Measuring - sensitec

Measuring - sensitec

Measuring - sensitec

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

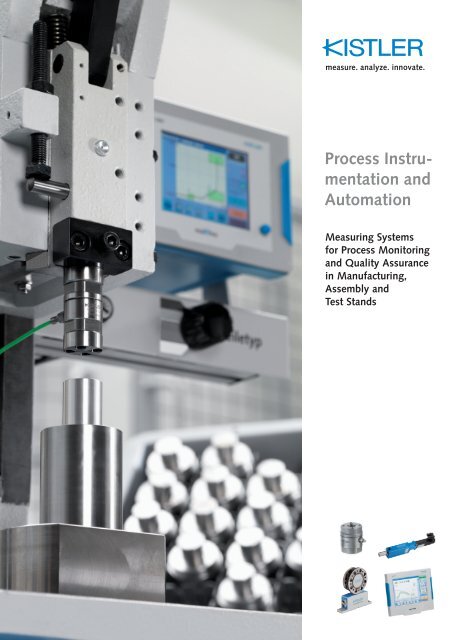

Process Instrumentation<br />

and<br />

Automation<br />

<strong>Measuring</strong> Systems<br />

for Process Monitoring<br />

and Quality Assurance<br />

in Manufacturing,<br />

Assembly and<br />

Test Stands

Kistler –<br />

Your Partner for Efficiency and Quality<br />

Sensors and systems for measuring forces<br />

and torques, analyzing force-displacement<br />

and force-time characteristics, and documenting<br />

quality data during assembly and<br />

product testing are just a few elements<br />

of the solutions for the sector provided<br />

by Kistler Instruments AG. From our<br />

headquarters in Switzerland, we supply<br />

assembly and testing technology as<br />

well as specific sensors and monitoring<br />

systems for combustion engines, automotive<br />

engineering, plastics processing and<br />

biomechanical engineering.<br />

Year after year the company invests 10 %<br />

of its sales in R&D to facilitate technically<br />

innovative yet cost-effective state of the<br />

art solutions.<br />

With a combined workforce of around<br />

1 050, the Kistler Group is the world<br />

market leader in dynamic measurement<br />

technology. Twenty three group companies<br />

worldwide and more than 30<br />

distributors ensure close contact with the<br />

customer, individual application engineering<br />

support and short lead times.<br />

Kistler’s core competence lies in the development,<br />

production and implementation<br />

of sensors for pressure, force and acceleration<br />

measurement. Kistler electronic<br />

systems and expertise used for conditioning<br />

measurement signals allow analysis,<br />

control and optimization of physical processes<br />

as well as enhancement of product<br />

quality for the manufacturing industry.<br />

2 www.kistler.com

Contents<br />

A Clear Focus on 100 % Quality<br />

Process Monitoring in Assembly and Testing Technology 6<br />

XY-Monitors for Assembly and Testing Technology 8<br />

Functionality of XY-Monitors 10<br />

Process Monitoring with NC Joining Systems in Assembly Technology<br />

Compact NC Joining Systems and General-Purpose Manual Workstation 16<br />

Kistler Measurement Technology<br />

Basics of Piezoelectric Measurement Technology 18<br />

Basics of Strain Gage Measurement Technology 27<br />

Basics of Calibration 31<br />

Accuracy Evaluation 36<br />

Using Force and Torque Measurement Technology<br />

Monitoring Press-Fitting Processes 38<br />

Testing Rotary and Spring-Loaded Switches 41<br />

Monitoring Assembly of the Steering Column 44<br />

Assembling High-Frequency Connectors 48<br />

Fully Automated 100 % Testing of Gearboxes 50<br />

Gearbox Endurance Test for Landing Flap Systems 52<br />

Application Example of NC Joining Systems<br />

Fast, Flexible and Firm Joining 54<br />

NCFT for Lowest Joining and Test Forces using<br />

Wireless Signal Transmission 56<br />

Other Force and Torque Applications in Manufacturing,<br />

Assembly and Testing 58<br />

Product Range and Details<br />

Selection Criteria for Force Sensors 60<br />

Selection Criteria for Torque Sensors 64<br />

Kistler CAD Download Service 65<br />

Selection Criteria for Charge Amplifiers 66<br />

Selection Criteria for XY-Monitors 67<br />

<strong>Measuring</strong>: Sensors 68<br />

Amplifying: Charge and <strong>Measuring</strong> Amplifiers 116<br />

Analyzing: Monitoring and 124<br />

Documentation Systems<br />

Manufacturing: Electromagnetic 132<br />

NC Joining Systems<br />

Connecting: Cables 145<br />

Accessories 156<br />

Technical Literature 180<br />

Product Overview by Type Numbers 181<br />

www.kistler.com 3

A Clear Focus on 100 % Quality<br />

QUALITY JOINING powered by Kistler is the mark of 100 % quality when it comes to joining and assembly.<br />

It stands for zero-defect production with force and torque curves, for process and quality monitoring on the<br />

basis of force and torque, irrespective of the workpiece, machine, tools or jigs and fixtures.<br />

The ever increasing demands for quality<br />

and precision in industrial manufacturing<br />

and tight competition call for the whole<br />

production chain to be optimized and<br />

checked. Furthermore, companies must<br />

meet the continuously rising quality standards<br />

within the context of a zero-defect<br />

strategy. The integrated process monitoring<br />

system checks, during the respective<br />

process step, has proven to be the most<br />

economical solution towards quality<br />

assurance.<br />

The use of Kistler measurement and<br />

system technology guarantees that these<br />

requirements are satisfied, thereby assuring<br />

a zero-defect production in joining,<br />

assembly and testing technology – with a<br />

clear focus on 100 % quality at all times.<br />

In the automotive industry, aircraft<br />

construction and medical technology, to<br />

name just a few, quality is vital and strict<br />

standards are therefore set (i.e., ISO/TS<br />

16949). Especially in cases where many<br />

individual components converge into one<br />

product, it is important that these are already<br />

tested by the suppliers as this is the<br />

only way to guarantee the quality of the<br />

end-product. Here it is absolutely essential<br />

that monitoring systems are integrated<br />

into production.<br />

4 www.kistler.com

QUALITY TESTING is the mark of 100 % quality in production testing. It stands for zero-defect production<br />

through uninterrupted quality testing on the basis of force and torque – irrespective of the make of testing<br />

station. The quality tests can be implemented at all testing stations and test stands.<br />

