the product<br />

type „Motor“.<br />

The <strong>EIB</strong> interface is programmed through the ETS while<br />

commissioning by simply applying bus voltage to the<br />

system. 230V operating voltage is not necessary for<br />

programming.<br />

<strong>EIB</strong> <strong>Interface</strong> 500 I Communication Objects<br />

No. Name Function Description<br />

0 roller shutter position show 0 - 100 % Indicates actual roller shutter position. The shutter<br />

position can either be communicated to the bus<br />

periodically or when the shutter stops after moving.<br />

1 obstacle recognition UP show YES / NO Indicates an obstacle (e. g. frozen shutter) while the<br />

roller shutter is moving upwards (together with a SOMFY<br />

trip-free). An obstacle triggers the transmission of „1“,<br />

the signal can be displayed through a suitable actuator<br />

(display, binary output).<br />

2 obstacle recognition show YES / NO Indicates an obstacle while the roller shutter is moving<br />

DOWN<br />

downwards (together with a SOMFY trip-free).<br />

An obstacle triggers the transmission of „1“.<br />

3 window contact status show open / closed Indicates the actual status of the window contact. If the<br />

window parameter „window contact (external/local)“ is<br />

set to „local“, all Motor movements can be stopped via a<br />

local window contact. If the window is open, a „1“ is<br />

transmitted and the Motor is automatically disabled. If<br />

the window is closed, a „0“ is transmitted and the Motor<br />

is re-enabled.<br />

4 move command UP / DOWN A message to this object causes the drive to actuate.<br />

„0“ = upper final position, „1“ = lower final position.<br />

5 STOP command STOP A message to this object causes the drive to stop.<br />

10<br />

© by SOMFY Rottenburg

<strong>EIB</strong>-<strong>Interface</strong> 500 I/510 I<br />

Instructions for Use<br />

Nr. Name Function Description<br />

6 inhibit move commands YES / NO If the window parameter „window contact<br />

(external/local)“ is set to „external“, all Motor<br />

movements can be stopped via a local window contact.<br />

A „1“ stops the Motor automatically, a „0“ re-enables<br />

the Motor.<br />

7 safety priority command A „1“ generates a move command to the programmable<br />

safety position (upper or lower final position). The<br />

system is deactivated until a „0“ re-enables the system.<br />

If the parameter „receive safety signal (static/cyclic)“ is<br />

set to „cyclic“, the system can only operate if a „0“ is<br />

received periodically. If the required „0“ is not received<br />

within the specific period of time, the drive automatically<br />

move to the safety position.<br />

8 user setting move / save Drive moves to programmed user setting OR saves the<br />

actual position as the user setting when the system<br />

receives a message from this object. The value in the<br />

received message is not important. The actual value of<br />

object no. 9 (ìuser setting modeî) determines which<br />

function is performed.<br />

9 user setting mode save ON / OFF Selection of function for object no. 8. A moving<br />

command (i.e. object value = „0“) moves the drive to<br />

user setting if object no. 8 is engaged. If the save mode<br />

is enabled (i.e. object value = „1“), the drive saves the<br />

actual roller shutter position as the new user setting, if<br />

object no. 8 is engaged.<br />

10 sunshade position move Drive moves to programmed sun position if a „1“ is<br />

received and the roller shutter is above the sun position.<br />

The sun position is set during initial installation. A „0“<br />

moves the drive either to the upper final position or the<br />

drive ignores the command.<br />

11<br />

© by SOMFY Rottenburg

<strong>EIB</strong>-<strong>Interface</strong> 500 I/510 I<br />

Instructions for Use<br />

<strong>EIB</strong> <strong>Interface</strong> 500 I Parameter Descriptions<br />

(Factory settings are in italics!)<br />

Parameter Settings Description<br />

❐ Safety<br />

safety position upper final position Drive moves to upper final position.<br />

lower final position Drive moves to lower final position<br />

receive safety message static Drive moves to programmed safety position when noncyclically<br />

transmitted safety message is not received.<br />

cyclic<br />

Drive moves to programmed safety position when<br />

cyclically transmitted safety message is received.<br />

safety monitor cycles 14 Monitoring period for receiving cyclic safety message.<br />

in 5 sec. [1..63]<br />

The monitoring time must be greater than the cyclic<br />

period of the transmitting element.<br />

❐ Window contact<br />

window contact external Drive disabled through message to Object no. 8.<br />

local<br />

Locally connected window contact disables drive.<br />

window contact NO contact Disenabled by opening contact.<br />

NO contact<br />

Disenabled by closing contact.<br />

window contact: transmit value YES The actual window status indicated through object<br />

no. 3.<br />

NO<br />

Window status not indicated.<br />

❐ Roller shutter<br />

send roller shutter position YES Actual roller shutter position is transmitted<br />

