SOLUTIONS 13 - Moeller Electric Parts

SOLUTIONS 13 - Moeller Electric Parts

SOLUTIONS 13 - Moeller Electric Parts

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Operation<br />

in Minneapolis<br />

The situation:<br />

Siyeza Creative Foods, LLC is a company based<br />

in Minneapolis, USA, that produces all types of<br />

pasta for deep frozen products. A <strong>Moeller</strong><br />

touch display-PLC (HMI-PLC) controls the<br />

production machine. All signals are passed to<br />

the HMI-PLC via a XI/ON remote I/O with a<br />

Profibus gateway. Other <strong>Moeller</strong> components<br />

include five frequency inverters as well as<br />

RMQ control circuit devices.<br />

The fault:<br />

Normally the machine is switched on and<br />

started up around 7.00 am every morning. The<br />

screen, however, stayed dark several times,<br />

and the touch display PLC only booted up<br />

after the third or fourth power up attempted.<br />

Even after the devices were replaced and the<br />

Cable Train Operation<br />

at Airport Toronto<br />

The situation:<br />

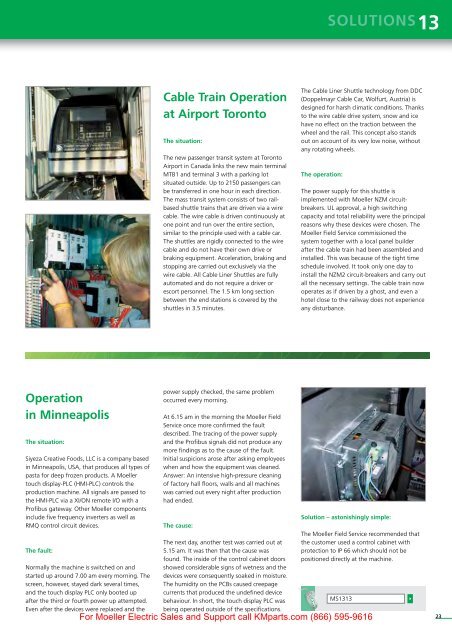

The new passenger transit system at Toronto<br />

Airport in Canada links the new main terminal<br />

MTB1 and terminal 3 with a parking lot<br />

situated outside. Up to 2150 passengers can<br />

be transferred in one hour in each direction.<br />

The mass transit system consists of two railbased<br />

shuttle trains that are driven via a wire<br />

cable. The wire cable is driven continuously at<br />

one point and run over the entire section,<br />

similar to the principle used with a cable car.<br />

The shuttles are rigidly connected to the wire<br />

cable and do not have their own drive or<br />

braking equipment. Acceleration, braking and<br />

stopping are carried out exclusively via the<br />

wire cable. All Cable Liner Shuttles are fully<br />

automated and do not require a driver or<br />

escort personnel. The 1.5 km long section<br />

between the end stations is covered by the<br />

shuttles in 3.5 minutes.<br />

power supply checked, the same problem<br />

occurred every morning.<br />

At 6.15 am in the morning the <strong>Moeller</strong> Field<br />

Service once more confirmed the fault<br />

described. The tracing of the power supply<br />

and the Profibus signals did not produce any<br />

more findings as to the cause of the fault.<br />

Initial suspicions arose after asking employees<br />

when and how the equipment was cleaned.<br />

Answer: An intensive high-pressure cleaning<br />

of factory hall floors, walls and all machines<br />

was carried out every night after production<br />

had ended.<br />

The cause:<br />

The next day, another test was carried out at<br />

5.15 am. It was then that the cause was<br />

found. The inside of the control cabinet doors<br />

showed considerable signs of wetness and the<br />

devices were consequently soaked in moisture.<br />

The humidity on the PCBs caused creepage<br />

currents that produced the undefined device<br />

behaviour. In short, the touch display PLC was<br />

being operated outside of the specifications.<br />

<strong>SOLUTIONS</strong><strong>13</strong><br />

The Cable Liner Shuttle technology from DDC<br />

(Doppelmayr Cable Car, Wolfurt, Austria) is<br />

designed for harsh climatic conditions. Thanks<br />

to the wire cable drive system, snow and ice<br />

have no effect on the traction between the<br />

wheel and the rail. This concept also stands<br />

out on account of its very low noise, without<br />

any rotating wheels.<br />

The operation:<br />

The power supply for this shuttle is<br />

implemented with <strong>Moeller</strong> NZM circuitbreakers.<br />

UL approval, a high switching<br />

capacity and total reliability were the principal<br />

reasons why these devices were chosen. The<br />

<strong>Moeller</strong> Field Service commissioned the<br />

system together with a local panel builder<br />

after the cable train had been assembled and<br />

installed. This was because of the tight time<br />

schedule involved. It took only one day to<br />

install the NZM2 circuit-breakers and carry out<br />

all the necessary settings. The cable train now<br />

operates as if driven by a ghost, and even a<br />

hotel close to the railway does not experience<br />

any disturbance.<br />

Solution – astonishingly simple:<br />

The <strong>Moeller</strong> Field Service recommended that<br />

the customer used a control cabinet with<br />

protection to IP 66 which should not be<br />

positioned directly at the machine.<br />

MS<strong>13</strong><strong>13</strong><br />

For <strong>Moeller</strong> <strong>Electric</strong> Sales and Support call KMparts.com (866) 595-9616<br />

23