QUALITY JOINING<br />

The joining and assembling of these<br />

individual components to produce an<br />

end-product must however be monitored<br />

and tested. Force and torque sensors<br />

record these assembly processes and<br />

transmit them to the relevant monitor<br />

systems, i.e. maXYmos, for evaluation.<br />

Direct monitoring within the process step<br />

means that deviations can be detected<br />

and corrected immediately by taking<br />

targeted measures. Quality defects are<br />

detected at an early stage, thus avoiding<br />

additional cost-intensive assembly steps.<br />

Missing parts can be discharged immediately<br />

and reworked if necessary.<br />

QUALITY TESTING<br />

Thanks to prior tests that have been<br />

carried out during the production and<br />

assembly of individual components,<br />

defective end-products are nearly ruled<br />

out. It is nevertheless essential that<br />

the functionality of the end-product<br />

is checked. The final inspection of<br />

pre-assembled shock absorbers, involves<br />

checking that they comply with the<br />

damping characteristics of a normal forcedisplacement<br />

curve. Kistler sensors and<br />

XY-monitors assume this task too.<br />

Uninterrupted process monitoring and<br />

uncompromising quality testing – with<br />

QUALITY JOINING and QUALITY<br />

TESTING powered by Kistler! With a clear<br />

focus on 100 % quality at all times.<br />

www.kistler.com 5

A Clear Focus on 100 % Quality<br />

Assembly processes are often accompanied<br />

by force-displacement or torquerotation<br />

angle curves. These are created<br />

when two joining partners are connected<br />

or when individual components are screwed<br />

together. Using special sensors, the<br />

relevant variables are recorded and then<br />

transmitted to a monitor unit.<br />

The ultimate aim in industrial manufacturing<br />

is zero-defect production. The requirements<br />

in respect of quality assurance<br />

and monitoring are therefore increasing<br />

all the time. Feasibility studies usually<br />

determine whether quality assurance is to<br />

be directly integrated into the production<br />

process, as this provides a means of being<br />

able to react as quickly as possible to<br />

process deviations or variations in quality.<br />

The subsequent non-destructive testing<br />

of press joints is simply not possible with<br />

many processes. This is why quality control<br />

must be integrated into the process.<br />

Assembly processes are usually characterized<br />

by dynamic force or torque curves.<br />

The piezoelectric measuring technique is<br />

well suited for recording such dynamic<br />

curves.<br />

Force monitoring during assembly<br />

The forces that occur during assembly<br />

(i.e., when joining and positioning) must<br />

be evaluated and documented for process<br />

and quality assurance purposes. With the<br />

press-fit process, the evaluation of the<br />

characteristic force-displacement curve<br />

is especially suitable for this purpose.<br />

Here, the interdependent variables, such<br />

as press-fit force and displacement are<br />

recorded and their functional correlation<br />

is evaluated. The result of the evaluation<br />

is used to eliminate bad parts that need to<br />

be reworked.<br />

The force is also measured in order to protect<br />

machines and individual workpieces<br />

from overload. Force thresholds are used<br />

for example to monitor the maximum<br />

press force.<br />

Press-fit forces can be measured either<br />

directly within the flux or indirectly via<br />

the strains of the machine structure, i.e.,<br />

a C-frame.<br />

6 www.kistler.com

Process Monitoring in Assembly and Testing Technology<br />

Advantages of Force or<br />

Torque Monitoring<br />

+ Permanent process control<br />

+ Trend analysis of process<br />

Parameters<br />

+ Prompt reaction to<br />

deviations<br />

+ Uninterrupted documentation<br />

+ Part-related traceability<br />

of process parameters<br />

Klick<br />

Kistler sensors and systems are used to test products<br />

with regard to the spring force, contact force, connector<br />

force, torque and tactile behavior (top)<br />

The electromechanical NC joining system NCFH<br />

Type 2151A... with integrated piezoelectric force<br />

monitoring automates joining and assembly<br />

processes (top)<br />

Correct torque curve is a quality characteristic of key<br />

switches. The Type 9339A... reaction torque sensor<br />

records the torque and transmits it to a XY-monitor<br />

(left)<br />

Joining systems with integrated force<br />

monitoring<br />

Electromechanical NC joining systems<br />

offer a high level of flexibility, exact positioning,<br />

extremely high repeatability and<br />

accurately defined press-fit forces. When<br />

it comes to press-fitting tasks in particular,<br />

they are increasingly supplanting the<br />

existing pneumatic and hydraulic joining<br />

systems. With the electromechanical NC<br />

joining modules with integrated forcedisplacement<br />

monitoring, Kistler offers<br />

particularly compact and precise system<br />

solutions for the joining technology.<br />

Torque-controlled screwing process<br />

Torque sensors and XY-monitors from<br />

Kistler (i.e., CoMo Torque Type 4700B...,<br />

etc.) are used to optimally monitor and<br />

log the specific torque curve during the<br />

screwing process. This avoids any overloading<br />

or preliminary damage to the<br />

screw joints, and the assembled products<br />

have greater operational reliability and<br />

quality.<br />

Quality assurance during product testing<br />

Force and torque measurements are not<br />

only taken to test and monitor production<br />

processes: During the manufacturing<br />

process, it can also be used to test finished<br />

products and its functions. Contact forces<br />

from plug-and-socket connections, actuation<br />

forces for pressure switches and keys,<br />

actuation torques for potentiometers,<br />

ignition and rotary switches or shut-offs as<br />

well as torque curves on gears and motors<br />

can hereby be called upon as a criterion<br />

with which to assess the quality. Piezoelectric<br />

sensors from Kistler are used to<br />

measure very large and very small forces<br />

or torques using the same sensor, without<br />

affecting the accuracy of the measurement.<br />

www.kistler.com 7

A Clear Focus on 100 % Quality<br />

The measurement of forces and torques<br />

during assembly makes the manufacturing<br />

and testing processes transparent.<br />

This is why the curves for force and<br />

torque against time, displacement or<br />

rotation angle are extremely suitable<br />

when it comes to creating a good/bad<br />

evaluation. They can be recorded via the<br />

relevant sensors and displayed, evaluated<br />

and documented on XY-monitors. The<br />

same applies to the testing of finished<br />

products, where the aim is to evaluate<br />

the haptic behavior during rotary or linear<br />

movements.<br />

*Available 2012<br />

For assembly processes and press-fit and<br />

screwing processes, automated production<br />

facilities and special machines are often<br />

used. In this case the quality control must<br />

also be done by machine and independent<br />

of any manual evaluation. Often mechanical<br />

quality monitoring is the only option<br />

due to the clock rates of the machines<br />

that are often high. XY-monitors such as<br />

maXYmos TL* can check up to 20 parts<br />

per second.<br />

Different factors determine when the<br />

quality of a particular production step is<br />

checked. For one thing, the quality of a<br />

production step can be checked immediately<br />

in a separate test stage. It only<br />

makes sense to use this method where<br />

non-destructive testing processes are<br />

possible. If this is not the case, checking<br />

must take place during the production<br />

step. As well as removing the need for a<br />

separate testing cycle, this method also<br />

has the advantage of being able to exactly<br />

locate the stage causing the error in the<br />

production step and able take targeted<br />

countermeasures.<br />

With certain processes, i.e., press-fit processes,<br />

it only makes sense to implement<br />

the latter testing method.<br />

8 www.kistler.com

XY-Monitors for Assembly and Testing Technology<br />

maXYmos BL<br />

Single-channel XY-monitor for force and torque sensors<br />

in assembly technology and product testing<br />

Standard monitor for the good/bad evaluation of XY curves, such as force against<br />

displacement or torque against rotation angle. Such curves arise in assembly or<br />

product testing as well as joining, engaging, snap-fit, swiveling, rotation and spring<br />

tests. Universal evaluation objects [EOs] such as UNI-BOX, LINE-X, LINE-Y and<br />

envelope curve band are available for curve evaluations. The handy size of the<br />

monitor means that it fits perfectly in the manual assembly station. It can however<br />

also be used in the automatic production line. Its very reasonable price tag makes it<br />

a very interesting choice for many applications.<br />

maXYmos TL*<br />

Multichannel XY-monitor for more complex measurement tasks<br />

in assembly technology and product testing<br />

High-end monitor for good/bad monitoring of XY curves. Very powerful evaluation<br />

objects supplementing those for the maXYmos BL are also available. This<br />

means that sophisticated curve evaluations can also be realized, i.e., from the<br />

field of product testing. Special evaluation objects can therefore for example<br />

determine the positions of two snap-in points of a slide guideway, or calculate<br />

and evaluate the distance between them. The option to upgrade up to eight<br />

pairs of XY channels means that the monitor is also designed for multichannel<br />