(0% - 100%).<br />

NO<br />

Roller shutter position is not transmitted.<br />

send periodically YES Roller shutter position updated every second.<br />

NO<br />

Roller shutter position updated when drive stops.<br />

❐ Sunshade position<br />

sun position (0% - 100%) 80% A „1“ moves the drive to the programmed sun position.<br />

open YES A „0“ move the drive from the programmed sun<br />

position to the upper final position.<br />

NO<br />

The drive remains in the sun position.<br />

❐ Obstacle recognition<br />

alarm YES Alarm signal issued if an upward movement obstacle<br />

upward movement obstacle<br />

is detected.<br />

NO<br />

No alarm signal if an upward movement obstacle<br />

is detected.<br />

alarm YES Alarm signal issued if a downward movement obstacle<br />

downward movement obstacle<br />

is detected.<br />

NO<br />

No alarm signal if a downward movement obstacle is<br />

detected.<br />

12<br />

© by SOMFY Rottenburg

<strong>EIB</strong>-<strong>Interface</strong> 500 I/510 I<br />

Instructions for Use<br />

<strong>EIB</strong> <strong>Interface</strong> 510 I Communication Objects<br />

No. Name Function Description<br />

0 roller shutter position show 0% - 100% Indication of actual roller shutter position in %. The<br />

position can be communicated to the bus periodically or<br />

only after the roller shutter has come to a complete stop.<br />

1 lower final position show YES / NO Indication of lower final position. When the drive reaches<br />

the lower final position, a „1“ is transmitted. When the<br />

drive leaves that position, a „0“ is transmitted.<br />

2 upper final position show YES / NO Indication of upper final position. When the drive<br />

reaches the upper final position, a „1“ is transmitted.<br />

When the drive leaves that position, a „0“ is transmitted.<br />

3 window contact status show open / closed Indicates the actual status of the window contact. If the<br />

window parameter „window contact (external/local)“ is<br />

set to „local“, all Motor movements can be stopped via a<br />

local window contact. A „1“ commands the Motor to<br />

automatically move to the disabled position (upper or<br />

lower final position, STOP or no move command).<br />

Further drive commands are ignored. A „0“ re-enables<br />

the Motor system.<br />

4 obstacle recognition show YES / NO Indicates an obstacle (e. g. frozen shutter) while the<br />

roller shutter is moving upwards or downwards (together<br />

with a SOMFY trip-free). An obstacle triggers the<br />

transmission of „1“ and disables the drive. A „0“ reenables<br />

the drive.<br />

5 alarm show YES / NO If the closed roller shutter is opened without a moving<br />

command (e. g. intrusion), a „1“ is transmitted. The<br />

alarm signal is reset with „0“. The alarm signal is only<br />

active at 85% - 100%.<br />

13<br />

© by SOMFY Rottenburg

<strong>EIB</strong>-<strong>Interface</strong> 500 I/510 I<br />

Instructions for Use<br />

No. Name Function Description<br />

6 move command UP / DOWN A „0“ message commands the drive to move to the<br />

upper final position, a „1“ message to the lower final<br />

position.<br />

7 STOP command STOP A message to this object causes the drive to stop.<br />

8 disable move command YES / NO If the window parameter „window contact<br />

(external/local)“ is set to „external“, all Motor<br />

movements can be stopped through this object. A „1“<br />

commands the Motor to automatically move to the<br />

disabled position (upper or lower final position, STOP or<br />

no move command). Further drive commands are<br />

ignored. A „0“ re-enables the Motor system.<br />

9 safety priority command A „1“ generates a move command to the programmable<br />

safety position (upper or lower final position). The Motor<br />

system is deactivated until a „0“ re-enables the system.<br />

10 move roller shutter move 0-100% The roller shutter can be moved to any position with<br />

position a 1 byte message (0% - 100%).<br />

<strong>EIB</strong> <strong>Interface</strong> 510 I Parameter Description<br />

