Inconel 600.pdf

Inconel 600.pdf

Inconel 600.pdf

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

MMPDS-01<br />

31 January 2003<br />

6.3.1 HASTELLOY X<br />

6.3.1.0 Comments and Properties — Hastelloy X is a nickel-base alloy used for combustorliner<br />

parts, turbine-exhaust weldments, afterburner parts, and other parts requiring oxidation resistance and<br />

moderately high strength above 1450EF. It is not hardenable except by cold working and is used in the<br />

solution-treated (annealed) condition. Hastelloy X is available in all the usual mill forms.<br />

Hastelloy X is somewhat difficult to forge; forging should be started at 2150EF to 2200EF and<br />

continued as long as the material flows freely. It should be in the annealed condition for optimum cold<br />

forming, and severely formed detail parts should be solution treated at 2150EF for 7 to 10 minutes and cooled<br />

rapidly after forming. Machinability of Hastelloy X is similar to that of austenitic stainless steel; the alloy<br />

is tough and requires low cutting speeds and ample cutting fluids. Hastelloy X can be resistance or fusion<br />

welded or brazed; large or complex fusion weldments require stress relief at 1600EF for 1 hour. Hastelloy<br />

X has good oxidation resistance up to 2100EF. It age hardens somewhat during long exposure between<br />

1200EF and 1800EF.<br />

Some material specifications for Hastelloy X are presented in Table 6.3.1.0(a). Room-temperature<br />

mechanical and physical properties for Hastelloy X sheet are presented in Table 6.3.1.0(b). AMS 5754 does<br />

not specify tensile properties for bars and forgings. Figure 6.3.1.0 shows the effect of temperature on<br />

physical properties.<br />

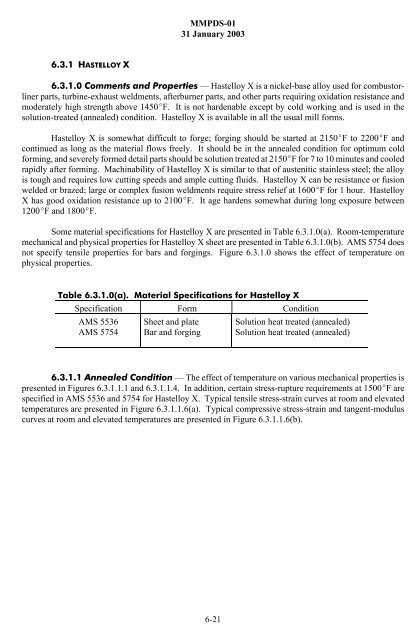

Table 6.3.1.0(a). Material Specifications for Hastelloy X<br />

Specification Form Condition<br />

AMS 5536<br />

AMS 5754<br />

Sheet and plate<br />

Bar and forging<br />

Solution heat treated (annealed)<br />

Solution heat treated (annealed)<br />

6.3.1.1 Annealed Condition — The effect of temperature on various mechanical properties is<br />

presented in Figures 6.3.1.1.1 and 6.3.1.1.4. In addition, certain stress-rupture requirements at 1500EF are<br />

specified in AMS 5536 and 5754 for Hastelloy X. Typical tensile stress-strain curves at room and elevated<br />

temperatures are presented in Figure 6.3.1.1.6(a). Typical compressive stress-strain and tangent-modulus<br />

curves at room and elevated temperatures are presented in Figure 6.3.1.1.6(b).<br />

6-21