applications.<br />

In this case, testing after the press-fit<br />

process would inevitably involve the<br />

destruction of the joint.<br />

Advantages of quality testing during the<br />

production step:<br />

1. No need for a separate testing station<br />

2. Shorter cycle time<br />

3. Non-destructive testing<br />

4. Immediate test results<br />

5. Early countermeasures<br />

Regardless of when a testing process<br />

takes place, a different sample density is<br />

required in each case. This ranges from<br />

so-called spot measuring to the virtually<br />

uninterrupted sampling of a measuring<br />

function, i.e., y = f(x). Whereas with<br />

spot measuring, usually triggered by a<br />

trigger signal (i.e., a proximity switch on<br />

the press stamp), only one measurement<br />

value is obtained and evaluated from a<br />

measuring function, and the quality of<br />

the whole process is determined, the<br />

virtually uninterrupted sampling of a<br />

measuring function permits a much higher<br />

degree of reliability of the evaluation<br />

result. Every sampled value can therefore<br />

be used for evaluation purposes.<br />

This is the only way of obtaining a clear<br />

evaluation with regards to the quality<br />

of a joint. Too many factors are able to<br />

influence the press-fit process. In unfavorable<br />

cases, disturbance variables may<br />

overlap or, at worst, they can cancel each<br />

other out. The maXYmos monitors record<br />

the whole measurement curve, thereby<br />

allowing conclusions to be drawn about<br />

the insertion process, surface condition<br />

and, not least, the fit between the joining<br />

partners.<br />

*Available 2012<br />

www.kistler.com 9

A Clear Focus on 100 % Quality<br />

The representation, evaluation and documentation<br />

of force and torque curves in<br />

assembly and product testing are provided<br />

by special XY-monitors from Kistler.<br />

The functionality of maXYmos BL and<br />

maXYmos TL meet the different requirements<br />

concerning sensor interfaces,<br />

evaluation diversity and data interfaces.<br />

The evaluation elements of the monitors<br />

can be easily configured and can be combined<br />

in a number of different ways.<br />

XY-monitors of the maXYmos series<br />

monitor and evaluate XY curves of two<br />

variables that have to stand in a certain<br />

relation to each other. Such curves arise<br />

in applications such as the press-fitting<br />

of ball bearings, pivoting and swiveling<br />

backrests, riveting and calking casing parts<br />

or in the tactile manipulation of rotary<br />

switches.<br />

In press-fitting, for example, the typical<br />

measurement curves are recorded by<br />

force and displacement sensors, and when<br />

monitoring the swiveling processes, torque<br />

and rotation angle sensors are used.<br />

Depending on the form of these measurement<br />

curves, it is possible to determine<br />

the quality of an individual production<br />

step, module or whole product.<br />

Quality related stages of the measurement<br />

curves recorded by the measuring<br />

functions Y=f(X), Y=f(t), Y=f(X,t) or X=f(t)<br />

are analyzed by the maXYmos monitors<br />

using evaluation elements. This includes<br />

checking whether the curves pass through<br />

the evaluation elements as predefined.<br />

If they do, an "OK" (OK) is generated,<br />

otherwise a "Not OK" (NOK).<br />

Good/Bad statement based on a variety<br />

of evaluation criteria<br />

Depending on the design of the XY-monitor,<br />

many different evaluation functions<br />

can be activated and freely combined to<br />

monitor a process. For each evaluation<br />

element, the intersection of the curve with<br />

the element can be displayed as a trend<br />

or statistic in the form of a mean value,<br />

standard deviation, cp- or cpk-value.<br />

10 www.kistler.com

Functionality of XY-Monitors<br />

Type UNI-BOX<br />

Type ENVELOPE CURVE<br />

Type CALC<br />

Entry and exit side can be freely selected. No breaching<br />

of "closed" sides allowed. Each side can be defined as<br />

entry or exit<br />

The measurement curve must not breach the top and<br />

bottom line of the envelope curve band. Quick to teach<br />

evaluation element<br />

Element obtains two specified process values and<br />

performs the calculation operations, i.e., calculates the X<br />

difference between two ripples and evaluates them<br />

Type LINE-Y<br />

Type LINE-X<br />

Type NO-PASS<br />

Line must be crossed once. A value Y is monitored at<br />

the crossing point<br />

Line must be crossed once. A value X is monitored at<br />

the crossing point<br />

Line must not be crossed. Otherwise NOK and realtime<br />

signal "NO-PASS"<br />

Type GRAD-Y<br />

Type GETREF<br />

Type BREAK<br />

Y1<br />

X1<br />

X2<br />

Y2<br />

Evaluates the gradient dY/dX between two vertical<br />

lines<br />

GETREF BOX detects significant curve characteristics and<br />

delivers the XY coordinates as reference points for other<br />

EOs or as input for the CALC element<br />

Delivers NOK and online signal if there is a sudden<br />

change in gradient within an expectancy range (box)<br />

i.e., when a tool breaks<br />

The device is also used to display and<br />

save corresponding process values in<br />

numerical form. The process evaluation<br />

result (OK/NOK) is available as a control<br />

signal at digital outputs, bus or Ethernet<br />

interfaces.<br />

Evaluation objects UNI-BOX, LINE-X,<br />

LINE-Y, NO-PASS and ENVELOPE CURVE<br />

The curves of quality-relevant curve<br />

stages can be evaluated by different evaluation<br />

objects (EOs). First, the supervisor<br />

places them across a reference curve that<br />

has been classed as OK or even better<br />

across a whole batch of OK curves. The<br />

latter gives a sense of the distribution to<br />

be expected and thus the size of the evaluation<br />

element to use. maXYmos BL and<br />

maXYmos TL offer different types of EO,<br />

with each one evaluating according to<br />

different criteria. The evaluation objects<br />

UNI-BOX, LINE-X, LINE-Y, NO-PASS and<br />

ENVELOPE CURVE form the basis for all<br />

maXYmos monitors. The UNI-BOX for<br />

instance monitors whether the measurement<br />

curve enters and exits the prescribed<br />

sides of the box. It must be positioned<br />

manually via the respective curve<br />

stage. The ENVELOPE CURVE on the<br />

other hand positions itself automatically<br />

around the outer contour of a previously<br />

measured GOOD bundle of curves.<br />

Other evaluation elements<br />

With the additional evaluation elements<br />

GRADIENT, HYSTERESIS and CALCU-<br />

LATE, the XY-monitor maXYmos TL<br />

also optimally evaluates complex curve<br />

criteria. The CALCULATE element for<br />

example can calculate and evaluate the<br />

distance between two snap-in points on<br />

a force-displacement curve. GETREF elements<br />

send the positions of these snap-in<br />

points to the CALCULATE element.<br />

Extensive analyses from the PC software<br />

maXYmos PC<br />

The new PC software maXYmos PC<br />

enables the test report to be directly<br />

transferred from maXYmos to the PC<br />

and offers many functions for the display,<br />

measurement and analysis of measurement<br />

curves and process values as well as<br />

the evaluation of the process capability.<br />

www.kistler.com 11

A Clear Focus on 100 % Quality<br />

Display module (DIM)<br />

Cascadable up to eight XY channels. In<br />

this example, all MEMs are in the control<br />

cabinet and are therefore protected.<br />

MEM1 could also be positioned in the<br />

display module slot.<br />

Meas- and evaluation modules (MEM)<br />

MEM1<br />

MEM2 MEM3 MEM4<br />

.......<br />

MEM8<br />

Server<br />

Data export<br />

X<br />

Y<br />

Torque/<br />

Rotation angle<br />

X Y Y<br />

Y X<br />

Force/Displacement<br />

Pressure/Displacement<br />

Force/Time<br />

X<br />

Displacement/Time<br />

EtherNet/IP<br />

Profinet<br />

Profibus<br />

PLC<br />

Universal installation options<br />

The maXYmos TL is designed for desktop,<br />

wall, front panel and DIN rail mounting.<br />

The flexible case concept gives the machine<br />

designer ample scope. The MEM always<br />

has Profibus DP, ProfiNet, EtherNet/<br />

IP and Modebus/IP. Selections are made<br />

via the menu. Interfaces for all standard<br />

sensor types are also always mounted.<br />

Fittingly, Kistler’s program also includes a<br />

large selection of force and torque sensors<br />

or displacement and angle sensors.<br />

maXYmos TL – The system concept<br />

At the heart of the maXYmos TL is the<br />

measurement and evaluation module<br />

[MEM]. It operates as a standalone unit<br />

and is already equipped with all the<br />

measurement, evaluation, activation and<br />

data transfer functions. As a black-box<br />

module, the MEM can be fully configured<br />

via remote access.<br />

"Seeing" directly into the measurement<br />

module via the display module<br />

Using the display module [DIM] that is<br />

designed as a color touch screen, the<br />

MEM can be equipped with a graphical<br />

user interface [GUI]. Both components<br />