(Factory settings are in italics)<br />

Parameter Settings Description<br />

❐ Safety<br />

safety position upper final position The drive moves to the upper final position.<br />

lower final position The drive moves to the lower final position.<br />

STOP<br />

The drive stops.<br />

no move command The drive moves up or down when this command is<br />

issued. Any further commands are blocked.<br />

receive safety signal static The drive moves to the programmed safety position if a<br />

non-cyclic safety message is received.<br />

cyclic<br />

The drive moves to the programmed safety position if a<br />

cyclic safety message is received.<br />

safety monitoring cycle 14 Überwachungszeitraum zum Empfang eines zyklischen<br />

in 5 seconds [1..63]<br />

Sicherheitstelegrammes. Die Überwachungszeit muß<br />

größer eingestellt werden, als die Zykluszeit des<br />

sendenden Teilnehmers.<br />

14<br />

© by SOMFY Rottenburg

<strong>EIB</strong>-<strong>Interface</strong> 500 I/510 I<br />

Instructions for Use<br />

Parameter Setting Description<br />

❐ Window contact<br />

window contact extern Drive is disabled with a message to object no. 8. The<br />

locally connected window contact disables the drive.<br />

local<br />

Opening the contact disables the drive.<br />

window contact NC contact Opening the contact disables the drive.<br />

NO contact<br />

Closing the contact disables the drive.<br />

window contact: send value YES The actual window contact status is indicated<br />

through object no. 3<br />

NO<br />

The actual window contact status is not<br />

indicated.<br />

blocking position upper final position The drive moves to the upper final position.<br />

lower final position The drive moves to the lower final position.<br />

STOP<br />

The drive stops.<br />

no move command The drive moves up or down when this<br />

command is issued. Any further commands<br />

are blocked.<br />

❐ Roller shutter<br />

send roller shutter position YES The actual roller shutter position is transmitted<br />

(0% - 100%).<br />

NO<br />

The roller shutter position is not transmitted.<br />

send periodically YES The updated roller shutter position is transmitted<br />

every second.<br />

NO<br />

The roller shutter position is transmitted after<br />

drive has come to a complete stop.<br />

❐ Sunshade position<br />

alarm YES Alarm signal is issued if an upward/downward<br />

movement obstacle is detected.<br />

NO<br />

No obstacle alarm signal is issued.<br />

15<br />

© by SOMFY Rottenburg

SOMFY Motor ILT<br />

<strong>EIB</strong>-<strong>Interface</strong> 500 I/510 I<br />

Instructions for Use<br />

6.6 Technical data / terminal connection plan<br />

<strong>EIB</strong>-<strong>Interface</strong> 500 I List No.: 1860020<br />

<strong>EIB</strong>-<strong>Interface</strong> 510 I List No.: 1860021<br />

Dimensions<br />

85 x 45 x 26 mm<br />

<strong>EIB</strong> bus current<br />

consumption<br />

< 10 mA DC<br />

IP rating IP 20<br />

Ambient conditions clean environment<br />

Operating temp. range 0° – +45°C<br />

Storage temperature -20 – +70°C<br />

range<br />

max. line length for conventional<br />

manipulator<br />

10 m<br />

max. drive length for window<br />

contact<br />

10 m<br />

max. line length for window<br />

contact<br />

10 m<br />

recommended cable type<br />

for control line I-Y(St)Y 2 x 2 x 0.8<br />

recommended cable type<br />

for control line of drive AWG 26 (4 x 0.12 mm 2 )<br />

Compliance with EMC- guidelines in accordance<br />

guidelines<br />

with <strong>EIB</strong> Manual Version<br />

2.21<br />

-conformity EN 60730<br />

DIN EN 50081-1<br />

(emitted interference)<br />

DIN EN 50082-1<br />

( interference immunity)<br />

terminal connection plan<br />

RJ 9 connector<br />

<strong>EIB</strong><br />

mains<br />

230 VAC<br />

1 2 3 4 5<br />

local<br />

manipulator<br />

3 x 0.75<br />

window contact<br />

Antrieb<br />

control line 4 x 0.12<br />

Parallel connection of one to three drives<br />

using western connector/western connector adapter<br />

mains 230 VAC mains 230 VAC mains 230 VAC<br />

western connector<br />

control line 4 x 0.12<br />

1 2 3 4 5<br />

<strong>EIB</strong><br />

window contact<br />

local<br />

manipulator<br />

All rights reserved to alter specifications without prior notice SOMFY SAS, capital 20.000.000 euros, RCS Bonneville<br />

303.970.230 © SOMFY / COM ref COM020229<br />

In Germany:<br />

Feinmechanik und Elektrotechnik GmbH<br />

Felix-Wankel-Straße 50 . D-72108 Rottenburg/Neckar<br />

Postfach 186 . D-72103 Rottenburg/Neckar<br />

Telefon (0 74 72) 930-0 . Telefax (0 74 72) 930-9<br />

Internet: http://www.somfy.de<br />

In Austria:<br />

SOMFY Feinmechanik und Elektrotechnik GmbH<br />

Johann-Herbst-Straße 23 . A-5061 Elsbethen-Glasenbach<br />

Telefon ++43 (0)662 62 53 08 . Telefax ++43 (0)662 62 53 08 22<br />

Internet: http://www.somfy.at