are coupled mechanically and electrically<br />

via the rear slot of the display module. In<br />

just a few easy steps, the MEM is pushed<br />

into the DIM and secured. The resulting<br />

compact unit turns into a fully-fledged<br />

XY-monitor for monitoring a pair of XY<br />

channels.<br />

Cascadable up to 8 pairs of XY channels<br />

Overall, the maXYmos TL can be extended<br />

to up to eight pairs of XY channels. To<br />

do this, additional MEMs are connected<br />

to the Ethernet interface via a patch<br />

cable. External switches are not needed;<br />

the cables are simply looped through.<br />

The individual pairs of channels are then<br />

displayed either individually or in so-called<br />

Split Mode, i.e., the information concerning<br />

all pairs of channels is displayed on a<br />

single screen.<br />

12 www.kistler.com

Functionality of XY-Monitors<br />

maXYmos BL<br />

Standard monitor for good/bad<br />

evaluation of XY curves<br />

The monitor that is equipped with a pair<br />

of XY channels already has functions that<br />

do justice to many standard applications<br />

for assembly and product testing. It is<br />

ideal for use at manual workstations, but<br />

also has all the interfaces necessary for<br />

integration into the automatic machine<br />

environment.<br />

The maXYmos BL records all variables that<br />

stand in a relation to each other, these are<br />

then delivered by piezoelectric or strain<br />

gage sensors via the Y channel and by<br />

potentiometric sensors via the X channel.<br />

Based on the curves, it can then monitor<br />

and evaluate the quality of a product or<br />

production step.<br />

Quality related stages of the measurement<br />

curves recorded by the measuring<br />

functions Y=f(X), Y=f(t), Y=f(X,t) or X=f(t)<br />

are analyzed using evaluation elements.<br />

It checks whether the curves that consist<br />

of a maximum of 8000 pairs of XY values,<br />

pass through the evaluation elements as<br />

prescribed. If they do, an "OK" (OK) is<br />

generated, otherwise a "Not OK" (NOK).<br />

For each measuring program or measurement<br />

curve, a maximum of 4 evaluation<br />

elements Types UNI-BOX, LINE, NO-PASS<br />

or ENVELOPE CURVE can be allocated. All<br />

evaluation elements can be edited by means<br />

of numerical entry or graphical drag<br />

and drop and then aligned to absolute or<br />

dynamic reference points.<br />

The basic version maXYmos BL is optimized<br />

for front panel mounting. An<br />

optional additional case allows mounting<br />

on a panel of a machine or on a desktop<br />

and the continuous adjustment of the<br />

viewing angle.<br />

• Piezo<br />

• Strain gage<br />

• ±10 V<br />

• Poti<br />

• ±10 V<br />

• Profibus DP<br />

• EtherNet/IP*<br />

Channel Y<br />

Channel X<br />

Fieldbus<br />

Circuit diagram of the maXYmos BL<br />

maXYmos BL at a Glance<br />

• Monitoring of up to 10 parts<br />

per second<br />

• 16 measurement programs for 16<br />

different types of part<br />

• Up to 8 000 pairs X/Y values per curve<br />

• 2 real-time outputs for X- and<br />

Y-thresholds<br />

• Dig-IO (24 V), Profibus DP, Ethernet (TCP/IP*) and USB*<br />

• Memory for historical measurement curves for NOK diagnosis<br />

• Warning messages and alarms allowing early countermeasures<br />

• Serial numbers from PLC or internal SN generator<br />

• Access protection for different user groups<br />

• Channel X: potentiometer and ±10 V*, channel Y: Piezo or Strain gage and ±10 V<br />

• Bright, high-contrast 3,5"color touch screen display<br />

• Clearly structured user interface<br />

• PC software "maXYmos PC" as support tool<br />

• Extremely good value for money<br />

For further details on<br />

maXYmos BL, see page 125.<br />

1<br />

2<br />

ZERO-X<br />

Global<br />

area<br />

1 of 16<br />

MP-01 MP-02 MP-03 MP-16<br />

Scaling 1<br />

Scaling 1<br />

Area<br />

related to<br />

MP<br />

4<br />

S1<br />

S2<br />

Measurement program<br />

START<br />

Cycle<br />

control<br />

READY<br />

S-TEST<br />

Y<br />

NO-PAS<br />

Current<br />

measurement<br />

curve<br />

Control by means Dig-IO (24 V) or fieldbus<br />

Digital IO 2<br />

IO<br />

NIO<br />

maXYmos BL<br />

Type 5867A...<br />

MP-01<br />

1) Scaling and cycle control specific to MP here. Can also be obtained from GLOBAL<br />

2) Only the most important signals are shown<br />

TARA<br />

X<br />

1 2<br />

ZERO<br />

Ethernet<br />

USB<br />

• Export of<br />

measurement data<br />

• Measurement<br />

results to<br />

USB stick<br />

• Measurement<br />

program from<br />

USB stick<br />

• Backup file<br />

to USB stick<br />

• PC software<br />

maXYmos PC<br />

*Available 2012<br />

www.kistler.com 13

A Clear Focus on 100 % Quality<br />

maXYmos TL*<br />

High-end monitor for good/bad evaluation<br />

of complex XY curves<br />

Very powerful evaluation objects<br />

supplementing the performance of the<br />

maXYmos BL are available in the form<br />

of the maXYmos TL. This means that<br />

sophisticated curve evaluations can also<br />

be realized, i.e., from the field of product<br />

testing.<br />

The maXYmos TL spectrum ranges from<br />

the single force-displacement monitoring<br />

system to sophisticated multichannel<br />

applications. Functionality and operating<br />

concept build on the maXYmos BL. Key<br />

features include: more powerful evaluation<br />

processes, variety of sensor options,<br />

freely selectable fieldbus types, extension<br />

option up to 8 pairs of channels and a<br />

large 10.4" color touch screen display.<br />

With the additional evaluation elements<br />

GRADIENT, HYSTERESIS and CALCU-<br />

LATE, it can also optimally evaluate<br />

complex curve criteria. The CALCULATE<br />

element for example can calculate and<br />

evaluate the distance between two snapin<br />

points on a force-displacement curve.<br />

GETREF elements send the positions of<br />

these snap-in points to the CALCULATE<br />

element.<br />

maXYmos TL at a Glance<br />

• Monitoring of up to 20 parts<br />

per second<br />

• 128 measurement programs for<br />

128 types of part<br />

• Up to 8 000 pairs of XY values per<br />

measurement curve<br />

• Measurement curve recorded with<br />

up to 20 000 samples/s<br />

• Real-time outputs for quick response<br />

• Powerful tools for NOK diagnosis<br />

• Diagnosis memory for up to<br />

1 000 measurement curves with<br />

batch function<br />

• Warning messages and alarms<br />

allowing timely countermeasures<br />

• Cascadable up to 8 pairs XY channels<br />

• Serial numbers from PLC<br />

or internal SN generator<br />

• Access protection for different user<br />

groups<br />

If a constant display is not required, the<br />

CoMo View<br />

MEM can also act as black-box module:<br />

setup and process display is then via VNC<br />

access using the<br />

• Channel X: potentiometer, ±10 V,<br />

Incremental encoder, LVDT or SSI,<br />

Channel Y: Piezo, strain gage or ±10 V<br />

• Bright, high-contrast 10,4"color touch<br />

screen display<br />

• Clearly structured user interface<br />

• PC software "maXYmos PC" as<br />

support tool<br />

• Good value for money<br />

maXYmos TL<br />

Type 5877A...<br />

Ethernet interfaces or one of the USB interfaces<br />

using the PC program maXYmos<br />

PC that is available as an accessory.<br />

The maXYmos TL consists of a measurement<br />

and evaluation module (MEM) and<br />

a display module (DIM). Both components<br />

can either be installed separately so<br />

that they are only connected by the monitor<br />

cable, or they can act as a compact,<br />

mechanical and electrical unit.<br />

The latter is produced by pushing the<br />

MEM into the rear slot of the DIM. This<br />

combination already provides a pair of<br />

measurements channels (XY) and all necessary<br />

interface for control, data export<br />

and remote maintenance.<br />

selected from the menu<br />

• Piezo<br />

• Strain gage<br />

• ±10 V<br />

selected from the menu<br />

• Poti<br />

• ±10 V<br />

• Incremental<br />

• LVDT<br />

• Inductive<br />

• SSI<br />

selected from the menu<br />

• Profibus DP<br />

• ProfiNet<br />

• EtherNet/IP<br />

• EtherCat<br />

Channel Y<br />

Channel X<br />

Fieldbus<br />

Global<br />

Area<br />

1 of 128<br />

MP-000 MP-001 MP-002 MP-127<br />

2<br />

Area<br />

related to<br />

MP<br />

8<br />

1<br />

S1<br />

Measurement program<br />

START<br />

Cycle<br />

control<br />

READY<br />

Y<br />

X<br />

S-TEST<br />

Digital IO 2<br />

Y<br />

NO-PAS<br />

IO<br />

NIO<br />

MP-000<br />

Current<br />

measurement<br />

curve<br />

Control by means of Dig-IO (24 V) or fieldbus<br />

TARA<br />

X<br />

1 2<br />

ZERO<br />

Ethernet TCP/IP 3 x USB Monitor<br />

LVDS<br />

+USB<br />

• Measurement<br />

results to<br />

USB stick<br />

• Measurement<br />

program from<br />

USB stick<br />

• Backup file<br />

to USB stick<br />

• PC software<br />

maXYmos PC<br />

• Export of<br />

measurement data<br />

• Remote maintenance<br />

• Other MEM modules<br />

1) Scaling and cycle control specific to MP here. Can also be obtained from GLOBAL<br />

2) Only the most important signals are shown<br />

Circuit diagram of the maXYmos TL<br />

*Available 2012<br />

For further details on<br />

maXYmos TL, see page 126.<br />

14 www.kistler.com

Functionality of XY-Monitors<br />

CoMo Torque<br />

Evaluation Instrument for Torque Sensors<br />

The CoMo Torque Type 4700B... allows<br />

synchronous acquisition of torque<br />

and speed signals of rotating strain gage<br />

torque sensors Type 4501A... to Type<br />

4504B... and KiTorq Stator Type 4541A... .<br />

CoMo Torque is ideal for industrial and<br />

R&D applications. Strain gage sensors<br />

with standardized sensitivity or voltage/<br />

frequency output can be connected<br />

directly.<br />

CoMo Torque at a Glance<br />

• Time-dependent M(t) and n(t) or j(t)<br />

measurement<br />

• Correct display for measurand (torque,<br />

speed, rotation angle, force and mechanical<br />

power)<br />

• Units: N∙mm, N∙cm, N∙m, kN∙m, N,<br />

kN, rpm, W, kW, MW, degrees and<br />

Imperial/American units<br />

• 4x20 character display<br />

• Multilingual operator guidance<br />

• High measuring accuracy of

Process Monitoring with NC Joining Systems<br />

in Assembly Technology<br />

Our goal is to integrate process monitoring<br />

into automated production. When<br />

joining by means of press-fitting, we<br />

recommend force-displacement monitoring<br />

as the tested and approved option.<br />

Electromechanical NC joining systems<br />

with integral force monitoring continue<br />

to prevail over pneumohydraulic and<br />

hydraulic systems thanks to the many<br />

advantages. For a force range up to 300 kN,<br />

Kistler offers a complete program for such<br />

joining systems – from the compact single<br />

module to the full production solution as<br />

a manual workstation with integrated NC<br />

joining systems.<br />

NCFT Type 2157B…<br />

NC joining module with integral piezoelectric<br />

force sensor with measuring<br />

ranges of 0,05 ... 1,5 kN.<br />

• Ideal for applications in the clean room,<br />

i.e., for the production of medical<br />

commodities<br />

• Force signal is transmitted by telemetry<br />

for maximum measurement accuracy<br />

NCFH Type 2151B…<br />

NC joining modules with space-saving,<br />

gearless, hollow-shaft motor and integral<br />

piezoelectric force sensor. The measuring<br />

ranges are 1 ... 60 kN, depending on size.<br />

• Short design, 2 sizes<br />

• High speed<br />

• Dynamic processes<br />

At a Glance<br />

Electromechanical NC joining systems<br />

offer considerable advantages over<br />

conventional technologies such as<br />

hydraulics or pneumatics.<br />

Process<br />

Flexibility at joining<br />

and press-fit processes<br />

Installation work<br />

Maintenance and<br />

cost of ownership<br />

Energy consumption<br />

Environmental benefit<br />

high<br />

increase<br />

low<br />

reduce<br />

For continuous monitoring of joining and<br />

press-fit processes, the force-displacement<br />

monitoring system Type 4740A... is available.<br />

It uses a wide variety of tolerance windows<br />

to evaluate the force-displacement<br />

curves of virtually any application. It also<br />

allows the analysis of all four quadrants<br />

(forward and backward movement/compression<br />

and tension force). In addition<br />

to the conventional tolerance windows,<br />

dynamic windows for evaluation on the<br />

basis of the maximum position achieved,<br />

windows for evaluating the gradient, the<br />

change in gradient, point-by-point and the<br />

mechanical work (integral of the curve),<br />

are available. The standard system has an<br />

Ethernet interface. This allows easy connection<br />

to existing process and measurement<br />

acquisition systems via<br />

I-P.M. or Q-DAS ® .<br />

The curve and associated setpoints and<br />

actual values can be documented in detail.<br />

The NC compact firmware Type 2159A<br />

loaded into the servo controller is ideal<br />

for the force-displacement evaluation of<br />

standard joining processes with a simple<br />

documentation function. For very modest<br />

capital and installation costs it facilitates<br />

integration into existing user control environments.<br />

NCFS Type 2152B…<br />

NC joining module with integral piezoelectric<br />

force sensor and two predefined<br />

measuring ranges of 25 and 15 kN.<br />

• Particularly slim design allows closely<br />

spaced individual workstations<br />

• More accurate guidance<br />

• Particularly rigid<br />

• Use in automated production facilities<br />

NCFB Type 2160…<br />

NC joining module with integral piezoelectric<br />

force sensor and two predefined<br />

measuring ranges 5, 15, 25 and 50 kN.<br />

• Reasonably priced<br />

• Rugged design<br />

• Ideal for standard joining processes<br />

NCFN Type 2153A…<br />

NC joining modules with integral strain<br />

gage force sensor for rated joining forces<br />

of 30, 60, 100, 200 and 300 kN.<br />

• Use in automated production facilities<br />

and manually controlled workstations<br />

• Optional safety brake<br />

• Several strokes available<br />

Special models available on request.<br />

Services<br />

• Worldwide support with startup<br />

• Global calibration service<br />

• Process and cycle time optimization<br />

• Maintenance contracts<br />

• Testing of customer samples<br />

16 www.kistler.com

Compact NC Joining Systems and General-Purpose<br />

Manual Workstations<br />

With the NCFH Type 2151B... with its<br />

overload safe piezoelectric force measurement<br />

technology, only two sizes cover<br />

the wide measuring range between<br />

1 ... 60 kN – a small one for up to 15 kN<br />

and a large one for up to 60 kN. The force<br />

signal employed for force-displacement<br />

monitoring gives a force-controlled<br />

movement for highly specialized joining<br />

tasks. The force control system increases<br />

the application versatility of the electromechanical<br />

NC joining system. Thus spring<br />

elements, for example, can be loaded to<br />

specific values or compensating force applied<br />

to continue the motion of a blocking<br />

ram set behavior.<br />

Two lubrication points for guide and<br />

bearing ensure very low-maintenance<br />

operation. As active deflection compensation<br />

system eliminates the effect of the<br />

bending of the spindle and customer’s<br />

assembly, the positional accuracy is no<br />

longer influenced by the force.<br />

Advantages of Piezoelectric<br />

Force Measurement<br />

The NC joining modules NCFT, NCFH,<br />

NCFS and NCFB have an integrated piezoelectric<br />

force sensor that offers several<br />

advantages:<br />

• A single electromechanical NC joining<br />

module covers a large number of<br />

measuring ranges<br />

• Preset of the correct measuring range<br />

unnecessary<br />

• Low sensitivity to disturbance variables<br />

• Wide variety of parts on a station, i.e.,<br />

makes mixed production feasible on<br />

single machine<br />

• Factor of safety against overload<br />

of up 15<br />

• Cuts spare parts inventory<br />

and design costs<br />

• High dynamic response because of<br />

high level of rigidity<br />

Mounting station of a German automotive supplier<br />

with an electromechanical NC joining module, NCFH<br />

Plus Points of Electromechanical<br />

NC Joining Systems, NCFH<br />

+ Gearing eliminated by hollow-shaft<br />

motor design<br />

+ Hollow-shaft motor assembled<br />

directly around the threaded spindle<br />

drive<br />

+ Long spindle stroke yet compact<br />

dimensions<br />

+ Active deflection compensation<br />

+ Force control system<br />

+ Standard holding brake<br />

+ Particularly dynamic operation<br />

+ Ideal for under-bench mounting<br />

For details about the<br />

electromechanical NC joining<br />

systems and manual<br />

workstations, see page 132.<br />

General-Purpose Manual Workstations<br />

with NC Joining Modules<br />

General-purpose manual workstations<br />

from Kistler are standalone workstations<br />

for joining processes with safety<br />

gate and integral force monitoring.<br />

They are designed for use in development,<br />

prototyping and small-scale<br />

production.<br />

Electromechanical NC joining modules<br />

Electromechanical NC joining modules<br />

are the core components of Kistler’s<br />

manual workstations. The six standard<br />

models with integral force-displacement<br />

monitoring cater for a very wide<br />

measuring range from<br />

0,05 ... 300 kN, thereby ensuring comprehensive<br />

coverage of requirements<br />

extending from the horological industry<br />

to mechanical engineering. Custom<br />

variants are also available.<br />

Monitoring via PC<br />

The manual workstation – NC Control<br />

Center (NCCC) – is controlled by a<br />

high-performance industrial PC with<br />

Windows ® 7.<br />

Time-tested by flexibility<br />

The manual workstation is readily<br />

adaptable to suit a wide variety of<br />

joining tasks. Any number of movement<br />

and measuring programs can be<br />

installed to facilitate changeovers. All in<br />

all, the manual workstation from Kistler<br />

is always a time-tested investment.<br />

Application areas for manual workstations<br />

in development and small batch<br />

production are:<br />

• Braking systems<br />

• Steering components<br />

• Injection systems<br />

• Drives<br />

• Electronic control<br />

• Chassis components<br />

www.kistler.com 17

Kistler Measurement Technology<br />

Kistler supplies piezoelectric, piezoresistive,<br />

capacitive and strain gage sensors.<br />

Piezoelectric designs are particularly<br />

suitable for measurement imposing<br />

extreme requirements in terms of geometry,<br />

temperature range and dynamics.<br />

Kistler therefore relies mainly on the<br />

piezoelectric principle for measuring<br />

dynamic forces in assembly and testing.<br />

Piezoelectric (derived from the Greek<br />

piezein, which means to squeeze or press)<br />

materials generate an electric charge when<br />

subjected to mechanical load. Pierre and<br />

Jacques Curie discovered the piezoelectric<br />

effect in 1880. As electric charges do not<br />

readily lend themselves to experimental<br />

research, piezoelectricity only gained<br />

practical significance in the middle of the<br />

20th century. With the help of so-called<br />

electrometer amplifiers, the charge produced<br />

by piezoelectric material could then<br />

be converted into a proportional electric<br />

voltage for the very first time.<br />

In 1950, Walter P. Kistler received a patent<br />

for the very first charge amplifier for<br />

piezoelectric signals, paving the way for<br />

exploitation of an effect that had been<br />

known for decades. The development of<br />

highly insulating materials such as Teflon ®<br />

and Kapton ® significantly improved the<br />

performance of these measuring systems<br />

and propelled the use of piezoelectric<br />

sensors into virtually all areas of modern<br />

technology and industry.<br />

Most Kistler sensors rely on a quartz force<br />

link, which basically consists of thin quartz<br />

plates, disks/washers or rods. The sensor<br />

is connected to an electronic device for<br />

converting the charge signal into a voltage<br />

signal proportional to the mechanical force.<br />

The conversion is made either by means of<br />

a separate charge amplifier or an impedance<br />

converter with coupler, which is usually<br />

integrated into the sensor.<br />

The finite insulation resistance means<br />

purely static measurements with piezoelectric<br />

sensors are not possible. However,<br />

together with suitable crystal measuring<br />

elements and signal conditioning devices,<br />

these sensors have excellent quasistatic<br />

measurement properties.<br />

The Piezoelectric Effect in<br />

Detail<br />

The term "piezoelectricity" refers to<br />

a linear electromechanical interaction<br />

between the mechanical and electrical<br />

state of anisotropic crystals that is<br />

those without a center of symmetry with<br />

lattice structure. These crystals have<br />

one or more polar axes along which the<br />

piezoelectric effect occurs as a result of<br />

an external force deforming the crystal<br />

lattice and pushing its positive and negative<br />

elements against one another. This<br />

produces an electric dipole moment.<br />

Depending on the orientation of the axes<br />

with respect to the applied force, three<br />

different effects can be discerned:<br />

• Longitudinal<br />

• Shear<br />

• Transverse<br />

18 www.kistler.com

Basics of Piezoelectric Measurement Technology<br />

Longitudinal effect<br />

A charge is developed on the surfaces to<br />

which the force is applied, where it can be<br />

measured. In the case of the longitudinal<br />

piezoelectric effect, the magnitude of the<br />

electric charge Q depends only on the<br />

applied force Fx and not on the dimensions<br />

of the crystal disks. The only way to<br />

increase this charge is to connect several<br />

disks mechanically in series and electrically<br />

in parallel. The magnitude of the output<br />

charge then becomes:<br />

Principle of the<br />

longitudinal<br />

piezoelectric effect<br />

Unloaded crystal<br />

Crystal under load<br />

Q x = d 11 · F x · n<br />

The piezoelectric coefficient d 11 is dependent<br />

on direction and indicates the<br />

crystal’s degree of force sensitivity in<br />

the direction of the corresponding axis.<br />

The position of the crystal cut therefore<br />

determines the properties and the area of<br />

application of the quartz force link. Piezoelectric<br />

elements cut to produce the longitudinal<br />

effect are sensitive to compression<br />

forces and therefore suitable for simple<br />

and sturdy sensors for measuring forces.<br />

Potential for increasing<br />

the charge output<br />

Crystal<br />

disk<br />

Shear effect<br />

Similarly to the longitudinal effect, the<br />

piezoelectric sensitivity involved in the<br />

shear effect is independent of the size<br />

and shape of the piezoelectric element.<br />

The charge is also developed on the piezo<br />

element’s loaded surfaces. In the case<br />

of a load in the x-direction applied to n<br />

elements connected mechanically in series<br />

and electrically in parallel, the charge is:<br />

Principle of the<br />

shear effect<br />

Unloaded crystal<br />

Crystal under load<br />

Q x = 2 · d 11 · F x · n<br />

Shear-sensitive piezo elements are used<br />

for sensors measuring shear forces,<br />

torque and strain. They are suitable for<br />

manufacturing sensors whose excellent<br />

performance is unaffected by temperature<br />

changes, as the changes in the stresses in<br />

the sensor structure caused by changes in<br />

the temperature act in a direction perpendicular<br />

to the sensitive shear axis.<br />

Direction of<br />

applied force<br />

z<br />

d 11 : piezoelectric coefficient<br />

( –2,3 pC/N for quartz crystals)<br />

F x : force in x-direction<br />

n: number of crystal disks<br />

www.kistler.com 19

Kistler Measurement Technology<br />

Transverse effect<br />

In the transverse effect, a force F y in the<br />

direction of one of the neutral axes y<br />

produces a charge on the surfaces of the<br />

corresponding polar axis x. In contrast to<br />

the longitudinal piezoelectric effect the<br />

magnitude of this charge, which occurs<br />

on unloaded surfaces, is dependent on<br />

the geometry of the piezoelectric element.<br />

Assuming element dimensions a and b,<br />

the charge is:<br />

Principle of the<br />

transverse<br />

piezoelectric<br />

effect<br />

Unloaded crystal<br />

Crystal under load<br />

Q y = –d 11 · F y · b/a<br />

The transverse effect therefore makes<br />

it possible to obtain a greater charge<br />

through suitable shaping and alignment<br />

of the piezoelectric elements. Elements<br />

exhibiting this effect can be used for<br />

high-sensitivity pressure, strain and force<br />

sensors.<br />

Practical<br />

exploitation<br />

Possible cutting angles in the quartz<br />

element<br />

Longitudinal<br />

cut<br />

Transverse cut<br />

Shear cut<br />

Quartz as a piezoelectric material<br />

Piezoelectric materials for sensor elements<br />

must primarily exhibit very high<br />

mechanical strength and rigidity. Another<br />

requirement is stability of the mechanical<br />

and electrical properties across a wide<br />

temperature range and for long service<br />

periods. High sensitivity, good linearity,<br />

negligible hysteresis that is the rising and<br />

falling calibration curves are identical and<br />

high electrical insulation resistance are also<br />

advantageous.<br />

In meeting all these requirements quartz<br />

is ideal for sensors. It can be synthesized<br />

and has other qualities beneficial for<br />

measurement. A synthetic quartz element,<br />

for example, can be used in temperatures<br />

of up to 400 °C. Quartz can be cut at<br />

different angles to exhibit sensitivity to<br />

compression or shear forces, depending<br />

on which of the three piezoelectric effects<br />

is to be used.<br />

Unlike piezoceramics, quartz is not pyroelectric<br />

and therefore does not produce<br />

a charge in the event of temperature<br />

changes.<br />

The quartz crystal produces a charge<br />

signal proportional to the acting force.<br />

Due to the high rigidity of the crystal, the<br />

measurement displacement is low, usually<br />

in the range of a few micrometers.<br />

The high natural frequency of the quartz<br />

element is advantageous for measuring<br />

instantaneous dynamic processes. Virtually<br />

displacement-free measurement produces<br />

minimal measuring errors when measuring<br />

slow, quasistatic phenomena.<br />

The extraordinary stability, sturdiness and<br />

compactness of quartz sensors has led to<br />

them being used not only in research and<br />

development, but also more widely for<br />

industrial production and testing.<br />

20 www.kistler.com

Basics of Piezoelectric Measurement Technology<br />

Quartz at a Glance<br />

Quartz has excellent properties for use<br />

as a force link:<br />

• High permissible surface pressure<br />

of 150 N/mm 2 or more<br />

• Withstands temperatures<br />

up to 300 °C<br />

• Very high rigidity<br />

• High linearity<br />

• Negligible hysteresis<br />

• Virtually constant sensitivity across<br />

wide temperature range<br />

• High frequency range<br />

• Withstands almost unlimited number<br />

of load cycles.<br />

Direct and indirect measurement<br />

Kistler quartz sensors are suitable for<br />

direct and indirect force measurement. For<br />

direct measurement the sensor is mounted<br />

right in the path of the force and measures<br />

the total force. This method delivers<br />

very exact measurement results, which<br />

are almost independent of the force application<br />

point. In cases where the sensor<br />

cannot be positioned directly in the path<br />

of the force, it will measure only a fraction<br />

of the total force, while the remainder<br />

passes through the structure in which it is<br />

mounted, the so-called force shunt. With<br />

indirect force measurement, strain sensors<br />

are used to indirectly measure the process<br />

force via the structural strain.<br />

For more information on this<br />

topic, please refer to page 24<br />

onwards.<br />

Force Sensors, Strain Sensors<br />

and Torque Sensors<br />

Quartz disks with piezoelectric properties<br />

can be stacked in sensors to allow the measurement<br />

of one or more force components<br />

or a torque vector. Kistler offers the following<br />

piezoelectric sensors for application in<br />

assembly and product testing:<br />

• Single-component force sensors<br />

• Multicomponent force sensors<br />

• Strain sensors<br />

• Torque sensors<br />

Single-component force sensors<br />

Single-component force sensors, which<br />

are available in different types, are particularly<br />

suitable for measuring forces in<br />

a specified direction. One variant is the<br />

so-called load washer, which is ideal for<br />

practical applications.<br />

Two lightly preloaded quartz disks are<br />

sandwiched between the base plate and<br />

Load washer<br />

Quartz force link<br />

Sensor for small<br />

forces<br />

the cover plate in a welded case. The<br />

electrode located between the two quartz<br />

disks receives the measurement signal and<br />

transmits it to the connector. Load washers<br />

are sturdy and highly versatile in application.<br />

Their central hole allows easy integration<br />

into various structures in a variety of<br />

different configurations and preloading by<br />

means of a screw.<br />

Preloaded between two special nuts, the<br />

washer forms what is termed a force link.<br />

The preloaded sensor is ideal for measuring<br />

compression and tensile forces, for example<br />

in rod assemblies. Preloaded sensors,<br />

which are supplied calibrated, are easy<br />

mounting for immediate use. Sensors for<br />

measuring small forces have an essentially<br />

different design. Slender quartz rods are<br />

mounted under preload between the parts<br />

used to introduce the force. Compared<br />

with the quartz rings used in load washers,<br />

the piezoelectric transverse effect in these<br />

slender quartz rods significantly increases<br />

the sensitivity.<br />

Multicomponent force sensors<br />

The piezoelectric measuring principle is<br />

also ideal for the manufacture of multicomponent<br />

force sensors. The design of<br />

the sensor is similar to that of a singlecomponent<br />

load washer. A pair of quartz<br />

washers cut for the longitudinal effect<br />

measures the normal component F z, while<br />

each of two additional pairs of washers<br />

cut for the shear effect measures one of<br />

the two shear components (F x and F y).<br />

As shear forces can only be transmitted by<br />

means of static friction, multicomponent<br />

force sensors must always be under a<br />

sufficiently high mechanical preload when<br />

mounted.<br />

Multicomponent force sensors are usually<br />

not used alone, but are mounted in a<br />

group of three or four of similar sensitivity<br />

in what is called a dynamometer or force<br />

plate.<br />

For more information on single-component<br />

force sensors, please refer to page 71 onwards.<br />

www.kistler.com 21

Kistler Measurement Technology<br />

The components of the resultant force<br />

acting on a dynamometer are proportional<br />

to the algebraic sums of the corresponding<br />

components of the individual forces generated<br />

as a result of parallel arrangement.<br />

A dynamometer is therefore nothing but a<br />

multicomponent force sensor that measures<br />

the three components of the force<br />

independently of its point of application.<br />

In order to determine the three components<br />

of the resultant moment as well, the<br />

individual sensor signals need to be added<br />

or subtracted as required. Most Kistler<br />

dynamometers and force plates are suitable<br />

for both three-component force measurement<br />

and six-component force-moment<br />

measurement.<br />

Strain sensors<br />

Strain sensors determine the process<br />

forces indirectly from the surface or structural<br />

strain. Kistler strain sensors convert<br />

strain into proportional force and generate<br />

a corresponding charge signal.<br />

Torque sensors<br />

The torque vector is measured by sensors<br />

containing several shear-effect quartz<br />

disks in a circular arrangement. The shearsensitive<br />

crystal axes of the quartz disks<br />

are tangential to the circle. The external<br />

shape of torque sensors is similar to that<br />

of single-component load washers. In<br />

order to allow transmission of the shear<br />

forces by means of static friction, the<br />

quartz disks must be mounted under high<br />

mechanical preload. Torque acting on the<br />

sensor generates tangential shear stresses<br />

in the quartz disks. As all quartz disks are<br />

connected electrically in parallel, the total<br />

output signal is proportional to the torque<br />

acting on the sensor.<br />

3-component force sensor<br />

Torque sensors are used in applications<br />

such as quality testing of rotary switches.<br />

Stationary torque dynamometers are ideal<br />

for testing pneumatic screwdrivers.<br />

Surface strain sensor for indirect<br />

force measurement<br />

3-component force link<br />

Transverse measuring pin<br />

Torque sensor<br />

Multicomponent dynamometer with four integral<br />

force sensors<br />

Longitudinal<br />

measuring pin<br />

Reaction torque sensor<br />

For more information on multicomponent<br />

force sensors, please<br />

refer to page 88.<br />

For more information on strain<br />

sensors, please refer to page 98.<br />

For more information on torque<br />

sensors, please refer to page<br />

102.<br />

22 www.kistler.com

Basics of Piezoelectric Measurement Technology<br />

Charge Amplifiers<br />

Charge amplifier<br />

Charge amplifiers convert the charge<br />

produced by a piezoelectric sensor into a<br />

proportional voltage, which is used as an<br />

input variable for monitoring and control<br />

processes. A charge amplifier basically<br />

consists of an inverting voltage amplifier<br />

with high open-loop gain and capacitive<br />

negative feedback. It has a metal<br />

oxide semiconductor field effect transistor<br />

(MOSFET) or a junction field effect<br />

transistor (JFET) at its input to create the<br />

necessary high insulation resistance and<br />

ensure a minimum of leakage current.<br />

Neglecting R t and R i , the resulting output<br />

voltage becomes:<br />

U o = -Q 1 ·<br />

C r 1 + 1 (C t + C r + C c )<br />

AC r<br />

Sensor<br />

Q<br />

U o = Output voltage<br />

A = Gain<br />

C t = Sensor capacitance<br />

C c = Cable capacitance<br />

C r = Range or negative<br />

feedback capacitor<br />

Cable<br />

R t = Time constant resistance<br />

(or insulation resistance of range capacitor)<br />

R i = Input insulation resistance<br />

(cable and sensor)<br />

Q = electric charge yielded by the<br />

piezoelectric element<br />

If the open-loop gain is sufficiently high,<br />

the quotient 1/ACr will approach zero.<br />

The cable and sensor capacitance can<br />

therefore be neglected, leaving the output<br />

voltage dependent only on the input<br />

charge and the range capacitance.<br />

U o = -Q<br />

C r<br />

The amplifier acts as a charge integrator<br />

that constantly compensates for the<br />

sensor’s electrical charge with a charge of<br />

equal magnitude and opposite polarity<br />

on the range capacitor. The voltage<br />

across the range capacitor is proportional<br />

to the charge generated by the sensor<br />

and therefore proportional to the acting<br />

measurand. In effect, the charge amplifier<br />

converts an electric charge input Q into<br />

an easily usable proportional output voltage<br />

U o . As most Kistler charge amplifiers<br />

allow adjustment of sensor sensitivity and<br />

measuring range, the measured value is<br />

displayed directly in mechanical units of<br />

the measurand and the output signal is<br />

an integer multiple of the measurand.<br />

Block diagram of a measuring chain<br />

Time constant and drift<br />

Two of the more important considerations<br />

in the practical use of charge amplifiers<br />

are time constant and drift. The time<br />

constant τ is defined as the discharge time<br />

of a capacitor by which 1/e (37%) of the<br />

initial value has been reached. The time<br />

constant of a charge amplifier is determined<br />

by the product of the capacitance<br />

of the range capacitor C r and the time<br />

constant resistance R t :<br />

τ = R t ∙C r<br />

Drift is defined as an undesirable change<br />

in the output signal over a long period of<br />

time that is not a function of the measurand.<br />

Even the best MOSFETs and JFETs<br />

have leakage currents (MOSFET: I l

Kistler Measurement Technology<br />

Force can be measured directly in the<br />

path of the force of a split component,<br />

in the force shunt mode or indirectly as<br />

a function of strain. With direct force<br />

measurement, the entire process force<br />

passes through the sensor, while with<br />

the force shunt mode, the sensor only<br />

measures part of this force. Strain sensors<br />

measure the process force indirectly as a<br />

function of strain on the surface or inside<br />

the structure of machinery.<br />

All elements through which part of the<br />

process force can pass in addition to the<br />

sensor form a force shunt n. Force shunts<br />

are also created by preloading elements,<br />

which are installed for direct measurement,<br />

but in most of these cases the shunt<br />

is less than 10 %. Measurement in the<br />

force shunt mode exploits this effect. The<br />

sensor is mounted so it only measures a<br />

fraction of the process force. The bulk<br />

of the process force passes through the<br />

machine structure. This approach allows<br />

measurement of forces greatly exceeding<br />

the measuring range of the sensor. As<br />

strain sensors only measure a negligibly<br />

small fraction of the process force, the<br />

force shunt created during indirect measurement<br />

is usually 99 % or more. If the<br />

force shunt is changed, calibration of the<br />

sensor must always be repeated, irrespective<br />

of the type of installation or sensor.<br />

<strong>Measuring</strong> Methods at a Glance<br />

Direct measurement in the path of the<br />

force<br />

The entire process force passes through<br />

the sensor (n >99 %).<br />

Direct Force Measurement<br />

in Path of Force<br />

Direct force measurement necessitates<br />

splitting the component or member<br />

perpendicular to the load path to allow<br />

mounting of the calibrated force sensor.<br />

The mounted sensor therefore has<br />

to meet the component‘s strength and<br />

rigidity requirements. The sensors used<br />

for direct force measurement are usually<br />

calibrated and preloaded prior to mounting,<br />

as installation does not affect their<br />

force shunt. Direct force measurement<br />

with calibrated and preloaded sensors is<br />

used wherever absolute force measurement<br />

is required and calibration of the<br />

system after mounting is not necessary,<br />

such as monitoring of joining forces or<br />

measurement of small forces during product<br />

testing.<br />

Direct Measurement at a Glance<br />

The sensor is mounted directly in the<br />

load path and measures the entire<br />

process force.<br />

Advantages:<br />

• High sensitivity<br />

• High measuring accuracy<br />

• High repeatability<br />

• Good linearity and low hysteresis<br />

• Wide range of preloaded, easy<br />

mounting, calibrated sensors<br />

Disadvantages:<br />

• Interference from acceleration forces<br />

when sensors are installed in moving<br />

parts<br />

• Alteration of strength or rigidity of<br />

machine<br />

• Possible restriction of workspace<br />

24 www.kistler.com

Basics of Piezoelectric Measurement Technology<br />

Force Shunt Measurement<br />

Sensors are often mounted in a force<br />

shunt configuration when large forces<br />

need to be measured or the sensor<br />

cannot be mounted directly in the force<br />

path. As the sensor then only measures<br />

part of the process force and the remainder<br />

passes into the force shunt, the<br />

measuring range can usually be narrower<br />

than that required for direct measurement<br />

and hence the solution more cost<br />

effective.<br />

Another benefit of force shunt measurement<br />

is a high level of protection against<br />

overload. In order to deliver absolute<br />

values, sensors mounted in a force shunt<br />

configuration always need to be calibrated<br />

after mounting. As the sensitivity is<br />

determined by the force shunt, and this<br />

in turn depends on the point of application<br />

of the force, calibration only remains<br />

valid while the force shunt remains<br />

unchanged. Force shunt measurement is<br />

therefore the preferred method of measurement<br />

for applications with a fixed<br />

point of application, for example for<br />

monitoring presses. It should be noted<br />

that the mounting configuration and the<br />

point of force application affect not only<br />

the sensitivity of the sensor but also its<br />

linearity and hysteresis.<br />

Force Shunt Measurement at a<br />

Glance<br />

The sensor is mounted in the structure<br />

of the machine and most of the process<br />

force usually passes into the force<br />

shunt.<br />

Advantages:<br />

• Overload protection<br />

• Cost-effective construction<br />

• Measurement of process forces up<br />

to 100/(100-n) times the sensor’s<br />

measuring range<br />

• Good measurement accuracy under<br />

constant conditions<br />

• High repeatability<br />

Disadvantages:<br />

• Measurement dependent on point of<br />

application and path of force<br />

Force shunt<br />

n [%] = 100 · F n / F p<br />

• On-site calibration required for measuring<br />

absolute values<br />

n = Force shunt (proportion of the<br />

process force not measured by<br />

the sensor)<br />

n = 0 (for unmounted sensors<br />

without preloading elements)<br />

F n = Shunt force<br />

Direct force measurement<br />

F p = Process force<br />

S 0 = Sensitivity of the unmounted<br />

sensor<br />

S = Sensitivity of the mounted<br />

sensor<br />

n<br />

S = S 0 · (1–<br />

100<br />

)<br />

Indirect force measurement<br />

n =<br />

0 %<br />

> 99 %<br />

n =<br />

100 %<br />

≈ 10 ... 99 %<br />

Force shunt measurement<br />

Sensitivity<br />

Force shunt<br />

www.kistler.com 25

Kistler Measurement Technology<br />

Indirect Force<br />

Measurement<br />

The deformation resulting from application<br />

of force to a structure can be<br />